Currently, there are many different adhesive compositions on the market, sold under the general name “Cold Welding”. In reality, such compositions have nothing in common with either hot or cold welding. Under this trade name, polymer composite materials are sold that can be used to repair products made from a wide variety of materials - from metals to wood, ceramics, glass and plastic. Sometimes it becomes necessary to remove such glue. The reasons for this can be very different. If such a need arises, you can dissolve the cold weld without any problems or remove it using other methods.

Cold welding can be used to repair any materials and products.

Helpful tips before you start

Before starting work, you need to prepare the necessary materials and tools. Their list will vary depending on which surfaces the adhesive needs to be removed from. You may need the following:

Nail polish remover containing acetone will help remove cold welds.

- Acetone or nail polish remover containing it.

- Sandpaper.

- Soap.

- Pumice.

- A piece of thick paper or cardboard.

- Unnecessary toothbrush. Instead, you can take a cotton swab or some cotton material.

- File.

- Solvent, gasoline.

First of all, you can purchase a special ready-made composition for removing cold welding at a hardware store. There are many different commercial products available that will remove adhesives without much trouble. Please read the instructions carefully before purchasing. Find out from which surfaces the solvent you are looking for can remove cold welding, and choose the most suitable composition.

In most cases, acetone works well with cold welding and other common adhesives. If “pure” acetone is not available, you can use nail polish remover containing it. Whether acetone is present in the composition is indicated on the label in the list of ingredients.

Using sandpaper, you can easily remove cold weld residues from the surface of products.

The main efforts should be directed to the edges of the “spot”. You need to try to grab this “spot” by the edge and tear it off the surface completely. Try to soak the cold weld as much as possible. As soon as the composition begins to peel away from the surface, carefully try to remove it.

Be careful when using acetone, gasoline, alcohol and other solvents. Especially if cold welding needs to be removed from wood, plastic, ceramics and other similar materials. Under the influence of a solvent, they may lose their color, and some may even melt. Any solvents must be used with caution. First, test the product on some inconspicuous part of the product. Work using personal protective equipment.

Removing Cold Welding from Wooden Surfaces

First, try soaking the cold weld with warm soapy water. Use your fingernail or some other suitable object to pick off the mixture. If all else fails, move on to more radical methods.

Typically, acetone helps remove such adhesive. It will help out if the wooden surface has a fine finish. It is not worth picking out a cold weld from such a surface, because... By doing this you risk damaging the coating. Solvents must also be used with caution. Everything is done in the following sequence:

It is very convenient to remove paint from a wooden surface using a silicone or rubber spatula.

- You take a rag and wet it with acetone.

- Rub the surface of the cold weld. Treat small areas with circular movements. If a large space is filled with cold welding, make circular movements in the direction from the edges of the spot to the center.

- It is most convenient to remove the softened composition using a silicone or rubber spatula. Under the influence of acetone, the edges of the composition will rise, and you can slip such a spatula under the raised edge and remove the stain.

- To remove acetone, thoroughly wash the freed surface with warm water. Finally, the wood will need to be treated with olive oil. Beeswax will also work. If there is a special furniture polish, use it.

You can try to remove cold welding using mineral oil. This method is only suitable if the wooden surface is not painted. Take a piece of cloth, soak it in mineral oil and wipe the cold weld spot. Rub and wet until the edges begin to peel away from the surface. Finally, the surface will also need to be rinsed with warm water and polished.

In some situations, the only possible solution to the problem is grinding. Everything is done very simply. First, you will need to cover the area around the stain with duct tape. This will protect the wood surface. After this, start sanding with sandpaper until the stain comes off. To restore a sanded surface, use the same compound that was used to originally open it.

Read also: Hall sensor circuit and operating principle

Purpose

In stores, all kinds of cold welding are sold at affordable prices; their use does not require special training or complex equipment. They are perfect for connecting parts that do not experience large mechanical loads during operation.

They are used to repair plumbing fixtures and quickly eliminate leaks. But still, the use of such adhesives is, as a rule, a temporary solution to the problem.

