Acetylene is a colorless flammable gas. This substance is a compound of carbon and oxygen resulting from a chemical reaction. Acetylene is used for welding metals, in the chemical industry, and also for the production of explosives.

This gas is completely synthetic, therefore, unlike methane, propane and other natural volatile substances, it can be prepared directly on site in the production process. To produce acetylene, generators are used in which this gas is formed by the reaction of calcium carbide with water.

Acetylene generator device

Technically simpler are “dry” type devices, in which calcium carbide is added to water. Such an acetylene generator consists of the following parts:

- Hermetically sealed hopper with carbide.

- A cylinder, the lower part of which is filled halfway with water, and the space at the top is intended for the formation of acetylene.

- A dispenser-feeder, which periodically supplies carbide to the cylinder.

- Stainless steel grates located at the bottom of the cylinder, on the surface of which the chemical reaction of the formation of flammable gas occurs.

- Sludge collector at the bottom of the cylinder.

- Check valve for acetylene selection to the place of its consumption.

- A pressure gauge, according to the readings of which the valve that controls the supply of carbide to the cylinder opens.

The layout of an acetylene generator that produces gas using the “wet” method is somewhat different. At the bottom of the cylinder there is a container with carbide, into which water is periodically supplied through a retort. The upper part of the cylinder, as in the previous design, is designed to collect the acetylene released during the reaction. The gas leaves the container through a vertical pipe and, passing through the water layer, is directed to the sampling unit, simultaneously displacing the water down. This ensures a continuous supply of water, which positively distinguishes this method from the “dry” method, where the supply of carbide is discrete.

In acetylene generators of the combined type, another unit is added to the “wet” type device - a displacer, which allows you to control the intensity of the reaction of carbide with water. If the gas pressure in the cylinder increases, the displacer lowers the water level required to continue the acetylene formation reaction. When the acetylene pressure in the cylinder decreases (which indicates the cessation of the chemical reaction), the water level rises and its access to the carbide is restored.

Combined generators

Often, welding equipment combines “water into carbide” and “water displacement” systems. The principle of operation is that in the gas collection chamber there is a basket with carbide into which water is supplied. The chemical reaction produces acetylene. If excess pressure arises in the system, water is displaced into the air bag of the displacement chamber. Acetylene is removed through a check valve, after which it leaves the chamber.

If the pressure drops, water from the displacer flows back into the basket and thereby stimulates the formation of acetylene. For the most part, such systems are made mobile. Combined acetylene generators have high smooth operation and the absence of such a negative factor as pressure drop in the system. The devices have low performance, but are in great demand.

Available technologies and equipment for acetylene production

In domestic and semi-professional conditions, acetylene can be obtained in three ways:

- When adding calcium carbide CaC2 to water: during the reaction, the amount of lump carbide decreases, and productivity depends on its quality and humidity. The method is sometimes called “dry”.

- When lump carbide is exposed to water, the productivity of acetylene production is determined by water consumption. This is the so-called “wet” method.

- By displacing the resulting gas, which itself passes the required amount of water into the reaction chamber. The method is called combined.

Although it is believed that a more modern way of producing acetylene is the joint use of two cylinders - with acetylene and oxygen - during welding and autogenous cutting, acetylene generators are quite in demand. Especially where refueling or cylinder exchange points are rare.

The classification of known designs of acetylene generators can be as follows:

- In terms of productivity, which can start from 1 m3/h for small-sized mobile devices and end with industrial-type installations producing up to 650 m3 of acetylene per hour.

- According to the acetylene pressure at the outlet. It can be up to 10 kPa for low pressure generators and up to 150 kPa for medium pressure generators. Higher pressure is not required for the burner to operate.

- In terms of mobility. The acetylene generator can be stationary or mobile. In the latter case, due to the dimensions of the device, acetylene production will be no more than 2.5...3 m3/h.

A significant limitation of all methods of chemical generation of acetylene is the high requirements for the state of the carbide, in particular, for the size of its granules, which must be in the range of 25...80 mm. Otherwise, the reaction proceeds unevenly, and the pressure of the resulting acetylene is not stable. Therefore, modern generator designs are equipped with gas reducers.

This is interesting: AC DC argon arc welding machine (TIG) - device, purpose, application

Water displacement system

The design difference of such acetylene generators lies in the features of the gas-forming chamber. It consists of two interconnected vessels (displacer and gas generator). Carbide is loaded into the latter, which is why water is displaced into the air cushions of the displacer. Acetylene is removed from the chamber through a separator.

