Such an interesting device as a flexible shaft for a drill is intended for drilling holes in hard-to-reach places. Hard-to-reach places are those areas when access to them is limited due to the large size of power tools. To make working with power tools easier, tool manufacturers have invented a device such as a flexible shaft for drills and screwdrivers, which can be easily purchased on the Internet or any tool store. It is a flexible attachment device that transmits torque to a tool that is not coaxial for the electric motor.

Specification

The seller has 4 options to choose from, differing in head size and shaft length.

After pressing water Material: Chrome vanadium steel. Length: 6″ 8″ 10″ 12″ Suitable for :1/4″ 3/8″ Screwdriver head I took a 10″ long (247 mm realistically) and a quarter inch head.

Moreover, when ordering, I was firmly convinced that the head was 6-sided - it was written!

But a 4-sided one arrived. After looking at the picture, I was convinced that the square in the picture was drawn. I wrote to the seller - sell the mother-to-mother adapter from square to hexagon for some money. But he hasn't. I scratched my turnip, decided that it was my fault, I needed to look better, and did not open a dispute. The review gave 4 stars, I noticed that it is 4-sided.

Homemade flexible extension shaft for drill

Sometimes you need to tighten or unscrew a screw or nut in an inconvenient place and this becomes a problem. To solve it, I suggest rummaging around in the garage and finding a few parts from which we will make a flexible shaft for a drill with our own hands. With it, you can crawl into almost any corner and unscrew or tighten a previously inaccessible screw, screw, self-tapping screw or nut.

Homemade flexible extension shaft for drill

In order to make a flexible extension shaft for a drill or screwdriver, we need a long spring and a thick cable.

Homemade flexible extension shaft for drill

Homemade flexible extension shaft for drill

Homemade flexible extension shaft for drill

We cut off the end of the cable using a grinder if there is a solder at its end or it is fluffed, and immediately wrap a wire around its end so that it does not unravel.

Homemade flexible extension shaft for drill

Homemade flexible extension shaft for drill

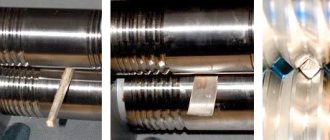

If you have a lathe, then you need to make ends in the form of tubes with limiters on both ends of the cable; if you don’t have one, you can order them from a lathe.

First we put one tip on the end of the cable, where the wire is wound, after that we unwind this wire, it is no longer needed. We weld the end of the tip with the end of the cable inserted into it.

Homemade flexible extension shaft for drill

We insert the cable into the spring and saw off a piece of the cable with a grinder, first winding the wire where the second end is ultimately formed.

Homemade flexible extension shaft for drill

We also put a tip on this end of the cable, which is made a little shorter; at one end of the tip the hole is narrower, along the diameter of the cable, and at the second it is wider, for an adapter-holder for drill bits.

Homemade flexible extension shaft for drill

We weld the inner part of the tip with the end of the cable; at the same time, the bored part for the bit adapter should remain inside.

Homemade flexible extension shaft for drill

We insert the adapter into the tip previously welded to the cable and weld it to this tip.

Homemade flexible extension shaft for drill

Homemade flexible extension shaft for drill

Homemade flexible extension shaft for drill

That’s it, in fact, here we have a homemade extension shaft for a drill from a spring and a cable.

Homemade flexible extension shaft for drill

Homemade flexible extension shaft for drill

Homemade flexible extension shaft for drill

Using this shaft, you can easily tighten or unscrew nuts, bolts, screws at an angle and in inaccessible places, so I advise you to make such a flexible extension shaft for a screwdriver. See other useful homemade products on our website.

Homemade flexible extension shaft for drill

Homemade flexible extension shaft for drill

Take home:000

Similar homemade products:

- Hand-held circular saw from a drill or screwdriver

- Simple hand vice for drill press or drill

- Compasses for large diameters from a pistol from...

- Ratchet wrench made from reinforcement and bearing...

- Universal quick-release handle holder for…

- Powerful match shooter from a clothespin

- How to replace a mosquito net on a plastic frame

- DIY nut bracelet

- Convenient universal door hinge holder

Tags:flexible shaft, drill, drill attachment

Appearance and specification

I can’t say that it’s really chromium vanadium, but it looks similar. In general, it gives the impression of a tool, and not a stray device, like the previous flexible shaft.

On the edges of the mother there are grooves for the ball so that it does not jump off. Couldn't catch it in the photo, but in the hole on the mother you can see that the shaft is made of wire of the same diameter as the outer wire.

The ball on dad is spring-loaded - everything is like people’s.

What operations are performed using an engraver with a flexible drive?

Special attachments help turn an engraver with a flexible shaft installed on it into a truly universal device, which include:

- grinding and polishing wheels, allowing you to bring the surface of the workpiece to a perfectly smooth state;

- brushes used for cleaning the surface of the product and polishing it in hard-to-reach places;

- cutting wheels for cutting products and processing their torn edges;

- drills, with the help of which the device turns into a miniature drill;

- cutters and abrasive wheels that allow processing of products in hard-to-reach places;

- pen-shaped attachments used for engraving work.

To ensure ease of operation with such a device equipped with a flexible drive shaft, you can purchase additional accessories - rubber grips on the handle, a power button lock, etc.

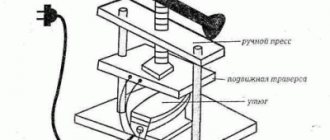

All kinds of holders are very useful, in which, in addition to the shaft and the engraver, you can attach various attachments

Engravers on which a flexible drive shaft is installed also include a drill used in dentistry, a manicure machine, equipment for processing natural stone and applying inscriptions and drawings to the surface of products made from it.

You can also use a flexible shaft for a drill or purchase a flexible shaft for a screwdriver. With this improvement to conventional power tools, a screwdriver attachment or drill can be successfully used to perform work even in the most difficult to reach places.

Quest: mother-to-mother adapter, 1/4″ square to hexagon

Well, okay, the Chinese didn’t sell the adapter, I’ll find it on Ali. But I didn’t find horseradish there, at least for reasonable money. Alexeast

found an almost identical (but shorter) flexible shaft While looking at nearby products, I found the adapter I was looking for for less than a dollar.

Yeah, right now! Who can guess what's wrong? I couldn't. It turned out that the bit was tightly pressed in. Well, that is, I can and will pull it out. But the other one will also have to be driven in with a hammer.

And without a bat? It turned out there is, but in a set of socket heads. 350 rub. I took the wrong money. Same with pressed bits. The desired mother is a quarter inch 4-6 top left. That is, they do it, but they don’t sell it separately. Also included is a 4-6 male-male adapter, but there are a lot of them everywhere.

In general, by the time I got to the store, another month had passed. On the question of how convenient and fast it is to buy everything offline, and how long to wait from the Chinese. And this is also in Nerezinova.

How does the engraver work and how does it work?

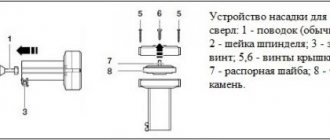

The engraver, which allows you to process parts with high precision and productivity, works on the principle of a conventional drill, and in appearance it is very similar to a large automatic pen. The main structural elements of such a device are:

- engine;

- a flexible drive shaft that transmits torque from the engine to the working attachment;

- gearbox;

- a fan used to cool the spindle;

- the spindle itself with a protruding working part;

- device body with special openings for the exit of heated air;

- a nut designed to fix the used nozzles;

- device power regulator;

- lock button;

- power switch;

- hook for hanging the switched off device.

Engraver device

Rotation from the engine is transmitted to the axis of the flexible shaft, the reverse side of which is connected to the working nozzle. The mounting locations of the nozzles are unified, so there are no problems with choosing the required tool and replacing it.

Total

Here's an interesting situation.

The product fully corresponds to the description. Efficient, can be used for its intended purpose. Looks beautiful. What else do you need? Well, I’m not happy - so who is to blame for the fact that my expectations were too high? No one. Apparently, there is no such shaft on sale as I dreamed of. We will look at the cardan if necessary. But the shaft under review has no advantages compared to the simplest Deshman shaft. So I ordered another cheap one for a dollar at a promotion on Girbest. At least it has a plastic case, it requires less holding with your hand.

Equipment selection criteria

When choosing an engraver, you should focus on a number of characteristics.

Power

Based on the power level of the device, on which its performance directly depends, one can indirectly judge the operating life of the drive motor. The power of the engraver, which for serial models can be in the range of 35–300 W, should be selected based on the tasks for which it is planned to use such equipment. In addition, you need to consider how long it will work between turning on and off. The duration of the operating process depends on the hardness of the material from which the product being processed is made. The longer the engraver is used at one time, the more power it should have.

The low-power compact engraver is suitable for simple work without a flexible drive

Number of revolutions

The speed at which the electric motor shaft and the flexible drive shaft attached to it rotate is also selected depending on the hardness of the materials that need to be processed using the engraver. Models offered on the modern market can provide tool rotation speeds in the range of 10–35 thousand rpm. Low-speed models can be purchased if they will be used primarily for finishing grinding and polishing. When performing such operations, a small load is placed on the tool, so the engraver itself does not overheat, and therefore does not fail.

If you need a more universal device with a flexible shaft, it is better to give preference to engravers that provide the ability to adjust the rotation speed of the tool.

The speed controller significantly increases the functionality of the engraver.

Dimensions and weight

The weight and dimensions of the engraver affect how convenient and easy it will be to manipulate such a device during processing with its help. Engravers that have significant dimensions and weight are much more difficult to work with, but such devices, as a rule, have higher power and productivity. The weight of an engraver with a flexible drive shaft can be in the range of 0.5–8.5 kg. When choosing such a device, first of all take into account the required power and functionality, and only then pay attention to the weight and dimensions.

Ergonomics

Since an engraver works by constantly holding such a device in his hands, its ergonomics, which characterizes the ease of working with the equipment, is an important factor when choosing. When assessing the ergonomics of a device, you should pay attention not only to its design, but also to the build quality, manufacturing materials, button placement and comfortable handle design.

Before purchasing a tool, you should hold the engraver in your hands, test the activation of buttons and latches

Level of noise, vibration and heating

These parameters are not indicated in the equipment passport. It is advisable to pay attention to them if the engraver will be used quite often. To evaluate how much noise and vibration the device makes during operation, you just need to turn it on and evaluate these parameters. As a rule, medium-power engravers make more noise, and in more high-speed equipment this problem is provided for by the manufacturers and is eliminated by including special elements in the design. You can only estimate how hot an engraver equipped with a flexible drive shaft gets during operation.