The thread riveter is a metalworking and assembly tool. It is designed for reliable fastening of thin-walled materials, for example: metal sheets, profiles, panels. The combined thickness of the connected elements can range from 0.5 to 6.5 mm. Threaded rivets, also called riveted or rivet nuts (from M3 to M12), are used as fasteners. The workpieces are connected through pre-drilled holes, and you can work “blindly” - without access to the back side of the structure.

Manual thread riveter

A riveter for threaded rivets has advantages over blind rivets:

- The ability to fasten materials and at the same time create fastening points into which you can tighten a bolt or hook.

- More careful, accurate, safe installation. Less likely to deform or damage parts, paint or decorative coating, or cause injury.

- Large diameter rivets (M8-M12) are fastened better.

- No residual stresses in the assembly unit.

- A stronger, more durable connection that is resistant to stress and vibration.

- The ability to fasten parts made of different materials: metal, plastic, fiberglass, fiberglass, composites, wood.

- Greater variety of rivet nuts, both round and hex. The latter are good because they do not scroll in the hole made. Fasteners are made of carbon and stainless steel, aluminum alloys, and copper.

Minuses:

The main disadvantage is that this manual riveter is more expensive, as are the consumables for it. The second disadvantage is the leaky connection point. However, you can insert a plug or use a special closed-type fastener.

Types of riveters for threaded rivets

The following types of rivet guns for threaded rivets are currently available on the market:

- Manual riveter Externally it resembles pliers or pliers. It works due to the physical efforts of the master. It is characterized by low cost and ease of operation.

- Pneumatic riveter The operating principle is based on the use of compressed air supplied by a compressor.

- Pneumohydraulic riveter The design is equipped with a hydraulic system with a piston, but also runs on a compressor. This combination provides increased force of the working mechanism.

- Electric riveter The process of installing a rivet is fully automated - you just need to connect the tool to the power supply and press a button.

- Cordless riveter They are considered the most mobile and autonomous, since they do not require “connection” to the electrical network.

Advantages of manual thread riveters:

- inexpensive price;

- compactness;

- wide range of rivet diameters – m10, m10 from m12;

- excellent connection quality;

- ease of use and maintenance.

You can buy a manual thread riveter with a set of accessories in our online store with delivery throughout Russia and neighboring countries. We have a competitive pricing policy thanks to close partnerships with manufacturers. To buy the selected product, contact us by phone or fill out a request on the website.

Modern rivets – blind and threaded

The riveting process has become faster not so much due to the advent of tools, but due to a radical change in the design of the rivet itself. To secure modern fasteners, it is enough to have access to only one side of the material, and the riveting process takes place in a matter of seconds.

A blind rivet (pull rivet, pull rivet) is a well-known type of fastener that is used in almost all industries related to construction, mechanical engineering, and electrical engineering. The product itself consists of a sleeve and a rod - just insert the fastener into the prepared hole and pull out the rod using a special tool to get a strong connection.

Blind rivets are made from different materials and are divided into groups of different sizes and types of flanges. The standard bead is a universal rivet that can be used everywhere. A hidden side is a fastener, when installed, the surface is smooth, without the head protruding onto the surface. A wide bead is used in cases where the pressure under the head needs to be distributed over a large area of material. This is relevant under increased loads or in cases where delicate, brittle materials are used.

- Copper rivets are very durable because they resist corrosion well and have a certain ductility. Most often, they are purchased for work on the roof, when installing facade elements and drainage systems. Structures secured with copper fasteners last outdoors much longer than their counterparts made of other metals. Due to the softness of the material, such products are pliable, so they are easy to work with hand tools. Copper fasteners can be found on everything from delicate electronic devices to a denim jacket.

- Aluminum rivets are also corrosion and weather resistant. They are extremely light and inexpensive, and due to the plasticity of the metal, they can also be worked with with a hand riveter. Due to their non-toxicity, they are widely used in the food and chemical industries, and because of their lightness they are used in aircraft construction. They are inferior in strength to steel ones, so their use is possible only in the absence of large loads on the structural elements.

- Steel rivets are made from carbon steel, making them quite lightweight and very strong. Such products are protected from the effects of weather and water by galvanizing. To create especially durable fasteners, stainless steel products are used, which, in addition to being resistant to corrosion, also have an aesthetic appearance.

How to choose a riveter for threaded rivets?

In order not to make a mistake in choosing a riveter for threaded rivets, you must take into account its following features:

- Weight The tool should fit comfortably in your hand without causing any discomfort.

- Rivet diameter The model should cope with the task.

- Power type The riveter can be powered by electricity, compressed air or battery power.

- Riveter material To work with steel surfaces, it is necessary to use a more reliable tool, the design of which can withstand significant loads.

- Head Type If the head can rotate 360 degrees, you can install the rivet even in hard-to-reach places.