To ensure a truly reliable and durable connection of metal products, you will have to use standard welding machines.

Step-by-step instructions for removing cold welds from plastic

Cold welding can be removed from the surface of the plastic using a soap solution.

This task is somewhat more complex than removing the composition from wood. The problem is that plastic does not withstand aggressive influences such as grinding, treatment with acetone and other solvents. Therefore, everything must be done as carefully as possible so as not to damage the material.

First, consider whether the cold weld spot is such a big problem. Does it interfere with using the item for its intended purpose? Wouldn't it be worse without it, because for some reason it was applied earlier?

Try to scrub the stain without using aggressive compounds. You can further soften it with warm water. The simplest option is for the edges of the weld spot to rise and you roll it off the surface. But this does not always happen. Any cold weld that has left the surface can be scraped off with a knife or plastic spatula.

You can try softening the composition with soapy water. To do this, take a rag and dip it in soapy water. Wring out the material until it is damp but does not leak water. Place wet material on cold weld requiring removal. Place plastic film on top and seal its edges with masking tape. This will create a humid microclimate. Wait a few hours. During this time, the damp cloth should slightly soak and soften the adhesive. Remove the adhesive with a rag soaked in warm, soapy water. You need to rub until the desired result is achieved.

Welding can also be removed from the surface of the plastic using ethyl alcohol.

You can use alcohol. Isopropyl composition is suitable. Do everything in the following order:

- Take a piece of soft cloth and soak it in alcohol.

- Place the material on the cold weld spot to soften it.

- After the composition begins to lag behind the plastic, try to remove as much of it as possible.

- To remove residue, use a cloth soaked in a soapy water solution.

- After achieving the desired result, rinse the surface with warm, clean water.

Removing cold welds from glass and ceramics

You need to be extremely careful with glass and ceramic products. If handled incorrectly, they can easily be damaged.

First of all, try to remove the cold seal from the glass using a sharp blade. If the layer is not thick, a razor blade should be able to cut through it without damaging the glass. Use warm soapy water to remove residue.

A sharp blade can be used to remove cold welds from glass and ceramics.

If the razor does not “take” cold welding, try soaking the composition. Place the item in a bowl of warm water. If it is large or cannot be placed in a container for other reasons, it will be enough to moisten the cloth with warm soapy water, place it on the stain and secure a layer of plastic film on top. Leave it for a couple of hours and then try scraping off the cold weld with a putty knife or blade. Acetone or alcohol can be used to remove residues. If necessary, polish the glass to finish the job.

To remove cold welding, you can try using solvents such as acetone, white spirit, etc. To remove the stain, you need to moisten it with water, and then try to remove the stain with a swab dipped in the solvent.

There is another removal method. At low temperatures, most adhesives lose their strength and come off surfaces without problems. Therefore, if it is possible to place the product in the freezer, or if the temperature outside the window has already dropped to at least -15°C, you can try this method.

You can try to remove cold welding from ceramics with a wet rag and a rubber spatula. First, the stain is soaked generously, after which it is carefully cleaned with a spatula.

In some situations, it is sufficient to use a regular solvent. Everything very much depends on the characteristics of the product and the thickness of the cold welding layer.

Precautionary measures

To avoid skin irritation, work with the liquid composition should be done with gloves. If the composition gets on open areas of the body or mucous membrane, immediately rinse the contaminated areas with water. The glued parts should not be subjected to loads until the resin has cured. If you heat the composition, it will harden faster. Welds produced by this method do not have the same high characteristics as those achieved with conventional welding. Their permissible tensile stresses are much lower. Therefore, there is no need to subject the products to tearing forces.

Tips for removing cold welds from metal surfaces

Welding from iron can be removed with dimethyl sulfoxide.

With metal everything is somewhat simpler. It is stronger and you can experiment with it more. First of all, you can try to soak cold welding or treat it with acetone, white spirit, gasoline, etc. Do everything as in the previous methods.

