Will the generator power the welding machine or not, that is the question.

Sometimes you have to weld in the absence of electricity and nothing can be done about it. Accordingly, there is a need to choose a generator for welding, which is not so easy to do.

First of all, this is a high cost, since special generators for welding are more expensive. However, even if we do not look at this factor, a number of difficult questions still arise.

For example, will a generator be able to power a welding machine? How to correctly calculate the power of a generator for welding? Which brand of generator is best to choose? These are the most pressing questions concerning this moment.

Is it possible to connect inverter welding to a Scat generator set?

You have a question!

Is it possible to connect an inverter welding machine to the generator? Theoretically, why not? If you look in more detail when calculating the load, you should take into account several important points. The inverter welding machine in its design has many capacitors, coils and electronic circuits and for the generator set is a reactive consumer with a real power factor (COS φ) of 0.7. Apparent power is calculated as the active power declared by the manufacturer and indicated in the technical specification, divided by the power factor (COS φ).

For example, let’s select generators for Arco inverter welding machines (link to the page with welding machines) with a maximum welding current of 160A, 180A, 200A.

| Welding machine power | Suitable Generator Model |

| No more than 160 amps | UGB-6000 Basic, UGB-6000, UGB-6000 E, UGB-6000E AUTO, UGB-6000 ET/6 kW |

| No more than 180 amps | UGB-7500, UGB-7500 Basic UGB-7500E, UGB-7500E AUTO |

| No more than 200 amperes | UGD-11500E |

160 A is the welding current, which is only sufficient to work with an electrode with a maximum diameter of 4.0 mm. The maximum active power consumption of such a device is 3.8 kW. Accordingly, the total power of the generating set, taking into account the coefficient of 0.7, will be 5.0-5.5 kW. Considering the recommended stock

20%, the power of the generating set must be at least 6 kW.

180 A – the device will allow you to carry out welding work with an electrode with a diameter of up to 5 mm.

The maximum active power consumption is 4.8 kW. When calculating the total power, we get 7.5 kW. The power of the generating set when connecting such an inverter, taking into account the 20% reserve, should be no less than 8.0-8.5 kW.

200 A - a serious device, powered by a three-phase network and will allow you to cook with an electrode with a diameter of up to 6 mm. The power consumption, taking into account the coefficient, will be 11.5 kW of three-phase current. The generator set for connecting a welding machine with such a current must be three-phase and with a power of at least 15 kW.

What if you buy a 250A welding inverter, but don’t use it at full power? Is it possible in this case to connect it to a generator of lower power? Advice: don't take risks. Only an electromechanical specialist will be able to determine at what welding current and how many watts the machine consumes.

The options for inverter welding machines should be taken into account. Functions such as “anti-stick” and “hot start” will require at least a little additional power for a short time.

Based on the above, we can conclude:

In order to preserve the life of the SKAT ® generator and simply not harm it, take a more serious approach to your choice. Carefully select the energy source for the device. Check all technical parameters, paying attention to indicators such as maximum power consumption and power factor. Be sure to leave a 20% power reserve for the generator.

Without any particular concerns, you can connect a welding machine with a current of 140-160 A to SKAT ® gasoline generators: UGB-6000, UGB-6000 Basic, UGB-6000E, UGB-6000T Basic, UGB-6000ET/ 6 kW, UGB-6000E/AUTO , UGB-7000, UGB-7000 Basic, UGB-7000E, UGB-7000E/AUTO, UGB-7500E, UGB-8500E, UGB-8500ET, UGB-11500E, UGB-10000ET ,

for diesel generators SKAT ® UGD-6000E, UGD-6000ET, UGD-6000EK, UGD-10000E, UGD-10000ET

Is it possible to connect welding transformers to generators?

There are three types of welders: transformers, semi-automatic machines and inverters.

You cannot connect a transformer to a brush generator - it will not withstand the load. A welder is a very powerful inductive consumer. A 130 A transformer (3 mm electrode) consumes about 7 kW at nominal value, and twice as much when igniting the arc. There is a high risk of burning the generator winding and being left without a generator and warranty repairs.

Inverter welding machines with a power of 160–200 A when welding with an electrode of 3–4 mm at a welding current of 120 amperes can be connected to gasoline generators UGB-5000, UGB-6000 or diesel generators UGD-6000E or UGD-6000EK.

