The process of storing a number of products, for example, beer brewed yourself, sometimes requires the creation of certain temperature conditions. To solve this problem, in the old days they used deep cellars and glaciers, the secret of which has now been lost. And making a glacier in a city apartment is sometimes quite difficult. You can purchase a separate refrigerator and use it for these purposes, but the cost of such equipment is quite high, and the volume of stored beer is limited.

A less expensive option is to assemble a refrigeration chamber using a small household refrigerator as a cold source with your own hands.

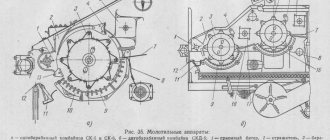

The dimensions of the camera proposed for self-production are 100x100x120 centimeters. This is quite enough to store several tens of liters of aromatic drink. The frame is made of wooden slats with a cross-section of 25×50 millimeters. The type of wood for this and other similar products does not play a big role. The main aspect is the quality of the material - the absence of large knots, wormholes, rot, which can negatively affect the mechanical properties of the parts.

Pre-planed parts manually or mechanically are sawed to length. Then we make two frames 100x120 centimeters, connecting the parts in the corners with self-tapping screws using a screwdriver. At the corners, we attach the resulting rectangles to meter racks, obtaining a parallelepiped with the dimensions indicated above.

Do-it-yourself refrigerator: radically different methods

Taking care of keeping food fresh for a long time is the price to pay for the opportunity to have it in large quantities. This question is relevant not only for those who own a small company that sells them, or a farm: even a standard home freezer is sometimes not able to accommodate all the “goods” that the owners bought after making their next raid on the stores. Purchasing new equipment is an alternative that attracts few because of the considerable amount that will need to be “thrown away.” The least expensive way to give yourself the necessary unit is a do-it-yourself refrigerator. Bonuses include savings and the level of energy consumption that the owners are free to choose.

Price policy

It goes without saying that the first question a potential customer will ask is: how much will all this pleasure cost me? The desire to immediately and without additional costs determine the cost is obvious and understandable - and therefore we offer a free surveyor’s visit within the Moscow Region. Moreover, you can also receive a free 3D project/visualization, as well as lists with an accurate calculation of the quantity and cost of materials, equipment and services. Moreover, to get basic information, you don’t have to go anywhere at all: you can use the feedback form to submit the key parameters of the refrigeration chamber you need - and then find out how much it will cost to make a custom-made chamber according to your dimensions within a given time frame.

Additional options:

- lamination or painting of panels

- racks made of prefabricated/welded metal structures

- lighting

We suggest making a preliminary calculation.

Completed projects.

Get to know the device and its operation closely

Familiarization with the unit and the principles of its operation will allow you to choose the most suitable solution, which in the future will give the owners the opportunity to modernize and improve the created device. Any homemade refrigerator must include a certain set of elements. These include:

“Pro” refrigerators sold in stores are equipped with dehumidifiers, automatic control devices and filters. The high power of the equipment is a good enough reason to equip the device with a fan.

You can also see the prices for ready-made refrigeration chambers:

Why do you need a beer cooler?

The beer cooler is the most important element in the beer bottling system. The device is a compression unit that helps reduce the temperature of beer. With its help, the bar maintains the temperature of the drink within 4-8 degrees on an ongoing basis. Temperature changes negatively affect the taste of beer and contribute to excessive foaming.

The cooler operates immediately before beer is served, i.e. the drink moves along the coils, is saturated with carbon dioxide and at the same time cools before getting into a glass or other container.

What you can build with your own hands

After the first acquaintance with the “insides” of a typical refrigeration chamber, you can begin to consider the possible range of home-made designs. In this case, it all depends on how much money the owners can afford to spend on making a freezer. There are several options to achieve the goal, but each of them requires its own “individual” set - both materials and equipment. The following can be turned into a refrigerator:

Purchasing a ready-made cooling system is necessary when choosing one of the first 2 options. Arranging a cellar chamber is a more labor-intensive method. There are often recommendations to choose a refrigeration chamber project assembled from sandwich panels, but it does not promise any special savings. Another potential alternative - foam blocks - is also not very profitable financially.