- Additional features For example, a built-in waste container will make work more comfortable.

Features of working with the tool

To quickly learn how to handle a riveter and easily perform reliable connections of elements, it is enough to learn a simple procedure for working with it:

- The first step is to select rivets of the appropriate diameter. Most often, fasteners with a diameter of 2 to 4 mm are used. When working with large-diameter rivets, you will need a specialized tool, which is best suited to a pneumatic or pneumatic-hydraulic riveter.

- A hole is drilled in the working surface taking into account the outer diameter of the rivet. When using fasteners with a countersunk head, it is often necessary to first countersink the surface, which makes the rivet invisible.

- Before work, you should install a rod with a thread of the required diameter in the rivet gun and screw a threaded rivet onto it. It is important to ensure that the rivet is securely fastened, otherwise it may come loose during installation.

- It is necessary to insert the fastener into the hole until it stops, making sure that its head is tightly adjacent to the surface of the material.

- The riveter is positioned strictly at right angles to the surface and begins to exert force on the handle. During operation, the rod will begin to move inside the tool, providing the necessary pressure to deform the fastener.

- After installing the rivet, you should unscrew the threaded rod from the socket and make sure that the rivet is seated in the hole correctly. This can be judged if there are no distortions and gaps, as well as thread deformation.

How to remove a rivet

Sometimes there are situations when the fastener was installed incorrectly or in the wrong place and needs to be removed. This can be done in several ways.

In the first case, you will need a drill with a drill slightly larger in diameter than the internal thread size. When installing the rivet, you need to monitor the process and promptly change the drill to a larger one. When the problem is solved, the fastener will be divided into two halves - the head and the inner part.

You can also remove incorrectly installed fasteners by grinding off the head. A drill will also help in solving this problem, and when the head is destroyed, all that remains is to knock the rivet out of the seat.

Installation nuances

Before installing the fastener, special attention should be paid to choosing its length. To correctly calculate this rivet parameter, you need to add the thickness of the material and the diameter of the rivet. For example, if the cross-section of the fastener is 4 mm and the thickness of the material is 2 mm, then to make a reliable connection it is recommended to use a rivet with a diameter of 6 mm. After installation, it will “sit” securely in the seat and will allow you to screw a bolt in if necessary.

It is no coincidence that the riveter is very popular, because it has such advantages as ease of use and practicality. Although home craftsmen very rarely share their impressions of the practical use of this tool in everyday conditions. In many construction stores, a riveter is a rarity, not to mention fasteners for it, which many are forced to order online.

This tool has only recently become popular among the population. Most often it is used to perform reliable installation of license plates. It is also perfect for installing fences made of sheet materials, as well as mounting electricity metering devices on thin walls of panels. This installation method has surpassed in popularity even such a common type of fastening as welding, due to its reliability. And this is not surprising, since even under conditions of high loads, if the rivets begin to fail, it will not happen to all of them at the same time.

Riveters for threaded rivets from TopRivet

The TopRivet store has been supplying professional tools to the market for 8 years. This allows us to guarantee high quality and reliability of each riveter, as well as prompt fulfillment of orders and low prices.

When placing an order, you can count on the following benefits:

- Convenient and prompt delivery We can send the goods by courier service, Russian Post or transport company to the points of issue.

- Inspection of products before shipment and after-sales service. Our company has a repair department and quality control department;

- Favorable promotions and discounts We regularly put up part of our assortment for sale and give gifts to our regular customers.

Order a riveter for threaded rivets by leaving a request on the website or by calling 8 (499) 450-94-95 (Moscow). The manager will help you make a choice free of charge and guide you on the delivery time of the goods.

Operating principle of threaded rivets, application and types

Bonding of metal (and other) parts is carried out using a variety of methods. Using a welding machine is not always possible (for example, in situations with plastics) or impractical, as is cutting threads for screws or bolts with preliminary drilling of the material. Special threaded rivets have virtually no restrictions in their use and provide reliable fixation at the joint. What kind of products these are and what is their feature is the topic of this article.

In fact, it is a hybrid of a traditional rivet (“hammer”) and a threaded fastener. Do not confuse such products with exhaust hoods!

Advantages of threaded rivets

- Simple installation technology.

- Possibility of reliable fastening of parts made of materials of increased fragility or low thickness (for example, sheet metal). The threaded rivet practically does not cause their deformation.

- If the total thickness of the connected samples exceeds the length of the fastening element, then the so-called one-sided fixation is performed, without a through passage. At the same time, the quality of bonding does not deteriorate.

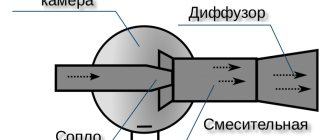

Operating principle

A reliable connection at the installation site is ensured by the thread, which in nut samples is located on the inner surface, in bolted samples - on the outer surface of the crushed part.

Types of threaded rivets

The assortment is so large that listing it in full is both impossible and makes no sense. Knowing what types of threaded rivets there are, it is easy to determine what exactly is needed for specific purposes.

According to the material of manufacture

- Copper.

- Aluminum.

Products made of non-ferrous metals are used in cases where the aesthetic component comes to the fore. Therefore, such rivets are used mainly for decoration.

- Steel.

- Made from stainless steel.

These samples provide greater joint strength and increased corrosion resistance.

By head type

- Flat.

- Secret.

By type of thread

- Nut (M4 – permanent connection. It is advisable to use when it is impossible to access the back side of the part or in conditions of limited movement.

- Screw (M3 – 16) – collapsible type.

According to the profile of the leg

- Round.

- Hexagonal (to prevent rotation in the seat).

By type of pile

- Open or closed.

- Secret.

- Small or large.

By purpose

- Electrically conductive.

- With increased force (or pressing, or stretching).

- For highly leak-tight connections.

- With an enlarged head.

- With inch thread.

- With tags (allow for visual identification).

- With vibration isolation.

This list of varieties according to the specific application can be continued, but it is already clear that the industry produces threaded rivets for literally all occasions.

Specifics of working with fasteners

In principle, it is not much different from installing conventional rivets “under a hammer”.

Algorithm of actions for a rivet nut:

- Drilling a hole in the material.

- Installing a threaded rivet into a special tool.

- Placement in place (in the hole).

- Squeezing (compression) of the fastener.

For bolted:

Application

Basically, anywhere. As already stated, there are no restrictions. The main thing is to choose the right type and size. It is especially convenient to use threaded rivets to connect products, after installing them in place, access to the reverse side will be difficult or impossible.

For example, anyone who has done electrical installation work in power (signal) cabinets knows how difficult it is sometimes to dismantle a panel if the nut screwed onto the bolt (screw) on the “other side” turns.

Price

The price for such products is usually indicated for 1,000 pieces. Minimum - approximately 1,446 rubles (M4; 10 mm; for connecting parts with a thickness of 0.5 to 3 mm; steel).

The cost of riveters for threaded fasteners starts from 3,050 rubles (manual model).

Installing the Fastener

Installing a threaded rivet is practically no different from using conventional rivets. All work is carried out in several stages:

- A hole of the required diameter is drilled in the workpiece.

- The threaded rod of the rivet gun is screwed into the rivet and the rivet is inserted into the hole.

- The threaded rod is pulled into the body of the rivet gun and the part of the rivet that does not have an internal thread is compressed, securely fixing the rivet in the hole.

If a large number of installation operations are to be performed, then to increase productivity, it is recommended to first make the required number of holes. And then start installing fasteners.

>

Other types of rivets

In addition to threaded rivets, there are blind and standard types of rivets. Previously, the standard rivet version was more used. It is a cylinder, one of which has an extension. The latter is made in a semicircular shape or with a hidden part. Installing such a rivet requires more effort than with other types. Such clamps are practically out of use. The first step for installation is to fix the two parts in the position in which they will be fixed. Clamps are used for these purposes. After this, the location where the drilling will be done is marked. The diameter of the hole should be 10% larger than the diameter of the rivet itself.

After this, a rivet is inserted into the prepared hole; it must be placed on the reverse side so that the part without the head is directed upward. After this, the parts must be positioned in such a way that there is a good stop for the rivet head. After this, the straight section is riveted, as shown in the photo. To do this, you can use a hammer or a special electric tool. The protruding part of the rivet must be given the same shape as its head. Riveting must be carried out in such a way that the body of the rivet completely fills the hole in the parts. If this does not happen, then under the cutting force the rivet will fail and the assembly will be destroyed. The length of the rivet should not be too long or too short. In some cases, for greater ductility, a regular rivet can be heated with a gas burner.

The type of exhaust fastener is shown in the illustration above. Installing such an element is several times easier, since the entire process is automated. Each fastener has a steel or other rod, which performs the task. The rod is connected to a small ball, which is located at the end of the element. Selecting the diameter and drilling the hole is carried out as in the above option. After this, the latch is installed in its place. The riveter is installed in such a way that the core is fixed in its chuck. As the handles are squeezed, the rod pulls up the ball, which flattens the back side of the fastener and thus fixes the two parts. The rod is cut automatically as soon as the force reaches the limit value.

Principle of operation

The principle of operation of threaded rivets is that after installing such a locking element, a thread is created. A screw or bolt is then screwed into it.

Installation of threaded rivets is carried out very quickly and efficiently, but only when using a special tool. Such devices can be purchased at different prices.

If there is a need to use this type of fastener, then each master can easily choose the most suitable type of riveter for himself.

The video shows the working principle of a threaded rivet: