Home / Welding technique

Back

Reading time: 3 min

0

3655

Polyethylene film is widely used in various fields. Some uses of it involve the connection of several elements.

For example, when covering greenhouse frames or forming insulating layers during construction.

Welding of polyethylene materials, including film, can be done at home. This article will tell you about the equipment necessary for welding polyethylene, as well as the technology for independent soldering of this material.

- Soldering technology

- Tools and appliances Soldering iron

- Soldering with a soldering iron

Soldering technology

Welding of different parts of a polyethylene film occurs by exposing its edges to a temperature equal to the melting point of the material, followed by tight compression of the layers.

The compression of molten polyethylene connects the parts of the elements at the molecular level, forming a strong weld seam.

However, in order for this seam to be reliable and withstand the load, you need to use suitable welding equipment, as well as observe the nuances of the technology. It is important to maintain a suitable temperature level, which ranges in a narrow range from 130 to 160 degrees Celsius.

Despite the fact that the film polymer compound does not look much like metal in appearance, the rule of thoroughly cleaning the surface also works with it.

Particles of foreign inclusions can disrupt the molecular structure of the junction of two films. Therefore, surface cleaning plays a key role in preparation for welding.

In addition, the following rules must be observed:

- All parts of the material that will be soldered must be made in one batch

- The melting temperature during welding must not be violated. An underestimated temperature will create a weak connection, an overestimated one will deform the material.

- Re-welding of edges that have already been heat treated is not permitted.

Also, the quality and strength of the film seam is influenced by the tool with which it is created. You need to choose the right welding device. It is advisable to take one that will have fewer problems in handling.

How to glue greenhouse film

To understand how to glue a film for a greenhouse, you need to distinguish what material is used for the structure and what properties it has. The choice of tool, the heating time of the edge and other nuances of soldering the artificial fabric depend on this, which should result in a uniform, even seam without holes or traces of thermal deformation.

Different types of film are used in the construction of the greenhouse:

- Polyethylene film is a non-flammable polymer that begins to melt at a temperature of +110...+130 degrees. Moreover, after cooling, it does not change its properties, remaining impenetrable to steam, gases, moisture and other substances.

- Reinforced polyethylene film - durable and resistant to any physical impact. The melting point is +120...+130 degrees Celsius. Structurally, it is a mesh frame with square cells (the thread material is fiberglass, lavsan, polypropylene, etc.), covered on both sides with polyethylene film. Unlike ordinary polyethylene, it has a rough surface.

How to combine plastic film for different types of greenhouses?

The main rule: you can only solder the same materials, for example polyethylene with polyethylene. Rough surfaces and edges made of different materials must be glued together using glue.

The technology for joining polyethylene is selected depending on the properties of the material. In the next subsection you will learn how to solder polyethylene film for a greenhouse at home.

Tools and devices

A strong connection of polyethylene film can be made with an iron, soldering iron, or special equipment.

Soldering with an iron

This is a fairly simple way to connect parts of fabrics, because household irons are found in almost every home.

Welding with an iron

An important step in polyethylene lap jointing is rapid cooling of the seam area. How to properly join the film with your own hands using an iron:

- lay the material on a wooden or other flat heat-insulating surface;

- place a sheet of thick paper on top;

- the iron is set to the “cotton” mode (the required temperature is 120–150°C);

- the seam is made with the sharp edge of the sole, it is tilted so that there is an angle of 5–10° with the surface of the paper;

- The iron is moved slowly, after which a wet rag is placed on the paper.

To ensure the strength of the seam, the operation is repeated 3–4 times.

Ordinary household iron for gluing polyethylene film

Craftsmen make attachments for irons with metal guides similar to skates. They are used to make double and triple seams. For the manufacture of nozzles the following is used:

- heat-resistant stainless steel, if you have the skills to install it;

- copper-based non-ferrous metals;

- aluminum-magnesium duralumin alloy.

Special equipment

Large jobs require the use of more serious tools. To create a large-area film joint, you will need special welding equipment.

Such equipment is equipped with settings for the level of pressure, temperature, and the speed of movement of the heated element along the surface of the polyethylene. In household options for forming film seams, there are no such functions.

When welding polyethylene sheets from one batch, the settings are set once. There is no need to reconfigure the equipment for each seam, which speeds up the work.

In addition to setting regulators, soldering machines are equipped with roller mechanisms. These are setting and tension elements that stabilize the speed of advance of the film sheets being welded.

This improves the quality of polyethylene soldering and increases the strength of the connection.

There are devices that use different heating methods: air and contact. Air heating is produced by exposing the material to hot air. Contact involves a heating element in contact with the material.

A connection created by welding polyethylene sheets has a higher strength threshold than one created by gluing with special materials. After all, a soldered seam connects the canvases themselves at the molecular level, without any intermediaries.

Polyethylene and its properties

Polyethylene is a very common material with many excellent properties. It is used for insulation, for packaging, for protection from moisture, is an excellent electrical insulator, absorbs the most dangerous type of radiation - neutrons and is therefore used in protection against them, and is completely chemically resistant. This latter sometimes turns from an advantage into a disadvantage. How to glue polyethylene? Gluing is a chemical and a little electrical process, oddly enough. The molecules of the substances being glued are attracted to each other due to the difference in their electrical charges.

That is, there must be an adhesive in nature (and on the market) that adheres well to polyethylene, and when hardened, firmly holds the glued parts. So, the problem is that gluing polyethylene is very difficult. Its molecules are electrically very “balanced”, hence the extraordinary chemical resistance of the material. And a reluctance to stick to anything. However, the industry has found something to glue polyethylene with. True, not all of this is suitable for home, but some may come in handy. Here are the suitable methods, selected according to the resulting strength rating:

- Welding polyethylene

- Weicon Easy-Mix PE-PP Adhesive

- Epoxy glue plus oxidizing agent

We will consider these three methods further.

DIY film soldering

Polyethylene pipelines are installed in two ways: using fittings and flanges or several types of welding.

The connection requires special fittings (couplings and sockets) and without them. For pipes with a wall thickness less than 4.5 (diameters 50-110 mm), welding using fittings is used; for larger pipes with a thicker wall, butt welding and extruder welding are acceptable.

Diffusion

The diffusion method involves heating the ends to a viscous flow state. The prepared ends of the workpieces are joined and slightly compressed. Movable polymer molecules, under the influence of pressure, move into the parts being connected, mix, freeze in a new position when cooled, form new chemical bonds and ensure reliable adhesion of the pipes to each other.

Bell method

Not the most typical way. There are two options for implementation: using socket pipes and couplings. The method itself is reminiscent of welding polypropylene pipelines: the socket or coupling and the workpiece are heated using a soldering iron with a special nozzle.

Then the workpiece is inserted into the socket of another pipe or coupling, fixed, pressed and held. Welding time – 20 seconds. If couplings are used, then the second pipe is soldered into the coupling in the same way. The cost of couplings is low; products with a socket are rarely found in stores.

The connection is reliable and durable; small diameters can be welded.

Butt welding

Before carrying out work, cut off the polyethylene pipe strictly perpendicularly and thoroughly clean the ends. Then fix the pipe in the welding machine and carefully center it.

Cool the joint, then remove the machine. The work has its own subtleties; it requires two people.

Extruder welding

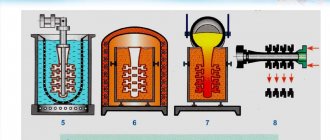

Extrusion - welding using a small apparatus from which molten polyethylene is extruded under pressure. Raw materials in the form of rods or granules are loaded into the extruder.

Extrusion is used on pressure communications with a wall thickness of more than 6 mm, but it can also be used to patch non-pressure sewer pipelines with a thinner wall. The connection point is heated by a stream of hot air.

It is advisable to chamfer the ends.

Gluing with acrylate glue with filler

The best glue is Weicon Easy-Mix PE-PP. It is specially designed for materials with weak adhesion. Most liquids “stick” to polyethylene very poorly and are simply squeezed out from the point of contact between the surfaces.

But this glue contains the addition of tiny glass beads, which prevents the glue from leaving the gluing area, forming a gap of the required thickness. Therefore, the gluing surface is sufficient and the glue, when hardened, holds the surfaces firmly together. It’s hard to find anything better than gluing polyethylene.

Surfaces must be thoroughly degreased and dried before gluing. Glue can only be supplied from a branded packaging mixer. The best temperature for performing work is +21…+23°С. Liquid glue is good for no more than 2-3 minutes. After applying the layer, you must immediately join the surfaces. Full readiness of the seam (maximum mechanical strength) for polyethylene will be achieved in a few hours (4-5 according to the experience of those who worked with glue). The adhesive joint is cured at a temperature from +15 to +70°C.

Welding polyethylene

The strongest seam is obtained when welding polyethylene. If done correctly. The fact is that polyethylene is hot molded, usually under very high pressure, which reaches hundreds of kilograms per square centimeter. And when it is reheated at atmospheric pressure until it melts, it tends to shrink, a little, but this is enough to make welding difficult. Two types of welding can be distinguished: film welding and thick polyethylene welding (canisters, pipes, etc.)

To weld the film, heated objects or a special apparatus for gluing polyethylene, or more precisely, welding, are used. It works like this: both layers of film are pulled along a heated wedge, and then immediately welded with a pair of compressed rollers. With the correct selection of temperature and pressure of the rollers, an excellent result is obtained - complete sealing of the seam.

But with a little practice, you can learn how to glue polyethylene even with an electric soldering iron or iron through paper, so as not to spoil its sole. The clean edges of the film are placed on top of each other and driven through the paper with the edge of the sole of a heated iron.

A soldering iron with a clean tip, if turned on through the voltage regulator, welds the seam even better, and no paper is needed. You can also make a clamp on the tip with a small nozzle of a convenient shape made of metal. Then the tip can be used for its intended purpose, and the polyethylene will not be stained with solder or carbon deposits from flux.

Gluing thick polyethylene is more difficult and requires good skill. The best heating method: a portable gas burner (it’s convenient to use), or a hair dryer with a nozzle for a narrow jet of +250°C.

The procedure could be as follows:

- Thoroughly clean and dry surfaces before welding.

- Prepare polyethylene filler for the seam. It is best to take a narrow piece of the same material.

- Heat the edges of the seam until melting begins and let them “settle” a little. But don't get carried away with this process.

- Start introducing the additive (see point 2), fusing it evenly into both sides of the seam to a thickness equal to the material.

- Allow the seam to cool completely.

The same method is applicable when deciding what to use for gluing foamed polyethylene. The surface of foamed polyethylene is not very conducive to bonding, and it is better to weld it carefully.

For another method of welding thick polyethylene, see the video:

Scope of use of PVC materials

First of all, it should be said that products made from polyvinyl chloride materials are easy to transport, install, and so on. Similar products can be used in the following areas.

- They are perfect for the manufacture of tent-type architectural structures: various kinds of pavilions, canopies, cafes, and so on.

- Agricultural type construction - shelters for equipment, warehouses, parking lots, and so on.

- They can be used for car awnings.

- Safety devices, in particular pool covers.

Advantages of purchasing a welding machine for PVC film from SIGN SERVICE

Purchasing a unit for welding sheets requires quite a significant investment, so it is important to buy a reliable and durable device. Our models are characterized by an optimal price-quality ratio; they are worth every ruble spent. The devices consist of two key components: industrial Swiss hair dryers and a wheelbase. The high level of performance of the equipment is confirmed by a long warranty.

Welding a banner or any other product with such devices will no longer be a problem, all work is carried out promptly, and our specialists are ready, if necessary, to advise each client on any issues that arise.

Bag sealers

Tabletop bag sealers are used for sealing finished bags made of polyethylene or polypropylene with a thickness of up to 200 microns or producing bags from a sleeve of this film. The advantages of such sealers are high-quality seams, reliability and versatility of film type and thickness.

The pulse manual bag sealer is used for sealing finished bags from heat-resistant films up to 0.2 mm thick. Thanks to this device, a strong seam is ensured and labor productivity increases. All equipment is equipped with a time relay for adjusting the seam sealing time.

Thanks to manual and floor-mounted bag sealers with a knife, it is possible to cut off excess film after sealing and thus make a bag. Sealers with a mechanical knife are the most convenient equipment for hermetically sealed packaging and are used for food and non-food products.

Welding machine for PVC film in

To buy a welding machine for PVC film, you no longer need to choose a seller for a long time - you have already found it! Absolutely anyone can buy high-quality equipment with a guarantee on our website. To purchase a welding machine for PVC film from us, you just need to place an order for the product, and then all you have to do is wait for the parcel to arrive. We work on a flexible system of mutual settlements, so clients do not have to worry about payment. Call at any convenient time and order high-quality equipment at competitive prices!