Hammer rivets have been an integral part of every builder's kit for quite some time. At their core, they are a kind of rod, on top of which there is a special head, which can be made in the form of various shapes (the most common are round).

Types of rivets

There are not as many varieties of rivets as it might seem at first glance:

- A simple general purpose rivet in accordance with GOST 10299 80. They can be easily distinguished by their mushroom shape, also called a system with a closing head. This rivet is characterized by high strength and durability under any load;

- A blind rivet is used to “join” two sheets of metal in cases where access to the joined sheets is possible only from one side. Parameters and description are determined by GOST 15973-2005;

- Threaded rivets are considered to be the most technologically advanced; they are more convenient to use and allow you to create a collapsible connection, DIN 7338

.

Important ! Materials for riveted joints must have a certain plasticity and toughness, therefore low-carbon steel, copper, and aluminum wrought alloys are used for their manufacture.

Countersunk rivets

Similar elements have other names - impact, driving. Riveting with this part is carried out in several cases:

- when welding is prohibited;

- when joining non-metallic materials.

Rivets can be riveted overlapping, end-to-end, as well as using the chain and staggered method.

For more information on hammer rivets, watch the video below.

A rivet is one of the simplest types of fasteners for creating permanent connections. In the general case, this is a rod or tubular part that has a supporting “embedded” head of a certain shape at one end. It is installed in the connection, as the name suggests, by the riveting method (as well as shrinkage, rolling, broaching, explosion).

Based on their shape, rivets can be divided into several main types:

- Rivets with a closing head (there are solid, hollow and semi-hollow)

- Rivets with broaches (also called tear-off or pull-out rivets)

- Threaded rivets (also called riveting nuts)

Rivets with locking head

Historically, rivets with a closing head were the first to be invented, which is why they became the most widespread. These rivets have a head on one side. The second head, called the closing head, is formed using a rolling or riveting tool: riveting hammer, pliers.

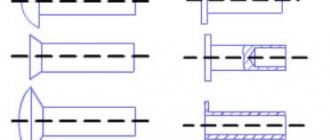

According to the shape of the head, rivets with a closing head are divided into:

They also differ structurally by the presence of a hole inside the rivet:

- Solid rivets - no hole

- Hollow rivets - tubular - have a through hole

- Semi-hollow rivets - for flaring - have a blind hole

Materials for rivets

Rivets with a closing head can be made from a variety of metals and alloys that lend themselves well to plastic deformation.

The most widely used materials are:

- Steels - mainly ductile high-boiling steels 03kp, 05kp, 08kp, 10kp, 15kp, 20kp

- Stainless steels - austenitic steels 12Х18Н9, 08Х18Н10, 03Х18Н11, 12Х18Н10Т

- Aluminum alloys - the most applicable alloys are AD , AD1 , aluminum-magnesium alloys AMg2, AMg5, AMg5P, AMg6, alloys AMts, V94, V65, D1, D16, D16T, D18, D18P, D19P are also used

- Brass alloys - mainly L63

- Copper - grades MT, M3

Marking of rivets by materials

Rivets can be marked on the head for subsequent identification. The marking can be convex or concave (branding).

The following is a table with the accepted marking of basic materials in the form of dots or dashes.

Application of rivets

The choice of specific parameters and types of fasteners is determined by three main criteria:

- Ensuring the necessary strength of the connection, taking into account additional parameters and requirements for the seam;

- Technological capabilities of equipment for working with a specific type of rivet connection;

- Economic feasibility of using riveted joints;

Threaded rivet nuts

The connection method using threaded rivets can be called the most universal today. The main idea of the connection is the ingenious idea of fixing the body of the rivet in the riveting hole. For these purposes, a riveter for threaded rivets is used. The threaded structure itself is a hollow sleeve with an internal thread.

