Any motorist or just a home craftsman has a whole arsenal of various kinds of devices that make work easier. Assembly and disassembly of complex mechanisms and structures is accompanied by unscrewing the nuts. Some of them cannot be removed with a regular key due to their placement in hard-to-reach places. In such cases, they resort to the help of end modifications. They greatly simplify solving such problems. Having such a kit on hand, you can easily carry out almost any preventative and repair work on your car. The scope of use is not limited to transport; they are in demand when repairing furniture, plumbing fixtures and even household appliances.

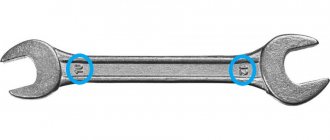

Open-end wrenches

When people talk about a wrench, the first thing that comes to mind is the open-end wrench. The nut is fixed with jaws that resemble horns, hence the name. But according to GOST it is called an open-ended wrench. The longitudinal axis of the handle is located at an angle of 15° to the axis of the head. It is specially designed to work freely in confined spaces. There are keys with an angle between the head and the handle of 70° . In combined versions, the angle is 15° at one end and 70° at the other.

Often open-end ones have two heads, at the ends of the handle, for different sizes of nuts. This significantly reduces the number of tools needed in the kit. Carobs have become widespread because of their versatility, ease of use, and this despite the shortcomings. The main one is that the contact area is small and with strong pressure the corners of the nut are crushed, and if the tool is larger than the required size, then this often happens. If the correct size is used, the impact force will be greater. The thinner the jaws on the key, the higher the likelihood of damaging the corners .

An impact wrench is used to unscrew rusty bolts and nuts; at the other end it has thickenings where blows are applied with a sledgehammer or hammer.

Manufacturers often produce keys with their own lip profile. IBEX instruments have one horn that is shortened, with a short protrusion, and the other has a convex recess of a modified shape. This modification has two obvious advantages:

- Fast operation - easy to remove and rearrange with a simple pull.

- The contact spots are located at a greater distance from the corners of the nut, which reduces the chance of lubricating the edges.

In simpler modifications, corrugation or convexity is applied . This helps to work with bolts and nuts with crumpled edges.

Spanners

A ring wrench, a more advanced type of open-end wrench.

It was made to solve the main drawback - the minimum contact patch. The head rests on the entire area of the nut and the load is evenly distributed over the entire surface. On all six sides, instead of two. And the fact that the contact patch is located far from the corners almost eliminates their crushing in the process. The size of the cap head is smaller than that of the carob head and it is much more convenient for them to work. The spanner wrench profile comes with 12 edges (the most popular option) or 6 (TORX). The advantages of a twelve-sided tool are ease of use; 30° is enough to turn, when TORX requires twice as much. But the second, thanks to the design of the edges, has a larger contact area, which makes it possible to apply more force without fear of blurring the corners.

The ring on the tool can be at the same level as the handle, or at an angle of 15° (with the head bent). A certain position of the ring (sometimes the only correct one) is suitable for different conditions. Flat keys are almost never used. The most common type is with a bent head. The tool has a ratcheting mechanism and is often equipped with a swivel head.

Slip-on, like hinged, are equipped with two rings of different sizes . Percussion modifications are also available, as in horn versions. For cases in which it is impossible to place the tool on top, use a variation with an open ring. This is common when servicing pneumatic and hydraulic installations.

For ease of work in hard-to-reach places, on some models, the handles have a curved shape, and the motor key is shaped like a crescent.

The best socket wrenches in the mid-price segment

Felo 30407880

According to the developers, the model is aimed at daily intensive use in home and industrial environments. Positioning is justified by a strong chrome vanadium rod with increased wear resistance. The two-component plastic T-handle is non-slip and virtually unrestrictive.

Felo 30407880

Advantages:

- chrome rod with black tip;

- ergonomic shape;

- German quality.

Flaws:

- short rod.

Proskit HW-V810 10 mm

Prokit's Industries is well known to all consumers. For 20 years, it has established itself as a supplier of high-quality and professional equipment in various fields of activity. Replenishment was no exception. The new product is designed to work with internal hexagon screws. The non-slip two-color handle is covered with a dielectric layer for protection against voltage. Withstands up to 1000 V. High wear resistance is ensured by forged alloy steel.

Proskit HW-V810 10 mm

Advantages:

- light weight;

- universal;

- oil-hardened steel;

- high wear resistance.

Flaws:

- no corrosion protection.

ROCKFORCE RF-802334U

An indispensable assistant in places with limited space, as well as during repair and installation work. Equipped with a hexagon. Thin walls will facilitate access to any place.

ROCKFORCE RF-802334U

Advantages:

- comfortable rubberized handle;

- hinged design with ratchet mechanism;

- two-component handle to reduce fatigue;

- Cr-V steel;

- made in Taiwan.

Flaws:

- quickly disappears from shelves.

Combination keys

The instruments combine a carob on one side and a cap on the other. They lack the disadvantages of both, while maintaining the advantages. This option is the most common and in demand. Companies are not limited to combining cap and horn tools. You can often find other options, for example, with an end cap. But if we talk about a combination wrench, without specifying which one, then it is a horn-socket wrench .

With modifications with the head rotated 90°, the palm places emphasis on the large plane of the head, and not on the small one.

Adjustable wrenches

An adjustable wrench is a regular open-end wrench, in which you can change the gap between the jaws. Most often they are used in everyday life, not in professional activities. Masters avoid them because of the following disadvantages:

- The large size of the head makes it difficult to work in hard-to-reach places.

