Effect of protective coating

Electric arc welding under a layer of protective powder is a simple, but high-quality and reliable connection of various metal structures and parts.

The peculiarity of submerged arc welding lies in the connection of molten metal of two parts under a layer of special granular powder. At high temperatures of the electric arc, the metal and flux melt.

The film formed when the granules melt protects the weld pool from exposure to oxygen and the environment and prevents metal from splashing.

A thin layer of slag appears on the seam, which allows the welded joint to cool evenly. The crust is easily removed from the surface of the seam. It is necessary to perform removal for visual control of welding quality.

To remove slag, just hit it lightly with a hammer and it will crumble. Before this, it is necessary to remove the remaining flux from the parts; it can be used at the next joint.

Welding equipment

For flux welding, stationary conditions and equipment will be required:

- welding plate;

- fused wire;

- non-consumable electrode;

- flux supply system;

- control system.

Welding plates are made on a concrete base made of heat-resistant materials with the possibility of fastening parts. The wire is taken from the material of the parts being welded, thickness from 0.3 to 12 mm. The electrode is made of tungsten alloy with ceramic braid.

The flux supply system consists of a reservoir and a hose, the end of which is 10-30 cm from the electrode. The diameter of the flux supply hose should allow granules to flow freely in front of the electrode.

Automatic submerged arc welding process diagram

Automatic and semi-automatic submerged arc welding is controlled by software that regulates the direction and speed of movement of the electrode along the welding line.

Working methods

To make a connection using submerged arc welding, two methods are most common.

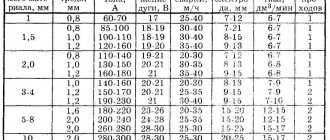

Connection using semi-automatic welding. To ensure optimal feed speed of flux-cored wire, the welder selects the appropriate operating mode on the machine, taking into account the thickness of the metal and the type of connection.

The arc is directed manually. At the same time, the wire feed speed, current strength and angle of inclination of the holder are the main factors affecting the quality of the work performed.

The automatic (robotic) welding scheme is designed for connecting butt and corner parts. In this case, the machine sets the direction of arc movement, wire feed speed and carriage travel. Such a device produces a high-quality seam at high welding speed.

One of the varieties of the automatic method allows you to weld with two electrodes at once - this is the tandem method. In this case, the electrodes run parallel to each other and are in the same plane, which makes it possible to increase the weld pool when the electric arc is instantly excited. The flux protects the seam from oxygen and ensures uniform cooling .

Types of fluxes

Each substance included in the flux is intended for welding certain metals and alloys. When choosing a brand of flux, it is taken into account whether the steel to be welded is high-alloy or high-carbon, or whether non-ferrous metals, alloys, and so on will be welded.

According to the production method, fluxes are divided into two types:

- unfused (baked and ceramic) – granules with alloying additives that ensure high quality welded joints;

- fused - with inclusions of glass or pumice.

Baked and ceramic fluxes are made by grinding a base material and combining the solution with liquid glass. They are used to add alloying additives to the weld body. Fused fluxes are made by sintering base materials.

Fluxes for seam protection are produced separately for electric and gas welding. They differ in chemical composition. Granules, which contain a certain amount of fluorides and chlorides, are intended for electric arc welding with remelting of slags with active metals. These are salt granules.

The combination of saline and oxide solutions allows the use of mixed fluxes for weld penetration of alloy steel. Oxide flux is intended for joining structural steels with a high fluorine content.

The role of flux

With automatic welding everything is clear. But what about flux? What it is?

Flux is a special substance (can be produced in the form of powder, granules, pastes and liquids) with positive properties. Fluxes are fed in a thick layer directly into the welding zone, protecting it from the negative effects of oxygen. Flux also protects the metal itself, promotes stable arc burning, reduces the likelihood of metal spattering, and even changes the chemical composition of the weld if necessary.

Welding wire classification

Semi-automatic welding is performed with flux-cored wire without gas to improve the quality of joining parts. The mechanical performance of the welding joint depends on the type of rods and chemical composition.

Important. Steel wire for submerged arc welding must comply with GOST 2246 of 1970 and be used depending on the material of the parts.

Wire is made from three types of steel:

- alloyed;

- highly alloyed;

- structural, low-carbon.