Cooler operating rules

To ensure that the device does not lose its effectiveness, it is important to follow the operating instructions and adhere to the following rules:

- flow-through units cannot be turned on without water (the compressor may fail);

- you need to monitor the water level so that it does not freeze in the tank along with the drink itself, which will also lead to damage to the cooler;

- Ventilation is important for the device so that it does not overheat, so the distance between it and other objects must be at least 1.5 cm;

- Do not exceed the operating mode and overcool the beer; increasing peak loads will lead to excessive foaming.

To avoid problems with the operation of the beer cooler, choose a high-quality device and follow the instructions that come with each unit.

Refrigerator for draft beer and drinks.

Ready-made or custom-made according to your sizes.

The longest shelf life of live beer is achieved at a temperature of +4°С…+7°С. Most often, to maintain a given temperature regime, specialized refrigeration chambers, “coldrooms” and kegerators are used.

carries out projects of any complexity related to the organization of storage conditions for beer in kegs. Individual sizes of refrigeration chambers made of sandwich panels allow them to fit perfectly into the architecture of any room. Our Customers independently (with the consulting support of a personal project manager) choose the appropriate type of unit, size and location of doors, if necessary, complete the chamber with double-glazed windows or hinged/sliding structures with glass; we offer reliable turnkey beer chambers to suit your budget.

If you are “closely familiar” with beer (whether as a seller or as a consumer), then you know very well that good beer must be at the right temperature. And the point here is not only in taste (although it is well known what kind of epithet is bestowed on warm beer): for long-term storage without loss of quality, both canned/bottled and keg beer must be kept in strictly controlled temperature conditions. Thus, if you are planning a business selling beer, then you cannot do without a good refrigeration chamber!

Freezer from an antique refrigerator

This is the simplest and most inexpensive way to quickly achieve your goal. Greater efficiency from the equipment can be expected when there are old models of refrigerators in the “bins”: for example, Polyus, SVYAGA or ZIL will do. In this case, the refrigerator compartment will freeze very well, and there is no need to complain about the reliability of Soviet designs. The work is carried out according to the following algorithm:

If there is an old device, but it is faulty, then only establishing the cause of the breakdown will give an answer about the advisability (or impossibility) of using it in a new capacity. There is one more disadvantage in the “rebirth” of old refrigerators: this is the greater amount of energy that they need to operate, when compared with store-bought models of chambers.

How does a beer cooler work?

To understand the principle of operation of a beer cooler, you need to decide on the types of devices. There are two types of them depending on the installation location:

- over-rack;

- rack-mounted

The units are either flow-through or dry based on their operating principle. So, a rack beer cooler is placed under the bar counter. This is a stationary device, located in a vertical or horizontal position. Cooler advantages:

- high productivity (up to 350 l/h);

- high power levels;

- ample cooling capabilities (up to 20 varieties simultaneously);

- free bar counter.

The disadvantage of the rack design is its impressive size, so the use of such devices is advisable in establishments where large volumes of beer of different types “leak”. Among the models of subrack coolers on the market, the best proven ones are “Typhoon”, “Pegasus”, “Nord”, etc.

The over-counter beer cooler has compact dimensions and fast filling. The design does not include a casting column. It is easy to install. The productivity and power of the devices are small, so they are best used in establishments where no more than 4-5 types of beer are bottled, and the volume is 50 l/h.

Flow-through (wet) devices cool beer using water, ice or refrigerant. The main structural elements are: compressor, fan, condenser, freon lines, choke, coils, evaporator, ice bank, pump-mixer and after-cooling line. This is especially important because if the cooler is placed far from the bar, the beer may become warm again as it flows through the wires.

Advantages of flow-through beer coolers: reliability, ease of operation, affordable price, efficiency. However, there are also disadvantages. The outlet temperature is not regulated and the water used as coolant must be changed from time to time.