Another product you can try to remove cold welds is dimethyl sulfoxide. Sold in pharmacies. Copes well with a wide variety of adhesives.

Be careful with this product and wear protective gloves.

The substance easily penetrates damaged skin. Irritation and intoxication may occur.

If water and various solvents do not help, try cutting the cold weld from the metal with a sharp knife. Or remove it with a file.

Read also: Melting temperature of lead at home

Thus, there are quite a few ways to remove cold welds. Choose the most suitable one. Happy work!

#1 AlexS.59

- Users

- 2,355 messages

- On the forum: since 2009

- City: South of Ukraine

#2 Bezum

- On the forum: since 2007

- City: Saint-Petersburg

For MMG, I want to “brew” the sinks using cold welding or soldering them with tin. Question: will the “Clover” bluing liquid stick on this basis.

#3 AlexS.59

- On the forum: since 2009

- City: South of Ukraine

For MMG, I want to “brew” the sinks using cold welding or soldering them with tin. Question: will the “Clover” bluing liquid stick on this basis.

No, clover only reacts to iron. You can only weld it by real welding, so to speak, weld it onto the shells and smooth it, or remove a layer of the original material to reduce the shells; you can’t think of anything else if it’s blued. Under matte paint you can do anything - you want cold welding, you want tin, you can only put copper on tin by electrolysis - then, if desired, either nickel or chrome, it seems like that.

#4 Schwein

- On the forum: since 2009

- City: Nizhny Tagil

#5 AlexS.59

- On the forum: since 2009

- City: South of Ukraine

Clover burnishes zinc, zinc alloy, and tin solder. Only in color it will differ from iron. And abrasion resistance is not very good. Try it. Another question is that the MMG (even a pistol, let alone a machine gun) is difficult to warm up for soldering. I seal it with superglue with sawdust of the same metal as the main item. I file it, sand it and blacken it. It’s obvious that it’s different in color, but it’s better than paint.

#6 Schwein

- On the forum: since 2009

- City: Nizhny Tagil

#7 AlexS.59

- On the forum: since 2009

- City: South of Ukraine

You don’t need to pour sawdust into the glue - it will set right away, you won’t have time to stir it. If you have time, such a mass will not stick well. Drop the glue and immediately pour the sawdust. A pile. It will be saturated with glue from below and it will immediately set. Shake off what does not stick. If it’s enough, after a few minutes you can file it down. If the sink is deep, repeat the process. Saw the resulting mound with a file and sandpaper. It’s better to use regular liquid superglue rather than gel—it doesn’t dry for a long time. Instead of iron filings, you can use rust powder—it’s clear that the thing dug, but does not look disgusting. Brown specks against the background of bluing are an interesting peculiar effect, although not for everyone. Try it on something not valuable. You can pour sawdust into epoxy. But it is more fluid and hardens slowly; you can cut it only after a day. Pour it into it by eye until it becomes a thick porridge. But it will settle too early - the sawdust will fall to the bottom, the liquid fraction will remain on top. But it will not turn blue Superglue has the advantage of instant adhesion. Good luck!

#8 gaz-polutorka

- On the forum: since 2008

- City: St. Petersburg

Glue as a souvenir is, of course, beautiful, but the originality is completely killed and corrosion will develop under the glue, and quite quickly and deeply! It’s better to leave it as is, anoint it with oil so that it doesn’t rust further and that’s it. Or find a competent welder and weld not with a semiautomatic device or an electrode, but with a non-consumable electrode in a protective gas environment, such as argon. With a current of 15-25 amperes, not even the thinnest part will burn out right before your eyes, but the strength and functionality of the resulting results will be on an equal level with the rest of the metal. Of course, such welding is not cheap, but you can buy yourself a machine and go ahead.

Burnishing is a process of oxidation of metal, which occurs in special baths in a solution of caustic soda and with strict temperature control from 143-147, I think I don’t remember exactly, and at the same time quite good protection against corrosion is formed, which must be constantly moistened with oil, otherwise due to quite If the coating is sufficiently porous, rust will appear, especially if in a damp room.

