There are often situations in life when you need to unscrew or tighten bolts and nuts. Most often, an ordinary wrench is used for this: from the simplest (with different horns on both sides) to more expensive models (allows you to choose the required size yourself). And if experienced specialists can determine the size of a nut by its appearance, then an ordinary person will most likely have to make do with brute force.

In this article we will tell you how to correctly determine the size of a nut or bolt, provide a table with standard sizes for convenience, and also share some tips.

Wrench: what do you need to know when choosing?

A wrench is a tool designed for screwing and unscrewing fasteners (usually nuts or bolts). We have already stated above that keys come in different types. For example, by design they are divided into:

- carob;

- caps;

- end;

- combined;

- adjustable;

- clamping;

- tubular;

- drums;

- split;

- with ratchet.

The most popular type is the open-end wrench. The requirements for its technical characteristics are set out in detail in GOST 2839-80, but we are only interested in the size of the pharynx (the cavities between the jaws that resemble horns). Markings are usually found on each side of the key body.

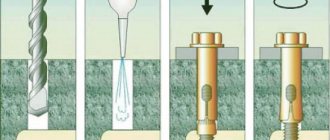

Stud sizing technology

Studs, like other hardware, are distinguished by the presence of metric threads, therefore they have the corresponding abbreviation MDxPxL. The decoding is also no different from the previous fasteners:

The type of measurement is selected in accordance with the appropriate GOST standard, as well as the type of stud. In total, there are 2 large groups for determining the ownership of hardware:

In the first case, the working part is presented along the entire length of the hardware; in the second case, only the shank is used, while the end for twisting is not taken into account.

Hairpins, like other hardware, are produced according to the following standards:

There are also other options that differ in the twisted end and length. For them, other GOST standards apply.

How to choose the right wrench for the size of the bolt and nut?

There are two designation systems: in millimeters (metric according to GOST) or in inches (standard for Europe and the USA, where 1 inch equals 2.54 cm). Therefore, it is important to determine which standard we are working with, and then select the size.

Wrench Size Chart for Metric Thread Nuts and Bolts

From this table you can easily determine what size wrench is required for fasteners with metric threads, from M1 to M110.

| Thread diameter, M | Key size | ||

| Main S, mm | Reduced S, mm | Increased S, mm | |

| M1 | 3.2 | — | — |

| M1.2 | 3.2 | — | — |

| M1.4 | 3.2 | — | — |

| M1.6 | 3.2 | — | — |

| M2 | 4 | — | — |

| M2.5 | 5 | — | — |

| M3 | 5.5 | — | — |

| M4 | 7 | — | — |

| M5 | 8 | — | — |

| M6 | 10 | — | — |

| M7 | 11 | — | — |

| M8 | 13 | 12 | — |

| M10 | 17 (16) | 14 | — |

| M12 | 19 (18) | 17 | 21 (22) |

| M14 | 22 (21) | 19 | 24 |

| M16 | 24 | 22 | 27 |

| M18 | 27 | 24 | 30 |

| M20 | 30 | 27 | 32 (34) |

| M22 | 32 (34) | 30 | 36 |

| M24 | 36 | 32 | 41 |

| M27 | 41 | 36 | 46 |

| M30 | 46 | 41 | 50 |

| M33 | 50 | — | 55 |

| M36 | 55 | 50 | 60 |

| M39 | 60 | 55 | 65 |

| M42 | 65 | 60 | 70 |

| M48 | 75 | — | 75 |

| M52 | 80 | — | 80 |

| M56 | 85 | — | — |

| M60 | 90 | — | — |

| M64 | 95 | — | — |

| M68 | 100 | — | — |

| M72 | 105 | — | — |

| M76 | 110 | — | — |

| M80 | 115 | — | — |

| M85 | 120 | — | — |

| M90 | 130 | — | — |

| M95 | 135 | — | — |

| M100 | 145 | — | — |

| M105 | 150 | — | — |

| M110 | 155 | — | — |

The sizes of modern ISO standards are indicated in brackets. For household ones, it is enough to use the numbers in the second column.

Size chart for inch wrenches for nuts and bolts

Inch hardware differs in size from the metric standard by literally fractions of millimeters. Therefore, metric wrenches do not fit tightly onto the edges of inch fasteners, and sometimes do not fit at all.