When making a connection, this sleeve is inserted into the drilled hole and aligned so that the parts to be joined fit snugly together. After this, the riveter rod is screwed into the threaded hole inside the workpiece. The front wall of the sleeve is fixed by the supporting surface of the tool, preventing the rivet from leaving the hole. To rivet the sleeve, the riveter rod moves with great force towards the supporting surface. At the same time, the sleeve crumples and settles, thereby forming a strong, stationary connection.

The rivet maker rod is freely turned out of the bushing body. The most commonly used rivets are aluminum, brass or copper. The use of the latter is limited by high cost, so they are installed in cases where it is necessary to ensure good electrical contact between the surfaces being connected.

The advantages of a threaded rivet connection include its “low-traumatic” nature. When the rivet rod is in operation, the metal being connected does not experience large loads or deformations. A threaded bushing can be used to easily connect thin-walled metal or a profile of complex configuration. Such fasteners are widely used in the assembly of household appliances, in connecting individual car cladding units, and in the manufacture of various types of structures from corrugated sheets.

Blind rivets

The disadvantage of threaded types of riveting is their high cost and relatively low speed of making connections. Therefore, in cases where the sheets of metal or profile being joined need to be connected using several hundreds or thousands of points, a blind rivet is used.

These can be steel, brass hardware, rivets made of aluminum, aluminum and silicon alloys. Unlike the threaded one, in the exhaust circuit the deformation of the sleeve is carried out using a rod with a thickening at the end, pressed inside the body of the fastening sleeve. As in the previous case, in order to upset the body of the rivet, its end is pressed against the supporting surface of the rivet maker; after alignment, the central rod is pulled out with force by several millimeters. As a result, the walls of the sleeve are deformed, forming a fairly strong permanent connection. The shank of the rod most often breaks off or is cut off at the level of the sleeve cut.

For your information ! The exhaust circuit provides a very good metal riveting speed.

What material should the rivet be made of?

Rivets are usually taken from the same material as the parts being connected - this avoids electrochemical corrosion. Pay attention to strength characteristics. But, as a rule, when connecting aluminum parts, the strength of aluminum hardware is sufficient.

In general, rivets are made from the following metals:

- steel:

- regular - brands St2, St3, St10;

- corrosion-resistant X18N9T;

- galvanized;

When connecting copper parts, it is permissible to install brass and copper. Aluminum is joined with aluminum alloys. Steel sheets - corresponding grades of steel rivets. There are also mixed hardware - from two different metals (chemically non-conflicting). The most common are aluminum-steel.

To install facade elements, slopes, ebbs, metal tiles and corrugated sheets, rivets made of galvanized painted steel are usually used. Painting - matching with details.

| H=0.54d | H≈0.5d+0.1S | |

| H=0.6d | H≈0.5d+0.1S | |

| H=0.8d | H≈0.7d+0.1S | |

| H=d | H≈0.9d+0.1S | |

| H=1.2d | H≈1.1d+0.1S | |

A schematic diagram of the installation of a threaded rivet is shown in the video: Welding is, of course, good, but it cannot be used everywhere. In this case, riveting is used - this is a mechanical connection of parts using special fasteners. These fasteners are called rivets; they are made from different materials and come in different types. | ||

Classic rivet design

The main hardware for riveting sheets in mechanical engineering are steel rivets, standardized by the requirements of the Soviet GOST 10299 80. They most often connect highly loaded steel structures used in construction. For example, in frames and support assemblies. The advantage of the classic form is the ability to connect two sheet surfaces with a thickness of more than 30 mm.

In some cases, GOST 10299 80 allows assembly connections of up to 35 mm. Unlike previous types of rivets, a classic rivet is installed only if there is a supporting surface on the reverse side of the connection plane. This is necessary to compensate for the shock load on the rivet shank.

The riveting technology is performed in the following order:

- The line along which the rivet connection will be installed is marked with dots for drilling holes in the metal being connected.

- Sheets of metal are fixed using mechanical devices such as clamps or even spot welding. Drill the extreme points of fastener installation into which centering metal pins are inserted. In this case, the diameter of the holes is chosen in accordance with the recommendations of GOST 10299 80, approximately 10% larger than the diameter of the shank body.