- The play of the horns does not allow the nut to be tightly fixed, which, with little effort, leads to smoothing of the corners and breaking, and this can result in injury.

- It is impossible to generate significant torque due to low strength.

- It is necessary to constantly adjust the jaws while working.

This tool has only one advantage - the ability to stretch the jaws to the desired size. This tool is easily replaced with a socket tool, with replaceable heads.

How to use?

Safety is influenced by two important factors: quality of execution and ability to use correctly. A few practical tips will help you get out of a difficult situation and use it for a long time.

- The size of the nozzle must strictly correspond to the element being unscrewed. Exceeding will result in rounded edges. This will make further manipulations more difficult.

- If the situation described above could not be avoided, resort to the help of a file. They use it to remove part of the metal from the side edges to a smaller size. Pay attention to the distance between them. The tighter the head fits, the better.

- Before operations, you need to make sure that the nut is not oxidized. To do this, make a trial attempt without making much effort. Otherwise, the thread or nut may be damaged.

- If difficulties arise, the element is lubricated with a special lubricant or kerosene. After some time, lightly knock on it. This makes further unscrewing easier.

- To increase the applied effort, an extended lever is used. An increase in the arm from the point of application to the axis of rotation leads to an increase in torque.

- Removable heads and extensions are inserted until the latch clicks. They should sit tightly in their nests.

- When using a ratchet socket wrench, it is important to set the lever to the correct position. Otherwise, when unscrewing, the mechanism will perform the reverse operation.

Socket wrenches

At the end of the tool there is a hexagon-shaped recess for a nut or bolt. Widely used in car repairs. Often, socket wrenches are made in an L-shape, with a notch on both sides, for the same size, and not like socket wrenches. This is due to different purposes : the long part of the tool will easily reach an inconvenient place, while the lever will be shorter and there will be less effort, and when covered with the short end, the torque will be large.

When unscrewing a bolt with a socket wrench, you need to apply more force than when tightening it, due to the souring of the thread. The shorter part of the end is used as a lever when tightening, and the longer part when unscrewing. This helps to cope with situations where it is impossible to unscrew a nut or bolt.

On some models of the socket wrench, a hole is provided in the bend for the protruding parts. The socket tool can be equipped with a twelve-sided notch, with all the associated pros and cons compared to TORX. Models are available with combined hexagonal and twelve-sided ends in one tool. When socket heads are attached through a hinge, they come in different sizes.

Examples of socket wrenches:

- L-shaped socket wrench KING TONY 1080-11 - used for installation of various components, assemblies, devices, products, in various equipment. Used in automatic, service stations and production. The geometry of the tool allows you to easily work in confined spaces. The profile is convenient for use with studs and fasteners located in the recess. The socket wrench is made of chrome vanadium steel with subsequent heat treatment, which ensures high reliability and strength.

- L-shaped socket wrench SKRABAR 27x27. The weight of the tool is 950 grams, the head size is 27 mm. The end tool is made of stainless steel. Well suited for use in a car repair shop, for working in confined spaces.

Models of T-shaped socket wrenches are available, in the form of a cross, with replaceable heads. There are tools with 8 heads , but it has one drawback - its large size. Face tools are widely used in car repairs by both professionals and amateurs.

About extension cords

Used for work in confined spaces. They act as an auxiliary element that transmits the applied forces from the lever to the object being acted upon. They are most in demand when carrying out plumbing work (installation of a mixer).

The metal rod is equipped on one side with a cap with a square hole. On the other, a tetrahedron with a lock is installed.

As a rule, the device is similar to a regular metal tube, with or without hinges. The length depends on the manufacturer. Flexible extension cords are available. The element bends in all areas. It took the shape of a tetrahedron. There is a spring inside. It transmits torque from the lever to the nut. The surface can be polymer or rubber.

Tubular keys

The design of a tubular wrench is a pipe with hexagons at the ends, and holes are made in the body for the rod. Hexagon sizes vary. Very often such keys come with the car.

There are L-shaped tubular wrench models. These tools have the same hexagons at the ends.

A spark plug wrench is another type of tubular wrench; the hexagon is located on one side only. Used to replace car spark plugs .

Ratchet wrench

Some models of end and cap type are equipped with a ratchet mechanism (ratchet). An added advantage is the ability to throw the tool. And the small angle required for turning makes screwing and unscrewing the nuts much easier. Ratchet designs vary in the number and size of teeth. To rotate a tool with 72 teeth, 5° is enough, 40 teeth - 9° .

This is very helpful in cramped working conditions. It has one drawback - the ratchet often breaks due to excessive load. Such a tool is much more expensive.

How to choose?

There is a wide range of socket wrenches on the market; they differ in the nature of the tasks they perform. The purchase will not be a problem if you consider the following.

- Dimensions. A defining characteristic, since the working part is not adjustable. Standard nut sizes in the CIS countries are considered to be 13x17 and 8x10 millimeters. For home use, up to 15 mm is sufficient. Professional service centers will need a size guide from 8 to 24 mm.

- Material of manufacture. The key is subject to increased mechanical stress during operation. Considering the specifics of the work, the body must be light and resistant to deformation. Chrome vanadium alloys and tool steel fully comply with this requirement. To protect against corrosion, they are coated with zinc and oxidized layers. This nuance is worth special attention if you have to work in conditions of high humidity.

- Lever. The comfort and efficiency of performing assigned tasks depends on it. As a rule, the handle is made of the same material as the working part. There are models with rubber with an anti-slip coating installed on the handle. They provide proper grip. A coating with a dielectric will increase the safety of interaction with live objects.