Source

Gasoline generator for welding inverter

Every welding inverter requires electrical power. But sometimes situations arise when the work area is located far from fixed networks. However, there are no hopeless situations, and one of the ways to solve the problem is a portable generator. It is the most optimal device that provides autonomy to any electrical equipment. However, a gas generator for a welding inverter is not suitable for everyone, since there are certain requirements and technical conditions. The parameters of each unit must correspond to each other; only in this case is their productive collaboration possible.

What power generator is needed for welding with an inverter?

Reading time: 7 minutes There is nothing impossible for inverter welding in everyday life and in the garage. Need your gate repaired? Weld the gate? Build a greenhouse? Weld reinforcement when building a house? No problem. The inverter will cope with all tasks. It is compact and easy to use, it can be used by both a beginner and an old-school master accustomed to bulky transformer devices.

Naturally, any inverter needs power. To do this, just plug the device into a power outlet using a network cable. Nothing complicated. But what to do if the electricity in your area is turned off or there is no electricity at all? In such situations, you need a generator for the welding inverter. We have previously told you about what a welding generator is and how it differs from a regular generator. Today we will tell you what kind of generator is needed for a welding inverter or how to choose a generator for a welding machine so as not to make a mistake.

How can you understand what current strength is in a particular inverter?

If you need to know this indicator absolutely precisely, then it will be useful to get a current clamp with a Hall sensor, then you can check the current output by the welding machine right at the time of purchase by turning on the inverter, setting its regulator to the maximum value and measuring the current that the tool can generate.

Moreover, measuring the current alone is not enough, because the device can produce a current of 200 or 250 Amperes, but this current can hardly be called operational. Here you will need to measure the welding voltage, and if, with a rated current of 200 Amps, the voltage is lower than required, then 200 Amps in the welding inverter cannot be called working.

It is worth understanding that the operating welding voltage for different current strengths will be different, but calculating what is required will not be difficult. To do this you need to apply the following formula:

Operating welding voltage=20+0.04*device current

It is so easy to calculate that for a 160 Ampere device the voltage should be 26.4 Volts; for 200A - 28V, and for 250A - 30V

What kind of gas generator is needed for a welding inverter?

For professional welding work, special monoblocks are produced, or, as they are called, welding generators. As a rule, such devices are intended for work professionals. We will focus on selecting a generator for connecting welding inverters or a transformer for working at home, we will dwell on their features and how to choose a gas generator for a welding inverter, taking into account some of the nuances.

In newly purchased generators, it is necessary to take into account some circumstances:

- Workload;

- Power of an inverter;

- Whether there are protective functions on the inverter or not;

- Let's look at each in more detail.

How to choose a generator?

How to choose a generator? In fact, there is nothing complicated here. You only need to consider a few parameters: the power consumption of the generator, the maximum current of your inverter, the diameter of the electrodes you will use, and the compatibility of the generator with the device.

The first and second criteria are interconnected, we will talk about this later. But as for compatibility, here you need to pay special attention to the type of generator. There are synchronous, inverter and asynchronous generators. There are also hybrids that can work both synchronously and asynchronously.

Now many beginners will probably say that there is nothing to think about here, you need to take an inverter. And therein lies the biggest mistake. Because to power the device, you must choose either a synchronous generator or a hybrid. They have sufficient power and are designed for high starting loads.

We also recommend purchasing a gasoline generator rather than a diesel one. It is not as economical, but with relatively low power it works many times better than a diesel generator. In addition, the choice of gasoline generators is much larger.

If you are selecting a generator for professional equipment (for example, for expensive semi-automatic welding machines), then keep in mind that their operation from a generator does not always go smoothly. Some manufacturers explicitly say this in their instructions. Therefore, in any case, consult a specialist in the store.

Steps to connect to the inverter

Since converting a car model into a welded equipment is not the best idea, it is worth figuring out how, if necessary, to connect a real welding unit to it.

To begin with, the relay-regulator is removed from the autogenerator. The circuit between the relay regulator and the brushes is broken. After this, power must be supplied to the brushes.