The amount of loaded carbide, as well as the productivity of the device, are adjusted automatically. True, the process depends on pressure. The higher it is, the slower it flows, and vice versa. Interestingly, the operation of an acetylene generator of this type can be continuously controlled, which is a strong point of the device. Also, the “water displacement” system is famous for its reliability. The main disadvantage is that maintenance of productive installations is very difficult. That is why acetylene generators of this type are made mobile and have low productivity.

Device design for gas welding

The simplest device is considered to be a dry type acetylene production device. The dry type generator consists of elements that are described below:

- Container with carbide. It is equipped with a tight-fitting lid.

- Cylinder body. It is filled fifty percent with water. The space at the top is left for gas to form.

- Dispenser-feeder. He sometimes feeds carbide into the cylinder.

- Anti-corrosion steel grille. It is located at the bottom of the cylinder. Here the carbide and water are mixed.

- Sludge collector.

- Check Valve. It supplies gas to the hose for welding or cutting and other activities.

- A mechanical pressure sensor or device for determining the value of pressure.

- Number of the plant that manufactured it.

- Year of manufacture of the generator.

- The pressure at which it operates.

- Quantity of loaded carbide. Indicated in kilograms.

- Temperature limit. Conditions under which the generator will operate properly.

- Brand of cylinder.

In general, refueling of such generators occurs like this. Pour water through the neck of the device. When it enters the overflow tube, it flows into the washer. The overflow plug is made to control the filling. Calcium carbide is loaded into a specialized basket. It is pressed with a specialized lid with membrane fabric. It is tightened with a screw.

Acetylene generator device

The fundamental part of any such gas generator is the safety plug. It protects against flames during a reverse strike. It also prevents air from the working part of the unit from getting inside the device. Thus, it protects the cylinder from explosion.

When a backlash occurs, a fire is formed in the middle of the cutter, and it spreads along the hose into the cylinder. After the impact, the burning gas returns to the hose. If there is no shutter preventing the entry of burning gas, it enters the working apparatus.

Check valves are divided into liquid, or water-filled, and dry, in other words mechanical. Valves in which water plays the main role are manufactured for ASP 10 acetylene generators.

The device has a cylindrical shape. It contains the lower and upper bottom. The lower bottom has a check valve. It is made in the form of a container and a rubberized valve with a cap. The cap prevents the check valve from rising.

On top of such a shutter there is a flame-blocking device, and at the bottom there is an aerator. This cylinder is filled with water. And the gas passes through the tube and goes up through the return valve. There it passes through the reflector and goes into the cutter or burner through a specialized tap.

When a backfire occurs, the check valve is activated. It falls down and prevents acetylene from getting from the generator into the valve.

Homemade generator at work

The fire is extinguished by releasing water. Due to the pressure that appears, the water is thrown upward. After the check valve is activated, the liquid must be replenished up to the flow valve mark. If there is not enough water, gas will begin to enter the atmosphere through the valve.

The design of the acetylene generator for the “wet process” of acetylene production has been slightly changed. A container with carbide is placed at the bottom of the cylinder. Sometimes water is supplied to it. Water enters there through a retort. The top of the cylinder serves to collect gas. Acetylene rises through the pipe through the water layer directly to the extraction point. By moving upward, it displaces water downward. In a similar way, the systematic supply of carbide and gas formation occurs. This method is considered the best.

In mixed type generators, gas filling occurs as follows. A displacer has been added to the “wet process” apparatus. It reduces the level of water formation when gas exits, thus slowing down the process of acetylene formation. When the pressure in the cylinder decreases, the water level increases. Water again enters the acetylene formation chambers.

The disadvantage of such a device is that if it is heavily clogged, the valve shifts. As a result, this displacement cannot be restored to its normal position. After this, pressure losses begin to occur. The container has to be shaken regularly.

Classification

The use of these devices is advisable in places where there is no mass production of acetylene. The installations differ in the following characteristics:

- Execution type. There are units of stationary and mobile types.

- Performance. Stationary devices are small in size, so they are capable of synthesizing no more than 0.7 m3 per hour. Mobile devices have the ability to generate from 1 m3.

- Pressure. They produce low, medium and high pressure devices, depending on the type of purpose. For example, high pressure is necessary for gas cutting of metal.

Due to the high danger, the production of installations is strictly regulated by the requirements of interstate standard 519-78.

The operating temperature does not depend on the type of design - for reliable operation it is necessary to operate in the range from -30 to +40 Cº.

Working with a generator requires certain skills to independently adjust the locking mechanism and pressure force.

To perform welding work, acetylene generators ASP-10, as well as ASP-15 and Malysh are most often used. They are distinguished by a successful combination of compact size and high performance.

Classification of acetylene generators - what kind of devices are they?

The controlled connection of the components occurs in an acetylene generator - a device in which the interaction between calcium carbide and water takes place with a dosed release of acetylene and thermal energy. Classifying generators is quite simple. There are mobile and stationary devices - as a rule, mobile ones are designed for a capacity of up to 3 cubic meters of gas per hour, while stationary ones produce from 5 to 160 cubic meters! Based on the pressure of the gas produced, generators are divided into low-pressure and medium-pressure devices. If the former are designed for 0.01 MPa, then the latter can withstand up to 0.15 MPa.

Content

- Classification of acetylene generators

- Operating principle of acetylene generators

- Generators operate on the “carbide into water” principle

- Operation of water-to-carbide generators on the “wet process” principle

- Operation of water-to-carbide generators on the “dry process” principle

- Generators operating on the “water displacement” system

- Generators with a combined operating system

- Design and principle of operation of the low pressure generator ANV-1.25

- Design and principle of operation of the medium pressure generator ASM-1.25-3

- Requirements for the design and operation of acetylene generators

An acetylene generator is a device that synthesizes acetylene by chemically reacting calcium carbide with water when they are mixed. They are used as part of mobile and stationary gas welding stations as a source of acetylene, a flammable gas for gas welding. We have already discussed their purpose on the page “Equipment for gas welding. Gas welding equipment."

Design and principle of operation of the low-pressure acetylene generator ANV-1.25

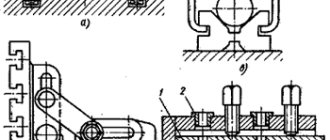

The figure shows the internal structure of the single-station mobile acetylene generator ANV-1.25 and its appearance.

The generator operates on the principle of “water on carbide”, the acetylene productivity is 1.25 m3/h, and the gas pressure does not exceed 0.01 MPa. The generator housing (item 7) consists of two chambers: upper and lower. The upper chamber is called the water collector (pos. 6), and the lower chamber is called the gas collector (pos. 9). The chambers are separated from each other by a horizontal partition (pos. 8).

At the bottom of the gas collection chamber there is a retort (item 14), into which a basket with carbide is placed. After loading the carbide, the retort is hermetically sealed with a lid (pos. 12) with a rubber lining.

Water is supplied into the housing from above, which is supplied to the retort using a tap (item 10). When water enters the retort, it reacts with the carbide, forming acetylene, which, passing through the pipe (item 11), is collected in the gas collection chamber. Then, acetylene passes through the dryer (item 5) and the water seal (item 3) and through the hose (item 2), supplied from the generator to the gas burner or cutting torch.

Pressure regulation in the acetylene generator occurs automatically. When the gas pressure in the housing increases, water begins to be forced out of the retort into the displacer (item 4). When the water level drops below the level of the tap (position 10), water stops flowing into the retort and the formation of acetylene sharply decreases. The gas pressure begins to decrease and the water displaced by it returns from the displacer (item 4) to the retort (item 14).

The ANV-1.25 type generator operates at temperatures down to -25°C, because its water supply system is located inside the housing and is heated by the heat released during the chemical reaction of water and calcium carbide. When working in winter conditions, the water safety valve is fixed inside the housing, in the circulation pipe (item 1). When working in summer, the shutter is attached to the outside of the body.

Operating principle

There are three main ways to produce gas:

- Water on carbide;

- Carbide into water;

- Displacement of water.

Devices of the first type are distinguished by their simplicity and reliability .

This technology is known as the “wet process”. A distinctive feature is that the water supply regulator is pressure. When it falls, the liquid level is replenished. The main advantage is the ability to work with carbide of any fraction. The downside is incomplete processing of the solid fraction and excessive gas temperature in the synthesis zone. The main area of application is mobile posts.

[stextbox system water on carbide there is a so-called “dry process”. It is distinguished by a dosed method of supplying water to the reaction zone. Its quantity must be twice the required volume - in this case, the excess evaporates under the influence of high temperature, and the lime is obtained in the form of a dry powder, which gives the name to the process.

Experts consider the second type of technology to be the best , since the carbide-to-water system allows solid particles to be completely dissolved, increasing the productivity of the system. Carbide is fed into the gas-forming chamber through a filling hopper, the walls of which open under the action of steam pressure.

The disadvantages include high water consumption and dimensions, which are much larger than installations using other technologies.

The water displacement system is a combination of the above methods . In generators of this type, a container with carbide is placed in a gas collection chamber into which water is supplied. As the pressure increases, acetylene displaces water into the air bag and passes through the check valve. After the pressure drops, the liquid flows back into the tank.

These installations are characterized by high productivity and stable operation, with one drawback - the high temperature after dispensing acetylene.

Acetylene - why can’t you do without it?

Despite the danger of spontaneous combustion and explosion, acetylene is widely popular in the construction industry. This is exactly the case when irreplaceable materials do exist - only acetylene, produced on an industrial scale, is capable of giving a combustion temperature of up to 3100 ° C, which no other gas can boast of. These indicators are in great demand in cutting and welding ferrous metals - at such a high temperature it is not a problem to melt even a thick sheet of steel.

In addition to its main purpose, acetylene is used in the organic synthesis of aldehyde, synthetic rubbers, acetic acid and polyvinyl chloride, the same one from which PVC panels are made. For operation and storage, gas is pumped into cylinders, which are traditionally painted gray-silver or white, over which they are marked with red paint. For safety, the cylinder is filled with a neutral porous substance, which is saturated with acetone with acetylene gas dissolved in it.

It is important to know that silver and copper, as well as alloys with their high content, are not used with acetylene, since explosive compounds are formed as a result of the chemical reaction

Classification of acetylene generators

An acetylene generator is needed to produce acetylene gas. Such generators are especially needed where there is no acetylene production. They are divided into three categories:

Below are some types of units. The design of such devices must comply with GOST 519-78. Each type of device manufactured according to GOST has its own pros and cons.

Portable and small-sized medium-pressure units include the acetylene generator “Malysh” BAMZ. It is intended for the production of acetylene gas. Acetylene is used to power a torch or cutter. It is recommended to use for such work as cutting metal and welding trusses. It performed well in temperatures ranging from –30 to +40 °C.

The device requires attention to care for it. The adjustment of the shut-off-motor equipment is carried out by the gas welder himself. And the pressure level at the very beginning is set by the welder himself. Therefore, the welder must have such skills to cope with it.

Portable generator ASP-10

Acetylene generator ASP for gas welding equipment. This mobile device is used on construction sites and in household work. It produces acetylene up to 1.25 cubic meters per hour. These generators are produced only for oxy-fuel welding.

GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

1.1. This instruction applies to workers performing maintenance work on portable acetylene generators designed to produce acetylene gas from calcium carbide and water to supply acetylene to gas-flame metal processing equipment. 1.2. Persons at least 18 years of age who have undergone a medical examination and technical training in this specialty, passed an exam and have a certificate for the right to work on servicing portable acetylene generators are allowed to work on servicing a portable generator. 1.3. Permission to work is issued by order of the enterprise after introductory and initial workplace safety briefings, training in safe work methods, on-the-job training and successful testing of knowledge of labor protection requirements. 1.4. At least once every 3 months, the employee is required to undergo repeated training on labor protection. At least once every 12 months, a knowledge test is carried out by a specially created commission chaired by an employee appointed by order of the head of the enterprise. 1.5. Workers must comply with the work and rest schedule established by the administration. 1.6. The production of acetylene in portable generators falls into the category of explosive and hazardous industries. 1.7. Failure to comply with labor protection and fire safety rules, as well as technical regulations, can lead to accidents. Therefore, workers are required to be especially attentive and have a clear knowledge of safe work practices. 1.8. Workers performing maintenance work on portable acetylene generators may be exposed to the following hazardous and harmful production factors: - acetylene; — gaseous toxic impurities in acetylene: hydrogen sulfide and hydrogen phosphorous; - aerosols generated during welding or cutting. 1.9. In accordance with the Standard Industry Standards, the welder is provided with free work clothing, safety footwear and other personal protective equipment (PPE): - rubber and canvas gloves; — rubber aprons; — respirators; — closed-type safety glasses with lenses having the appropriate light filter density, or shields. 1.10. An employee engaged in servicing portable acetylene generators, in addition to these Instructions, should know: - an emergency response plan at his workplace; — operating instructions for the acetylene generator; — instructions for emergency stop of the acetylene generator; — fire safety instructions at your workplace; — rules for using PPE (respirators, shields, goggles, etc.); — rules for providing first aid in case of accidents; — rules of personal hygiene. 1.11. If a welder is injured, the shift supervisor or station manager should be reported immediately. 1.12. Employees are responsible for violating the requirements of this Instruction in accordance with the current legislation of the Russian Federation.

Safety measures after completion of work.

5.1. It is prohibited to leave unprocessed carbide in the generator.

5.2. Before cleaning acetylene installations, all openings must be open for ventilation (blow taps, hatches, etc.). Safety valves should be washed at least once a month.

5.3. Lime sludge removed from the generator must be unloaded into a container adapted for this purpose and drained into a sludge pit.

5.4. Workers unloading sludge from the generator must wear respirators, canvas gloves and safety glasses.

5.5. Within a radius of up to 10 m from sludge storage areas, safety signs prohibiting smoking and the use of open flame sources must be posted.

4987

Bookmarks

Comment 2

Comments 2

Comment is being verified

The text of the comment will be visible after verification by the administrator.

August 25, 2022 at 00:21

Bookmarks

Is it possible to assemble such a device yourself?

An acetylene generator can be assembled at home with your own hands. To do this we will need the following tools and materials:

- Steel body.

- Partition.

- Water seal.

- Carbide.

- Water.

- A device in the form of a tube inside a cylinder for removing gas.

- Cutter or torch.

The main thing is to strictly follow the rules for making a cylinder. Otherwise, acetylene vapor will combine with air and a strong explosive mixture will form.

A steel cylinder is used. Using a partition, which must be installed slightly lower from the center of the cylinder, divide it into two parts. One part of this cylinder is filled with ordinary water, and the other is filled with calcium carbide, from which acetylene gas will then be obtained. Water will flow through a dropper into the other half of the steel container and drip onto the calcium carbide. Mixing with water will cause a chemical reaction. As a result, acetylene gas is formed, which enters the outlet through a special tube, and the slag is sorted to the side.

Everything seems simple and great. But this is only what it seems at first glance. Pressure surges must be taken into account. This reaction is not constant. Sometimes it proceeds more slowly, other times faster. Therefore, you can simply fly into the air, thanks to a homemade generator. Because he was not certified.

Therefore, it is recommended not to make homemade generators to create acetylene. In this way, you will protect yourself and those who will be with you at this time.

Advantages and limitations of the design

As mentioned above, the acetylene welding generator ASP-10 is the most popular among consumers - the manufacturer is not important. Due to its wide popularity, its production is carried out by many manufacturers of welding equipment throughout the CIS.

This unit synthesizes gas using a combined system

It has stable pressure, which is very important when performing work. With proper adjustment of the primary pressure, the consumption of combustible gas will be minimal

Experts note that ASP-10 is dependent on routine maintenance.

Failure to comply with the repair interval may result in interruptions in operation. They are associated with clogging of the displacement chamber with decomposition by-products, as a result of which a forced displacement of the partition towards the displacer occurs.

Experience shows that some manufacturers equip devices with low-quality gas reducers, which reduce the operating gas pressure. Therefore, you should trust only trusted manufacturers.

[stextbox To normalize pressure, just shake the bottle.

Medium and high pressure generators

The acetylene generator ASP-10 belongs to equipment operating in the medium pressure range. The operating principle of the device is identical to low pressure generators. But here - large dimensions and corresponding performance. Among the design features, it is worth noting the presence of a box through which water passes. In addition, basic water cooling of acetylene is provided here. This need is due to the high operating pressure and high gas temperature.

Requirements for the safe operation of acetylene generators

When calcium carbide reacts, an explosive gas is released, and the decomposition process of CaC2 is accompanied by the release of a large amount of temperature. To reduce the likelihood of emergency situations occurring at production facilities and during various work, it is recommended to adhere to the following rules for operating acetylene generators:

- Operate at temperatures ranging from -25 to +40 degrees Celsius.

- Regardless of the design of the generator, it is necessary to ensure complete tightness of the working tank and the integrity of the hoses or pipes connected to the gas selector.

- Mobile units must only be operated in a vertical position.

- Mobile generators may only be transported in a discharged state.

- When cleaning the inner walls of the working container, do not use materials that may spark upon impact.

- It is strictly prohibited to work with acetylene without using a water seal.

- If the device freezes in winter, you cannot warm it up using an open fire. Only hot water should be used for this purpose.

- Work with open fire should be carried out no closer than 10 meters from the generator.

- Calcium carbide should only be used in the granulation grade approved by the manufacturer of the unit.

If you follow these recommendations, the operation of the gas generator will be safe and as efficient as possible.

Source

Collection of rules for the mechanism of the unit and welding

Acetylene gas is an explosive substance. Mixing with oxygen it creates explosive mixtures. Any gas welder must know by heart the safety requirements when working with acetylene gas. He must memorize the safety manual when welding using an acetylene unit.

- The container is half filled with water until the liquid reaches the level of the special tap.

- Wash the plug and container well and dry.

- Add the substance to create acetylene gas as written in the manual. Also follow the granulation prescribed in the rules.

- Before the initial start-up of the gas welding tool, the gas mixed with O2 is released into the atmosphere.

- In winter, during lunch breaks and smoke breaks, the water in the cylinders should be above zero. In winter, generators are insulated. Typically, saline solutions are used to prevent the liquids in the apparatus from freezing. But they spoil the container faster, as the salt water begins to eat away at the metal walls of the container. Most often, ethylene glycol or glycerin is used for these purposes. It is mixed like this - two liters of glycerin with one liter of water. This mixture allows the liquid not to freeze at -76 degrees Celsius.

- In winter, cylinders should also be packed in special insulated booths to prevent the device and its interior from freezing.

- It is also not recommended to place sludge near the device. It must be carried into sludge pits dug for waste.

- The slaked lime that remains after dissolving calcium carbide must also be removed in time so that the inlets and outlets of the cylinder do not become slagged. The formation of slag leads to cylinder failure and the possibility of an explosion.

- During fairly long breaks, it is better to drain the water from the cylinder. It is especially recommended to do this on winter days.

- The generator needs maintenance every 90 days. To do this, you need to disassemble the water seal, the gas outlet tube, and the gas supply tube.

- All work on disassembling and cleaning the device should be carried out outdoors.

- Once a year, an inspection should be carried out by the production administration. Then you need to draw up a special verification document.

- Under no circumstances should you light matches or go with an open flame to the device itself or to the slaked lime left after work. If the remaining gas is released, an explosion will occur.

- Do not leave a running generator unattended.

- After welding, be sure to remove all sludge from it and wash it thoroughly.

- A passport and manual are prescribed for each acetylene unit. The chief production engineer approves them.

- Portable acetylene generators should only be used in open areas.

- Do not operate portable devices while tilted or near an oxygen cylinder.

- Thoroughly ventilate the space where the generator is installed. It is not recommended to work in confined spaces with an acetylene generator.

- The device must function stably.

If all rules are followed, the device will function for a long time without causing problems. If the foreman constantly checks the work of gas welders and their compliance with safety rules at work, no disasters will occur due to the foreman’s oversight.

Is it possible to assemble this device on my own?

You can assemble an acetylene generator at home with your own hands. For this we will need the following materials and tools:

- The body is made of steel.

- Partition.

- Siphon.

- Carbide.

- Water.

- A device in the form of a tube in the middle of a cylinder for removing gas.

- Cutter or torch.

The main thing is to strictly follow the rules for making a cylinder. Otherwise, acetylene vapor will combine with air and a strong explosive mixture will form.

A steel cylinder is used. Using a partition, which must be placed a little lower from the center of the cylinder, divide it into 2 halves. One part of this cylinder is filled with ordinary water, and calcium carbide is poured into the other, from which acetylene gas will then be obtained. Water will flow through a dropper into the other half of the steel container and drip onto the calcium carbide. Connection with water will cause chemical. reaction. As a result, acetylene gas is formed, which flows through a specialized tube into the outlet hole, and the slag is sorted to the side.

Everything seems simple and cool. However, this is exactly what it may seem at first glance. Pressure surges should be considered. This kind of reaction is not constant. Sometimes it flows very slowly, other times it flows faster. Therefore, you can simply fly into the air, thanks to a homemade generator. Because he was not certified.

Therefore, it is recommended not to make homemade backup power plants for creating acetylene. This way you will protect yourself and those who will be with you at this time.

If you find an error, please select a piece of text and press Ctrl+Enter.

Operating principle of an acetylene generator - systems overview

There are several systems for ensuring the chemical reaction of components, each with its own advantages and disadvantages. Let's look at each of them in detail:

The “Carbide into Water” (CV) system - the design of an acetylene generator using such a system is quite simple. Water is poured into the body up to the inner mark, and calcium carbide is poured into a special basket. The container is sent to the generator, which is closed with a lid. Thanks to a special device, a dosed supply of the active ingredient is opened, which is poured into the water. The gas from the reaction is collected in a gas collector. The advantages of the “Carbide into water” system are the complete decomposition of carbide, as well as good cooling of the gas and its washing from foreign impurities. At the same time, the disadvantages include high water consumption - about 12 liters of water are needed for 1 kg of calcium carbide.

The “Water to Carbide” (WK) system, in turn, is divided into dry and wet options. The dry version is often used in stationary generators that produce up to 10 cubic meters of gas per hour. The generator is a drum into which calcium carbide is poured through loading hatches. After closing the hatches, the unit begins to rotate, and water is injected into the drum, the amount of which depends on the pressure in the gas collector. The advantages of such a system include simplified waste removal (slaked lime is easily removed from the drum using a special hatch) and minimization of losses that occur in other options due to the dissolution of acetylene in water. The disadvantages of such devices include overheating of acetylene and incomplete reaction of the active components. The wet version of the VK system proceeds as follows - water is poured into the housing to the required mark, and calcium carbide is poured into the retort located under the housing. When the reaction needs to start, the valve opens and water from the housing drips or pours in a thin stream onto the carbide. The resulting gas enters the gas collector through the tube, which interacts with the upper chamber - when the pressure increases, the water is pushed into the housing and the reaction stops. When the gas needs to be used, the required valve opens, the pressure in the device drops, water again has access to the retort, and the reaction resumes. The advantages of the method are its simplicity and reliability, but the disadvantages include incomplete decomposition of the component and the possibility of its overheating due to a small dosage of water; in addition, the maintenance of such a device is quite labor-intensive.

The “Water Displacement” (WW) system is designed as follows: water is poured into the housing, then the basket with the active component is lowered inside and covered with a lid. As a result of the reaction, the pressure in the device increases, and water from one cylinder enters the spare one, followed by the cessation of the reaction. As the gas from the apparatus is used, the pressure drops, the water returns to the first compartment, and the reaction begins again. What is good about the system is its reliability, but, like the previous option, the devices of such a system are difficult to maintain.

“Water on carbide” according to the “dry process” principle

The essence of the operation of such generators is that there is a drive drum with carbide in the gaseous chamber. There is also a semi-automatic carbide feeding system. It is loaded into the drum through special hatches. Water is also added here.

In this case, it is extremely important to maintain the correct dosage of liquid. Its amount should be exactly twice as much as is necessary for the decomposition of carbide

Since a chemical reaction produces a lot of heat, excess water evaporates and does not need to be removed. As for the slaked lime, it falls through the bottom grate of the drum and is then removed.

In this case, the acetylene generator device makes it possible to obtain dry lime due to the complete evaporation of the liquid in the system. This is where the name “dry process” actually came from. As for the advantages of this solution, they consist in simple maintenance and removal of spent carbide. Typically these are stationary generators with average productivity.

Basic requirements for acetylene generators:

- The ambient temperature at which the operation of acetylene stationary generators is allowed is from +5 to -35°C, mobile - from -25 to +40°C.

- The generator performance must correspond to the acetylene consumption.

- The decomposition of calcium carbide in the generator should be adjusted automatically depending on the gas flow.

- The generator should not contain parts and fittings made of alloys containing more than 70% copper, as well as devices that can cause the formation of sparks during operation.

- The calcium carbide utilization factor (CCU) must be at least 0.85.

- The generator must be designed to work with a specific calcium carbide granulation.

- The generator must be sealed and have a gas collector of sufficient capacity so that when gas extraction stops, acetylene does not escape into the room.

- Generators must be provided with purging of all volumes before filling them with acetylene to remove residual air.

- The design of the generator must provide good cooling in the reaction zone, so that the temperature of water and slaked lime in the reaction zone does not exceed 80°C, and that of acetylene does not exceed 115°C.

- The dimensions and weight of mobile generators should be minimal.

How does a water-to-carbide generator work?

In this case we will talk about the so-called “wet process”. The principle of operation of such a generator is similar to that described above with the only difference. Here, water is periodically supplied to the carbide, which is where the name comes from. The clear advantage of this solution is that, with maximum simplicity of design, the reliability of the unit is quite high. Of course, there are also disadvantages here, which are expressed in the incomplete decomposition of calcium carbide, as well as possible overheating of acetylene due to the insufficient size of the loading device. Such units are very rarely stationary, which is due to their low productivity, which does not exceed 10 m3/hour. For example, the acetylene generator ASP-10 works precisely according to this principle. It has a light weight of 16.5 kg and a productivity of 1.5 m3/hour.

Accommodation requirements

The devices in question are a source of increased danger

During operation, care must be taken, namely:

- Observe the temperature conditions specified in the product data sheet.

- Monitor the stable operation of the gas reducer.

- Choose devices with a coating that prevents sparks.

- Monitor the stability of the device. In case of air leaks, stop work immediately.

- Do not allow the permissible pressure to exceed 40%.

- Ensure that the housing is sealed. There should be enough space inside for gas to form.

- Do not allow gas leaks into the atmosphere during operation.

- It is necessary to ensure sufficient cooling of the device.

- Installation on walkways and on evacuation routes is prohibited.

Generators are only allowed to be used in rooms with a functioning ventilation system. If working outdoors, the device should be placed under a canopy. Operation near sources of fire is prohibited. The distance between the welding station and the generator must be at least 15 meters.

1. GENERAL PROVISIONS.

1.1. These instructions have been compiled taking into account the requirements of the technical specifications / passport / of the generator, fire safety rules when carrying out welding and other hot work; rules for the design and safe operation of pressure vessels; safety rules in the gas industry. 1.2. All acetylene generators must have a passport of the established form, an inventory number, and must be supplied with operating instructions.

1.3. Portable acetylene generators should be installed outdoors or under cover. To perform temporary work, it is allowed to install acetylene generators in production and office premises with a volume of at least 300 m3 for each device, provided that these premises are well ventilated. If the generator is installed in a cold room, and gas welding work is carried out in another, adjacent room, then the volume of the room in which the generator is installed must be at least 100 m2 for each device.

How to make your own hydrogen welding machine

Hydrogen welding is useful to any craftsman. The hydrogen cutter is not a cheap piece of equipment. In addition, commercially available machines are often unsuitable for soldering small parts, especially jewelry.

The way out of this situation is to make atomic-hydrogen welding yourself. All the parts necessary to create such a device can be easily purchased at any hardware store. So, let's look at how to do this at home.

Main capacity

Installation for welding with hydrogen.

The hydrogen welding machine operates as a result of the combustion of hydrogen, due to the dissociation of an aqueous alkali solution. This process is carried out in a container for which a half-liter jar is perfect. It must be closed with a plastic cover with two holes made to remove contacts from the electrodes.

All terminals must be tightly sealed. Moment glue is suitable for these purposes.

Four-centimeter strips of stainless steel can be used as electrodes. For the best performance of a welding machine, the entire volume of liquid must be used.

To do this, the plates are drilled along the upper and lower edges and connected to each other with dielectric pins. Terminals are made on the resulting block: two negatives located at the edges, and a pole between them.

Each terminal is bent and fixed to the container with a bolt. The terminals from the power source will be attached to these bolts.

The container must be filled with a syringe with working fluid through the gas outlet fitting. The electrolyte is an 8-10% mixture of sodium hydroxide in distilled water. When the electrolyzer is operating, the temperature of the working liquid of the alkaline solution usually does not exceed 80 °C.

The second vessel acts as a hydrodispenser. In it, gases are saturated with vapors of flammable substances. Then the resulting mixture is sent to a third container filled with ordinary water. It acts as a shutter for the release of gases.

An ordinary medical needle can be used as a nozzle through which oxygen, hydrogen and flammable substances will come out.

Current source for atomic hydrogen welding

A regular 12 volt battery can be used as a power source. This option is perfect for working with metal of a fixed thickness.

Its disadvantage is the inability to control the burner flame strength, since its performance is determined by the production of hydrogen and oxygen, which depends on the current strength.

Choosing a charger for car batteries will be more preferable. To work with thin metal plates or jewelry, charging can be set to 3 volts.

Hydrogen welding can be powered with oxygen from a regular 220 V network, which allows you to use this device at home.

Exchange camera

Schematic diagram of a hydrogen welding apparatus. To select hydrogen and oxygen supplied to the burner, another container is used - an exchange chamber. You need to make 3 holes inside it:

- for refilling with working fluid;

- at the bottom there is a fitting for supplying working fluid to the main tank;

- fitting for supplying the gas mixture to the nozzle.

The design of the additional container must also be carefully sealed. Gases and liquids should not leak through the hydrogen seals of the hydrogen generator. This is also solved with the help of "Moment".

Making a burner

To make a burner, you can use a regular rubber hose. It is through this that hydrogen and oxygen will be transported from the exchange chamber to the nozzle. You can use a needle from a syringe or dropper as a nozzle. The latter will be a more preferable choice, since the walls of this needle are thicker.

The hose must be tightly secured to the exchange chamber fitting and the needle base. This is achieved using clamps. After completing all operations to assemble the device, you can begin testing it.