Electrical steel is a type of ferrous rolled metal, unalloyed or alloyed with silicon and aluminum with specified ferromagnetic properties. It is widely used in high- and low-current production of electrical equipment and electrical goods for general consumption. Magnetic cores are made from it, designed to operate in magnetic fields when the magnetization vector changes with a frequency of up to 400 Hz. At the same time, steel has a low affordable price and a high level of induction.

Electrical steel

This term in the metallurgical industry refers to silicon electrical steel, as well as pure iron. Electrical steels are the materials from which various parts are produced for the needs of the electrical and electronics industry. Certain properties of this type of metal ensure normal operation and extend the service life of devices made from it.

Silicon steel

This type of metal is the main soft magnetic material that has mass consumption. Silicon is contained in steel in varying quantities. This depends on what level of magnetic properties is required. Thanks to silicon, the resistivity of steel increases, and the coercive force decreases, and hysteresis losses are also reduced.

If silicon contains 5% or more, the mechanical properties deteriorate significantly: fragility and hardness increase. This type of steel is not suitable for stamping.

Manufacturers

This material is produced all over the world. Its main consumers are Japan and China. They consume and produce up to 50% of all electrical steel. The main producer is China, and Japan mainly exports this type of steel.

Much more metal is produced on the territory of the Russian Federation than is necessary for use within the country. The cost of this species on the Russian market is 80-180 rubles per kilogram. In recent years, the Russian Federation has managed to reach production volumes that amounted to 10% of global steel imports. The main producers are:

- Severstal.

- VIZ-Steel.

- Novolipetsk Metallurgical Plant.

These institutions produce products in quantities several times greater than the needs of the domestic market. This makes it possible to sell the material to Western countries such as Italy, Switzerland, and also send steel to India.

If you pay attention to a specific type of steel in the total production volume, then the emphasis is on the dynamic range of metal. Steel for creating electrical equipment makes up only 30% of the total production volume, since it is not needed in unlimited quantities. Its cost is in the range of 120-180 rubles/kg.

Pure iron

Alloys with a carbon content of 0.02% or less are called pure iron. It technically belongs to electrical steels and is a material called soft magnetic. It is used to produce cores, electromagnets, pole pieces, and plates for batteries.

Technically pure iron is called low-carbon steel, in which the carbon content is up to 0.05%. If it contains other impurities, it is in minimal quantities. This steel is obtained by reducing pure ores. Its magnetic properties depend on the amount of impurities it contains.

To obtain pure iron with a low content of impurities, two methods are used:

- Electrolysis, resulting in electrolytic iron.

- Thermal decomposition by which carbonyl iron is produced.

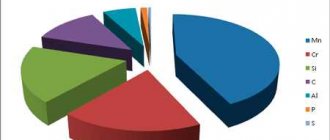

Impurities in the composition

Electrical steel may contain other components in its composition: sulfur, carbon, manganese, phosphorus and others. The most harmful of them is carbon (C). It can be in the form of either cementite or graphite. This affects the alloy differently, as does the percentage of carbon content. To avoid unwanted inclusions of element C, the steel cannot be rapidly cooled for further aging and stabilization.

The following components have a negative effect on the properties of the material: oxygen, sulfur, manganese. They reduce its magnetic qualities. Industrial iron necessarily contains impurities in its composition. Here they have to be taken into account in aggregate, not in the same way as for pure iron.

You can improve the properties of steel by removing impurities. But this method is not always profitable in large-scale production. But with the help of cold rolling, sheet electrical steel forms magnetic properties in its structure. This allows you to achieve better results. But further firing is definitely necessary.

Types of steel

Production technology affects the final product. Depending on this, electrical steel is:

- Cold rolled with a silicon content of 3.3%, which is divided into isotropic and anisotropic.

- Hot rolled - isotropic, silicon content is 4.5%.

The alloying additive can be aluminum, its amount in the steel composition is 0.5%. This type of metal is sometimes divided conventionally, according to which steel can be:

- Dynamic (isotropic).

- Transformer (anisotropic).

- Relay (isotropic, unalloyed).