For this, a voltage of 12V is used, which is supplied from the battery. Now the device is in working condition, which means you can disconnect the wire connecting it to the battery.

After this, the engine starts. It should run at 3000 rpm. In a self-generator, this number will increase to nine thousand, and it will be able to generate voltage power up to 80V.

This occurs due to the removal of the relay regulator, which in the mechanism is responsible for limiting the current strength.

Eighty volts is enough to power a low-power inverter up to a power of 100 A. This will allow welding work. However, the duration of the work process with such power supply must be limited.

This mode of operation greatly wears out both the inverter and the apparatus powering it.

How to choose power?

How much power does a generator need for a welding machine? Let's figure it out.

First of all, the power of the generator for welding should be 20-30% greater than the power of your welding inverter. This is necessary not only for stable arc ignition, but also for proper use of generator resources. It is not recommended to use the generator at its maximum power limit. Therefore, if you buy a generator that is a little more powerful, you will be able to set a more gentle mode for welding. This way you will extend the life of the device, and the arc will burn more stable.

Let's give a simple example. If you have an inverter capable of delivering up to 180 Amperes of current, then we recommend purchasing a 6-6.5 kW generator, taking into account the power reserve. Based on this information, you can independently select the generator power for the welding inverter if it has different technical characteristics.

Operating rules

When operating a gasoline generator for welding machines, you should strictly adhere to the recommendations from the user manual and advice from professional welders. After purchase, you should carry out a run-through check - approximately the first 20 hours of active use allow the parts to fit together.

It is best not to run the device at a power higher than 50% of the rated documented value at this time. If we are talking about working at heights, then it is worth requiring/selecting a device with a modified carburetor capable of operating in conditions of oxygen-enriched air.

It is also worth familiarizing yourself with the rules for the following operating procedures:

- Checking the oil level;

- Fuel selection;

- Refueling and checking fuel level;

- Starting the unit;

- The procedure for turning on the load;

- Stopping the engine, etc.

Competent action in any situation, both normal and emergency, will allow you to maintain the functionality of the installation for the entire operational period without the need for unscheduled repairs.

Best Cheap Generators

To make it easier for you to choose a generator for your welding machine, we will additionally tell you about four high-quality models for your home and garage. This is not a rating, but rather a list of excellent generators that have performed well in a variety of conditions.

Huter DY6500L

The Huter DY6500L generator is an excellent helper in the household. Its power is 5 kW, which is enough to power a low-power inverter delivering up to 150 Amps. This is a synchronous generator running on gasoline fuel. For full operation, it is recommended to use gasoline of a grade not lower than AI-92. This model can also run on propane. Tank with a capacity of 22 liters.

Huter DY6500L is started using a recoil starter. There is a built-in forced cooling system, it is of the air type. The weight of the generator is about 80 kg, which is quite a lot. But two or three people can move it to the right place without any problems.

BRIMA LT 8000 B

We also recommend the LT 8000 B model from the famous German brand BRIMA for inverter welding. Its power is slightly more than that of the previous generator - 6 kW. But this is its rated power. And the maximum is 6.5 kW. However, remember that we do not recommend constantly using the generator beyond its capabilities. The LT 8000 B model is useful for those whose machine produces up to 180 Amps of welding current.

This is also a gasoline generator. Tank capacity - 25 liters. Powered by a reliable 190F engine. It is four-stroke, equipped with forced air cooling. Starting is carried out using built-in electronics. The generator can work without a break for up to 8 hours, then it needs a break to avoid overheating.

Gasoline generators with welding function

Welding gas generators provide a full guarantee of identical characteristics . In one housing are connected: an inverter-type welder and a generator with a gasoline engine.

Amateur models produce current up to 170 A, professional 220 A and higher.

Models

Popular types of welding gas generators are suitable as a power source in the country. It can power the tool during periods when welding is not working.

The most popular models in stores are from Germany:

- RID RH5221 S – gasoline power station has a built-in welding machine;

- RID RH7220 S – constant welding current up to 220 Amps.

RF equipment from Svarog is popular among professionals and amateurs..

Operating rules

The generator must always be clean. Dust and dirt settling on electrical terminals and windings lead to overheating and malfunction. To excite the current in the winding of gasoline generators, a battery is installed. It should be charged periodically. In addition, there is an oil level indicator on the panel. A red light means that the coolant and lubricant level is low and needs to be topped up.

