To make your own flocator, powder coating gun or electrostatic smoker, a high voltage source is required. And if the first two devices require 75-100 kilovolts, then a high-voltage generator for a smokehouse operates at 15-20.

There are many circuits of high-voltage generators on the network made using line transformers from monitors, TVs or car ignition coils. For the most part, their circuit design is depressing - as a rule, these are the simplest flyback converters, which means the transistor in them will work as a boiler because For a beginner who probably doesn’t have an oscilloscope, calculating a snubber is almost impossible.

Circuits from the last century using thyristors powered by a 220-volt network are dangerous and, if careless, can lead to dire consequences. We will make a resonant half-bridge on TDKS.

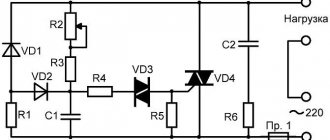

Let's look at the diagram:

Switching power supply with microcircuit

The diagram of a power supply with a microcircuit from the same company Power Integration is shown in Fig. 6. The device uses a semiconductor voltage limiter - 1.5KE250A.

The converter provides galvanic isolation of the output voltage from the mains voltage. With the ratings and elements indicated in the diagram, the device allows you to connect a load that consumes 20 W at a voltage of 24 V. The efficiency of the converter approaches 90%. Conversion frequency - 100 Hz. The device is protected from short circuits in the load.

Rice. 6. Circuit diagram of a 24V switching power supply on a microcircuit from Power Integration.

The output power of the converter is determined by the type of microcircuit used, the main characteristics of which are given in Table 1.

Table 1. Characteristics of TOP221Y - TOP227Y series microcircuits.

| Chip type | Рmax, W | Protection current, A | Open transistor resistance, Ohm |

| TOP221Y | 7 | 0,25 | 31,2 |

| T0P222Y | 15 | 0,5 | 15,6 |

| T0P223Y | 30 | 1 | 7,8 |

| T0P224Y | 45 | 1,5 | 5,2 |

| T0P225Y | 60 | 2 | 3,9 |

| T0P226Y | 75 | 2,5 | 3,1 |

| T0P227Y | 90 | 3 | 2,6 |

How it works

After pressing the button, the IR diode turns on and the light beam hits the optocoupler sensor, this sensor has an output resistance of about 50 ohms, which is enough to turn on the 2n2222 transistor. This transistor supplies battery energy to power the 555 timer. The frequency and duty cycle of the pulses can be adjusted by changing the ratings of the trim components. In this case, the frequency can be adjusted using a potentiometer. These oscillations, through the BD679 transistor, which amplifies the current pulses, enter the primary coil. An alternating voltage increased by 1000 times is removed from the secondary and rectified by an explosive multiplier.

Basic elements of the electrical spark equipment circuit

The diagram is represented by the following elements:

- electrode;

- a clamp screw used to secure the positive wire and electrode;

- guide bushing;

- body made of fluoroplastic;

- hole used to supply oil;

- tripod.

The body, which is used to connect all the elements, is machined from fluoroplastic. A grounding pin is used as a bushing, in which a threaded hole is machined along the axis for attaching the electrode. All structural elements are mounted on a tripod, which is made with the ability to change height. A hole is also created through which oil is supplied.

Electric spark machine diagram

Often cutting is carried out using a device that is powered by a starter with a coil connected to a voltage of 220V. The starter rod can have a stroke of 10 millimeters. The starter winding is connected in parallel with the lamp. That is why the lamp is lit when the capacitors are charging, and after this process is completed, it goes out. After the rod has been lowered, a spark charge occurs.

The principle of the considered processing method

A special feature of processing with an electric spark unit is that the evaporation of metal occurs due to the effect of a certain charge on the surface of the workpiece. An example of such an effect is the short circuit of a capacitor on a metal plate - a hole of a certain size is formed. EDM creates a high temperature that simply evaporates the metal from the surface. It is worth noting that a machine from this group has already been used over the past 50 years in various industries. The main condition for using such an electric spark machine is that the workpiece must be made of a certain metal. In this case, it is not the degree of machinability that is taken into account, but the electrically conductive properties.

Boost Converter Basics

In a boost converter (Figure 2), energy is stored in the inductor (L1a) during the time the transistor (T1a) is turned on. When the transistor is turned off (toff), energy is transferred in series with the input Vin to the output filter capacitor (Cout) and the load (RL). This configuration allows the output voltage to be set to any value greater than the input voltage.