Dry devices are becoming more and more popular. They are compact, quickly cope with cooling the drink, and operate silently. Metal blocks are used as a cooling element in the design. It is important to place the cooler directly near the filling point, since it is not possible to retrofit the system with an after-cooling circuit.

Small refrigerator plus large chamber

This option is also one of the least expensive methods. In this case, the cold source is inexpensive, and a chamber assembled with your own hands will cost much less. Here we look at a homemade “room” that can be used, for example, to store beer. Its dimensions are 1000x1000x1200 mm. The frame is made of wooden slats 25x50 mm. In this case, there are no special complaints about the material, the main thing is the absence of defects - rot, knots, wormholes.

The dimensions may be different, but one cannot expect any special miracles from such structures, since the large volume of the room will not allow drinks to be cooled quickly, but it is possible to store vegetables and fruits in them. If lower temperatures are required, the cooling system must be more powerful.

Refrigeration equipment for draft beer and any keg drinks

Proper storage of a drink is respect for the buyer. In order for the establishment to be successful and the customer to return, the drinks must be fresh and chilled. Equipment for cooling beer at the heart of the beer line. If everything else works like clockwork and the temperature lets you down, you could lose customers. The establishment is successful if the customer returns.

The choice of cooling method depends on several factors:

1. Format of the point of sale - store or bar

2. Room area

3. Number of varieties

Coldroom for draft beer (cold room, coolroom, cold room)

Coldrooms are necessary for storing kegs and cooling the drink in the bottling system. Structurally, a coolroom is a room whose walls are thermally insulated, equipped with refrigeration units or split systems, and there are racks installed inside on which kegs are stored. The rooms are designed to order, taking into account the size of the room and the number of kegs to be stored. The temperature in the rooms can be set in the range of +4 ... +18 0C. Coldrooms store more than just closed kegs. There are also kegs that are already connected to the bottling system, and one of the walls of the coolroom adjacent to the retail area is used as a place to install Pegasus defoamers or bar taps. Most often, such refrigeration rooms are installed in beer stores. The Pegasus wall mount saves space on the counter; there is no need to buy beer columns and beer coolers.

Coolroom is a stationary permanent structure. Most often, it cannot be moved or transported. Just install a new one.

Don't need a beer cooler?

Let's take a closer look at this issue.

It is necessary to distinguish between the storage temperature and the drink bottling temperature. In the cold room, all kegs are kept at the same temperature. When storing kegs at a low temperature of +2...+4 0C, the beer begins to become oversaturated with CO2 and carbonize. The drink is over-carbonated, its taste changes, bitterness and harshness appear, and the notes intended by the manufacturer are lost. Bottling becomes more difficult due to excess foam.

To avoid this, we recommend separating the storage and bottling temperatures. Connect the beer cooler for bottling and provide a temperature of +4...+8 0C, and leave the storage temperature in the cool room at +8..+10.

When to choose a coldroom:

1. When selling 10 varieties or more

2. If there is space for building a room

3. With a permanent location of a store or bar

Advantages:

- Storing kegs in stock. There is less logistics, unloading work, there is always a replacement for sold kegs.

- Saving work space by installing the filling line inside the room, and Pegasus on the outside wall.

- Self-adjustment of temperature in the coldroom.

Wherein:

- Low storage temperatures oversaturate the drink with carbon dioxide.

- The structure is stationary, it is difficult to move it as a module to another room

Kegerators for beer

Universal equipment for cooling kegs and maintaining the desired temperature of the drink and bottling. Used for any keg drinks - beer (live/non-living pasteurized/unpasteurized), kvass, lemonade, cider. A kegerator or keg master is a module, a block, which consists of a refrigeration chamber and a counter (countertop, bar counter). The package may include beer columns, taps, and drip trays, depending on the model.

A kegerator is a mobile refrigeration unit that can be installed in a store or bar. When a store (bar) moves, the module can be installed in a new location.

The refrigerator compartment can accommodate from 1 to 20 kegs with a volume of 20 to 50 liters. Condensate from the refrigeration unit is collected in a special container. The kegerator does not require an additional connection to the beer cooler, and the entire line is compactly and neatly placed inside the cabinet.

A CO2 cylinder is installed inside or outside the refrigerator compartment to displace the drink from the keg. All equipment is connected to each other in the same way as a regular beer line. The kegerator runs constantly, like a regular refrigerator, so the beer is properly stored and its shelf life and taste are preserved.

Manufacturers pay attention to the design of the kegerator, creating models with metal facades - white, chrome or wood-look.

In the Farvater company you can buy kegerators Krio 520M for 2 kegs, Krio 720M for 3 kegs, Krio 920M for 4 kegs with a volume of up to 50 liters.

When to use a kegerator:

1. In small cafes, in small shops or departments in stores where they sell up to 8 varieties. 2. Temporary places of sale - summer cafes, beaches.

Advantages:

- Block mobility

- Modular solution. A full-fledged trading block in which the entire bottling system is located.

- Self-adjusting temperature in the kegerator.

Wherein:

- The limit on the number of kegs placed is up to 8 pcs. keg 50 l.

Beer coolers

Beer coolers reduce the temperature of the drink during dispensing. The equipment does not provide beverage storage.

Based on the type of placement, they are divided into rack-mounted and above-rack. By type of cooling: flow-through (“wet”) and “dry”. They represent a block that is built into the filling system. Beer, moving through hoses from the keg to the beer tap (defoamer), passes through the cooler and is cooled. There are models on the market for cooling of 2-16 grades.

When to choose a cooler:

1. Bottling line outside the coldroom

2. Kegs are connected to the bottling system, which is located in the cold room. Additionally, a cooler is used to avoid oversaturation of the drink with carbon dioxide.

3. The store/bar has commercial equipment - a table top (counter), a bar counter.

4. Temporary sales points, for example, outdoor cafes.

5. There is no cold room, beer is chilled “here and now”, kegs are supplied based on previous sales.

Advantages:

- Cooling up to 16 varieties.

- The taste of the drink is preserved

- Guaranteed cooling to t +4…+8 C

- Fast cooling

Wherein:

- Additional space is required to install the cooler.

- Does not provide beer storage conditions.

We talked in detail about the coolers that are sold in our review.

Cryonis

A simple, inexpensive and compact device for lowering and maintaining the temperature of beer and other keg drinks in the range of +4..+10 C. Preserves the taste of the drink and increases sales time. Cryonis cools the keg, which cools the beer. This device works both for bottling and storing drinks.

The device works in conjunction with a cooler, using its pump and ice water. Water passes through the Kryonis pipelines and cools the keg. Cold water also follows the beer hoses all the way from the keg to the tap.

When to choose Cryonis:

1. There is no cold room and there is no separate room for storing kegs in the cold. Cryonis will keep the drink cold at all times.

2. Sale of live beer, for which constant maintenance of the correct cooling temperature is especially important.

3. Selling on the street in summer.

We sell Cryonis in 20 L and 30 L kegs.

Advantages:

- Ultra-compact solution! Does not take up space under the counter or bar counter.

- You can connect several Cryonises to one cooler, depending on the power of the pump, and simultaneously cool several kegs.

- A good alternative solution when placing kegs in a warm retail area.

Wherein:

- Must be removed and put on each new keg.

- Designed to maintain temperature. Not suitable for cooling warm beer to normal storage temperature.

You can always contact us for advice on cooling equipment at 8-800-250-62-45.

© When using materials in full or in part, a link to odl.ru is required

Interesting? By

Collapsible chambers made of refrigeration sandwich panels

Cameras from Polair and Ariada have become widespread. Let us immediately note that Polair cameras are of higher quality, in our opinion (the panels fit into the grooves more easily, both right and left door openings are possible). At the same time, Ariad cameras are slightly cheaper.