Cold rolling

For a long time it was believed that silicon increases the brittleness of steel. Production took place mainly by hot rolling. The profitability of cold rolling was low.

It was only after it was discovered that cold working along the direction increases the magnetic properties of the material that it became widely used. Other areas showed only the worst side. Cold rolling had a beneficial effect on the mechanical properties, as well as improving the quality of the sheet surface, increasing its waviness and making it possible to stamp.

The distinctive properties that electrical steel obtained through the use of cold working can be explained by the formation of a crystallographic texture in it. It differs in several degrees. They, in turn, depend on the temperature at which the rolling takes place, also on the thickness of the required sheet and on the degree to which it is compressed.

The cost of a sheet of one thickness of hot-rolled steel is 2 times lower than that of cold-rolled steel.

But this negative quality is fully compensated by low heat losses (they are about two times less), high quality and the possibility of good stamping of the cold-rolled alloy. The difference in these steels is the silicon content. Its amount ranges from 3.3% to 4.5%, respectively.

How does silicon affect the magnetic properties of steel?

Silicon in the solid state dissolves in iron at temperatures reaching 800 °C. Its solubility in this case is 15%. Alloys containing up to 2.5% silicon have a region that has the ability to expand as the carbon content increases.

These include electrical steel grades 1212, 2011 and others. Silicon is the only element that increases the magnetic permeability of steel and its electrical resistance. It also helps to reduce the coercive force, resulting in reduced magnetization reversal losses. Steel smelting technology is designed so that the finished product contains fewer impurities with sufficient silicon content.

NORMAN GOSS TEXTURED TRANSFORMER STEEL

In 1933, Norman P. Goss, a researcher and inventor from Cleveland, Ohio, USA, managed to obtain transformer steel by double cold rolling and heat treatment, which had very high magnetic properties along the rolling direction with a silicon content of 3–3.5%. For this technology he received US Patent No. 1965559 “Electrical sheet steel, method and equipment for its production and testing” (application - 1933, published - 1934, author N.P. Goss, patent holder - Cold Metal Process Co). According to this patent, the manufacturing process consisted of annealing hot-rolled material at a temperature of 900 ºC, cold rolling with a thickness reduction of 60%, secondary annealing at 900 ºC, repeated cold rolling with a thickness reduction of 60%, annealing first at 1,100 ºC, and then — at 700 ºС to reduce aging. The maximum magnetic permeability μm in the first samples of this steel was equal to 15,000 Gas/E, which is 1.5–2 times higher than the permeability of the best grade of hot-rolled transformer steel. Watt losses are correspondingly smaller.

In 1937, the American scientist Williams HJ, as a result of laboratory research, proved that the high magnetic characteristics of the steel obtained by Goss are explained by the presence in it of a directional arrangement of crystallites - grains (texture), obtained under certain conditions of cold rolling and heat treatment in cold-rolled steel Goss, the direction of easy magnetization and the smallest coercive force in its unit cell (edge of a body-centered cube of the crystal lattice) coincides with the rolling direction, the direction of difficult magnetization is at an angle of 55º to the rolling direction, and the axis of the medium magnetization direction is at an angle of 90º to the rolling direction. The last two directions lie in the transverse plane of the cube. This texture is called “rib texture” or “Goss texture” (Fig. 1, a).

Since the publication of Goss's report on his work, many methods have been proposed for producing grain-oriented steels by cold rolling and annealing. Goss himself in 1937 produced a material with good properties using rolling at a temperature of approximately 800 ºC, annealing, cold rolling and final annealing at 1,100. In 1938 ºС. Hiemenz used successive decreases in temperature during rolling, ending the process with cold rolling. The resulting material was then annealed at a temperature of 1,250 ºC. In 1941, Carpenter decarburized the alloy before cold rolling by annealing hot-rolled sheets without the scale removed and finishing the process by annealing at 800ºC in a controlled atmosphere to prevent contamination. As a result of all these studies, it was found that the best results are obtained by combining texturing of the material and cleaning it at various stages of production - from smelting to the final annealing.

Industrial production of grain-oriented transformer steel was mastered in 1940–1945. first in the USA and then in European countries.

