February 26, 2020

Bends GOST 17375-2001 and other types

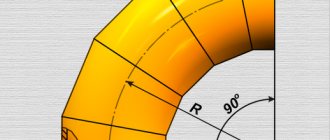

Bends are a piece of curved pipe. The bending angle can be 30, 45, 60, 90 and 180 degrees. For the manufacture of bends, steel of different grades is used. Also, bends can be made of polymers.

Bends are manufactured using a seamless and welded method. They can be steeply curved and bent. Steeply curved bends have a small radius and dimensions. Bent elbows are larger and have a larger radius. They are used where the operation of steeply curved bends is impossible.

GOST 30753 bends and other types of bends are needed in those sections of the pipeline where it makes a turn to change direction. Steel bends can withstand the highest temperatures and adverse conditions, so they can be used in aggressive work environments. At the same time, their service life will be quite long.

Bends can have a variety of angles, but the most popular are 45 and 90 degrees.

Types of bends

Different types of products are used for different pipelines.

Main types:

- steeply curved;

- stamp-welded;

- welded sectional;

- welded sector (segment);

- bent;

- point.

Steeply curved bends are made in accordance with the requirements of GOST 17375-2001 and GOST 17375-83.

Most often, parts are made from stainless and carbon steel using the pipe drawing method. The part is of high quality and sealed.

The angle of such bends ranges from 30 to 90 degrees, and the section of the part is from 18 to 426 mm. The working pressure that the part can withstand reaches 16 MPa.

Stamp-welded bends have thick walls, and due to this they are considered especially durable; they are made from sheets of stainless and alloy steel by welding. Parts can be of different sections, which reach 1420 mm. They are mainly used in the oil and gas industry. This is due to their special strength and large range of sizes.

|

Steel bends are pipeline connecting parts designed to change the direction of flow of the transported substance. The need to turn the main pipe is determined by natural and artificial obstacles along the pipeline route, as well as the construction of curved sections in order to compensate for structural deformations that occur due to temperature changes. During installation, steel bends are used with a bend angle of 90°, 60°, 45° and, less commonly, 30°.

According to the manufacturing method, the described shaped products are divided into steeply curved bends (OK), stamped-welded bends (OKSh), welded sectional bends (OSS), as well as bent bends (OG and GO) and turned bends.

Steeply curved bends are made by drawing steel blanks heated to the required temperature. The product is pulled through a special shape with the geometry of a horn, using particularly strong mechanical force.

The production technology of steeply curved bends involves the production of products with the smallest possible bending radius. They are manufactured in accordance with the following technical standards:

- GOST 17375-01;

- GOST 30753-01;

- OST 34-10-418-90;

- OST 34 10.699-97;

- TU 468-284-20872280-2005 and others.

Branch 90 GOST 17375-01

The OK bend, made in accordance with GOST 17375-01 and GOST 30753-01, has a bend radius of 1.5 DN and 1 DN, respectively. The list of products manufactured in accordance with these standards includes steeply curved bends with a nominal bore from 15 to 1000 mm for version 1 and from 25 to 800 mm for version No. 2. Bends OK GOST 17375-01 and GOST 30753-01, as a rule, they are used on supervised pipelines (including at nuclear industrial energy enterprises). Such products are distinguished by their reliability and long service life.

Steeply curved bends OST 34-10-418-90 and OST 34 10.699-97 are manufactured with a nominal diameter from 40 to 300 mm (in some cases up to 600 mm) from lightly alloyed and alloyed steels (both structural and instrumental). The products are actively used in the installation of pipelines of groups B and C of nuclear power plants built according to the “Nuclear Power Plant Rules”. The maximum design temperature during operation of steeply curved bends OST 34-10-418-90 and OST 34 10.699-97 is limited to 400-425°C.

Bend 90 GOST 30753-01

Bends according to TU 468-284-20872280-2005 are used in the oil industry for transporting highly corrosive media with a nominal pressure of up to 32 MPa. Such products have a long service life and are used at ambient temperatures from -65°C to 45°C. The temperature of the transferred substance must be in the range from 5°C to 40°C. For bends TU 468-284-20872280-2005, made of heat-resistant steels, the maximum permissible temperature limits are expanded - in some cases up to 650°C.

Steeply curved stamp-welded bends (OKSh bends) are products made by electric arc welding of blanks, which are first given the required shape using stamps. This manufacturing method is used to produce parts with significant diameters (usually up to 1420 mm).

OKSh bends are actively used for the installation of pipelines in the oil, gas, and processing industries - industries in which aggressive substances are transported. In such areas, thick-walled pipelines of large diameters are in demand, the operating pressure in which can reach 100 MPa.

Stamp-welded steeply curved bends have two welds and are manufactured with a bending radius of 1.5 DN, in accordance with the technical specifications of TU 102–488-95, and also with a radius of 1 DN - in accordance with TU 102-488-05. One of the main advantages of the described production technology is the technical ability to produce bends with a wide variety of diameters. Alloyed, galvanized and stainless steels are used as blanks for OKSh bends, and the quality of stamped and welded products is practically not inferior to bent and steeply curved bends made in accordance with GOST 17375-01 and 30753-01.

Branch OKSh TU 102-488-95

Welded sectional bends (OSB bends) are special shaped products made by connecting three or more ring sections. Depending on the number of welded sections, OSS bends are made at 45°, 60° or 90°. One of the indisputable advantages of such products is the ability to manufacture parts with a wide variety of parameters. Among the disadvantages of welded sectional bends is the inevitable occurrence of a pressure drop during transportation of the substance. This is due to the geometry of the joints in the outlet, which increase the mechanical loads on the walls of the product due to the formation of turbulent flows.

The technical features of manufacturing OSS bends are fixed in two main industry standards - OST 34.10.752-97, OST 36-42-81 and a number of others. These standards describe the production of sectional bends for pipelines with diameters up to 1620 mm, which are actively used on pipelines with operating pressures up to 2.5 MPa.

Normal functioning of OSS bends made in accordance with OST 34.10.752-97 and OST 36-42-81 is demonstrated at temperatures up to 230°C. However, parts manufactured in accordance with a number of specifications are allowed for installation within extended temperature limits - from -30 to 300°C.

Branch OSS OST 36-42-81

In accordance with the characteristics of the transported substance and the characteristics of the environment, blanks for the production of welded sectional bends are made from high-alloy and stainless steels, as well as materials saturated with carbon. In order to increase resistance to corrosion, OSS bends are additionally coated with special materials or galvanized.

Bent bends (EG or GO bends) are pipeline connecting parts made from seamless pipes by hot or cold bending while maintaining straight sections. The bending radius of the product is maintained in the range from 2 to 20 DN. Almost all types of steel are used as a material for the production of bent elbows.

Bent bends GOST 24950-81

The production of products using the cold bending method is carried out in accordance with GOST 24950-81. The production technology of hot-bent bends is regulated by TU 102-488-95, TU 102-488-05, as well as a number of industry standards, according to which the bending angles of the described products are widely varied.

In a number of operational characteristics, exhaust exhaust outlets are superior to their steeply curved counterparts, and therefore the scope of their application is significantly expanding. Thus, such products are actively used in the installation of pipelines of all categories in almost every industrial sector. Among the main technical characteristics of bent elbows are the pressure on the walls of the pipeline during its operation (up to 16 MPa), as well as the operating temperature of the transported medium (ranging from -70 to 450°C).

In a number of cases, bent elbows are often replaced with analogues due to their high cost. Preference is given to them in cases where such replacement is impossible (which may be due to special requirements for the pipeline configuration, materials, properties, etc.). Thus, during the construction of some sections of the pipeline (for example, U-shaped ones), which act as compensators, bent bends are most often used. In addition, in the manufacture of exhaust exhaust outlets, a wide range of steel grades are used as raw materials for workpieces, therefore, for some products, replacement with steeply curved analogues is impossible from a technical point of view.

Turned elbows (angles) are made from cast square blanks by processing them on a lathe. Due to the technical complexity and high costs of labor and material resources, angles are the most expensive in comparison with all other types of bends.

The production of turned bends is carried out in accordance with the technical standards set forth in GOST 22820-83. The nominal diameter of the angles varies from 6 to 200 mm.

Turned elbow (angle) GOST 22820-83

The main advantage of machined bends is primarily their reliability, because Thanks to production technology, they can be manufactured with almost any wall thickness and can withstand pressure from 10 to 100 MPa. The material used for the angles is low-alloy and carbon-rich steel.

Turned bends are mainly used at petrochemical industry enterprises, as well as for the installation of structures in mineral fertilizer production, therefore they are designed for harsh operating conditions: water vapor supplied under high pressure, or chemical compounds. The angles have increased resistance to corrosion and oxidation and are operated at temperatures of the transported substance from -50 to 510°C.

Material for making bends

Most often, bends are made of steel, this is largely due to the loads that the part will have to withstand. The steel for making bends can be alloyed, carbon, or stainless.

Steel can withstand large pressure differences, is suitable for unfavorable climatic conditions, and is resistant to corrosion. Different steels for making bends have their own advantages. For example, 12x18n10t has increased resistance to corrosion, and steel 09g2s is suitable for pipelines located in cold or moderately cold climates.

Alloy steel bends can operate at temperatures from -60 to +40 degrees Celsius. Such parts are suitable for use in pipelines located in cold climates.

If the working environment is aggressive, it is better to use GOST 30753-2001 bends made of stainless or alloy steel. Carbon steel is suitable for general purpose piping.

Steel bends work with steam, hot water, chemically active substances, alkaline media and acids. The main important characteristic of parts for such a pipeline is corrosion resistance, and steel bends meet these requirements. In some cases, galvanized steel parts are suitable for the job. Their inner layer is additionally protected from corrosion by a layer of zinc.

Also, for some pipelines, bends are made of low-density polyethylene and polyvinyl chloride.

Polymer elbows are suitable for mild operating conditions. They cannot be used in pipelines with an aggressive working environment or in unfavorable conditions.

Bends GOST 30753-2001 and other similar parts have several advantages. They are versatile and suitable for a wide variety of systems to change the direction of pipes. Steel bends are resistant to climate conditions - temperature changes or precipitation. At the same time, the price of bends is always affordable. And the GOST requirements, according to which parts are manufactured, ensure their safe and efficient use.

|

Key Features

The products are characterized by high performance characteristics. Among their advantages is resistance to the effects of almost all unfavorable external factors of any origin: biological, atmospheric, chemical, man-made. In addition, the list of product advantages includes:

- the ability to smoothly rotate the pipeline axis;

- being integrated into the main line using electric welding, they provide maximum connection reliability;

- are immune to temperature fluctuations, since steel has a low coefficient of thermal expansion;

- can be used in harsh operating conditions;

- have high mechanical strength;

- absolutely gas-tight.

Steel bends successfully withstand high operating pressures and are capable of operating in conditions of critically high and low temperatures. They are resistant to excess ambient moisture, reliable, and operate for a long time.

Bends GOST 30753-2001: areas of application

The main function of bends is to change the direction of flow. Therefore, they are mounted on the pipe in the place where the pipeline must change direction. Installation of bends is possible using welding, flange and threaded connections.

Bends are used for assembling oil pipelines, at metallurgical and energy enterprises. They are also used in the housing and communal services system. These parts are necessary when installing water pipes and heating systems.

The bends are suitable for the operation of pipelines that pump liquid media, as well as for transporting gas, chemicals and steam.

The bends are connected to other parts by welding or threading. This greatly expands their use cases.

For example, seamless steep bends can be used in oil and gas chemical pipelines. Thanks to installation by welding, the entire pipeline system is sealed.

The bends can be operated at temperatures up to 450 degrees Celsius. The lowest operating temperatures are -70 degrees Celsius.

The parts are made in a variety of diameters. For example, DN 15, DN 25, DN 40, DN 45. Also, bends can have a larger diameter - from DN 426 and above.

Thanks to these characteristics and the bending angle (possible from 3 to 90 degrees), bends are used in a wide variety of pipelines. They are suitable for pipes with different wall thicknesses. This expands the possibilities of their use.

Examples of using bends

They are often used when wiring communications for various purposes. Only the types of taps differ. For example, in a pipeline with a large cross-section there will be high pressure for the movement of the working fluid. And in this case, steeply curved seamless bends or bent parts made of stainless steel are suitable.

In the housing and communal services sector and for other household communications, steeply curved and bent bends can also be used.

Bends are installed not only on pipelines that transport gases, oil, water and other working media. The parts are also used in ventilation systems and air purification systems.

Classification

The above division - hot-deformed, hot-stamped, bent, welded, stamp-welded - is the main classification of products. Sometimes, when describing products, they operate with other parameters of the fittings: sector options (obtained by electric welding) and smooth (all others). Steeply curved bends are also distinguished - these are those that have a small diameter. They are made mainly by stamping and bending. If the pipeline is not required to be compact, the outlet fittings for it will most often be stamped or welded; they are large in size.

There is another classification of the product: 2D and 3D. This parameter characterizes the ratio of the bend radius to the internal diameter of the product. In 2D these two values are approximately the same; in 3D the turning radius is one and a half times larger than the diameter. This designation can also look like: R-1.5D (this is a 3D type) or R-1D (a 2D option).

Marking

The main parameter characterizing steel bends is DN (DN in some documentation). This is their nominal diameter, or nominal diameter, the main criterion for choosing the exact model of the product when installing it in a pipeline and matching it with adjacent sections of the pipeline. DU must be indicated in the product designation.

Another important value is the wall thickness, since the elbow must fit perfectly into the pipeline line. The diameters of steel bends and wall thickness are standardized and correspond to the size range of pipes used today in everyday life and in production.

According to the angle of rotation of the knees, they are divided into models designed for an angle of 15, 30, 45, 60, 90 degrees. This value is also indicated in the designation.

An example of a short marking is 45° 38x2 09G2S, where:

- 45° — rotation angle;

- 38 – internal diameter, mm;

- 2 – thickness of its wall, mm;

- 09G2S – steel used.

Full marking of the product may also include length, GOST or other regulatory document according to which production was carried out, brand or identification number of the manufacturer, batch number.

The designation is applied to the product by embossing, paint or a sticker/label.

Installation of bends using welding

Since the bend has a curved shape, welding the product requires certain skills.

Before starting welding, you must make sure that the parts are free of defects. The displacement at the junction of two pipes should not be more than 2 mm. You can center the outlet and pipe using a rotator.

If manual electric arc welding is used, processing of the first root weld is performed with direct current. Once the first seam is completed and sanded, the second seam is made. It is important to maintain a constant temperature at the welding site, so the break between two seams cannot be more than five minutes. After welding, facing seams are made, which should protrude by 1-3 mm. above the surface of the pipeline.

When are rotators used?

A rotator is a special equipment that can be used to make high-quality welding. Rotator welding is suitable for large diameter pipes, and the rotation speed can be adjusted. This method also helps to align the parts. The rotator is suitable for working with pipes and other parts of more complex design.

GOST 30753-2001 bends and other parts are suitable for use on various pipelines. Since the parts have different bend radii, wall thicknesses and internal sections. In addition, GOST 30753-2001 bends and other steel products are resistant to corrosion, withstand large temperature changes and are capable of operating at high pressure of the working environment.

You can order the production of bends GOST 17375-2001 and 30753-2001 from the MK NHTS company. The company's specialists have developed their own specifications, approved by Rostechnadzor.

| Read also: Transitions, tees and bends: review of articles

Main components of round air ducts

Ventilation outlet 90⁰

Ventilation outlet 60⁰

Ventilation outlet 45⁰

Ventilation outlet 30⁰

Ventilation outlet 15⁰

For ordering there is a symbol: d - diameter (mm)

α - turning angle ° R - turning radius (mm)

When R=d - not specified R =1 xd In a standard bend, the turning radius is equal to its diameter. The radius, if necessary, can be any.

Go to the air duct catalog

Go

Round ventilation transition

Central Single-sided Offset

Used to narrow or widen the cross-section of the air duct. It is extremely difficult to do without such a product on site, since manufacturing the transition is quite a complex and lengthy process if done manually during installation.

When ordering, indicate small and large diameters. If the order is non-standard, then the length and offset (for offset transitions) are also indicated.

d1 - diameter (mm) d2 - diameter (mm)

When ordering a non-standard length, please indicate:

Length (mm) - L Offset (mm) - C

Round ventilation tee

First type:

Used to branch air flows. Sometimes, in order to save money, they order tie-ins instead of tees and make a branch on site, but this method takes more time in installation.

There is an ordering symbol:

d1 - diameter (mm) d2 - diameter (mm) L - length (mm) H - height (mm)

Any size ratio possible (subject to technical limitations)

Second type:

There is an ordering symbol:

d1 - diameter (mm) d2 - diameter (mm) L - length (mm) α - angle

Any size ratio is possible (subject to technological limitations).

Third type:

There is an ordering symbol:

d1 - diameter (mm) d2 - diameter (mm) d3 - diameter (mm) L - length (mm) α - angle

Any size ratio is possible (subject to technological limitations).

Fourth type:

Sometimes you have to make a branch of a rectangular section. This may be necessary, for example, to connect small rectangular distribution grids that are inserted into the channel.

There is an ordering symbol:

d - diameter (mm) H - height (mm) A×B - insert size (mm) n - flange: 20 (mm), 30 (mm), (without flange: 0) L - length (mm)

Any size ratio is possible (subject to technological limitations).

Round ventilation cross

For a standard part: H2 = H3 − 0.5d1 + 50 (mm)

If l > (d2 + d3) / 2 + 120 (mm), then it is possible to consider using two tees. Typically, such products are not ordered in advance, but are manufactured on site using tees.

There is an ordering symbol:

d1 - root diameter (mm) d2 - diameter (mm) d3 - diameter (mm)

Height (mm) — H2,H3 L — part length (mm) If l = 0, do not indicate l — distance between cut-ins (mm) α — angle between cut-outs from d3 to d2, °

Any size ratio is possible (subject to technological limitations).