| Thread diameter (key size), inch | Nut size, inch | Nut size, mm |

| 1/4 | 7/16 | 11.11 |

| 5/16 | 1/2 | 12.7 |

| 3/8 | 9/16 | 14.29 |

| 7/16 | 5/8 | 15.88 |

| 1/2 | 3/4 | 19.05 |

| 9/16 | 13/16 | 20.63 |

| 5/8 | 15/16 | 23.81 |

| 3/4 | 1 1/8 | 28.58 |

| 7/8 | 1 5/16 | 33.34 |

| 1 | 1 1/2 | 38.10 |

| 1 1/8 | 1 11/16 | 42.86 |

| 1 1/4 | 1 7/8 | 47.63 |

| 1 3/8 | 2 1/16 | 52.39 |

| 1 1/2 | 2 1/4 | 53.15 |

| 1 3/4 | 2 5/8 | 66.68 |

| 2 | 3 | 76.20 |

| 2 1/4 | 3 3/8 | 85.73 |

| 2 1/2 | 3 3/4 | 95.25 |

| 2 3/4 | 4 1/8 | 104.76 |

| 3 | 4 1/2 | 114.30 |

Hex bolts and nuts

When assembling and repairing machines, bolts with a cylindrical head are widely used, which require a special hex key to work with. Such bolts are manufactured according to DIN 912 (Europe) or GOST 11738-84 (Russia) standards. For us, only one parameter is important: the distance between the opposite faces of the internal hexagon.

| Thread, M | Key size, mm |

| M4 | 3 |

| M5 | 4 |

| M6 | 5 |

| M10 | 8 |

| M12 | 10 |

| M14 | 12 |

| M16 | 14 |

| M18 | 14 |

| M20 | 17 |

| M22 | 17 |

| M24 | 19 |

| M27 | 19 |

| M30 | 22 |

| M33 | 24 |

| M36 | 27 |

Main types of keys

A wrench is a lever, at the ends of which there is a device, with the help of which the head of a bolt or the corresponding nut is securely grasped and turned. It is made of high-strength steel with special additives. This allows you to apply significant force to them without the risk of breaking the tool. Manufacturers offer models with double or single-sided grip. The single-sided grip allows for increased torque by extending the handle using a pipe or other removable handle. There are several types of wrenches available that can be used in different situations:

- Open-end wrench. This is the most popular instrument standard, usually of the double-sided type. It has an open mouth on one side, reminiscent of horns, which is where its name comes from, which meets the characteristics according to GOST 2839-90. The main parameter of such a wrench is the distance between the jaws, expressed in metric or inch measurement systems. For quick selection, the key number is marked on the handle on each side. In wrenches for metric threads, this number corresponds to the distance between the jaws in millimeters; inch wrenches are marked according to a different principle.

- Socket wrench. It has a closed working part with an internal hexagon, which fits onto the head of a bolt or nut. It does not need to be thrown over during operation, which speeds up the installation or dismantling of fasteners; in addition, it is characterized by increased strength. In this case, the tool does not break off like in an open-end wrench, but this type is not suitable if the space around the fastener requires periodic repositioning. Single- and double-sided options are available, as well as wrenches with removable heads into which the lever is inserted.

- Socket wrench. It is also called tubular, which is most often used by motorists when removing wheels or working with spark plugs. It is a tube in the form of a hexagon of a certain size. To tighten and unscrew, the key is placed on a nut or bolt and turned using a lever threaded through the hole in the pipe. Finished products with L-shaped handle are available.

- Adjustable wrench. It has universal characteristics, which is why it is the most popular tool among home craftsmen. It has one working part with jaws adjustable using a special screw and the shape of an open-end wrench. The same screw securely fixes the jaws of the key in the specified position. For ease of use, some models have special markings indicating the length of the jaws. To make use more comfortable, they offer three types of adjustable wrenches with a maximum size of 20, 30 and 46 mm.

- Pipe (gas) wrench. Another universal tool that allows you to work with any threaded connections, pipes, fittings, studs, etc. It has a wide range of adjustments and a long lever that allows you to develop high torque.

- Combination key. A double-sided tool that combines an open-end and a spanner wrench. Its peculiarity is that both working parts are the same size, which facilitates the practical use of the tool.

To provide maximum capabilities, manufacturers offer two types of keys - metric and inch sizes. The first is adopted in Russia and other countries with the metric system of lengths and is measured in millimeters. The second meets the standards adopted in the USA, Canada and Great Britain and uses inches and fractions of inches. If a conversion from one system to another is required, you can use the corresponding table or the ratio 1 inch = 25.4 mm. But in practice this is not required, since the tools of different systems are not suitable for working with different types of fasteners.

To work in explosive or flammable environments, special wrenches are used that, when dropped on concrete or metal, do not create sparks that could cause a fire. According to the requirements, they are marked in red, copper or yellow.

When assembling mechanisms that require high precision connections, for example, internal combustion engines, it is recommended to use torque wrenches. This is due to the fact that insufficient tightening force will lead to oil leakage or failure of components, and overtightening will weaken the bolts or studs, which will lead to their destruction and failure of the mechanism. Such keys have a mechanical or electronic device on which the required torque is indicated, upon reaching which the limiting mechanism is activated. The tightening torque for each specific connection is indicated in the technical documentation.

Adjustable wrench - 120 photos and tips for choosing the optimal model

Currently, there are a large number of tools, some of which help to loosen or tighten nuts and bolts. In the plumbing industry, the adjustable wrench is becoming increasingly popular and widespread. It replaces a large number of other tools in this area.

Deciding on the model of adjustable wrenches

Many people who want to buy a tool are interested in the question of which adjustable wrench is better. Size is one of the parameters for choosing the necessary tools for plumbing work. The ability to unscrew and tighten nuts and bolts depends on the size of the wrench, which can be small, medium and large.