- The hardware is inserted into the drilled hole so that the head is on the back side of the surface to be joined. The length of the fastener is also selected in accordance with GOST 10299 80. This will ensure the formation of a second head from a shank of normal dimensions after riveting it with a hammer or electric hammer.

For your information! Dimensions selected in accordance with GOST 10299 80 ensure maximum joint strength.

If you choose a rod with a thinner diameter, its strength may not be enough for a rigid connection. In this case, the cutting force in the radial direction is capable of breaking most of the connections in turn. After riveting, the fastener metal should completely fill the holes with a slight interference fit.

The recommendations of GOST 10299 80 should not be neglected when choosing the length of the fastener shank. A shank that is too long will prevent proper deformation and settling of the metal. Too short will not provide the formation of a second head of the required size and strength.

To increase ductility, rivets made of certain grades of steel can be heated to high temperatures before installation, with the heads forged and the fasteners hardened. Before installation, aluminum, copper, and brass rivets can be treated with special liquids that prevent the development of electrochemical corrosion.

Main stages of work

The master places the main mechanism, removed from an old rivet gun, inside a piece of tube with internal thread. Another piece of tube is screwed into it from one side. And then all this is inserted into a body made of steel water pipe with threads cut along the edges.

Using a grinder, the master makes a small slot in the body of the semi-automatic riveter. Then a handle is made from a piece of square metal rod.

It has three threaded holes for storing replaceable heads for blind rivets. Then you can begin assembling the device.

For details on how to make a semi-automatic riveter for blind rivets with your own hands, watch the video on the website.

Source: morflot.su

How it works?

A riveter is needed when you have to repair clothes. It is difficult to do without it when fulfilling large orders (for example, in an atelier). The principle of operation of the unit is elementary. It is shaped like a pistol, and the base is a lever. There are two components to this. One retracts the fastener and is then flattened. As a result, the two parts are fixed, and their thickness can reach up to 10 millimeters.

To expand the range of applications, the kit includes special attachments that allow you to work with different rivets. If something is missing, then it is quite possible to purchase additionally. For personal use, a large arsenal is not required. Before setting a rivet, you need to understand how the device works.

Often it is quite possible to do without a tool, although the quality will be lower. The sales network sells various types of devices that differ in their characteristics, purpose, and operating principle. There are complex mechanisms. They are more expensive and are not necessary for personal use. There are options that are being rolled out. They are convenient to use in hard-to-reach places. The riveting procedure itself is quick and easy. You don’t need to make any special effort, reviews say.

Hand tools

Before you rivet the rivet correctly, you will have to understand the entire range of products offered. Most often, there are two types of riveters on counters: manual and pull-out. Their operating principle is not the same:

- Exhaust. The basis is traction, due to which fixation occurs. To do this, the element ends up in the device; with simple squeezing and squeezing, riveting occurs. The fastener itself has a special ball that is flattened. Without it, fixation will not occur even with manual influence.

- What does a lever mechanism do? The operating principle is simple, which is why this manual unit has a low price. The action process is similar, but the ball is fixed in the tube when the handle starts to move. It is used infrequently (for things that are too thin). The choice is made by the buyer, assessing the complexity of the work and the activity of use.

Mechanism and technology of riveting

Devices are divided into pneumatic, mechanical, pneumohydraulic. Each type has its own operating principle and scope of application. If we summarize all the procedures, then using such a unit will not be difficult. You have to do some basic steps:

- Prepare the components. They must match each other in diameter.

- After which they are placed on a tree and secured. Mark holes for fastening. It is important to be precise so that subsequent steps are error-free.

- Next, using a drill, a hole of the required diameter is made. This step is not always necessary.

- Afterwards, the fasteners are fixed in the sharpener.

- A riveter is placed on the upper part.

- Only after this is a sharp, strong compression done. It happens that nothing works the first time. Then the process repeats.

The procedure seems simple, but many people have problems. What to do if you don’t have such a device at hand? How to rivet a threaded rivet without using special tools? It is quite possible to cope with this, but it is worth taking useful recommendations as a basis.

How to work manually?

A rivet is the most basic way of fastening two parts. There is evidence about it even in ancient times. Today they sell a wide variety of types, the assortment is off the charts. To highlight the strength, pay attention to the material. There are several types:

The first three most often act as decorative finishes, but the second two are quite suitable for containment. But before riveting the fastening element, two components from the same material are selected on the clothing.

The simplest option is the overlap of two elements. When the fabric of a garment (for example, a fastener) overlaps another. This method is known to many and is often used in the studio. When making clothes, you will certainly have to use special devices to perform several procedures. But if a part breaks, you can return it to service manually at home.

Why does fastener breakage occur? There are many reasons for this - the fabric was pulled sharply to the right, to the left, impact, load, etc. Before riveting the rivet on the clothing, you will have to remove the deformed part, but carefully, without damaging the fabric. To do this, use any sharp object - a knife or scissors.

However, you need to know that mortgage heads have different shapes. They are mostly semicircular. Having removed the broken structure, you will have to select a new one that matches in size, diameter, and density. It is not always possible to purchase a completely identical one. It consists of two parts - the hole and the head itself with the base.

Installation process

The algorithm for installing a threaded element can hardly be called overwhelming, but it is important to know certain nuances. If possible, it is better to use a factory riveter. If desired, you can assemble it yourself; one option will be discussed below. The first step is to determine the type of metal on which the rivet will be installed. Next, you need to know what the diameter of the bolt or module that will be fixed thanks to this rivet is. According to the specified diameter, the appropriate rivet is selected. Its outer diameter is measured and a drill is selected that will be one tenth in diameter larger than the rivet. This is necessary so that the latter fits into place without much effort or obstacles.

Electric or cordless drill. The metal is drilled in the required location. After this, the fastening element is inserted into the seat. If it needs to be placed in a certain position, then it is better to hold it with your hands. For hexagonal holes, you can use special punches if we are talking about thin metal. If the thickness of the metal is greater than the length of the fastener, then the hole must be drilled a little deeper than the fastener, but there is no need to make a through penetration. After this, a rivet maker core is selected that fits the thread to the element being installed. The handles are brought together or the bolt is rotated so that part of the rivet is deformed and fixed in the hole.

You should not apply too much force, as you can tear off the thread, which will later be used to fix the required part. It is necessary to ensure that the rivet is installed in the required position. After this, you can fix the required product using a screw or bolt.

Ticks

Specialized stores sell pliers that are convenient for making clamps; they look like pliers. It is better to make sure that there is a suitable attachment for riveting. Before this, a puncture is made at the fixation site, but a little less than is necessary for the part itself. This is done with a knitting needle or a blade - they are prepared in advance.

The front part fixes the button. Everything is done smoothly so that after fastening there is no shift. A plastic figure is mounted for easy mounting. It is made with two holes (top and bottom). After this, the riveting is carefully placed into the created structure. When using forceps, use maximum force. There should be no fear, otherwise nothing will come of it.

What's next?

Place the pliers as expected, after which you press until you hear a peculiar click. Simple pliers are suitable - a hammer, iron tongs. To prevent tearing of the fabric, a rubber gasket is installed. You should not exclude such additional gaskets, otherwise you will have to redo the work again. The process of sewing and repair will not be complete without such procedures.

Now it’s clear how to rivet a rivet without a riveter. If we talk about clothes, then a rivet is not only fashionable, but also practical. Although breakdowns occur frequently, for this reason you should know the instructions for performing the work. At the same time, not every person implements a project without losses - mistakes are not excluded.

Sometimes it is impossible to rivet a garment without a riveter. In such a situation, they turn to professional studio workers. Although the masters say that with the help of a special tool it will be possible to do the required process correctly. With it you will no longer need to use a lot of effort and technical knowledge. Finding the entire set of required tools for the job is easy.