Round ventilation nipple

Serves to connect air ducts of the same diameter to each other. The air ducts are inserted from different sides of the nipple in one simple movement. Without nipples, it can be extremely inconvenient to connect pipes, since you have to roll them (“make a flower”) and insert one into the other. It looks ugly and is inconvenient to do.

There is an ordering symbol:

d —diameter (mm)

Total length of ventilation nipple:

up to Ø 500 - 140 (mm) up to Ø 900 - 180 (mm) up to Ø 1250 - 200 (mm)

Round ventilation coupling

Connects shaped products and air ducts. Made from galvanized steel. become. Unlike a nipple, it is put on top of the parts to be fastened. For small diameters they are usually not used, but are cut from pieces of pipe, but for large diameters (more than 400mm) it can take much longer to cut the pipe on site, so it is more profitable to order them in advance.

There is an ordering symbol:

d—diameter (mm)

Each diameter corresponds to a certain coupling length L–mm. (See Appendix 1).

Round ventilation plug

It is the end element of the system to block the channel cross-section.

Required when ordering:

d—diameter (mm)

From 100 to 1250 mm.

It is also possible to choose any diameter and length and make it with a handle at the end.

Round ventilation duck

It is a shaped product and is used at the joints of multi-level air ducts. Can also be used at the junction of air ducts located to the left or right of each other. You can also get by using two bends of 30 or 45 degrees instead of a duck.

When ordering please indicate:

d1 - diameter (mm) d2 - diameter (mm) L - part length (mm) H - height (mm).

If d1= d2, then indicate one size

It is also possible to use any size (subject to technological limitations).

Throttle valve for round air ducts

Galvanized steel is used for production. It consists of a pipe, a canvas and a control sector. The so-called vane, located on the outside of the valve, is installed on the control unit. It can be rotated using the handle. The valve cross-section is closed at the required angle using a spatula. The blade is secured with a wing nut. Using a graduated scale, the angle of rotation is determined. Throttle valves are recommended for use on main lines or at air duct branch points.

The correct location and number of throttle valves is very important so that you can correctly balance the system and set the required flow rates for the branches.

Roof umbrella for round air duct

Protects the air duct from precipitation. Typically used on vertically installed exhaust pipes.

To order use:

d - diameter (mm) (from 100 to 710 mm)

D and height H depend on d.

Round ventilation insert

A shaped part installed in the walls of air ducts. Used instead of a tee to branch the flow. It takes a little longer to install than a tee, but is cheaper and allows you to install it anywhere.

There are three types:

- For installation in a rectangular duct or a round duct

- For connecting round ducts

- For corner ducts

When ordering please indicate:

d - diameter from 100 to 1250 mm I - length 40, 60, 80, 100 mm,

also for if necessary

H - height (not less than 50 mm) α - angle, °

It is also possible to use any size ratios (subject to technological limitations).

Roof passage unit for air ducts

It is used in places where ventilation shafts are installed on the roof. The main task of the passage unit is to seal the passage opening.

When ordering please indicate:

d – diameter 100 – 400 mm H – height (mm). α - angle °

It is also possible to use any size ratios (subject to technological limitations).

Round ventilation damper

Shut-off and control device. Made from thin sheet galvanized steel. They are divided into direct (in aspiration and pneumatic transport systems) and oblique (in general ventilation systems) dampers. In this case, the pressure in the system should not exceed 1000 Pa. The main function is to regulate the air flow.

Flexible round inserts for air ducts

Eliminate vibration when connecting high-power equipment, such as radial fans or air handling units, so that vibration noise is not transmitted into the duct system.

Use from 100 to 1600 mm.

Installation rules

Installation of bends on pipelines is carried out using the welding method. This is a labor-intensive process that requires certain skills from the welder. When welding, it is necessary to constantly monitor the alignment of the internal surfaces and edges of the parts being welded. To do this, alignment is performed using a special vice (for small diameter pipelines) or rotators. The latter are used for welding large-diameter pipes and guarantee strong adhesion of the elements to each other during the welding process.

When welding bends and pipelines, you must follow the installation rules:

- Before installation, you need to check the availability of accompanying and regulatory documentation and study the instructions.

- Welding work is carried out only by trained specialists who have the appropriate permits and regulations.

- Work is carried out only in special protective clothing with a mask.

- No foreign objects are allowed in the workplace. There must be a fire extinguishing agent and ventilation.

- Welded edges of parts must be prepared. Products are not allowed to have defects or irregularities, chips, cracks, delaminations, etc.

- During the welding process, it is necessary to control the specified mode, selected based on the characteristics of the materials being welded.

Manual electric arc welding is carried out at direct current in two stages.