The cross-section of the cores, depending on the thickness of the metal, is made with a diameter of no more than 12 mm. Supplied in coils no more than 80 m long. At the request of customers, winding on cassettes or reels is possible.

Steel wire should be stored in dry rooms. When rust forms, the coils are treated with gasoline or kerosene.

For welding aluminum parts, the wire is made in accordance with GOSTs 7871 and 16130. For this purpose, copper-plated wires are produced and most often used, which do not require processing during welding.

Features and Benefits

The advantages of semi-automatic and automatic welding under a protective layer of flux allow this type of permanent connection to occupy one of the leading places.

High level of performance

According to this characteristic, the advantage over manual welding is at least 6 times, some experts believe that it is much more. But this is not the limit; by increasing the operating coefficient of the welding machine, the amount of labor productivity increases. Another reason for achieving such results is the use of high current values during welding.

A dense layer of flux material does not allow the metal to spread, while good weld formation occurs. At higher current values, this equipment can reliably provide penetration of even thick metal without extensive cutting of edges. Therefore, productivity increases even more. The time required to clean up splashes and heavy metal spreading is reduced.

Improved seam quality

The quality of the connection increases due to the fact that the molten metal is not exposed to oxygen and other atmospheric substances.

There is a wide choice of welding wire material available. By using the brand that is best suited for welding, you can obtain a weld with a homogeneous composition.

It becomes possible to give the seam an excellent shape, with the required seam leg. Thanks to the protective film that forms when the flux burns, there are no undercuts, lack of penetration, pores or cracks in the seams. Finally, there is no need to replace electrodes, so the seam is smooth and without tears.

Economical consumption of materials and improved working conditions for the welder

When welding with submerged arcs, wire consumption is reduced by up to 35%, when compared with welding with electrodes. The material is not wasted in the form of cinders and metal spattering.

With this method, carbon monoxide is released in smaller quantities; the specialist’s eyes and face are not exposed to strong ultraviolet radiation, as with electric welding.

Flux-wire combinations in submerged arc welding

If the welding and technological characteristics of the submerged arc welding process are determined mainly by the properties of the flux, then the mechanical properties of the metal of the seams and welded joints depend on the flux-wire combinations.

Obtaining high-quality welds on carbon and some low-alloy structural steels is achieved by using the following combinations of fluxes and welding wires: fused high-silicon manganese flux and low-carbon or manganese welding wire, fused high-silicon manganese-free flux and manganese welding wire, ceramic flux and low-carbon or manganese zinc wire.

When using fused high-silicon manganese flux and low-carbon or manganese welding wire or fused high-silicon manganese-free flux and manganese welding wire, the latter must be made of boiling or semi-quiet steel. Calming the metal of the weld pool and preventing porosity when welding boiling steel is carried out as a result of introducing a certain amount of silicon from the flux into the welding zone. Alloying of the weld metal with manganese in order to increase its resistance to the formation of crystallization cracks is done through flux (first and third combinations) or through wire (second and third combinations).

The welding properties of high-silicon manganese fluxes are somewhat better than those of high-silicon manganese-free fluxes. A positive characteristic of high-silicon manganese fluxes is the high resistance of welds against the formation of crystallization cracks. This is due to the small transfer of sulfur from fluxes of this type into the weld metal and the relatively strong burnout of carbon from the metal of the weld pool. In addition, the quality of the weld is positively influenced by the lower carbon content in low-carbon wire used in combination with high-silicon manganese fluxes compared to manganese wire. When welding under them, the porosity of the welds is less than when welding under high-silicon manganese-free fluxes.

If the strength and chemical composition of the weld metal are determined by the chemical compositions of the welding wire and the base metal, then its impact strength largely depends on the flux. High impact strength of the weld metal is ensured by its fine-crystalline structure and low content of inevitable harmful impurities and non-metallic inclusions. To meet these requirements, the SiO2 content in the flux is usually reduced. Therefore, when welding low-alloy steels, low-silicon fluxes are predominantly used. An additional requirement is the lowest possible hydrogen content in the weld metal. Refinement of the structure of the weld metal is also facilitated by a decrease in the heat input of welding. However, this reduces the efficiency of the welding process due to an increase in the number of passes.

In the welding process of modern low-alloy high-strength steels, only limited heat input is allowed to avoid damage to the structure of the base metal in the heat-affected zone. This requirement is met by applying multilayer seams when welding metal of medium and large thickness. In this regard, fluxes intended for welding such steels must ensure easy separation of the slag crust, high quality of weld formation and its mechanical properties. By increasing the mechanical properties of the weld metal by using the appropriate combination of flux and wire, the need for uneconomical thin welds in multi-pass welding of thick metal is eliminated.

Slag-metal and gas-metal reactions, reduction and burnout of elements

During fusion welding, interaction occurs between the liquid slag and the metal. The duration of this interaction is usually very short. In electric arc welding, it ranges from 10 s to 1 min. The interaction stops after the metal and slag have solidified. Despite the short duration, the interaction reactions between slag and metal during electric arc welding can occur very vigorously, which is due to the high heating temperature of the metal and slag, the large surfaces of their contact and the relatively large relative amount of slag.

The interaction between slag and metal is described by reactions of displacement of one element from slag into metal by another or distribution between slag and metal. Displacement reactions predominantly lead to the enrichment or depletion of the weld metal with alloying elements, while distribution reactions lead to the formation of non-metallic inclusions in the weld metal.

During displacement reactions, metal atoms and slag oxide molecules interact on the contact surfaces of liquid metal and slag. A very significant role is played by the reduction reactions of silicon and manganese:

(MnO) + [Fe] = (FeO) + [Mn]; (SiO2) + 2 [Fe] = 2 (FeO) + [Si].

Symbols in round brackets indicate elements and compounds found in the slag, and symbols in square brackets in the metal. At high temperatures, reactions predominantly proceed from left to right (reduction of manganese and silicon from slag to metal), with decreasing temperature - from right to left (oxidation of manganese and silicon and their transition from metal to slag). The direction of reactions also depends on the concentration of reactants. If the metal of the weld pool contains little manganese and silicon, and the slag contains a lot of MnO and SiO2 and little FeO, manganese and silicon are reduced from the slag to the metal at high temperatures (near the arc). If there is a lot of manganese and silicon in the metal of the weld pool, and there is no MnO and SiO2 in the slag, or a lot of FeO, manganese and silicon are oxidized even in the high temperature zone of the weld pool.

The interaction reactions between the slag and the metal of the weld pool take place under conditions of rapid temperature changes and constant updating of the composition of the reacting phases. In this regard, both the intensity of these reactions and their direction change. However, although the interaction of slag and metal during welding does not reach a state of equilibrium, it is always directed towards its establishment.

The intensity of interaction between slag and metal depends on the welding mode, and it is most strongly influenced by current and arc voltage; Current density and welding speed have little effect. A decrease in current and an increase in arc voltage enhance the interaction of slag and metal, increase the intensity of reduction or oxidation of silicon and manganese during welding, and enhance the transition of sulfur and phosphorus from slag to metal or from metal to slag. In automatic submerged arc welding, the specified mode is maintained constant, certain amounts of electrode and base metals are melted per unit time, and the processes of interaction between the metal, slag and gas phases at high temperatures proceed in the same way. Thanks to the consistency of the automatic welding mode, a seam of a stable chemical composition is obtained. If the chemical composition of the base metal and the welding or filler wire is known, as well as the nature of the change in the chemical composition of the metal of the weld pool as a result of interaction with the slag or gas phase, then it is possible to approximately calculate in advance the chemical composition of the weld that will be obtained when welding in the selected mode.

Equipment

We produce 2 types of equipment for submerged arc welding of parts. In the first type, welding wire with a thickness of no more than 3 mm is used.

The design principle of such a welding machine involves self-adjustment of the arc (voltage on it), while the wire is fed at a constant speed.

The second type is equipment in which the current is automatically adjusted depending on the feed speed of the welding wires. The diameter of the electrode wire for such equipment starts from 3 mm.

We produce semi-automatic welding machines and devices for automatic welding. They produce universal machines that can be used for welding with flux-cored wire, submerged arc welding, MIG, as well as electric arc gouging. The current reaches values of 300…1500 A.

Modern automatic models are equipped with a mechanism that allows you to collect unmelted flux and send it back to the loading container. There is a seam proportionality control function.

Self-propelled vehicles (tractors, suspended heads) are common in industry, allowing automatic welding of voluminous and extended structures. If the welding machine is equipped with a laser, this makes it possible to monitor the position of the electrode. Moreover, the screen can be installed at a distance of about 20 meters.

Argon

When working with critical products made of alloy steel, flux is additionally used in the form of a paste, which increases the protection of the seam. The substance is inert to tungsten and gas and does not interfere with the process in any way.

Gas

In gas welding, fluxes are used to join non-ferrous metals together. To a large extent, this is soldering, not welding. In this way you can connect copper, brass, bronze, iron, nickel. Fluxes can be in powder or paste form. Everywhere, preliminary application to the edges is provided, and the substance melts at the temperature of the flame.

Electroslag welding

The process is similar to using a welding tractor, only the joint is protected by two copper slides. The space between them is filled with flux and an electrode is supplied. Copper slides prevent molten slag and metal from flowing out, which allows you to deposit large volumes of filler metal in one pass or connect sides with a large gap to each other.

Application area

It is necessary to understand where submerged arc welding is used, which is rightfully considered one of the main methods for obtaining a permanent connection. Welding is performed in the lower position, for connecting parts end-to-end, overlapping, for corner connection methods.

Previously, the method was used only for welding metal structures made of structural steels. With the development of new technologies, it became possible to weld all types of steel and nickel alloys. For this purpose, a wire suitable in its composition is used.

Titanium and its alloys, copper and copper-based alloys, aluminum alloys and pure metal - these materials are successfully and reliably joined using submerged arc welding.

Using the submerged arc method, complex building structures, bridges, pipes, tanks, sea and river vessels are welded. It is economically profitable to use this method for sheets with a thickness of 6 mm or more.

It is important to choose the right operating mode, wire material and type of flux . The seam will be able to withstand large temperature changes and exposure to aggressive environments. A joint made by a professional will withstand very high pressure and will be reliable in conditions of complete vacuum.

Flux production technology

According to technology, all granular welding mixtures are divided into two large classes: fused and unfused. This division is due to the composition of the chemical elements of these mixtures.

Unmelted fluxes

The base material of unmelted fluxes is a ceramic base, which is obtained by mechanical grinding in special ball mills. These mixtures are fine-grained if the size of an individual grain is less than 1 mm; normal if the grain fits in dimensions from 3 to 4 mm.

Fine-grained fluxes are used in welding using wire with a small diameter, no more than 1.5 mm. The markings of such mixtures contain the letter M. If the welding flux is multicomponent, that is, the mixture contains a large number of different components in addition to ceramics, then first these elements are glued together, and only then they are sent to the mill for grinding to the required size.

Flux brands.

In addition to traditional components such as silica and manganese, unfused fluxes may contain oxides, metal powders or ferroalloys. The main criterion for the appropriateness of mixture components is their ability to improve the metallurgical processes occurring in the working area.

These are surface alloying, deoxidation of metals, fine-grained structure of the weld, reducing the proportion of harmful impurities in the weld. And in addition to all these benefits, in welding with unfused fluxes, you can use cheaper wire.

Of course, there are also disadvantages. Such mixtures do not tolerate moisture in any concentration; they are very hygroscopic and, having absorbed moisture, they significantly deteriorate the quality of the material. All this can be solved by proper packaging and, of course, compliance with the correct storage conditions. In addition, it is necessary to strictly control the entire welding process so as not to miss changes in alloying conditions.

Magnetic flux mixtures are also classified as unfused. They are very similar in composition to ceramic options, but contain metal powder to increase the efficiency of the welding process.

Fused fluxes

The technology for producing fused fluxes is more complex than unfused ones. They are light yellow in color or completely transparent. The density is very moderate.

Flux and steel grades.

The production of granular fused mixtures includes stages clearly separated by time:

- crushing all elements of the mixture to the required size;

- mixing the mixture elements in a specialized mill;

- melting in a stove;

- converting particles into granules of the exact required size using water in which the molten flux mixture is cooled and solidified into balls.

- drum drying;

- final sifting to screen out non-standard granules, packaging with insulation from moisture.

The composition of fused fluxes is not original: they are based on the same silicon and manganese. Silicon has excellent deoxidizing properties, which work to homogenize the molten metal during the process, reducing the proportion of carbon monoxide.

Manganese is needed primarily for the reduction of iron oxides. Additionally, manganese promotes the formation of an easily removable crust by binding sulfur from slag into sulfides.

https://www.youtube.com/watch?v=elCSbt438e0