The photo shows forest parts from GAZ AA, blued with zinc.

Before bluing, it is necessary to remove corrosion by sandblasting. When using acid, the base metal is etched and it is not easy to wash off the acid efficiently at home, and the dry residue of the acid will continue to eat the metal several times faster than rust.

Cold welding has recently become a very popular way to avoid the need for real welding when it comes to minor breaks and repairing cracks. As the name implies, when using it, the material does not heat up, the workpieces do not melt, and so on. There is also no mutual penetration of molecules of one substance into another, as happens in standard versions. Based on this, many may have a question about how to use cold welding to achieve the desired result. To do this, you need to understand the very basis of the material.

First of all, you need to understand that this is not welding in the traditional sense. This is an adhesive that may contain a metal filler. It allows not only to very firmly glue various substances, including metal, but also to seal cracks in containers and pipes, and to build up individual metal elements that have broken or worn out on parts. Each operation has its own characteristics; accordingly, there are several main varieties that differ in composition, physical condition and how to use cold welding.

Read also: How to restore a rubber seal

For the technical field, this is a fairly easy-to-use substance that is universal in application. In terms of strength and reliability, all this cannot be compared with either gas or electric welding, but for minor repairs there is no better option. After all, to work, you do not need to dismantle parts and look for a special place for carrying out procedures. For those things that are exposed to high temperatures, you can choose high-temperature cold welding that will withstand temperatures over 1 thousand degrees Celsius without losing its properties.

Main types

Cold welding can be two-component or one-component; there are serious differences between these two groups. One-component glue is easier to work with, but it is not always the most effective in its segment.

As for two-component metal adhesives, they are literally sold in two separate tubes. And one component must be mixed with the second before use. It is recommended to create the working mixture in non-metallic containers. Stirring tools should also not be made of metal.

In addition, cold weld adhesives can be liquid or plasticine-like. Liquid ones are almost always two-component, and one of the components is a hardener.

Plasticine-shaped received this name for obvious reasons. Their structure and consistency resembles children's plasticine. These adhesives come in the form of a single-layer or two-layer bar. If there are two layers, then they need to be carefully kneaded and mixed with each other.

High-temperature cold welding for metal should be included in a special group. They differ from others in that they can easily tolerate extreme temperatures above zero. The acceptable operating temperature of such compositions can reach +1000 or, say, +1300 °C.

The amazing properties of such welds make it possible to use them for repairing exhaust pipes, exhaust manifolds, mufflers, furnaces, boilers, and chimneys.

That is, they will be appropriate wherever conventional welding work is needed and where contact with open fire or highly heated substances and environments is possible.

Interestingly, as the temperature increases, such a mixture only becomes stronger.

Application of cold welding

Regardless of the chosen variety, the substance is universal in use. It can be useful both for home and industrial applications. With its help, you can combine metals of various types, metals with non-metals and other substances in absolutely any combination. Similar to standard welding, cold welding is used to seal cracks, holes and openings. With its help, material is deposited onto various parts. It can also create a permanent joint seam that will hold the parts tightly. In many cases, thanks to high-quality filler, the material for repair may be stronger than on the parts themselves, but for all this you need to strictly adhere to the rules of use. To do this, you need to know how to use cold welding correctly.

This glue is widely used in the plumbing sector, as it can easily cope with the pressure that exists in the water supply and sewerage pipes. It is also indispensable when repairing cars, when you need to repair a leaking fuel tank without removing it or washing it, since everything happens without dismantling the device itself. Nowadays it is increasingly used for gluing aquariums, linoleum, furniture and various tools.

Popular manufacturers

For work, it is better to use materials produced by well-known manufacturers. These include:

- Adro Steel. Produced by a well-established manufacturer from the USA. This is a plastic material. Packaged in a cylindrical tube. Used for repairing automotive parts: body, radiator, fuel tank. It can also be used at home, for example, to brew a pot. Just don't use it for cooking.

- Proxypol. Has good adhesion to the material being processed. Connections made from it are characterized by high strength and are subject to mechanical processing.

