The actions of machines on a large construction site seem coordinated and very fast. Just yesterday a huge bucket was digging into the ground, and today there is already the first level of the future building. This is on large-scale construction sites. But even if you need to build a small country house, the principles are the same: first you need to prepare the soil and tamp it down. Buying expensive mechanisms for temporary use is not advisable. Do-it-yourself vibrating plate is a real and affordable solution.

A vibrating plate is a special unit designed for compacting soil, concrete surfaces, and asphalt surfaces.

Vibrating plate: scope of application and technical characteristics

A vibrating plate is a unit whose main function is compaction. It is used in various fields: for soil compaction during construction, landscape planning, for compacting bulk materials (sand, pebbles, gravel), when laying asphalt, paving slabs, paving stones.

Vibrating plates are suitable for performing work volumes not exceeding 1000 sq. m.

The machine is small in size and therefore maneuverable. It can be used both in open areas (when compacting land, parking, road surfaces, floors in large industrial premises, etc.) and in confined spaces (in ditches, trenches, near buildings, near curbs, wells, hatches etc.).

A vibrating plate for compacting soil and other bulk materials is recommended for use in areas not exceeding 1000 m². In large areas, large-sized and more powerful equipment is used for these purposes.

Each vibrating plate model has its own performance indicators, which determine the features of its use and scope of application. So, when choosing a vibrating plate, you should pay attention to the following technical characteristics:

- dimensions of the base plate, mm;

- vibration frequency, Hz;

The process of compacting the required mass with a vibrating plate is carried out as a result of the occurrence of shock vibrations in the unbalance.

- compaction depth, mm;

- vibration amplitude, mm;

- power, kWt;

- unit weight, kg;

- electricity or fuel consumption, kW/h or l/h;

- maximum productivity, m2/h;

- Overall dimensions of the device, mm.

Working surface area

Typically, the vibrating plate base is made of cast iron. Its size is the working surface area of the equipment. When compacting material with a vibrating plate with a smaller base size, less force will be required; it is also true that a vibrating plate with a large base will be more effective when performing complex, large-scale work, although it will require more power. For example, the vibrating plate with a gasoline drive, the Evolution Hulk, has a sole size of only 40x32 cm. With its help, you can tidy up garden paths and tile a “patch” at the main entrance of a store, or compact the soil for building a shed or garage. But if you plan to lay a sidewalk with tiles, pave the yard, or prepare a place for the foundation of a house, then vibrating plates with wide bases are used - this helps save time. A model with large dimensions, for example, 53x50 like TCC MS120-HT 207211, will cope with such work faster.

Vibrating plate: main types, differences, advantages and disadvantages

Vibrating plates are divided according to several indicators. The first of these is the type of engine. Depending on which engine is installed on the unit, the plates are:

- gasoline;

- diesel;

- electric.

Progressive vibrating plate with diesel drive for compacting soil, asphalt and crushed stone.

An electric vibrating plate 220 V is the cheapest and most affordable option. According to technical criteria, it is somewhat inferior to the other two types, since it is light in weight and has a low degree of compaction. Most of all, this model is suitable for use on a private plot, in agriculture, and in landscape work. Its disadvantage is the mandatory presence of a power source and the limited range of operation by the length of the cord.

If there is no source of electricity or it is impossible to connect to the electrical network, you should buy a gasoline vibrating plate. It is more expensive than electric, but has no restrictions on operating conditions. It is easy to transport and move. Diesel fuel is cheaper than gasoline, but the engine itself is more expensive. Diesel units are the most powerful and are most often used on construction sites. The disadvantage of a diesel vibrating plate is the significant noise level during operation and high cost.

Note! Engine power directly affects the movement of the plate. At high rates, the unit moves itself. If the power is low, the slab may become buried. This disadvantage is aggravated if a layer of fine-grained material is compacted.

Gasoline vibrating plates are a very maneuverable device due to their compact dimensions.

Vibrating plates are also divided according to their purpose: for compacting asphalt and compacting soil. The first ones are distinguished by the presence in their design of a device for supplying water irrigation. It is necessary for wetting; a wet surface prevents sticking to the base. The surface of such a vibration plate is smooth, the edges are rounded.

The unit for compacting soil is heavier, the surface texture of the slab is embossed.

There are machines with forward motion and reverse ones. Translational ones move in one direction and have one unbalance. The second type of vibrating plates has a reciprocating direction of movement. They have two unbalances, so they can move in different directions. Vibrating plates are controlled manually or remotely. The latter option is convenient and safe, but the price is much higher.

A vibrating plate with an electric motor is less functional; it is lightweight and has a low degree of compaction.

Manufacturers, recommended models of vibrating plates

For small-scale work, it is recommended to buy an electric vibrating plate. It is not heavy, has a folding handle, which allows you to move and transport it to the desired object. The unit has an adjustable frequency converter that allows you to change the vibration frequency, limit starting currents, save energy, and set the optimal operating mode for given conditions. You can buy an electric vibrating plate, the price of which is several times less than types with fuel engines, from any manufacturer that offers similar products.

Ammann vibrating plates are universal and can be easily adapted to various types of work

Vibrating plates with gasoline engines are the most in demand, and therefore widely represented. The units of the Swiss company Ammann, whose factories have long been operating throughout Europe and have already expanded beyond its borders, are very popular. The line of units includes almost all types (from ultra-light to the heaviest) diesel vibratory rammers.

Ammann vibrating plates are distinguished by a high level of comfortable conditions necessary for the operator’s work. The guide handle is isolated from the engine as much as possible to reduce vibration. An additional vibration-damping guide has also been patented, which can be used as an additional option. Engines are economical. There are models that run on both gasoline and diesel fuel.

Splitstone vibrating plates today have taken a strong place in the construction equipment market as equipment that has a high level of quality and reliability

Among domestic manufacturers, the Russian group of industrial companies Splinstone supplies competitive products to the market. Vibration units have good technical characteristics and low prices. Particularly worth highlighting is the Splitstone VS-244 vibratory plate. This is the most popular vibrating plate with a balanced combination of performance, productivity and cost. Weighing 74 kg, it compacts a layer of 100 mm. The VS-244 vibrating plate provides compaction of bulk materials, various soils and asphalt in small areas and in confined spaces.

The Champion PC9045F vibrating plate is a product of American design and high-quality Chinese assembly. This model can be used both for personal purposes and on construction sites. Powerful, compaction depth 300 mm. The noise level is acceptable. Air cooling, no bulky water tank. The disadvantage of the unit can be considered the lack of reverse.

Wacker Neuson gasoline vibrating plates are German-made products. The company of the same name (Wacker Neuson) has been operating in Germany since 2007 and specializes in light construction equipment. The products are of high quality and at a reasonable price. The Wacker Neuson MP15 vibrating plate in the model range represents the best option for matching an affordable price and good technical characteristics. Small dimensions allow the vibration compactor to be used even in narrowly limited places. The device has a water-irrigated system, which allows the use of hot mixtures. The folding guide and convenient lifting handles ensure easy transportation. Wear-resistant bearings extend service life. The unit is linear, this somewhat limits its capabilities.

Compact, light-weight petrol vibrating plate Champion PC9045F is effective for use in limited areas and for small volumes of work

Vibratory plates with Honda engines are in particular demand in the construction equipment market. These mechanisms are characterized by their small size, efficiency and long service life. Honda gasoline vibrating plates have different characteristics. They are represented in significant numbers in both light and medium-heavy models.

Helpful advice! To buy a gasoline vibrating plate profitably, you need to look at prices in at least 3-5 price lists. Sometimes the difference in their cost is 15-20%.

What is better: renting a vibrating plate or buying a used one?

If funds are limited or it is not practical to buy a unit for one-time work on a small area, you can rent a vibrating plate. The main advantages of this operating option are a significant reduction in financial costs and the absence of the need for preventive maintenance. The process of renting a gasoline vibrating plate (as well as an electric or diesel one) should include a number of mandatory points:

- drawing up an agreement that stipulates the terms of use of the equipment and the obligations of the parties;

- drawing up acceptance certificates for the unit;

If there is no large volume and constant work for the vibrating plate, then it is best to rent the unit

- providing instructions on safe use.

The price for renting a vibrating plate ranges from 700 to 5000 rubles. per day. It depends most of all on the weight of the machine and the period of use. Heavy units are more expensive. Long-term rentals offer discounts. When renting a gasoline vibrating plate, fuel is not included in the payment. The unit is refilled at the expense of the tenant.

To save money when it is necessary to compact soil and other surfaces, you can buy a used vibrating plate. But in such a situation, you need to be prepared for the fact that the guarantees will only be verbal. The further service life of the machine cannot be determined. The degree of wear can only be determined relative; by visual assessment, it is not determined by the date of issue. There is always a risk of buying a unit that is disposed of for some technical reason. Most often, it is impossible to return a used mechanism to the seller.

Helpful advice! If you decide to buy a used vibrating plate, be sure to check the operation of the engine. If there are problems, they will accordingly manifest themselves as unusual noise, delayed start-up or other abnormalities.

Vibrating plate rental is a very popular service among builders, because... there are a number of advantages of renting before buying

Do-it-yourself vibrating plate: classification of vibrating rammers by weight

Along with power, weight is an important technical indicator. This is what you need to pay attention to when choosing a device model or when creating a tamper with your own hands. According to this parameter, vibrating plates are divided into four types:

| Vibrating plate type | Weight | Features and scope |

| Lungs | Up to 100 kg | Low degree of compaction, used in agriculture and landscape planning |

| Universal | 100-200 kg | High-frequency with low amplitude, used for thin layers of fine-grained soil and asphalt pavements |

| Medium-heavy | 200-500 kg | Used for thick layers of coarse-grained soil |

| Heavy | More than 500 kg | They have a high vibration amplitude and are used when a high degree of compaction is required |

Note! When choosing a vibrating plate, it should be taken into account that a heavy device is less maneuverable, but more efficient. If the mass does not match the soil thickness and is less than recommended, compaction will take a long time and additional fuel or electricity will be consumed.

Before you buy a vibrating plate, you need to decide for what purpose and where it will be used; its weight will depend on this.

Additional items

Additional elements are:

- handle (carrier) used to guide the vibrating plate during operation;

- a trolley on which the device is installed when moving from one place to another;

- tension mechanism, which ensures tight contact of the drive belt with the pulleys of the engine and vibration mechanism.

The handle is a long U-shaped bracket made of a tube. It is attached to the plate through a swivel joint, which partially compensates for vibration and protects the worker from its effects.

The trolley is a separate element, although rigid mounting options are available. It is brought under the stove, the unit tilted towards itself by the handle, supported on a trolley and transported to the desired location. When rigidly mounted, the legs with wheels are installed on the base in an inverted position. If it is necessary to move the vibrating plate, the installation is turned over and transported to another location.

The tensioning mechanism ensures tight contact between the drive belt and pulleys

It is important that the roller has a groove that matches the groove of the pulleys. This will help extend the life of the belt.

If the vibrating plate roller is installed on the outside, the groove size must match the back of the belt. For tensioning, an adjusting screw is used, which allows you to loosen the belt for replacement or tighten it to working condition.

Vibrating plate device: main components and connection methods

To buy a vibrating plate, it is recommended to choose the price by looking at the characteristics of the units and price lists of any trading organization. But you can use it correctly, and even more so make it yourself, only if you know its structure.

The vibrating plate design consists of the following main components:

- engine;

- vibrator;

- slabs;

- centrifugal clutch;

- motor frame;

- control knobs;

- protective covers.

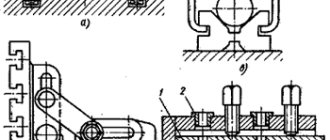

A vibrator is installed on a heavy platform, the basis of which is an unbalance shaft placed in bearing supports and a cylindrical housing. The structure is fixed with clamps and bolted to the slab. An important part in the design of the vibrating plate, which is also attached to the platform, is the motor frame. It is attached using shock absorbers.

The main components of a vibrating plate.

The engine is located above the vibration exciter. The motor and vibrator are connected by a coupling and a V-belt drive. During operation, the engine creates rotational movements, which are transmitted to the vibrator, which converts them into oscillatory ones. These movements are communicated to the slab and then to the surface layer, which is compacted.

If the functions of a vibrating plate include compacting paving slabs or paving stones, then the model must be equipped with a softening plastic nozzle or a special polyurethane support surface.

The role of the control knob in the vibrator plate device

In a device such as a vibrating plate, when the market is replete with various models, often differing only in design, it is important to think about the safety of workers. Honestly, it would be better if the model had no handle at all. But such devices will have a significant impact on your wallet and will weigh from 700 kg, but they are controlled remotely. If the handle is present, then it is necessary to ensure that it is equipped with a vibration-proof pad.

Look

All advertisements for the sale of vibrating plates

The device of the vibrating plate does not involve complex schemes and mechanisms of action. But since this equipment is often actively used in difficult conditions, it is necessary to pay attention to proper care of it. Replacement of vibrating plate filters, spark plugs, oil, timely maintenance - and your vibrating plate will serve faithfully for many years.

Bomag vibrating plate device

Do-it-yourself vibrating plate: how the device works

The working mechanisms have an impact effect on the surface of the slab, which produces a certain number of movements when in contact with the ground - this forms the basis of the operating principle of this device. Kinetic energy upon impact is converted into other types of energy. The pressure on the surface instantly increases, and then the same instantaneous decrease occurs. Therefore, in addition to impact force, speed and frequency are effective. As a result of this action, small particles fill the voids, resulting in a very dense, even coating.

Its characteristics depend on the quality of the material from which the work plate is made.

To make slabs with your own hands, two types of materials are used: cast iron and steel.

Note! When choosing a unit with a cast iron stove, be sure to pay attention to the grade of metal. A low-quality cast iron slab may develop cracks when used over gravel for a long time.

The size of the slab is also important during operation: the smaller its area, the better its tamping qualities. Vibration indicators determine how well the surface will be compacted. If the slabs have the same mass, but different vibration forces, then a unit with higher performance will compact better.

Read the continuation of the article on the next page. To move to the next part of the article, use the page navigation numbers.

What to look for when choosing a vibrating plate or soil compactor

- Drive power is one of the main factors ensuring comfortable work. If this indicator is insufficient in relation to the weight of the slab, then during vibration the compactor will simply bury itself in the ground. This is especially noticeable when moving uphill. If with light options the operator can still somehow influence the device using physical effort, then during the operation of heavy samples this will not be possible. If the drive power is sufficient, the vibrating plate itself will move in the given direction.

- The presence of a folding handle and wheels for transportation will greatly simplify the process of operating the rammer. These elements will not be required during operation, but will certainly come in handy during transportation.

- An irrigation system is an additional feature that can be not only useful, but necessary. So, while compacting asphalt, it is necessary to constantly irrigate the surface, otherwise the slab will simply stick to the material.

- The presence of protective covers and couplings allows you to extend the life of the device and reduce the likelihood of its failure. These elements protect the working parts from particles of compacted soil falling on them.

- You should not chase a low price or a famous brand. In the first case, you will receive an unreliable device, and in the second, you will overpay. It’s better to analyze the assortment and prices yourself, which can be found on Yandex Market. And to learn more about the current models recommended for purchase, read our following articles.

I hope today's article was clear and useful. In one of our next materials we will talk about how to assemble a vibrating plate with your own hands, and of course, we will take a detailed look at the most popular models offered on the Russian market.

Manufacturing process

Stage 1. A piece of metal for the work plate should be cut (the depth of the cuts is no more than 5 mm), retreating 10 cm along the edges.

Next, the edges need to be bent 25° using a regular hammer. Such “wings” will not allow the slab to bury itself when compacted.

To prevent them from falling off, the cuts should be fixed by welding them.

It is also necessary to weld two pieces of channel in the center, parallel, at a distance of 7-10 cm from each other, across the working plate itself. Consider the engine dimensions.

The result should be the following.

Stage 2. It is necessary to attach the vibrator to the plate, having previously drilled holes for bolts (usually M10, M12) on the welded channels to the size.

Stage 3. Attaching the handle. Of course, you can attach it directly to the stove, but your hands will get tired very quickly from such a load. It is necessary to install gaskets in the form of pillows.

The handle itself is welded from a pipe. Use sizes based on your height. The pipe where the hands will be can be wrapped with soft material, or you can even use a loop of rope. In this case, vibration will be practically not felt by your hands.

Step 4. To make such a heavy structure easy to move from one area to another, attach plastic or metal wheels to the device. To do this, cut a piece of metal from the pipe and weld it to the stove. Then insert the wheels.

The cost of such a homemade construction vibrating plate ranges from 10,000 rubles.