Norman P. Goss

In the USSR, important research on the development of technology for the production of cold-rolled transformer steel was carried out by the Central Factory Laboratory of VIMZ and the Central Scientific Research Institute of Ferrous Metallurgy (TsNIIChM) during 1944–1945. Although cold-rolled transformer steel has been produced in the United States since 1942, there has been no published data on its properties and production technology. Therefore, the development and production of this steel in the USSR were based mainly on domestic research data. After successful laboratory experiments, VIMZ produced the first batch of cold-rolled transformer steel in the USSR with a thickness of 0.35 mm, the specific losses of which at Vm = 10,000 Gas and a frequency of 50 periods per second of the applied voltage were equal to 0.79 W/kg.

The production of cold-rolled transformer steel for the first time in the Soviet Union was organized at the Leningrad Steel Rolling Plant in 1947 (0.08 mm thick strip), then in 1949 at the Novosibirsk Metallurgical Plant (0.35 and 0.50 mm thick sheets). Subsequently, the production of cold-rolled transformer steel was mastered in (Moscow) with heat treatment in continuous furnaces in an atmosphere of electrolytic hydrogen, at and at the Magnitogorsk Iron and Steel Works.

Transformer steel with ribbed texture is manufactured under various factory and brand names (in the USA - grain-oriented, electric steel, M, etc.; in the USSR - KhVP, HT18, EZ10, EZ20, EZ30, E330A; in England - unisil, alfasil; in Germany - hyperm), however, the chemical composition of these steels is almost the same in all countries (silicon content 2.8–3.5%, the rest is iron and impurities). The difference in magnetic properties is explained by the degree of texture perfection, the content of harmful impurities and the peculiarities of cold rolling and heat treatment.

Reducing harmful impurities (decarbonization to 0.005% C), improving smelting, cold rolling and heat treatment modes, and improving surface quality made it possible by the end of the 50s. last century, increase the maximum magnetic permeability of industrial transformer steel with rib texture to 50,000–60,000 Gauss/E, and reduce hysteresis losses at B = 15,000 Gauss to 0.4 W/kg at a frequency of 50 Hz. The anisotropy of energy losses in steel with a rib texture (the ratio of losses at an angle of 90º to losses at an angle of 0º in the rolling direction) is approximately 2.5–3.0.

Rice. 1. Arrangement of crystallites: a) rib texture, b) cubic texture

Along with high magnetic properties, grain-oriented steels have a low aging coefficient (0–3%), high ductility, high fill factor and high surface quality. The surface of grain-oriented transformer steel, as a rule, has high electrical insulating and anti-corrosion properties, obtained through special processing.

It should be noted that the use of steels with magnetic anisotropy requires a magnetic core design in which the magnetic flux passes only in the direction of the best magnetic properties, i.e., in the rolling direction. Fulfillment of the stated condition is possible as a result of the use of tape cores (Fig. 2, where a, b - solid tape cores; c, d - split tape cores).

The use of textured steels in powerful transformers makes it possible to reduce energy losses by 20–30%, the cost of transformers by 5%, weight by 10%, and steel consumption by 20%. For low power transformers the weight gain is even more significant.

It is also important for electrical machine-building plants (consumers) to produce electrical steels in the form of tape wound into rolls, which allows mechanization and automation of continuous production at these plants, as well as at the manufacturer - at metallurgical plants. Therefore, starting from 1940–1948, cold coil rolling of electrical steel in the form of a strip on continuous or reversible mills began to be widely used.

Electrical steel coils

Creation and industrial development in the 30s - 50s. last century, cold-rolled anisotropic electrical steel with rib texture was an outstanding achievement in the development of soft magnetic materials, however, the expansion of the scope of its application and the increase in the number of its grades revealed some, not always positive, features of its use, namely:

— high magnetic properties of cold-rolled steel with a ribbed texture are obtained only along the rolling direction, while for the magnetic cores of electrical machines with a round stator and rotor shape, it is necessary that the anisotropy of the magnetic properties be minimal, since the requirement of parallelism of the magnetization and rolling directions in this case is met hard enough;

— the magnetic properties of transformer steel, which has a ribbed texture, deteriorate greatly as the strip thickness decreases to 0.15–0.10 mm or less.

Rice. 2. Tape cores

In light of these reasons, the efforts of researchers were aimed at creating cold-rolled steel that has equally high magnetic properties both along the rolling direction and across it, while not losing its magnetic characteristics when the thickness of the cold-rolled strip is reduced to 0.1 mm or less. And such isotropic steel was created.

Sheet steel

This type of metal is most used in electronics. Electrical steel sheets are an alloy consisting of iron and silicon, and its content can reach 4.8%. Steels with a low content of substances, due to which their properties are improved, are called alloyed.

Open hearth furnaces are used to produce electrical steel. For the production of sheets, steel ingots are used, the condition of which determines the rolling method: cold or hot. According to this feature, electrical steel can be cold-rolled or hot-rolled.

In addition to alloy steels, textured steels are produced, which have higher magnetic properties than conventional steels obtained by hot rolling. This is achieved by repeated rolling of the sheets, where they are subjected to strong compression. In addition, this is followed by annealing in an atmosphere filled with hydrogen. The use of these manipulations cleans the steel of elements such as carbon and oxygen. To produce textured sheet steel, both types of rolling are used, but metal produced by the cold method is more valued.

Distinctive features of isotropic and anisotropic steels

What properties a compound will have depends on how much silicon was added to it during the manufacturing process. Hot rolled and cold rolled steel have different cell sizes. If a material has large crystals, then its magnetic permeability is greater, but the coercive force is insignificant when compared with materials with small crystals. The grain size depends on the mechanical or heat treatment used.

During annealing, the internal stress in the metal decreases, and at the same time the crystals increase, forming a structure. If you do hot rolling, you will not be able to form the grains stable in a certain position, so they are placed randomly. This is isotropic steel. It has magnetic properties that are independent of direction.

In order to obtain a textured material, they resort to cold rolling of steel a second time, accompanied by annealing under special conditions. This makes it possible to obtain anisotropic steel. The ribs in it are located as they were rolled. Placing the material in the correct position helps to increase magnetic permeability and reduce coercive force, improving the performance of devices.

Electrical steel is produced and sold in coils or individual sheets. Their length is from 720 to 1000 mm.

Classification

It is based on differences in steel in such parameters as purpose, magnetic properties, and chemical composition. Metal is classified according to the following indicators:

- Depending on the rolling method and structural condition, steel is divided into first, second and third classes.

- According to the quantitative composition of silicon. If it contains less than 0.4%, then this steel is not alloyed.

- Depending on the main standard characteristics, steel is divided into groups: from “0” to “7”.

- The numbers indicated in the steel grade indicate: first - class depending on the type of rolling and structural condition; the second is the amount of silicon; the third - a group of main characteristics, the fourth - the type of steel by serial number.

GOST electrical steel meets the standards and is designated by numbers: for sheets - 11036, for strips - 3863.

Conclusion

Transformer steel is produced with the addition of silicon. This element provides improved electromagnetic characteristics; it is used to create transformer cores, core and armor magnetic cores. Product markings contain information about the type of steel and the main standardized characteristics. The cost of the material on the Russian market is 120-180 rubles. per kg.

Various companies are involved in the production of this material, but the largest amount is produced in Kitara, if we consider indicators around the world. Russia managed to enter the market and produce up to 10% of the world's steel.

Properties of steel

Electrical sheet steel has the following properties:

- Specific resistance. The quality of the material is better if this indicator is high. Due to resistance, electric current experiences obstacles as it passes. For the production of conductors, steel with minimum values of this indicator is used. But for their shielding, as well as for the manufacture of cases, on the contrary, it is important that the electricity is kept inside and its losses along the way are minimal. Therefore, steel as a raw material must meet these requirements.

- Low coercivity. The indicators of this parameter determine how capable the magnetic field inside the material is of demagnetization. Electrical steel for transformers and electric motors must be well demagnetized, that is, have a high ability to do so. Electromagnets, on the contrary, are made from steel, which has a high coercive force. This metal is called anisotropic electrical steel.

