Circulation pumps of various types are often used today in country houses and cottages, which makes the operation of autonomous heating systems more efficient and at the same time saves on energy resources. Meanwhile, if such a hydraulic machine fails, the entire heating system stops functioning, which forces its user to choose: use the services of qualified specialists or repair the heating circulation pump with his own hands.

Disassembling the circulation pump

The reasons for the breakdown of circulation pumps, the types of which differ from each other in certain design features, are associated both with non-compliance with the operating rules of such equipment, and with the quality of the coolant, fluctuations in the power supply network, as well as with a number of other factors. Before deciding to repair the circulation pump yourself, you should have a good understanding of the design and operating principle of such a device, which will allow you to determine the exact cause of its failure and eliminate it.

Common faults and solutions

The pump makes a loud noise when starting the pump, but the impeller does not spin. This usually happens if the engine shaft itself is oxidized or heavily rusted.

This happens due to the fact that the pump was installed at an angle from a horizontal reference, or due to the circulation pump being idle for a long time without use.

The process of restoring functionality is carried out as follows:

- The first step is to completely disconnect the device from the power supply.

- Drain the coolant from the pump and the adjacent piping circuit.

- Unscrew all pipeline connections (the so-called American ones), remove the motor along with the rotor.

- Take a strong plastic or wooden object, rest it on the pump body and force the impeller out of its dead position. After this, the pump should be reassembled in the reverse order; at first it will be a little noisy, but gradually it will get used to it and quiet down.

In rare cases, the pump begins to hum after a foreign object gets under the impeller. In such a situation, the pump is disassembled according to the instructions described above, the foreign body is removed, and then reassembled in the reverse order.

Only now you need to install a filter mesh before the coolant inlet so that a similar malfunction does not happen in the future.

The pump does not make any sounds and does not work

In this case, you should look for a fault in the power outlet or switch. An indicator screwdriver for determining the phase or a multimeter will help you with diagnostics. If everything is fine with the power in the outlet, then you should check the cable for a break.

If everything is fine here, then with a 90% probability the motor winding has been broken. Then the circulation pump needs to be replaced, since no one is restoring the winding.

We install the circulation pump ourselves and check it, or we call a specialist to your home for this work.

After a short period of operation, the pump turns off by itself.

This usually happens due to the fact that the water in the heating circuit is extremely highly mineralized, so lime deposits appear on the impeller during operation.

- Here the restoration work is not particularly complicated, you just need to disassemble the pump, dismantle it, and then disassemble it (just unscrew a few bolts around the perimeter of the device).

- Next, the impeller is cleaned; a brush and warm water with citric acid are ideal.

- After this, the working mechanism is washed under running water. At the end of the work, the circulation pump is assembled and subsequently installed.

When started, the pump spins and circulates coolant, but during operation it makes a loud noise.

This happens due to strong air in the heating system. To restore normal operation of the pump, you need to add water or antifreeze to the system, and then remove air from all pipes and radiators.

Basic safety rules

Although the design of the circulation pump is quite simple, it will require certain qualifications to eliminate any breakdowns that occur. Therefore, it is easier to prevent a problem than to heroically eliminate it later. One sign that something is wrong with your equipment is if it becomes excessively hot during operation.

Compliance with the simplest operating rules will help prevent this:

- Under no circumstances should the wiring come into contact with moisture.

- Particular care should be taken to check the tightness of the connection between the pumping equipment and the pipeline. If there are leaks, the gaskets should be replaced.

- It is forbidden to turn on the device without first grounding it. The heating pump device includes special terminals.

- The internal pressure force should not exceed operating standards.

To figure out why the heating pump is not working, it is recommended to seek help from a professional technician. You can try to fix simple problems yourself.

The pump works but vibrates a lot

There are only 2 reasons for this:

- The rotor has somehow shifted from its normal axis of rotation;

- The working shaft bearing is worn out.

The problem is solved by replacing the bearing (if possible) or replacing the pump.

The cost of installing heating systems

Heating system installation

| Heating radiator installation | PC | from 2,000 ₽ |

| Installation of a floor-mounted convector | PC | from 4,500 ₽ |

| Installation of a heating radiator ( non-standard size, cast iron, design) | PC | from 4,500 ₽ |

| Installation of distribution heating cabinet | PC | 4 500 ₽ |

| A set of works for installing a heating system for a house up to 100 m² | from | 49 500 |

| A set of works for installing a heating system for a house up to 150 m² | from | 52 500 |

| A set of works for installing a heating system for a house up to 200 m² | from | 72 500 |

| A set of works for installing a heating system for a house up to 250 m² | from | 87 500 |

