How to buy Hydraulic guillotines

supplies Hydraulic guillotines to all cities of Russia, including Moscow, St. Petersburg, Chelyabinsk, Perm, Simferopol, Ulyanovsk, Kazan, Kaluga, Novosibirsk, Yekaterinburg, Nizhny Novgorod, Kaliningrad, Samara, Omsk, Ufa, Saratov, Krasnoyarsk , Vladivostok, Rostov-on-Don, Voronezh, Volgograd, Makhachkala, Grozny and others, as well as to Belarus, Kazakhstan, Armenia and Kyrgyzstan.

It is very easy to purchase Hydraulic guillotines from us:

- Select the product you are interested in in the table above

- Find out its characteristics, look at photos and videos by clicking on the model name

- Buy Hydraulic guillotines: call for free from any city in the Russian Federation 8-800-333-51-02 or send a request to [email protected]

Design and principle of operation

Hydraulic sheet benders

Structurally, the shears consist of the following elements:

- hydraulic cylinder with piston;

- rod;

- cutting knives;

- pressure hose;

- drain valve;

- rotary coupling;

- handles;

- carrying handles.

Metal cutting shears operate on the principle of a lever, the action of which is enhanced by a hydraulic pump or cylinder. With a small weight of the tool, the pressing force ranges from several units to hundreds of tons.

A person applies force to press levers connected to a hydraulic cylinder, and at this time a force increases on the working rod with a blade, several times exceeding the initial one. This makes cutting metal much easier.

Hydraulic shears have the following features:

- the hydraulic drive is fixedly attached to one lever, and the other is connected to the lever that pumps pressure into the cylinder;

- a hand lever or a compressor can be used to pressurize the cylinder.

The hydraulic drive can be made in the following options:

- In the form of a cylinder built into the body with a swinging rod. Used in compact hand-held designs. The generated force is enough to cut wires, cables, fittings with a diameter of up to 4 mm.

- As a remote drive with a lever mechanism operated by foot or hand pressure.

- In the form of a separate pump powered by an internal combustion engine.

Technical properties of scissors

The hydraulic machine has universal, high-class functionality that allows it to be used in almost any production workshop in a wide variety of industries. Because hydraulic press shears are a combined type of metalworking machine, which are often used as an integral element of complex and fully automated production lines or as a separate device for a wide variety of technological processes.

When purchasing hydraulic press shears from our company, you can additionally get advice from one of the professional engineers who will explain all the advantages of such equipment. And there are quite a lot of them:

This is interesting: Fire hazard category of the facility

FABTEC

| QC12Y - 4x2500 | Working length 2500 mm | Metal thickness 4 mm | In stock | How to sharpen scissors at home? 760 247 q 21,276 BYN 3,632,387 KZT 673,207 KGS 4,201,912 AMD $8,653 7,331 € |

| QC12Y - 4x3200 | Working length 3200 mm | Metal thickness 4 mm | To order | 1 233 227 q 34,514 BYN 5,892,240 KZT 1,092,036 KGS 6,816,090 AMD $14,036 11,893 € |

| QC12Y - 4x4000 | Working length 4000 mm | Metal thickness 4 mm | To order | 1 284 255 q 35,942 BYN 6,136,046 KZT 1,137,222 KGS 7,098,123 AMD $14,617 12,385 € |

| QC12Y – 6×2500 | Working length 2500 mm | Metal thickness 6 mm | In stock | 1 050 235 q 29,392 BYN 5,017,921 KZT 929,994 KGS 5,804,686 AMD $11,953 10,128 € |

| QC12Y – 6×3200 | Working length 3200 mm | Metal thickness 6 mm | In stock | 1 229 080 q 34,398 BYN 5,872,426 KZT 1,088,364 KGS 6,793,169 AMD $13,989 11,853 € |

| QC12Y – 6×4000 | Working length 4000 mm | Metal thickness 6 mm | To order | 1 552 522 q 43,450 BYN 7,417,800 KZT 1,374,775 KGS 8,580,845 AMD $17,670 14,972 € |

| QC12Y – 8×2500 | Working length 2500 mm | Metal thickness 8 mm | To order | 1 107 472 q 30,994 BYN 5,291,394 KZT 980,678 KGS 6,121,037 AMD $12,605 10,680 € |

| QC12Y – 8×3200 | Working length 3200 mm | Metal thickness 8 mm | In stock | 1 391 276 q 38,937 BYN 6,647,383 KZT 1,231,990 KGS 7,689,632 AMD $15,835 13,417 € |

| QC12Y – 8×4000 | Working length 4000 mm | Metal thickness 8 mm | To order | 1 712 340 q 47,923 BYN 8,181,395 KZT 1,516,296 KGS 9,464,164 AMD $19,489 16,513 € |

| QC12Y – 10×2500 | Working length 2500 mm | Metal thickness 10 mm | To order | 1 393 000 q 38,985 BYN 6,655,620 KZT 1,233,517 KGS 7,699,161 AMD $15,854 13,434 € |

| QC12Y – 10×3200 | Working length 3200 mm | Metal thickness 10 mm | In stock | 1 503 054 q 42,065 BYN 7,181,447 KZT 1,330,971 KGS 8,307,433 AMD $17,107 14,495 € |

| QC12Y – 10×4000 | Working length 4000 mm | Metal thickness 10 mm | To order | 2 097 617 q 58,705 BYN 10,022,212 KZT 1,857,463 KGS 11,593,604 AMD $23,874 20,229 € |

| QC12Y – 12×2500 | Working length 2500 mm | Metal thickness 12 mm | To order | 1 712 340 q 47,923 BYN 8,181,395 KZT 1,516,296 KGS 9,464,164 AMD $19,489 16,513 € |

| QC12Y – 12×3200 | Working length 3200 mm | Metal thickness 12 mm | In stock | 2 021 513 q 56,575 BYN 9,658,594 KZT 1,790,072 KGS 11,172,975 AMD $23,008 19,495 € |

| QC12Y - 12x4000 | Working length 4000 mm | Metal thickness 12 mm | To order | 2 290 255 q 64,097 BYN 10,942,618 KZT 2,028,046 KGS 12,658,321 AMD $26,067 22,087 € |

| QC11Y – 6×2500 | Working length 2500 mm | Metal thickness 6 mm | To order | 1 091 617 q 30,551 BYN 5,215,641 KZT 966,639 KGS 6,033,406 AMD $12,424 10,527 € |

| QC11Y – 6×3200 | Working length 3200 mm | Metal thickness 6 mm | To order | 1 391 276 q 38,937 BYN 6,647,383 KZT 1,231,990 KGS 7,689,632 AMD $15,835 13,417 € |

| QC11Y - 6x4000 | Working length 4000 mm | Metal thickness 6 mm | To order | 1 605 319 q 44,927 BYN 7,670,059 KZT 1,421,527 KGS 8,872,655 AMD $18,271 15,481 € |

| QC11Y – 8×2500 | Working length 2500 mm | Metal thickness 8 mm | To order | 1 305 659 q 36,541 BYN 6,238,313 KZT 1,156,175 KGS 7,216,424 AMD $14,860 12,591 € |

| QC11Y – 8×3200 | Working length 3200 mm | Metal thickness 8 mm | To order | 1 562 510 q 43,729 BYN 7,465,522 KZT 1,383,620 KGS 8,636,049 AMD $17,784 15,068 € |

| QC11Y – 10×3200 | Working length 3200 mm | Metal thickness 10 mm | To order | 1 969 191 q 55,111 BYN 9,408,605 KZT 1,743,740 KGS 10,883,789 AMD $22,413 18,990 € |

| QC11Y – 12×3200 | Working length 3200 mm | Metal thickness 12 mm | To order | 2 129 723 q 59,604 BYN 10,175,611 KZT 1,885,893 KGS 11,771,055 AMD $24,240 20,539 € |

Technological features

The scope of application of guillotine shears is transverse and longitudinal cutting of sheet metal and workpieces of various shapes: round, corner, rectangular. The sheet thickness for the most powerful equipment models can reach 35mm, depending on the type of machine. In any case, the guillotine guarantees high cutting accuracy and an impeccable cut appearance without defects: scratches, gouges, etc. If a metal sheet is coated with a polymer or paint layer, the use of guillotine shears does not contribute to its damage and further destruction.

The design of guillotine shears is simple. This simplifies the maintenance and operation of equipment, and also contributes to high accuracy and quality of work operations performed. The main elements are two knives mounted on a frame on the table, a motor and a sheet clamp. The upper knife moves in a vertical direction, the lower one is fixed motionless. Depending on the principle of operation, manual, electromechanical and hydraulic models are distinguished. The latter are recognized as the most effective due to their outstanding characteristics and design advantages. They are successfully used in large enterprises where the emphasis is on productivity and significant volumes of output. Thanks to their increased power, hydraulic models can easily handle thick sheets of workpieces that pneumatic or electric models cannot handle.

The operating principle of the guillotine is simple. The material is securely fixed on the machine thanks to hydraulic clamping cylinders. The knife is driven by a hydraulic drive. The distance between the cutting surfaces of the upper and lower knife is adjusted mechanically. It is possible to achieve high cutting accuracy using the ruler included in the delivery set. Thanks to the hydraulic drive, it was possible to significantly reduce the dimensions and weight of the machine without compromising the productivity and reliability of the equipment. The hydraulic pump is capable of providing a pressure of more than 200 atmospheres, which is quite enough for a cutting effect on a metal sheet. At the same time, the design of a hydraulic guillotine is simpler, in contrast to the electric model, with the exception of the more complex structure of the pressure hydraulic pump. Thanks to its operation, the machine is capable of creating an impact on metal of up to 500 tons. This cutting pressure is quite sufficient for successful cutting of thick metal sheets.

Depending on the parameters, there are manual and stationary models of hydraulic guillotines for metal. Manual samples are more mobile and lighter, they can be used in confined spaces and in open areas. The machine is powered by a hand pump, which creates the cutting force of the knives. The diameter of workpieces that can be processed with a manual machine can be up to 20mm. The scope of application of such models is rescue work, small enterprises and production workshops, construction, etc.

The group of stationary models consists of industrial hydraulic shears that can easily cope with dense metal alloys. The tool can be fed vertically or at an angle using a rotating beam

Combined shear press NG5222

The NG5222 combined shear press is designed for cutting strip, long and shaped steel, punching holes in sheet, strip and shaped steel, as well as cutting open grooves.

Press shears are widely used both in small enterprises and in large industries, reinforced concrete plants, etc.

Designed for cutting strips, circles and squares.

Press shears NG5222 produce:

- Section for cutting long products - a section of an angle, a circle, a channel, an I-beam, a shaft profile. Cutting rolled products without marking up to 1000 mm along the stop

- Strip, sheet cutting section - strip cutting is carried out at different angles

- Punching section - punching holes of round, rectangular, square and any other shape in sheet and shaped rolled products

- Grooving section - punching open triangular and rectangular grooves

Specifications

| Machine parameters | NG5222 | NG5223 |

| Largest dimensions of processed rolled products, mm | ||

| strip thickness and width | 16x150 | 18x190 |

| circle diameter | 45 | 60 |

| side of a square | 40 | 45 |

| Equilateral angle, segment | ||

| at an angle of 90 degrees | 125x12 | 125x14 |

| at an angle of 45 degrees | 90x9 | 100x10 |

| Largest profile: | ||

| I-beam | 18 | 18a |

| Channel | 18 | 18a |

| Punchable hole, mm | ||

| Diameter | 30 | 32 |

| material thickness | 16 | 16 |

| The largest dimensions of punched rectangular grooves, mm | ||

| Thickness | 10 | 10 |

| Length | 70 | 60 |

| Width | 65 | 65 |

| Nominal press force, kN | 400 | 830 |

| Weight, kg | 2270 | 2500 |

| Overall dimensions, mm | 1900x1600x1950 | 1800x1700x1885 |

| Electric motor power, kW | 4.8 | 4.0 |

Combination press shears NG5222 are used for cutting strip, long and shaped rolled products and punching holes in sheet, strip and shaped rolled products, as well as for performing notching operations.

Combined shear presses can be used in machine-building, repair and other factories, when operating in climate zones with moderate and cold climates, version UHL, in dry and humid tropical climates - version O, placement category 4 according to GOST 15150-69.

Additional requirement: the lower air temperature must be at least +5°C.

General view of combined press shears

Components of combined shear presses

Press shears combined with four working zones allow you to perform several types of operations on one machine without preliminary reconfiguration of the shears, in any sequence and without changing tools, which ensures flexible and economical processing of rolled products, both in large engineering production and in any repair shop.

The frame is a welded structure, consisting of front and rear sheets welded to the base. To install drive shafts and section drives, four borings are made in the frame. Drive the sheet metal and hole-punching sections from an electric motor through V-belt and gear drives to the eccentric shaft of the sections. The notching device lever is connected by means of a rod to the slider of the sheet section.

The slider of the punching section is balanced by spring balancers.

The centering mechanism is designed to perform the basting operation by moving it using the handle of the punch holder with the punch. The tool for cutting corners, circles and squares consists of movable and fixed plates. The movable plate is attached to the socket of the slider of the sheet section, the fixed one - in the socket of the frame using L-shaped springs.

The sheet and notching tool consists of two movable and three fixed knives. Movable knives - guillotine for cutting sheet material and rectangular - for rectangular notching. The punching section tool consists of a punch and a die. The punch is attached through a punch holder to the slide, and the matrix is attached to the body of the punching device.

The shear press has three workstations served by one operator. The electrical circuit ensures the operation of the press shears in continuous and single strokes. Push-button and pedal controls. Thick, combined lubricant.

Kinds

Metal scissors come in the following types:

- Cutting machines are high-power stationary equipment, the hydraulic drive of which is connected to a compressor. Allows you to perform all types of cutting of metal parts of any complexity, as well as cutting.

- Manual hydraulic shears are a compact tool that allows you to cut thin sheets of steel, rods, and fittings. Unpretentious in work, easy to maintain.

- Guillotine - suitable in terms of power and compact size for use in workshops or small-scale production of metal products. Allows you to perform quick cutting and create smooth seams.

Lever and guillotine tools are used only for cutting along a straight line. Hand scissors are suitable for cutting complex shaped parts.

By blade location:

- Rights. They have a green marking. Designed to work with the left hand and create a right bend. When cutting, the right blade goes under the workpiece.

- Left. Marked in red. When cutting metal sheets, the left blade goes under the workpiece.

By blade type:

- symmetrical;

- asymmetrical.

Asymmetrical designs are twice as expensive as symmetrical ones, so they are quite difficult to find on sale. When working, they are quite convenient, since they allow better control of the cut, and it is more convenient to fix them in space.

According to manufacturing technology:

- cast - characterized by low strength, low reliability, and fairly fast grinding of blades;

- forged - wear-resistant, durable, universal in use, and have a long service life.

According to the design form:

- open;

- edge;

- guillotine.

In cutting direction:

- checkpoints;

- curly;

- universal.

Guillotine shears for metal

Hydraulic guillotines for metal cutting

Hydraulic guillotines are especially popular in industrial enterprises involved in the serial production of metal products. And all because the cutting process using hydraulic guillotine shears is the most productive compared to other types of cutting.

Excellent quality of cutting sheet metal, impeccable accuracy, convenience and speed of operation - these are the main characteristic features of CNC hydraulic guillotines.

Device

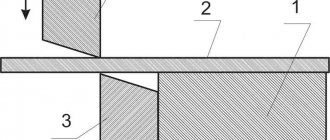

Hydraulic guillotines have a massive structure that can withstand heavy loads. The main components include: frame, hydraulic system (1), electrical system, upper and lower beams (rotary beam - 3), back stop (10).

The welded steel frame gives the machine the necessary rigidity and strength. The modern hydraulic system ensures smooth and stable cutting. Another advantage of the hydraulic drive is its quiet operation.

The presence of CNC in the design of a hydraulic guillotine increases productivity and automates the process.

Principle of operation

The principle of operation of a guillotine with a hydraulic drive is as follows: the hydraulic drive transmits pressure to a movable upper beam, which lowers the knife under high pressure, thereby cutting sheets of metal of large thickness.

Specifications

Important technical characteristics for guillotine hydraulic shears are parameters such as metal thickness and working length of the material being processed.

Our website presents models that allow processing metal sheets with a width of 2500 mm, 3200 mm and 4000 mm with a thickness of up to 12-13 mm.

Advantages of hydraulic guillotines

- Accurate and high-quality cutting without burrs;

- Ability to work with thick metal;

- Increased equipment reliability;

- Convenient control of the machine using CNC;

- High level of process automation;

- Maximum performance;

- Work safety;

- Low noise level.

Areas of application

Hydraulic guillotines are used in various areas of production. They are used for cutting roofing materials, for the manufacture of ventilation systems, and for the production of various metal structures and parts. For example, for procurement industries, hydraulic guillotine shears are the main equipment for cutting sheet metal.

Selecting a hydraulic guillotine

When choosing one or another model of guillotine shears, you need to consider a list of equipment requirements.

For example, modern guillotine models can be equipped with additional devices to increase efficiency and safety. This includes increasing the rear support, installing rear and front supports, installing safety guards and laser pointers.

Hydraulic shears photo.

In the photo hydraulic shears section, photographs of hydraulic shears for an excavator are published, used in the dismantling of building structures made of metal, concrete, reinforced concrete, including models for cutting and cutting scrap metal.

| Photo of hydraulic shear MS-500 Delta Engineering Group, Co, Ltd, Korea | Photo of hydraulic shears MS-2000 Delta Engineering Group, Co, Ltd, Korea | Photo of hydraulic shears MS-3000 Delta Engineering Group, Co, Ltd, Korea |

| Weight of scissors, kg - 500 Developed force, t- 152 Jaw opening, mm - 288 Excavator weight, t - 4…8 | Weight of scissors, kg - 2000 Developed force, t- 172 Jaw opening, mm - 522 Excavator weight, t - 18…26 | Weight of scissors, kg - 2450 Developed force, t- 256 Jaw opening, mm - 571 Excavator weight, t - 26…32 |

Operating rules

To extend the service life of the tool, it is important to follow the basic operating rules:

- the tool and cutting part must be kept clean;

- oil changes are carried out at least once every six months;

- Before storage, scissors should be cleaned and lubricated with an anti-corrosion compound;

- during operation, the thickness of the metal being cut should not exceed the standards stated by the manufacturer.

Possible faults

The main malfunctions of hydraulic tools for metal are:

- the rod does not return to the neutral position - the return spring must be replaced;

- no or insufficient oil pressure - requires changing the oil, closing the lever to relieve excess pressure or cleaning the hydraulic drive;

- There are oil smudges on the outside - the seals need to be replaced.

To avoid various breakdowns, you must follow the operating rules of the tool described in the technical data sheet. Before use, the tool must be checked for defects.

Guillotine shears - a classic solution for cutting sheet metal

The guillotine is designed for cutting and chopping sheet metal. As a rule, guillotine shears are used almost always and everywhere, because before bending or processing a sheet of metal, it must be prepared to a certain size. Metal cutting is carried out both along the entire length of a sheet from a batch of metal, and is also suitable for very small workpieces. The choice of equipment consists mainly of two most important indicators - metal thickness and working length.

- Electromechanical guillotine shears

- Hydraulic guillotine shears

Electromechanical guillotines

The most popular type of this equipment, due to its fairly simple maintenance, high speed of operation and the absence of special requirements for the machine operator. Processing of minimal and medium thicknesses with high precision, a large number of options for ease of use, which ultimately increases production speed. Often used in conjunction with another guillotine or laser/plasma metal cutting machines.

Hydraulic guillotine shears

For precise cutting of heavy and extremely thick sheets of metal, an exceptionally powerful and reliable machine is suitable - a guillotine with a hydraulic beam drive. The approach to developing this type of equipment is as complex and serious as it is in industrial hydraulic press brakes, where both machines are often used in pairs. Unique developments to increase the rigidity of the frame, a reliable hydraulic drive and oil pump system, cylinders from European brands known throughout the world. The best components even in the smallest details. The hydraulic guillotine is designed for maximum service life, constant operation and serial cutting accuracy at large thicknesses.

From us you can buy any guillotine for cutting metal. We are the official dealer of such companies as: MVD inan, Say-Mak, Ostas

Areas of application of guillotines

Both electromechanical and hydraulic guillotines can find their application at completely different production sites; it is not uncommon that there may be a need for both types of guillotines in one workshop. Cutting metal from a batch of sheets is used everywhere. The guillotine can be in a workshop that produces additional roofing and façade elements, in a production facility for the production and assembly of ventilation and smoke removal systems, in production workshops for the production of sea containers or the creation of road lighting poles, and many others.

- Equipment versatility

- High precision cutting of metal sheet batches

- Bed made of rigid and all-welded frame made of high-quality metal

- Quite a simple process of work, minimal requirements for personnel

- Low power consumption for minor tasks in a workshop with various metal cutting equipment

НВ5222 combined press shears. Purpose, scope

Combined press shears НВ5222 were developed in 1975 and mass-produced since 1977. Developer: SKB KPO and AL, Azov. Manufacturer: Mechanical Press Plant in Kuvandyk.

Combined press shears НВ5222 are used for cutting strip, long and shaped rolled products and punching holes in sheet, strip and shaped rolled products, as well as for performing notching operations.

Combined scissors НВ5222 can be used in machine-building, repair and other factories, when used in climate zones with moderate and cold climates, version UHL, dry and humid tropical climates - version O, placement category 4 according to GOST 15150-69.

HB5222 shears with four working zones allow you to perform several types of operations on one machine without preliminary reconfiguration of the shears, in any sequence and without changing tools, which provides flexible and economical processing of rolled products, both in large engineering production and in any repair shop.

HB5222 scissors perform the following operations:

- sheet metal cutting, strip cutting;

- rolled section without marking from 70 to 1000 mm along the stop;

- punching triangular and rectangular grooves;

- circle segment;

- a piece of angle, channel, I-beam, shaft profile;

- punching holes of round, rectangular, square and any other shape.

Description of the design of the shear press NV 5222

The frame is a welded structure, consisting of front and rear sheets welded to the base.

To install drive shafts and section drives, four borings are made in the frame. Drive the sheet metal and hole-punching sections from an electric motor through V-belt and gear drives to the eccentric shaft of the sections. The notching device lever is connected by means of a rod to the slider of the sheet section.

The slider of the punching section is balanced by spring balancers.

The centering mechanism is designed to perform the basting operation by moving it using the handle of the punch holder with the punch.

The tool for cutting corners, circles and squares consists of movable and fixed plates. The movable plate is attached to the socket of the slider of the sheet section, the fixed one - in the socket of the frame using L-shaped springs.

The sheet and notching tool consists of two movable and three fixed knives.

Movable knives - guillotine for cutting sheet material and rectangular - for rectangular notching.

The punching section tool consists of a punch and a die. The punch is attached through a punch holder to the slide, and the matrix is attached to the body of the punching device.

Press shears HB 5222 have three workstations, served by one operator.

The electrical circuit ensures the operation of the shear press on continuous and single strokes.

Push-button and pedal controls.

Thick, combined lubricant.

The design of the HB5222 press shears and many options for additional equipment allow the use of press shears for processing rolled products of various profiles and different parameters.

To facilitate the movement of strip, long and shaped products when feeding them into the working area of the shears, it is possible to use a roller conveyor module of the MRP drive model.

Additional requirement: the lower air temperature must be at least +5°C

Main parameters of press shears НВ5221:

The parameters are valid for metal with a tensile strength (tensile strength) σ BP = 500 MPa (50 kg/mm2).

- The largest thickness of the sheet to be cut is 16 mm

- The greatest thickness and width of the cut strip is 18 x 190 mm

- The largest diameter of the cut circle is Ø 50 mm

- The largest dimensions of the cut corner are 14 x 125 x 125 mm

- The largest diameter of the hole to be punched is Ø 32 mm

- Frequency of continuous strokes of the slider – 53 min-1

- Drive power – 4.8 kW

- Total vehicle weight – 2.5 tons

Structural elements

A manual guillotine for cutting metal has the following components:

- Bed;

- Desktop;

- Knife;

- Vertical guides;

- Toothed racks (drive);

- Gearbox;

- Lever arm;

- Ruler.

Desktop Features

The working surface is a metal plate no less than 1 cm thick. It is not recommended to use wood for this, even a very thick panel, as it will spring and become deformed

It is important for the equipment to remain in one unchanged position

2 guides are installed on the plate (round or profile pipe). The upper beam with the knife will move along them. It is advisable to choose thick-walled material. In this case, the guides must be placed in such a way that they are exactly parallel to each other and in a perpendicular plane to the table.

The knife will subsequently be attached to the horizontal beam. The beam must be allowed to move freely along the guides. In this case, there should not be excess resistance, but there should also be no backlash. This can be achieved by welding bushings along the edges of the beam, which will be inserted into the guides with a small gap. The inner surfaces of the bushings should be lubricated.

Drive mechanism

The vertical movement of the beam can be ensured using gear racks by welding them at its ends. By placing the slats on both sides, you can achieve uniform movement. The forces on the rack will be transmitted from the gears connected to the lever mechanism. By considering different leverage ratios and gear diameters, it is possible to achieve the required force applied by the knife. In this case, the impact on the drive will be minimal.

In order to ensure uniform rotation of the gears, they must be connected by a common shaft, which can be placed under the working plane. An analogue of the design can be a pedal drive. To prevent spontaneous lowering of the beam, it is recommended to install an upper position lock or a return spring.

Choosing the right version

Naturally, the existing capabilities of the excavator are taken into account first. However, if such equipment is purchased together with an attachment kit, then pay attention to the following:

- Knife design: the jaws of hydraulic mounted shears must have a composite configuration that provides the most reliable grip of scrap at the moment it begins to separate.

- A method for reinstalling and adjusting the gaps between knives, which should be simple and reliable.

- The presence of protective plates that prevent the crushing of thin-sheet scrap due to the increased gap between the working knives.

- The rigidity of the control system is movable with a knife, which makes it possible to cut material with the maximum height dimensions of the divided structure.

- The degree of protection of the power cylinder rod from external influences.

- Reliability of routine maintenance and lubrication of shear mechanisms.

The choice of hydraulic shear model should also be made taking into account the minimum overall dimensions of the site where their subsequent use is expected (taking into account the current maintenance area).