Like all electrical equipment, the generator should be periodically checked for insulation integrity, the terminals should be cleaned of oxides and the contacts should be tightened.

Source

Rules for using a gas generator

The lifespan of a generator largely depends on proper use. Compliance with the established rules begins at the start-up stage:

- By this time, the entire electrical load is turned off. The generator must be idling for several minutes, otherwise the power plant may be subject to significant overload.

- The oil level is at its standard level.

- Devices and equipment for welding with an inverter are allowed to be connected no earlier than after 5 minutes. During this time, the generator will warm up and function much more efficiently.

How to increase the service life of an electric generator

Use quality fuel

The power plant engine requires good fuel. As a rule, gasoline is used grade A-92 or A-95 . It is important that it is of good quality and does not stagnate in the tank. The shelf life of gasoline should not exceed 60 days . If stored for a longer period of time, the gas generator may not start at all.

Low-quality gasoline can interfere with the operation or damage the carburetor.

Do not fill the tank up to the neck because gasoline tends to expand under the influence of temperature and vibration. This can cause it to rip off the lid and spill onto the body.

Monitor the oil level

Oil is no less important factor in engine operation than fuel. Suitable oils for gasoline generators are 15W-40, 10W-40, 10W-30 and 5W-30. The choice of oil brand depends on the time of year and ambient temperature.

Choosing which generator is needed for the welding inverter

Some construction teams use ordinary household power supply devices to connect the welding machine, which is extremely incorrect and reduces its operating time. This is mainly due to the peculiarities of welding, as well as the different types of voltage that are used in both equipment. In this regard, the question arises: “What kind of generator is needed for a welding inverter?”

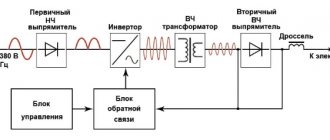

Design and principle of operation of a generator for inverter welding

A welding inverter requires a gas generator that will produce a voltage suitable for its operation. What is the essence of the problem?

The operation of a conventional generator involves the conversion of mechanical energy into electrical current. But the problem is that the output produces an alternating voltage, which is characterized by large wave fluctuations or power surges. As a result, the efficiency and productivity of the equipment is reduced, and its service life is shortened. There are two options for getting out of this situation:

- Use gas generators for inverter welding with a large power reserve.

- Connect the equipment to an inverter station, which supplies a more stable voltage.

Each option has its advantages, but when choosing, you should take into account both the advantages and disadvantages that each solution provides.

How much power does a generator need for inverter welding?

As already noted, one of the common options for resolving the issue of equipment incompatibility is the situation when connecting a gas generator for an inverter welding machine of higher power to compensate for possible voltage surges. But there are some pitfalls here. A competent calculation of equipment power will be required. The calculation is made as follows:

- The generator power for an inverter welding machine is selected according to the maximum power consumption. Additionally, a small margin is left, approximately 20 to 30% of the total station capacity.

- The calculation of power consumption is calculated by multiplying the maximum current requirement of the device with the expected voltage on the arc. You can find out these coefficients in the operating instructions. The resulting product must be divided by the efficiency of the installation. The total amount will be the maximum voltage.

Varieties

The classification of electric generators takes into account their rated power:

- Household (0.5 - 5 kW) - small power stations that are designed to power household electrical appliances, lighting devices and tools. Such units are distinguished by their compact design and low weight, which greatly simplifies the process of transporting them.

- Synchronous (5 - 10 kW) are reliable and universal sources of electric current, which are at a power level that allows both to power household electrical appliances and to be a source of electricity for welding equipment. Such a device is capable of supplying electricity to a private house or plot.

- Welding machines (4-20 kW) are a full-fledged technical complex, which consists of a generator set and an inverter. The market offers both stationary models of electric generators for welding and mobile stations.

Calculating the power required for your welding machine is quite simple. First, you need to find on the case or in the instructions of the welding device its maximum current consumption level I max (for example, 21 Amperes), multiply this number by the voltage (220 Volts) and get 21*220=4600. To this number you need to add a power reserve of 30%, as a result, to power a welding machine with a consumption of 21 A, you will need a 6000 W (6 kW) generator.