| Please call for exact cost | 84957446774 |

The cost of installing heating systems . The price was adjusted as of May 05, 2022 Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Installation of an underfloor heating system (warm floor)

| Water heated floor | m² | from 500 ₽ |

| Distribution manifold cabinet for underfloor heating (external) | PC | 4 500 ₽ |

| Heated floor temperature control device | PC | from 2 000 ₽ |

| Heated floor temperature control groups (thermostatic valve, thermostat with clamp-on sensor, bypass valve, starter) | PC | 3 750 ₽ |

| Main pipes heating system and pipe insulation (cross-linked polyethylene, metal-plastic) up to 20 mm | m/linear | 100 ₽ |

| Main pipes heating system and insulation with pipe insulation (cross-linked polyethylene, metal-plastic) up to 32 mm | m/linear | 230 ₽ |

| The exact cost is calculated after check-out | engineer |

The cost of installing heating systems . The price was adjusted as of May 05, 2022 Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Installation of heating systems for warehouses, hangars, workshops, car service centers

| Installation of a fan heater , with pipes, fastening to a concrete wall | PC | from 15 000 ₽ |

| Installation of automatic fan heater control | PC | from 4 500 ₽ |

| Pressure testing, commissioning, filling with coolant | m2 | from 100 ₽ |

| Register mounting, thread | PC | from 6 750 ₽ |

| Register installation, welding | PC | from 15 000 ₽ |

| The exact cost is calculated after check-out | _engineer_ |

The cost of installing heating systems . The price was adjusted as of May 05, 2022 Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

The pump creates a weak coolant circulation pressure

Main reasons:

- The pump impeller rotates in the opposite direction.

- The wiring in the electrical distribution box is incorrectly connected (with a 3-phase connection).

- Increased density of the coolant (this can happen due to the fact that dirty water was drawn into the system after repair work was carried out on the water supply main).

- The heating system filter element is clogged.

This problem is solved depending on the cause.

Revision of the motor part

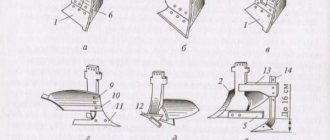

Deep well pumps are equipped with a single-phase, mostly brushless induction motor. The connection diagram contains a starting capacitor. The stator of the electric motor has a monolithic attachment to the housing; it is often filled with epoxy compound.

In pumps of a monolithic design, the motor must be squeezed out of the glass by pressing on the connection outlet of the outgoing pipeline with the impellers removed. In rod pumps, the motor part is disconnected when the two halves are separated, in screw pumps - after removing the working screw. In all cases, the insides of the engine (capacitor, connecting terminals) can only be accessed after removing the sealed plug. It is fixed with 2-3 screws on the side surface of the sleeve and a powerful locking ring. In some types of pump, the plug may require the use of a special puller.

Well pump motor stator

All well pump motors are filled with oil, which performs lubricating, cooling and dielectric functions. The oil used is special food grade, but it is commercially available. Signs of low quality may be a cloudy color of the oil when mixed with water, darkening or the presence of mechanical impurities, as well as insufficient levels. If the oil is normal, it should be drained into a clean, dry container, leaving the motor housing for 15–20 minutes until the residue completely drains from the walls. Insufficient oil filling of the engine indicates wear of the oil seals.

In addition to spoiled oil, engine malfunctions can be caused by worn bearings, which can be determined by play and free-wheeling noise. If the pump has been operated for a long time under extreme conditions, the shaft may be bent (twisted) and the winding insulation may overheat. Burnt stators are practically beyond repair, but they are quite easy to replace.

Burning of the stator winding due to water entering the motor

The pump gets very hot even when the boiler is cold

Excessive heating of the pump using cold coolant indicates that it is operating at increased load. Therefore, you should disassemble it yourself and check everything or send it to a diagnostic center, where this work will be performed by qualified craftsmen.

Replacing the repair kit

Replacing the circulation apparatus repair kit includes:

- disassembling the pump part of the device;

- replacement of components;

- checking engine operation;

- device assembly;

- diagnostics of equipment operation.

Some manufacturers offer ready-made repair kits for pumping equipment. For example, a repair kit for a circulation pump u4814 with a capacity of 5200 l/h, voltage 12/24 V and a pipe diameter of 38 mm. Purchasing such a kit will reduce the waste of time and money.

Air removal scheme

You should repair the circulation device yourself only after the warranty period has expired or if it is impossible to call a repair specialist. Some pump components are difficult to find on the open market, which is explained by the trade policies of the manufacturing companies.

How to disassemble a circulation pump

You need to understand that it is impossible to carry out high-quality repairs without disassembling the unit itself, so you need to learn how to disassemble it correctly.

First of all, the pump should be disconnected from the power supply.

- To disconnect the cable from the junction box, you need to remove the housing from the pump supply unit.

- After this, you need to close the ball valves at the edges of the pump, this is done so that the main part of the coolant remains in the system.

- Then all the bolts are unscrewed from the circulation pump housing, for this you use a socket wrench or hexagon

Note! You may encounter such a problem that the fasteners are thoroughly stuck. The popular WD-40 product will help you here; after half an hour you can try to unscrew the bolt again. This product is characterized by increased fluidity, so it is often used not only in everyday life, but also by plumbers and car mechanics.

Then carefully remove the cover of the unit, there you will see the pump motor itself, as well as the impeller, which distills the water in the system.

You need to remove the rotor; it is secured with several bolts in a circle. After this, you will have full access to all parts of the device, then it will be easier for you to diagnose and carry out repairs.

We are confident that you will be able to apply this material in practice and carry out competent repairs of the boiler circulation pump. Good luck to you!

Design

Almost all circulation pumps are centrifugal type. They have an impeller mounted on the motor shaft and placed in a special “shell” chamber. The entrance to the shell is located in the center, while the exit is the outer edge of the shell with a channel extending around the circumference in the direction of movement of the impeller. The engine spins the impeller, and water, under the influence of centripetal force, rushes from the center to the edges of the sink from inlet to outlet.

Pump structural elements:

- pump part, sink and impeller mounted on the shaft;

- electric motor;

- electronic control unit.

The most susceptible to wear is the moving part of the pump - the motor shaft and impeller, as well as the bearings on which they are mounted.

Photos of reliable circulation pump models

Modern boiler room

| Name and technical characteristics | Qty | Unit. | Materials and equipment | Installation work | Total materials | Total work | total cost |

| Hydraulic leveler | 1,00 | PC. | 8 500 ₽ | 2 500 ₽ | 8 500 ₽ | 2 500 ₽ | 11 000 ₽ |

| Distribution manifold number of consumer circuits 2 | 1,00 | PC. | 9 500 ₽ | 2 500 ₽ | 9 500 ₽ | 2 500 ₽ | 12 000 ₽ |

| Distribution manifold number of consumer circuits 3 | 1,00 | PC. | 10 500 ₽ | 2 500 ₽ | 10 500 ₽ | 2 500 ₽ | 13 000 ₽ |

| Distribution manifold number of consumer circuits 4 | 1,00 | PC. | 11 500 ₽ | 2 500 ₽ | 11 500 ₽ | 2 500 ₽ | 14 000 ₽ |

| Distribution manifold number of consumer circuits 5 | 1,00 | PC. | 12 500 ₽ | 2 500 ₽ | 12 500 ₽ | 2 500 ₽ | 15 000 ₽ |

| Distribution manifold fasteners | 2,00 | PC. | 1 200 ₽ | 350 ₽ | 2 400 ₽ | 700 ₽ | 3 100 ₽ |

| Pump module without mixing valve and pump | 1,00 | PC. | 6 500 ₽ | 2 500 ₽ | 6 500 ₽ | 2 500 ₽ | 9 000 ₽ |

| Pump module with mixing valve without pump | 1,00 | PC. | 8 500 ₽ | 2 500 ₽ | 8 500 ₽ | 2 500 ₽ | 11 000 ₽ |

| Pump module with mixing valve and servomotor without pump | 1,00 | PC. | 12 500 ₽ | 2 500 ₽ | 12 500 ₽ | 2 500 ₽ | 15 000 ₽ |

| Connection of the pump module to the consumer circuit | 1,00 | PC. | — | 3 500 ₽ | — | 3 500 ₽ | 3 500 ₽ |

| Pressure testing of a modular boiler room | 1,00 | PC. | — | 3 000 ₽ | — | 3 000 ₽ | 3 000 ₽ |

| Connection of a modular boiler room with a heating boiler | 1,00 | PC. | — | 3 500 ₽ | — | 3 500 ₽ | 3 500 ₽ |

| Fittings and adapters for boiler room assembly. Copper pipes ⌀22-28, footage no more than 25 m/linear. | 1,00 | computer | 14 000 ₽ | — | 14 000 ₽ | — | 14 000 ₽ |

| Heating system circulation pump 25*40 | 1,00 | PC. | 4 312 ₽ | 720 ₽ | 4 312 ₽ | 720 ₽ | 5 032 ₽ |

| Heating system circulation pump 25*60 | 1,00 | PC. | 4 560 ₽ | 720 ₽ | 4 560 ₽ | 720 ₽ | 5 280 ₽ |

| Heating system circulation pump 25*80 | 1,00 | PC. | 8 670 ₽ | 720 ₽ | 8 670 ₽ | 720 ₽ | 9 390 ₽ |

Modern boiler room

| Total cost of work | RUB 32,860 |

| Total cost of equipment | RUB 113,942 |

| Total total cost | RUB 146,802 |

Modern boiler room

Boiler room maintenance cost

Technical (service) maintenance of the boiler room

| Name of works | Volume | Price |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 1st scheduled departure | from 14 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 1st scheduled departure | from 20 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 2 scheduled trips | from 22 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 2 scheduled trips | from 30 000 ₽ |

| Service contract for wall-mounted gas boiler | with 1st scheduled departure | from 10 000 ₽ |

| Service contract for wall-mounted gas boiler | with 2 scheduled trips | from 15 000 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Boiler room repair, diagnostics and prevention

| Name of works | Volume | Price |

| On-site inspection and diagnostics (without repair) | up to 50 km from MKAD | from 3,500 ₽ |

| On-site inspection and diagnostics (without repair) | from 50 to 100 km from MKAD | from 5,500 ₽ |

| Cleaning the burner (atmospheric) | power up to 60 kW | from 2,000 ₽ |

| Cleaning the burner (supercharged) | power up to 60 kW | from 3,500 ₽ |

| Cleaning the burner (atmospheric) | power from 60 to 170 kW | from 8,500 ₽ |

| Cleaning the boiler combustion chamber | power up to 60 kW | from 4,000 ₽ |

| Cleaning the boiler combustion chamber | power from 60 to 170 kW | from 6,000 ₽ |

| Checking and pumping up pressure in the expansion tank | without dismantling work | from 2,500 ₽ |

| Checking and pumping up pressure on the expansion tank | with dismantling and installation | from 4 500 ₽ |

| Refilling the heating system with a pump | system volume up to 200 liters | from 3 000 ₽ |

| Replacement of heating element, pump, heat exchanger, with coolant drain | for a unit | from 3 000 ₽ |

| Conversion of a gas boiler to liquefied gas | for a unit | from 3 000 ₽ |

| Burner settings | gas / diesel | from 2 500 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Recommendations for using the device

In order not to encounter a situation where urgent repair of the device is necessary, or it completely fails, you must comply with all operating requirements.

The most important condition is that if there is no water in the pipeline, then the circulation pump cannot be started.

The generated water pressure must be within the characteristics indicated on the technical data sheet of the device. If during operation the pump produces increased or decreased pressure, then during such operation rapid wear of the product may occur, which is bad in itself.

During the period when the heating system will not be used, it will be necessary to turn it on once a month for circulation for at least 15 minutes. Thanks to such actions, blocking of moving mechanisms and their oxidation will be prevented.

You also need:

- Make sure that the temperature in the system does not exceed 65 degrees;

- Inspect the device regularly and check for correct operation monthly.

Such manipulations will allow timely identification of malfunctions at the initial stage and thereby promptly take appropriate measures.

Before you start using the heating pump, you should watch the training video

Step-by-step verification algorithm:

- Switching on the hydraulic machine to operating mode;

- Checking noise and vibration levels;

- Controlling how the engine heats up;

- Checking how the pump pumps, makes noise or whistles;

- Mandatory grounding control.

In addition, you need to pay attention to leaks from the water boiler. Perhaps during disassembly you will find that the motor spins too much, crackles and turns on too often. Additionally, you need to inspect the terminal box and check the fixation of the wire in it.

Heating repair

Heating repairs must be carried out in a timely manner so as not to leave the house without heat in the winter. This could be clogged pipes or radiators, a boiler malfunction, or other reasons. An audit of all nodal points is required, and the serviceability of the fittings is also checked. Only timely maintenance guarantees the functionality of the heating system.

carries out heating repairs of any complexity. We are ready to offer you peace of mind, as we have a prompt mobile repair and technical service. A properly functioning heating system will keep you warm all year round.

- Administrator for Heating the cottage 02/20/2022

- Administrator for Gas heating02/04/2022

- Administrator for Autonomous water supply at home01/08/2022

- Technical department for home heatingDecember 31, 2021

Pipes

| Pipe replacement | Installation of metal-plastic pipes | Repairing pipe leaks |

| Installation and soldering of copper pipes | Installation and soldering of polypropylene pipes | Rehau pipe installation |

| Installation of heating pipes | Installation of cross-linked polyethylene pipes | Water distribution with Rehau pipes |

| Soldering of polypropylene pipes | Laying heating pipes in the house | Water supply installation |

| Defrosting pipes | Copper pipe repair | Welding of water supply and heating pipes |

Heating pipe repair

Heating repair

in a private, country

house is a complex matter that can only be done by professional specialists with the appropriate qualifications, in some cases special SRO approval, as well as experience in this area of repair work.

Heating system repair

Middle of content

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.