- The corresponding width of the hysteresis loop. This indicator affects the ability of the elements involved in the operation of the electrical circuit to return to their initial state again after the device is turned off. When the supply of electricity to the circuit is stopped, voltage, which is called mechanical, remains in its components for some time. In the device parts, the original state will be restored much faster if the hysteresis loop has a smaller width.

- Magnetic permeability. If this indicator is high, this means that the material copes with its functions perfectly.

- A significant indicator, especially in electronics, is the thickness of the sheet, which should not exceed one millimeter.

Application of sheet steel

The industry produces sheets reaching a width of 240-1000 mm, a length of 720-2000 mm, and a thickness of 0.1 to 1.0 mm. In addition, narrow tapes 0.15 - 1.0 mm thick are produced. The properties of sheet steel allow it to be used in electronics. Cores, magnetic circuits, chokes, rotors and stators for dynamos, relays, electric motors, stabilizers, current transformers and much more are made from it. In most cases, grain-oriented steel is used, since its magnetic characteristics are more important.

Designation

It is marked with the letter “E”, followed by a number, the numbers of which have a specific meaning:

- The first digit in the marking value indicates the degree of alloying of steel with silicon. From lightly alloyed to highly alloyed, respectively, in numbers from 1 to 4. Dynamic steels are steels from the E1 and E2 groups. Transformer - E3 and E4.

- The second digit of the marking has a range from 1 to 8. It shows the electromagnetic properties of the material when used under certain operating conditions. By this marking you can find out in which areas a particular steel can be used.

The number zero following the second number means that the steel is textured. If there are two zeros, then it is slightly textured.

At the end of the marking you can find the following letters:

- “A” - specific material losses are very low.

- “P” is a material with high rolled strength and high surface finish.

Steel defects

Why does electrical steel have defects? The reasons for their appearance are various. During the steel production process, metallurgical defects can appear due to the high silicon content in the alloy, resulting in the formation of gas bubbles and growth of ingots.

Another defect appears when crusts curl up when steel is spilled. As a result, films are formed that significantly reduce the quality characteristics of the steel surface.

Significantly reducing the quality of the metal is such a defect as internal cracks, which are called “birdhouses”. They appear if cooling occurs at high speed and low temperature - 120 oC.

Explanation of markings

Each grade of steel is designated by certain numbers that carry the following information:

- At the beginning of the marking there is a number indicating the structural structure and type of rolling. The first class includes hot-rolled isotropic, the second – cold-rolled isotropic, and the third – cold-rolled anisotropic.

- The second is the amount of silicon in the material from 0.4 to 4.8%.

- The third is belonging to a standardized group.

- The leading digits are used to indicate the type.

The fourth and fifth digits show the main standardized characteristics in quantitative terms. The marking provides basic information about the material.

Electrical steel grades

Each sheet is stamped with numbers. It denotes the purpose of the steel.

- The poles of electric machines operating on direct current, engine parts whose power reaches less than 100 kW, and the magnetic cores of devices are made from low-textured cold-rolled steel grade 2211 or non-textured hot-rolled metal grades 1211-1213. The metal has high ductility.

- The rotors and stators of engines with a power of 100-400 kW are made of non-textured hot-rolled electrical steel of grades such as 1312 and 1311. The metal has good ductility.

- Rotors and stators of engines with a power of 400-1000 kW, low-power power transformers, and engines with increased frequency are made from low-textured cold-rolled steel grade 2411 or non-textured hot-rolled steel grades 1412, 1411.

Electrical steel core

For the manufacture of stator and rotor cores, which are equipped with electrical machines operating on alternating current, second class sheet steel is used. The electrical steel core is used in power transformers. For its manufacture, unalloyed metal of this type is used, which has standardized properties. This steel varies in its chemical composition. But its magnetic properties, both after firing, which is carried out at temperatures up to 950 °C and without the presence of oxygen, and after cooling for 10 hours at a temperature of 600 °C, should not be lower than the developed standards.

The core of the electrical steel armature, which is equipped with machines operating on direct current, is assembled from sheets of this particular metal. And why? The use of this material is advisable because a change in the magnetic flux in the core entails the occurrence of eddy currents. To prevent them from heating the armature core, insulated plates are used for its manufacture, which will block the path of current.