Criterias of choice

For many users, it is enough to know that when operating a fuel generator it is possible to generate electrical energy. Professionals distinguish for themselves separate categories of such devices, among which gas generators for welding and their diesel analogues are in the same row. However, it is inappropriate to consider these generators as a separate type of device that generates electricity from a fuel resource.

The principle of operation of a welding gas generator is not much different from conventional household analogues used on the farm. The key essence of its action is that when started, a welding arc is ignited, through the winding of which an electric current flows, sufficient to maintain the arc burning process.

The process of generating current is quite simple. An internal combustion engine is hidden inside the generator. This mechanism involves rotation of the internal crankshaft with the transformation of mechanical energy into electrical energy.

However, the technical simplicity of the process of generating energy for welding is not all that you need to know about such equipment. When choosing a high-quality gas generator for welding, you should rely on more significant criteria.

The most important parameter of the gas generator to which the welding machine will be connected is the maximum level of power generated. It should not be confused with consumption. You should look for this value in the user manual or data sheet.

Naturally, the generated power of the generator should be selected in comparison with the consumption of the existing welding machine. If the latter value is not in the technical documentation, then consumption can be calculated by multiplying the maximum welding current with the arc voltage and dividing this value by the efficiency of the welding inverter.

Important! The output of the generator should have a power value higher than the consumption of the welding machine (by about 30%), which will allow it to work without overload.

It is also worth noting that there are more nuances in the combination “welding unit - generator” than just “buy with a reserve”, and therefore when selecting one device for another, you should have a detailed consultation with a specialist.

Read other articles from our experts:

Advantages and disadvantages of Japanese gas generators, examples of devices and selection criteria, what should you pay attention to?

What to look for when buying Vepr gas generators, what advantages the company’s devices have, as well as examples of models and customer reviews.

Varieties and power

Gasoline generators are classified depending on the power they produce:

- Generator for domestic conditions (from 0.7 to 5 kW) - a mini-power station that allows you to power household appliances, is compact and easy to transport. In general, gasoline generators are excellent for welding under conditions of high mobility and spot distribution of objects.

- A synchronous generator (from 5 to 10 kW) is a more universal source of electrical energy, which, with its power, allows you to work with both welding equipment and household appliances. It is quite possible to power one country house/plot.

- A welding generator (from 10 to 20 kW) is a full-fledged welding complex that intelligently combines a generating generator set and an inverter. As a rule, due to its size, a gasoline generator with a welding function is used permanently, but it can also be made in a portable format.

Above, the power of the gas generator has already been determined by the key criterion for its selection. Calculation of this value when selecting the desired welding machine is carried out as follows:

- We find the maximum level of current consumption by the inverter (Imax). For example, Imax = 21 A. Information can be printed on the housing or written down in technical documentation.

- The power of this installation can be calculated using Ohm's law by multiplying the voltage by the resulting Imax value. In the described case: 220 V * 23 A = 4620 W.

- In addition to the obtained value, we add 30% of the power reserve. 4620 + 1386 = 6006 W. Thus, the optimal generator power level should be at least 6 kW.

We select a high-quality gas generator for welding

Gasoline generators (gasoline power plants) are miniature autonomous installations for energy production, which are used as a backup or main source of supply. Gasoline generators are divided into several types according to power and direction of use. Below in the article we will figure out how to choose a generator for welding without resorting to specialists.

Types and features of generators

Generators running on gasoline are mainly used as a backup source to supply electricity to any objects or, if necessary, to carry out field work with power tools that cannot be connected.

Gasoline generators for welding are designed for temporary operation (for several minutes or hours). If you need to work for a long time without breaks, it is better to get a diesel generator.

Gasoline generators for summer cottages and recreation - this type of generators is the most popular among buyers. The stations can produce power from 0.7 to 5 kilowatts, and are quite easy to transport.

Gasoline generators for welding machines - a variety with a power of 5 to 10 kilowatts. They are well suited for intensive work for 8 hours. It is very important to know the engine manufacturer so as not to end up with an option that will make its shortcomings known within a month. An important parameter is the size of the fuel tank and the presence of a sound insulation casing and the ability to start the generator with an electric starter.