In Soviet times and in the first half of the 90s, connections with rivets were performed using a bulky tool. In construction, as well as in everyday home conditions, the riveting process was extremely inconvenient and took considerable time. Hammer rivets of this type were used: which were manually riveted from the side on which the head was missing using hammer blows or inserts. At the same time, a stop is required on the side of the rivet head, which significantly reduces the scope of application of this type of fastening. And of course, such a “shock” method can cause damage to the coating of the fastened elements.

As a result, Western fastening technologies very quickly entered our everyday life and such a tool as hand riveters appeared, ideal for performing a number of household and construction works.

Problems that may arise with the riveter

After the exhaust part is removed with the tool, it should fall out through the hole. However, after some time of constant use, you may encounter the fact that the exhaust part will get stuck inside the tool.

Moreover, it will be impossible to get it out of there either with pliers or with several direct blows. The reason lies in the sponges that compress the exhaust part.

If blocking occurs, most likely the jaws inside the tool are misaligned. You will have to completely disassemble the tool and install the jaws in the correct position. After this procedure, the functionality of the equipment will be completely restored.

In the video, a home craftsman clearly demonstrates how to quickly and easily fix the problem of “biting” the rivet part:

We all know what a great thing threaded rivets are.

In some cases there is no alternative to them. Until one certain time, I somehow managed without them. But one fine day a wonderful car came to me and needed window protection installed. Like this:

Then I started working on collective farms, and in the end I ended up with a device that was not very presentable in appearance, but very functional, and with its help I have installed more than a dozen rivets. The base is an M6 bolt, strength 8.8

This is what it looks like assembled, with the rivet installed

Main parts: M6 bolt. A piece of M12 bolt. More precisely, there was no bolt, no stud. A nut is welded on one side, turning it into a bolt. The stud is drilled through D=6.5mm. Then comes the nut from the UAZ stepladder. Strong. Next is the support bearing, the dimensions are not important. Next is a washer with a fitting from the brake pipe. It doesn't matter either. I installed what was there.

I think the principle of operation is clear. We drill a hole, under the M6 rivet it seems 9mm. We insert the device. Use one wrench to hold nut 1, and use the second wrench to unscrew nut 2.

As the effort increases, the riveting is completed. We twist everything back until it loosens, unscrew the M6 bolt, and install the next one.

A practical and easy-to-use semi-automatic manual riveter for working with blind rivets can be made with your own hands if desired. At the same time, most of the components for it can be easily found in a workshop or garage.

A distinctive feature of this design is that it does not have a power lever, as on factory models - here a screwdriver acts as a drive. An electric drill will also work.

To make a homemade rivet gun, you will need a working bushing with collet jaws, a conical bushing and a spring, which can be borrowed from an old rivet gun. You will also need a head into which the rivet shank is inserted.

Riveter

A riveter or riveter is a tool used for permanent fastening and fixing of sheet metal elements using rivets.

No skills are required to operate this tool. It is convenient and quite easy to use.

When working as a riveter, access to both sides of the parts being fastened is not required. Simply drill a hole in the right place and then secure the rivet. Thanks to this, the riveting process is quite fast and simple.

Manual riveter: how to use

Using hand tools is easy and does not require any special skills. A properly purchased mechanism will do this job efficiently and quickly. The price when buying a tool should not play a big role, the main thing is to choose a good quality model. This will allow you not to worry about the tightness of the connection and the failure of the tool.

You just need to drill the holes correctly so that the diameter exactly matches the diameter of the rivet itself. We have already described the work of the riveter in detail above. After work, all that remains is to process the reverse flattened side of the rivet, that is, remove the resulting excess with pliers.

Rivets

The most commonly used in construction are blind rivets.

. They are available (can be purchased at any hardware store and market), are easy to use and completely provide a reliable permanent connection of materials.

Blind rivets are differentiated by size and type of material used to make the rivets.

The material of the rivet is an extremely important factor. The choice of rivets based on material directly depends on the type of material of the parts being fastened and the environment in which the fastener will be located.

The materials for making rivets can be the following:

- Cink Steel.

- Aluminum. There is pure aluminum and its options: anodized, varnished.

- Stainless steel. A2 - resistant to rust, A4 - resistant to corrosion and acidic environments (used in the chemical industry). Or imported analogues, for example, DIN 7337. Stainless steel is one of the most common and durable materials.

- Copper - Copper rivets are used to fasten copper materials.

- Copper-nickel alloy (Monel). Contains 70% nickel, 30% copper.

A pop rivet is a tube with a cap. Inside the structure there is a steel rod, one of the ends of which is slightly expanded. The riveter pulls the rod, causing the tube to gradually expand. When the force becomes maximum, the rod is bitten off.

In blind rivets, the process of deformation of the sleeve is carried out using a rod with a thickening at the end, pressed inside the body of the fastening sleeve. In order to seat the body of the rivet, its end is pressed against the supporting surface of the rivet maker; after alignment, the central rod is pulled out with force by several millimeters. As a result, the walls of the sleeve are deformed, forming a fairly strong permanent connection. The shank of the rod most often breaks off or is cut off at the level of the sleeve cut.

Types of riveters

Choosing the right model of such a tool can be difficult, because there are several varieties on sale. They all differ in their technical characteristics and cost.

Simple mechanical riveter

The cheapest and most common type of riveter. Widely used in construction and household work.

Riveter Accordion

Applicable for industrial work and not popular for construction.

Two-handed riveter

Considered a power riveter. Rarely used in construction.

Riveter with rotating head

This type is the most convenient for construction work. The rotating head makes it accessible for riveting in various places that are difficult to reach for other types of riveters.

Hammer rivets have been an integral part of every builder's kit for quite some time. At their core, they are a kind of rod, on top of which there is a special head, which can be made in the form of various shapes (the most common are round).

general information

Hammer rivets are used to create a reliable connection. To do this, the builder must have access to all sides of the elements that need to be connected. It is important to note that the holes in the materials being joined must be similar to the diameter of the rivet (possible errors are determined by GOST).

Rivet sizes can vary significantly.

Thus, the diameter ranges from 1 to 36 millimeters, and the length ranges from 2 to 180 millimeters. This spread makes it possible to use parts in various fields to connect materials of different thicknesses. However, at the same time, it is worth remembering that the size must correspond to the loads that the rivets will experience during operation. This is why experienced builders often advise and recommend using rivets with a “size margin” - it is better to take a larger part than a smaller one.

In general, all the requirements put forward for these building elements are specified in the relevant construction GOSTs adopted by the Russian Federation, and are also established by various documents legalized at the international level (for example, the production of hollow rivets is regulated by GOST 12639-80).

Material of manufacture

Hammer rivets can be made from various materials. For consideration are the most popular varieties.

Aluminum

This type of building parts is also often called exhaust. Their production is regulated by several domestic standards:

- with countersunk head - GOST 10300-80;

- with semicircular – GOST 10299-80;

- with flat – GOST 10303-80;

- semi-hollow - GOST 12641-80.

The size grid is quite varied: diameter - from 1 to 10 millimeters, length - from 5 to 45 millimeters. Moreover, these indicators may vary depending on the type of rivets (hammer, pull, threaded).

It is also important to note the fact that such aluminum parts can be made from several grades of material. Thus, the most popular raw materials are considered to be aluminum grades D18, V65, AMts, D19P, AMG 5P. They can also be duralumin.

Steel

Stainless steel parts occupy a special place among all hammer rivets. The production of these elements is carried out not only in Russia, but also abroad.

Most often, steel rivets are produced without any additional coating, and their sizes may vary. So, for example, the diameter of the cap can be from 1.8 to 55 mm, the height of the cap can be from 0.6 to 24 mm, the height of the entire element can be from 2 to 180 mm.

Due to such diverse indicators, these parts can be used for connecting sheets made of metal, for fastening facade plates to substructures, as well as for connecting metal structures with parts made of other materials.

Copper

Construction parts made from this material are characterized by several distinctive features:

- due to their antimagnetic properties, they are widely used in the radio industry;

- due to the fact that copper does not rust, rivets made from it are in demand in almost all areas (especially in cases where the materials fastened with them often come into contact with water and air);

- Copper elements are used to assemble apparatus and tools for the chemical industry, as they are quite resistant to the action of various substances manufactured artificially.

Most manufacturers produce copper rivets in standard sizes: from 2 to 8 mm in diameter.

Brass

Brass parts are quite flexible, but at the same time durable. And thanks to their appearance, they can perform not only their direct functions, but also serve as a decorative or design element. Most often, such elements are used in the industrial and instrument-making fields.

The length of brass rivets reaches 4–70 mm, and the diameter is 2–8 mm.

In order to choose the right crimp (mandrel) for brass parts with a semicircular head, you should choose crimps that have:

- long service life;

- uniform hardening;

- working ends are polished;

- Impact heads are inductively annealed.

- this is the production of permanent connections using rivets used in the manufacture of metal structures (trusses, beams, various types of containers and frame structures). A rivet is a cylindrical rod made of ductile metal, at one end of which there is a head called an embed. During the riveting operation

on the second side of the rod, installed in the holes of the workpieces being connected, a second rivet head is formed, which is called the closing head. The mortgage and closing heads are mainly semicircular and countersunk (Fig. 5.14). The need to use ductile metal for the manufacture of rivets is due to the fact that its heads are formed as a result of plastic deformation of the rivet rod. When making riveted joints, the rivets should be selected from the same material from which the parts to be joined are made. This prevents the appearance of galvanic couples, leading to corrosion at the point of contact between the rivet and the part. The riveting process consists of two stages - preparatory and riveting itself.

Preparatory riveting process

involves drilling or punching a hole for the rivet and forming a recess in it using countersinking for the rivet and closing heads, if necessary. The actual riveting includes installing the rivet into the prepared hole, tensioning the riveted workpieces, forming the closing head, and cleaning up after riveting. Depending on the nature of the rivet joint, riveting is performed in a cold (without heating) and hot (with preheating of the rivet to a temperature of 1000 ... 1,100 ° C) method. In practice, hot riveting is used in cases where steel rivets with a diameter greater than 12 mm are used.

Varieties

The difference between rivets of this type lies not only in their diameter, but also in other parameters, one of which is the metal of manufacture. The following can be used as a basis:

Each of these metals has its own advantages over others. Regular steel rivets are most often coated with zinc to prevent rust during use. In this regard, stainless steel products benefit, but their cost is slightly higher. They also have greater strength. Copper and aluminum are used in cases where interaction with a similar metal is required, and the rivet will not hold a module that is too heavy. Each element has a head that guarantees fixation on the front side. It can be flat or hidden. The second option will require widening the outer diameter of the hole to hide the sides. Blind rivets are used most often in case of one-sided installation. The latter is carried out in a situation where the thickness of the metal of the workpiece is greater than the rivet and the latter does not have the opportunity to fully compress it. In this embodiment, fixation occurs due to the expansion of the element body inside the hole.

Mounted modules have different pitches and thread diameters, so products are required to match them. That is why companies producing such fasteners are most often ready to provide their customers with rivets that have a diameter from M4 to M8. This applies to nut structures when there is no access to the reverse side of the metal. There is also a collapsible screw type, which is available in sizes from M3 to M16. The cut profile of the product may also be different. Most often, round is used, but hexagonal can also be used. In the second case, making a hole for such a unit requires some effort, but turning it is much more difficult, and in some cases impossible, when compared with the round version.

Threaded rivets can be specialized, so depending on the application, they may have reduced resistance to electrical current. Other elements have increased strength, because they are designed to work under heavy loads. Depending on the shape, the clamps are able to provide a tight connection. The heads of some elements have special marks that allow them to be identified among other products. Vibration-isolating rivets are often used in automobiles. Especially when it comes to mounting on body parts.