Rice. 2: Boost switching regulator circuit. The output voltage can be calculated as follows: Vout = Vin (ton / toff) + Vin or Vout = Vin ((ton / toff) +1)

Technical specifications for the design of a homemade machine

To make a homemade electrical discharge machine, you need to make a number of devices that will help automate the production process.

- A frame is needed; the mechanism for moving the electrode will be placed on it.

- You will need a mechanism that allows you to periodically bring and remove the electrode to the material being processed.

- To burn holes of different shapes you need to have a set of electrodes. Experts recommend using molybdenum wire.

- For different types of main tools, you will need to change the device power and amperage. Under different operating modes, the electrical circuit diagram must allow regulation of the discharge value on the electrode. It is necessary to provide for a change in the voltage ripple frequency.

- To cool the part (hardened steel cannot be overheated; tempering occurs with a decrease in hardness), coolant must be supplied to the work area. More often, ordinary water or salt solutions are used. The water simultaneously washes away sludge (destroyed metal particles).

Design of an electric spark machine

There are schemes that are quite difficult to implement. The scheme in question can be implemented with your own hands. Parts for the installed generator are not in short supply; they can be purchased at a specialized store. Capacitors are also widespread, as is the diode bridge. At the same time, when creating a homemade electric spark machine, the following points should be taken into account:

- on the capacitor the indicated voltage should not be less than 320 Volts;

- the number of energy storage devices and their capacity are selected taking into account that the total capacity should be 1000 μF. All capacitors must be connected in parallel. It is worth considering that the power of a homemade version increases if it is necessary to obtain a stronger spark strike;

- The lamp is installed in a porcelain socket. The lamp should be protected from falling; a circuit breaker with a current strength of 2 to 6 Amperes is installed;

- the machine is used to turn on the circuit;

- electrodes must have strong clamps;

- a screw clamp is used for the negative wire;

- The positive wire has a clamp with a copper electrode and a tripod for direction.

The homemade wire version has relatively small overall dimensions.

Homemade electric spark machine

Development of a horizontal electrical discharge machine

The installation diagram includes the main components and parts:

- 1 – electrode;

- 2 – screw for fixing the electrode in the guide sleeve;

- 3 – terminal for fixing the positive wire from the voltage converter;

- 4 – guide sleeve;

- 5 – fluoroplastic body;

- 6 – hole for lubricant supply;

- 7 – bed.

The unit is small in size and can be placed on a table. In the housing 5, the guide sleeve 4 can move in both directions. To drive it you need a special mechanism or device.

Electrode 1 is attached to sleeve 4, the positive wire is also connected using terminal 3. All that remains is to assemble the proposed circuit into a real installation at home. It uses the simplest equipment.

DIY electric spark machine

To change the shape and size of a metal workpiece, you can use the electrical discharge processing method. It has been used for many years in various industries, characterized by high accuracy but low productivity. To apply this processing method, you should use a special electric spark machine, which you can purchase or make yourself. The homemade version can be used in everyday life in small-scale production. The cost of making it yourself will be lower than purchasing an industrial version. Therefore, let’s take a closer look at how you can make the electric spark machine in question with your own hands, what you need for this and in what cases it can be used.

Main structural element

The EDM machine has a spark generator that acts as a capacitor. For processing, a large capacity storage element should be used. The processing principle is to store energy over a long period of time and then release it over a short period of time. The laser device also works on this principle: reducing the time period of energy release leads to an increase in current density, which means the temperature increases significantly.

Electrical circuit of an electric spark installation

The operating principle of the generator, which is installed on an electrical discharge machine, is as follows:

- the diode bridge rectifies industrial current with a voltage of 220 or 380 Volts;

- the installed lamp limits the short circuit current and protects the diode bridge;

- the higher the load indicator, the faster the charging of the electric spark machine;

- after charging is complete, the lamp will go out;

- Having charged the installed storage device, you can bring the electrode to the workpiece;

- after the circuit is opened, the capacitor begins to charge again;

- The charging time of the installed storage element depends on its capacity. Typically, the time period is from 0.5 to 1 second;

- at the moment of discharge the current reaches several thousand amperes;

- the wire from the capacitor to the electrode should have a large cross-section, about 10 square millimeters. In this case, the wire must be made exclusively of copper.

The generation frequency when the electrode is supplied to an electric spark machine is 1 Hz.