Scheme and structure of the device

Modern overhead valve generators can be compared with diesel ones in terms of the quality of the energy released. The units can provide very high performance while minimizing noise, and are compact and durable. It is advisable to buy this generator for welding if you plan to carry out work on a construction site or power a welding machine that periodically requires a powerful flow of energy.

A gas generator with a welding function for a cottage or enterprise produces power from 10 to 20 kilowatts. They are equipped with automatic start and are used as a stationary installation.

Design feature and operating principle

Many experts classify welding gas generators as a separate type of generator; their operating principle is no different from the usual one, and the circuit is quite simple.

When the arc is ignited, the welding current necessary to maintain the arc flows through the armature winding. Current is generated through the transformation of energy due to the rotation of the crankshaft in the power internal combustion apparatus, which converts mechanical energy into electrical energy.

What to look for when choosing

If you need high-quality welding, then you must clearly understand how to choose the right gas generator for welding. The continuity of welding will depend on it, which will directly affect its quality. A generator is also needed when it is not possible to connect to the electrical network. Thus, it will be an indispensable link in welding.

see also

Comments 79

So you need to go to the store and ask for the spark plug to check on the spot

I was walking here this week, saw men making fences and remembered the topic.

WELDING INVERTER AURORA MINIONE 1600 and Gasoline generator SPECIAL SB-6500E2 I bought the generator from Maxidom about a month and a half ago at a discount and cost 23,000 rubles with electric start. I took the Aurora in the winter for about six thousand, it also seems to be new. I have already welded the fence, I am pleased with the work of both.

Yamaha generator 7.5 kW Tesla inverter 5.6 kW at maximum speed without problems. there should be a reserve on the generator

Gasoline welding generator DDE DPW160i, I would take this one, it will weld accurately, the weight and dimensions are small. Order online with delivery, if the price doesn’t suit you, I’ll offer another option. In my garage I have a Champion 3300 generator and a Resanta 220 inverter, not even a Mon, but a regular one. I tried to cook with 3 MP3 electrodes, it cooks normally at a current on the device of 75-90 amperes. But I can’t imagine how long the generator will withstand this mode of operation.

5.5 kW pulls the welding inverter

As an option, a 6.5 kW gas generator and an inverter pulls at 5.5 kW, tested on myself

I saw a few years ago a two-in-one gas generator + welder of the Cayman brand

)))) Are you familiar with the repair and restoration authorities?

I'm not entirely sure about the organs. but, acting chief mechanic of RSU, three years...

We multiply the welding current by the arc formation voltage and divide by the efficiency of the inverter. We add a margin of 25% (if you don’t want to ruin the generator) and get the required generator power. For example, 80A*30V/0.85=2823 W +25% Fairly in the opposite direction, we multiply the generator power by the efficiency of the inverter and divide by the arc formation voltage, we get the maximum welding current. For example 3000*0.85/30=85A.

Is it possible to connect inverter welding to a Scat generator set?

You have a question! Is it possible to connect an inverter welding machine to the generator? Theoretically, why not? If you look in more detail when calculating the load, you should take into account several important points. The inverter welding machine in its design has many capacitors, coils and electronic circuits and for the generator set it is a reactive consumer with a real power factor (COS φ)

0.7. Apparent power is calculated as the active power declared by the manufacturer and indicated in the technical specification, divided by the power factor (COS φ).

For example, let’s select generators for Arco inverter welding machines (link to the page with welding machines) with a maximum welding current of 160A, 180A, 200A.

| Welding machine power | Suitable Generator Model |

| No more than 160 amps | UGB-6000 Basic, UGB-6000, UGB-6000 E, UGB-6000E AUTO, UGB-6000 ET/6 kW |

| No more than 180 amps | UGB-7500, UGB-7500 Basic UGB-7500E, UGB-7500E AUTO |

| No more than 200 amperes | UGD-11500E |

160 A is the welding current, which is only sufficient to work with an electrode with a maximum diameter of 4.0 mm. The maximum active power consumption of such a device is 3.8 kW. Accordingly, the total power of the generating set, taking into account the coefficient of 0.7, will be 5.0-5.5 kW. Considering the recommended stock

20%, the power of the generating set must be at least 6 kW.