- Diamond Press. The composition is designed specifically for car repairs.

- Skol from Rostcom LLC. Universal adhesive, used for repair and restoration work and gluing metal, glass, ceramics, plastics, wood, concrete.

The use of adhesives can solve many problems for motorists and eliminate breakdowns and leaks at home. But often this is a necessary measure. Due to its ease of use, you can make quick repairs using cold welding yourself. But adhesive joints are inferior in strength to welded ones, and subsequently they need to be replaced by welding or other methods of fastening surfaces.

How to use cold welding for metal

The first thing you should do is prepare, which is a very important process. With improper preparation, the quality of setting is reduced to a minimum and at the first check everything will have to be redone. The procedure is as follows:

- Cleaning the surface from dirt, oil and grease. This is done using sandpaper, abrasive cleaning and various cleaners. This helps improve adhesion.

- You need to work with the composition wearing protective gloves. If it is presented in liquid form, then it must be squeezed out of two tubes, and then mixed thoroughly. If it is plasticine-like, then simply separate the required amount from the total mass. You should not take too much, as after this you will not be able to use the material a second time.

- When kneading, the composition heats up and hardens, while maintaining the desired level of elasticity. Once it reaches the desired consistency, it can be applied to the surface of the parts.

- After application, you can secure everything with a tourniquet.

- When repairing pipes, smoothing movements must be carried out until the material completely takes the required shape.

- After application, you should wait 1 to 3 hours until everything hardens. As a rule, this is not complete hardening, so during this time 95% of the composition is set.

After the procedures have been carried out, the question arises of how to remove cold welding from metal. After all, at the end of the work, small, unaesthetic pieces may remain that will interfere. It is better to remove them immediately using a spatula or other similar means, while the composition has not yet completely hardened. If a long time has passed, a more serious approach may be required. One of the easiest ways to remove cold welding from metal is to tap it with a hammer so that the excess material comes off the surface.

Composition and release forms

Cold welding creates a strong connection between surfaces and can be used even in hard-to-reach places. The composition of the adhesive composite substance includes:

- Epoxy resins.

- Hardener.

- Reinforcing additives.

The strength of the adhesive material is increased by adding plasticizers, metal shavings, and ceramic powders. Glue is available in two types:

- Liquid welding . This is a two-component composition. One of the tubes contains glue, the other contains hardener.

- Plastic glue . The resin and hardener are in one tube and separated by a layer of film. Thickeners give the composition the desired consistency. In density it resembles plasticine. The two-component composition is better stored. Each time you can squeeze out the right amount of substance from the tubes. Plastic glue has a short shelf life after opening the package. It must be used quickly.

For different types of materials to be welded, different adhesive compositions are used.

How to use cold welding glue for linoleum

This glue is versatile and great for many applications. But for this you need to know the technology of application. If you want to understand how to properly use cold welding for linoleum, then you should adhere to the following points:

- At the place where the seam will go, double-sided tape is glued so that the glue does not spread over the entire surface;

- The strip should be cut exactly at the junction;

- An additional nozzle should be put on the tube, which will squeeze out the glue in a uniform small stream;

- The needle on the nozzle is inserted into the cut made with a knife, after which it can be filled by cold welding;

- As soon as the entire joint surface is filled, you should wait 15 minutes until it dries completely;

- After this, you can remove the tape and check the quality of the seam connection.

All actions should be carried out wearing protective gloves, avoiding direct skin contact with the material.

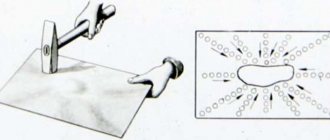

Punching machines

There is some confusion with the concept of “cold welding”. In practice, not only adhesives for metals are called this way. You can also find information about cold welding machines on the Internet. They really exist; another name for these machines is pudding machines.

These machines are capable of connecting thin metal products without any fasteners. Thanks to special tools, the upper metal plate is mechanically flattened and combined with the lower one - this is what this technology looks like in general terms. This has nothing to do with adhesives.