When ordering a camera, you receive a set of sandwich panels, which are connected to each other using tongue-and-groove technology, the corners of the walls are connected using corner elements. The kit includes a swing door equipped with a handle and a lock (an emergency button is also installed so that you can exit the cell even if the door is locked from the outside).

The camera is assembled in the following sequence. First, the floor of the chamber is assembled. The floor panels of the refrigeration chamber are laid out on the floor of the room (they are easy to distinguish from the rest, on one side they are covered with galvanized iron). The joining seams are coated with sealant and the panels are connected to each other. You can help with a hammer through a wooden block.

When the floor is assembled, the assembly of the walls begins. From any angle. Assemble a right angle (using two wall panels and a corner element). We pre-coat the seams with sealant.

When the angle is assembled and installed, we assemble the chamber hay. We start from the set angle and move in a circle. We close the walls.

We install the ceiling. This is the most difficult thing, since it is necessary for the wall tenons to fit into the grooves of the ceiling panel, and the angles between the walls will not be 100% straight. You can't do this without an assistant. You will have to try to align the tenons with the grooves.

Finally we hang the door. The camera is ready.

Video from Polair with step-by-step assembly of the refrigerator compartment:

Here is a table with prices for warehouse items of Polair cameras. The thickness of the panels is 80 mm, insulation is FoamPolyUrethane.

| Model | Dimensions, mm | Retail price, rub |

| KHN-2.94 | 1360*1360, h=2200 | 45 800 |

| KHN-4.41 | 1360*1960, h=2200 | 54 860 |

| KHN-6.61 | 1960*1960, h=2200 | 63 630 |

| KHN-7.71 | 1960*2260, h=2200 | 73 500 |

| KHN-8.81 | 1960*2560, h=2200 | 75 140 |

| KHN-11.02 | 1960*3160, h=2200 | 86 200 |

| KHN-11.75 | 2560*2560, h=2200 | 87 150 |

Frame assembly

The next stage of the work is covering the outer walls of the chamber with sheet materials - plywood or OSB board.

To fasten the sheathing, you can use the already mentioned screws or nails. It is convenient to cut parts according to preliminary markings with a jigsaw. In this case, the sheathing sheets must have the correct rectangular shape.

Conversion of an existing room into a cold storage room

Let's say you have a room from which you want to make a refrigerator. The main issue is thermal insulation. You can insulate the walls, floor and ceiling with foam plastic (the cheapest insulation is approximately 1,650 rubles per cubic meter). The layer must be at least 10 cm. A frame of timber/boards can be built around the perimeter (5000-6000 rubles per cube of edged board). It will look something like this:

Fill the gaps between the boards with insulation.

The cladding can be made with galvanized metal sheets or corrugated sheets (prices from 200-250 rubles per sq.m.). It will look something like this:

All seams must be filled with sealant to avoid condensation in the future.

When the refrigerator compartment is ready, you need to take care of a special insulated door for it. It should be thick enough and well insulated, and also fit snugly against the walls of the chamber.

Buy a good industrial door (or sliding gates for the refrigeration chamber), this will save you from problems in the future:

Prices for refrigeration doors:

| Insulation 80 mm | Retail price, rub |

| 1200x2040 mm | 26 670 |

| 1200x2300 mm | 27 927 |

| 1200x2560 mm | 29 591 |

| Insulation 100 mm | Retail price, rub |

| 1200x2040 mm | 27 508 |

| 1200x2300 mm | 29 172 |

| 1200x2560 mm | 32 105 |

Contents: set of handles and hinges, threshold plate, hardware.

Prices for sliding gates for refrigeration chambers:

| Price, rub. | |||

| SLIDING DOOR (without panels, with complete set) | 56 018 | ||

| Contents: 1 package - a set of parts for assembling a sliding door, a set of handle and lock, hardware 2 packages - canopy, brackets, aluminum profile L = 2,710 mm, door seal | |||

64 551

69 430

74 310

79 189