180 A – the device will allow you to carry out welding work with an electrode with a diameter of up to 5 mm.

The maximum active power consumption is 4.8 kW. When calculating the total power, we get 7.5 kW. The power of the generating set when connecting such an inverter, taking into account the 20% reserve, should be no less than 8.0-8.5 kW.

200 A - a serious device, powered by a three-phase network and will allow you to cook with an electrode with a diameter of up to 6 mm. The power consumption, taking into account the coefficient, will be 11.5 kW of three-phase current. The generator set for connecting a welding machine with such a current must be three-phase and with a power of at least 15 kW.

What if you buy a 250A welding inverter, but don’t use it at full power? Is it possible in this case to connect it to a generator of lower power? Advice: don't take risks. Only an electromechanical specialist will be able to determine at what welding current and how many watts the machine consumes.

The options for inverter welding machines should be taken into account. Functions such as “anti-stick” and “hot start” will require at least a little additional power for a short time.

Based on the above, we can conclude:

In order to preserve the life of the SKAT ® generator and simply not harm it, take a more serious approach to your choice. Carefully select the energy source for the device. Check all technical parameters, paying attention to indicators such as maximum power consumption and power factor. Be sure to leave a 20% power reserve for the generator.

Without any particular concerns, you can connect a welding machine with a current of 140-160 A to SKAT ® gasoline generators: UGB-6000, UGB-6000 Basic, UGB-6000E, UGB-6000T Basic, UGB-6000ET/ 6 kW, UGB-6000E/AUTO , UGB-7000, UGB-7000 Basic, UGB-7000E, UGB-7000E/AUTO, UGB-7500E, UGB-8500E, UGB-8500ET, UGB-11500E, UGB-10000ET ,

for diesel generators SKAT ® UGD-6000E, UGD-6000ET, UGD-6000EK, UGD-10000E, UGD-10000ET

Is it possible to connect welding transformers to generators?

There are three types of welders: transformers, semi-automatic machines and inverters.

You cannot connect a transformer to a brush generator - it will not withstand the load. A welder is a very powerful inductive consumer. A 130 A transformer (3 mm electrode) consumes about 7 kW at nominal value, and twice as much when igniting the arc. There is a high risk of burning the generator winding and being left without a generator and warranty repairs.

Inverter welding machines with a power of 160–200 A when welding with an electrode of 3–4 mm at a welding current of 120 amperes can be connected to gasoline generators UGB-5000, UGB-6000 or diesel generators UGD-6000E or UGD-6000EK.

Source

What is better, select welding and generator separately or buy a welding generator?

A welding generator is a structure consisting of a gas generator and a welding machine paired with it. The power plant is designed in such a way as to serve welding, so it has a longer service life. Other advantages :

- Short circuit protection installed;

- It is possible to work in areas remote from the central power supply (city outskirts, field, road);

- The design is more compact than if you connect welding separately;

- The cost is lower than a diesel generator of similar power.

- Such an electric generator can only be used for welding;

- Gasoline has better fuel consumption and is more expensive than diesel;

- Cannot be powered from the central network;

- Low motor life.

The most significant limitation is that it cannot be used as a backup power source for other consumers. It is intended for welding only .

If you select separate power for welding, it is better not to use it for other purposes, and vice versa, if you have a power station at home for backup power, try not to connect welding to it. This can result in breakdowns and costly repairs.

A welding generator is the best option if you are professionally engaged in repair work, constantly traveling to open areas without access to electricity. You don't have to connect or configure anything - just start the engine and adjust the current to the diameter of the electrode. Fewer wires and easier to manage.

But, on the other hand, this way you will not be able to connect the structure to the central network. The average gasoline consumption is 0.5-0.6 l/kWh, and this will cost 10 times more than when connecting the device to the central network. In addition, with such a consumption, electric generators have limited autonomy. On average it is only 3-5 hours.

If you carry out most of your welding work with access to a central power grid, it is cheaper and more profitable to buy a generator separately . But, no matter what design you choose, it still requires proper care and maintenance. This is the only way you can increase the service life. Better yet, ask all your questions to a good specialist (by following the link you will find a special feedback form https://axiomplus.com.ua/elektrogeneratory/).