The smallest in size is an adjustable wrench marked KR-19. A distinctive feature of this model is the adjustable range of movement of the jaws to the sides, ranging from 0 to 19 mm.

With a similar tool you can easily unscrew small nuts up to 19 mm in size. Convenience and ease of operation are distinguished by such a device.

Medium models are made with the marking KR-30, in which the jaws can be spread to 30 mm. This device helps you do all the housework. The most optimal model for installation of mixers.

To perform work with large dimensions, the optimal model is the one with the index KS-46. But in comparison with the first two modifications of the device, this model is used only occasionally.

Typically, an adjustable wrench also has another name - an open-end wrench. This name is given to the device because the ends of the instrument are similar to horns.

The device is purchased at various prices. They depend on parametric data and manufacturing features.

The adjustable ratchet wrench is equipped with markings in the form of a digital scale located on the body. It helps the device instantly determine which nut can be tightened with which sponge. A distinctive feature of such a device is the presence of a small allowance.

If a 30 mm key is selected, the jaws are moved apart by another 2 mm. Therefore, unscrewing and tightening nuts of 32 mm size is possible using a wrench model KR-30.

Price and quality of adjustable wrench models

Many craftsmen begin choosing a model with who is the manufacturer of this or that device. Depending on the manufacturer, models differ in quality, price and warranty.

Domestic manufacturers Intertool and Mastertool are the most famous among craftsmen. They have excellent quality at an economical price.

Now all adjustable wrenches can be purchased at various price categories:

- budget devices have a price ranging from 130 to 300 rubles;

- the average price ranges from 400 to 1500 rubles;

- There are tools that have additional capabilities, at a price of one and a half thousand rubles.

It is most optimal and profitable to purchase adjustable wrenches in a set. The price of the device is economical. Among other things, the technician needs to choose the wrench that is needed in this particular situation in order to unscrew or tighten nuts of any size.

It is worth paying special attention to whether there is rust on the instruments. It negatively affects the functionality of the device. When using such devices, it is impossible to adjust the wrench to the nut of the required size, so it is difficult to unscrew the elements with loose jaws.

It is difficult to unscrew nuts of different sizes in the absence of rubberized handles. When purchasing tools, it is worth paying attention to the functionality, visual appeal of adjustable wrenches, quality and price.

Photo of an adjustable wrench

Source: https://zdesinstrument.ru/razvodnoj-klyuch/

Unscrew the cut nut

It is not always possible to choose the right tool. Especially when you need to turn in the dark, with insufficient lighting. Or the second case. The nut was pinched. As a result, the sharp edges of the edges were cut off and became “bald.” What is the way out of the situation?

Tool manufacturers have developed helical sockets that are designed to remove problem fasteners. Due to its “corkscrew” shape, the key catches and securely fixes the nut. This is how you can emerge from the most hopeless situation as a winner.

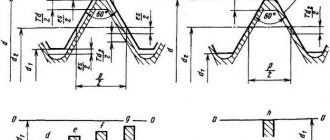

Marking

Let's say we saw this code:

Nut M10-6N.5 (S18) GOST 5915-70.

Here M10 is the thread diameter in mm, 6H is the tolerance range, 5 is the strength class, S18 is the spanner size, that is, the external distance between parallel edges.

We told you how to select a nut for metric, inch and hex keys. They gave advice on unscrewing the cut fasteners and provided a table with weights.

Source

Fastener weight

It's good if you need to tighten a couple of nuts. But what if you have to work on an industrial scale and the number of fasteners runs into hundreds and thousands. Then a weight table will come in handy. The main indicator here is the nominal thread diameter. of GOST 5915-70 start from it .

| Nominal thread diameter, mm | Theoretical weight 1000 pcs. nuts, kg |

| 1,6 | 0,074 |

| 2 | 0,141 |

| 2,5 | 0,272 |

| 3 | 0,377 |

| 3,5 | 0,497 |

| 4 | 0,800 |

| 5 | 1,440 |

| 6 | 2,573 |

| 8 | 5,548 |

| 10 | 10,220 |

| 12 | 15,670 |

| 14 | 25,330 |

| 16 | 37,610 |

| 18 | 53,270 |

| 20 | 71,440 |

| 22 | 103,150 |

| 24 | 122,870 |

| 27 | 175,280 |

| 30 | 242,540 |

| 36 | 416,780 |

| 42 | 623,880 |

| 48 | 956,200 |

How to find out the size of a rivet

Solid rivets equipped with a closing head and installed with a hammer are presented in the documents as the abbreviation DxL. The decoding is as follows:

Depending on the GOST standards used and the design of the solid rivet, there may be a difference between the methods for determining the length of the hardware, therefore there are 3 separate groups by type:

During production, different GOST standards are used:

There are also tear-off rivets, the installation of which is carried out using a gun. In this case, hardware is also designated as the previous ones.

If we consider production standards, we can highlight the following: