The main element of any autonomous water supply system is the pumping station, which, like any other technical device, can periodically fail. In order to return pumping equipment to working condition, you can use the services of specialized companies or repair the pumping station yourself. However, before starting to repair such technically quite complex equipment, it is necessary to identify the reasons why the water pumping station is not functioning.

Disassembling a submersible pump for diagnostics and troubleshooting

There are many reasons for malfunctions in a pumping station. They may be associated with a lack of power supply, improper water supply from a water supply source, breakdown of the pump itself, failure of the hydraulic accumulator or elements that provide automatic control of the equipment. Many of these reasons that lead to the fact that water supply stations do not work or function incorrectly can be identified and eliminated at home, and repairs do not require professional skills and complex equipment.

Construction of pumping stations

Pumping stations, which are often called hydrophores, are now actively used to organize autonomous water supply systems for country houses and cottages, so the question of how to independently repair such equipment, if the need arises, is quite relevant. Before you figure out how to repair a pumping station with your own hands, you need to understand what such stations consist of and on what principle they work.

Construction of a surface pumping station

A pumping station for equipping a domestic water supply system, which pumps liquid into the pipeline system, is installed on the surface of the earth, as close as possible to the well (as far as possible), and operates from the electrical power supply network. The main structural elements of pumping stations that ensure efficient and uninterrupted operation of such equipment in automatic mode are:

- the water pump itself, which pumps water from a well or a well and pushes it under pressure to the outlet pipe (to equip pumping stations, a surface pump, rather than a submersible one, is used);

- a water intake hose that is immersed in water to the maximum possible level;

- a check valve that prevents water from the suction pipeline from flowing back into the well or well;

- a mesh filter installed in front of the check valve and purifies the water pumped from the source from dirt and sand particles, the entry of which into the inside of the pump can become one of the reasons for its failure;

- a pressure sensor installed after the pump - on the pressure line (the main task of such a sensor, operating in automatic mode, is to turn on the pump if the water pressure in the water supply system drops to a critical value, and turn it off when it reaches the required parameters);

- a water flow sensor, which is installed before the pump and does not allow it to idle (when water stops flowing from a well or well, such a sensor automatically turns off the device, preventing it from overheating);

- a pressure gauge that allows you to measure the water pressure in the pipeline created by the pumping station.

What is it for?

Like the human body without a heart, the water supply system cannot function without a pumping station. Any autonomous water supply system must be connected to a well capable of supplying a certain area with the required amount of water.

People living in private houses extract water using pumps, since the depth of wells can sometimes reach several tens of meters. The pumping station serves to maintain constant pressure in the water supply system and pump liquid from one place to another.

Basic malfunctions and recommendations for their elimination

Malfunctions of a pumping station, as mentioned above, can be determined by a number of reasons, the exact clarification of which will allow repairs to be carried out promptly and with the highest possible quality, returning the equipment to working condition. Diagnostics carried out to determine the cause of a pumping station breakdown do not require the use of complex equipment and professional skills. Most of the typical malfunctions of pumping stations can be identified both by external signs and by using the instruments that such equipment and the water supply system were originally equipped with.

Among the malfunctions of pumping stations, several of the most typical ones can be identified, which each user is able to identify and eliminate independently, using the advice of specialists during repairs.

The pump works, but no water enters the system

When starting a pumping station, it may happen that the pump with which it is equipped works, but no liquid flows into the water supply. To determine why the pumping station does not pump water, it is necessary to analyze individual parameters and operating conditions of the elements included in the equipment.

- First, you need to assess the technical condition and correct operation of the check valve, which is located on the suction pipe in the inside of the well or well. Very often the pumping station does not pump precisely because this valve is clogged with sand and dirt: without opening, it simply does not allow water from the well to flow to the pump.

- You should check whether there is water in the part of the pressure pipeline that is located between the pump and the well. If there is no liquid there, then, accordingly, the device has nothing to pump. Often this situation occurs when there is a power outage and the pumping station stops operating. In order for the pumping station to start operating normally again, it is enough to fill this part of the pipeline with water, for which a special hole is provided in it.

- It is necessary to check (with the pump disassembled) how large the output is between the inner walls of its housing and the impeller. Such production is most intensively formed in cases where water containing a large amount of insoluble impurities (a kind of abrasive) is pumped. If this particular reason for the lack of water in the water supply system while the pumping station is running is identified, then repair of the pump is necessary, which consists of replacing the impeller and device housing, or its complete replacement. If you find components suitable for your equipment model, you can repair the water pump yourself.

- It is also necessary to determine whether there is water (and at what depth, if any) in the well itself. If there is water in the water supply source, then the problem can be solved simply: just lower the supply hose or pipe to a deeper injection level. In this case, it is necessary to follow the operating instructions for the pumping equipment in order to subsequently avoid its repair.

The pumping station operates jerkily

A pumping station operating in automatic mode may begin to turn off and turn on frequently, which indicates the presence of malfunctions. This type of operation of the pumping station, in which it is constantly switched off and on, is called jerking. This should be a signal to check (and, if necessary, repair) individual elements of the system.

If the pumping station operates jerkily (it turns off and then turns on), you should measure the pressure in the air chamber of the hydraulic tank. To perform this procedure, you can use a car compressor equipped with a pressure gauge. If this parameter in the air chamber or bulb for the pumping station is below normal, it must be raised using the same auto-compressor. A repeated drop in pressure in the air chamber of the device indicates that a depressurization of the system has occurred, the location of which must be identified. If the joints have lost their tightness, then repair of the hydraulic accumulator is not required; it is enough to simply replace the sealing tape in such places.

To find a leak, apply soap suds to the suspect surfaces. Bubbles will appear in areas of depressurization

The body of the hydraulic accumulator may also lose its seal if a crack or hole has formed in it. Repairing the hydraulic accumulator with your own hands in such a situation is not difficult: to do this, just close the resulting crack or hole using a “cold welding” compound.

Why does the pumping station often turn on and off during operation? The answer to this question may also lie in damage to the accumulator membrane. In such cases, the solution to the problem is to replace the accumulator bulb or such a membrane.

Replacing the membrane in the hydraulic accumulator

Unscrew the flange

Remove the membrane and clean the tank

The new membrane must fit the flange

Insert and straighten the membrane, install the flange

Check the nipple and pump up the pressure

Check the pressure after some time

Repair specialists are often asked why the pumping station often turns on or why the pumping station does not turn off when the liquid pressure in the water supply system exceeds the norm. This is usually due to a breakdown or malfunction of the pressure switch. Such malfunctions can also cause the pumping station to not maintain water pressure in the pipeline. Repairing a pressure switch is a rather complicated procedure that cannot always be done with your own hands. That is why, in many cases, the pressure switch of the pumping station is not repaired, simply replacing such a sensor with a new one.

Unstable pressure of the water flow coming from the pumping station

One of the fairly common situations when operating pumping stations is the supply of water from taps in pulsating jolts, which indicates that the water supply system is sucking in air from the outside. To identify where air gets into the pipeline, it is necessary to carefully check for leaks all the connecting elements present in the area located between the well or borehole and the pumping station.

Repairing pipeline leaks using improvised means

If the pumping station does not build up pressure or pumps water into the pipeline in a pulsating mode, this may also indicate that the water level at the source has decreased or that a hose or pipe of the wrong diameter is being used to pump out water.

When choosing a hose or pipe for placement in a well or borehole, you should always take into account that their diameter should be smaller, the lower the suction height of water from the source.

The automatic shutdown system of the pumping station does not work

The question of why the pumping station does not turn off automatically is quite common. A pumping station operating in such a mode, which is considered an emergency, cannot be operated; it should be immediately disconnected from the power supply. Otherwise, you may experience rapid equipment failure, which means that more complex and expensive hydrophore repairs will be required.

Why does the pumping station not turn off for a long time? The reason is incorrect operation or failure of the pressure sensor. A malfunction of this device, which operates in automatic mode, may cause the pumping station to not turn on when the pressure of the liquid flowing through the pipeline decreases. In most cases, this problem is solved quite simply - by adjusting the sensor to the required pressure to turn the pump on and off.

When the nut of the large spring is tightened, the shut-off pressure increases, and the tension of the small spring changes the delta (on-off range of the pressure switch)

The pressure switch may not work properly due to the fact that the elements of its internal structure are covered with salt deposits. In such cases, it is enough to disassemble the sensor and clean its internal parts from such deposits.

The pumping station does not turn on

In most situations, the station does not turn on (and, accordingly, the pump does not work) due to a break in the electrical circuit, oxidation of the elements of the contact group and malfunctions of the pressure sensor. In addition, the causes of problems may lie in a burnt-out winding of the drive motor, as well as in the failure of the starting capacitor.

Checking the electrical contacts of the pressure switch

As a rule, no problems arise with such repair procedures as eliminating breaks in the electrical power supply circuit of the station, cleaning the contacts of the starting device and replacing the capacitor. However, in order to rewind an electric motor, you need to know how to disassemble it and how to replace a burnt winding in it. That is why many users of pumping stations, when the drive motor burns out, simply replace it with a new one, avoiding repairs.

Often, when starting up a pumping station that has not been used for a long time, a characteristic hum occurs, but the equipment does not start working. The reason for this situation is that the pump impeller of the pumping station is simply “stuck” to the body of the device and cannot budge. In this case, it is necessary to partially disassemble the pump of the pumping station and manually move its impeller from its dead center.

Why doesn't it work and what to do about it?

If the diagnostics showed that the pumping station itself is working, then you should pay attention directly to the pressure switch. The algorithm of actions will depend on how the malfunction of this unit manifests itself

Works often

When the pressure in the hydraulic tank is stable, the main reason for spontaneous frequent starts of the pump is a failure of the automation settings. For adjustments, a pressure gauge must be connected to the system.

The most popular relay in local water supply is RDM-5, with preset response threshold settings:

- lower pressure - 1.4 atm.,

- upper - 2.8 atm.

Step by step, this standard relay is adjusted as follows:

- Remove the unit cover.

- By right-hand rotation of the larger spring nut, raise the shut-off pressure to the desired value, for example 3.8 atm. At the same time, the lower launch limit will also rise.

- By turning the regulator of the smaller spiral to the left, set the desired pressure delta.

Spirals, especially smaller ones, are very susceptible to adjustments, so they should be adjusted very carefully, with gradual tightening of the nuts at 45° turns.

Doesn't turn off the pump

The most common reasons why the relay does not operate to turn off the pump include:

- Sticking and, in severe cases with powerful starting currents, melting of the breaker contacts. If the contacts are not damaged, the defect can be eliminated by cleaning them with fine-grained sandpaper, a fine needle file or a nail file.

- The difference between the relay response thresholds is too high. You should set the settings recommended by the manufacturer or optimal for a particular pump.

It is advisable to maintain the pressure delta in the range from 1.2 to 1.6 atm.

Clicks and switches off frequently

In practice, you can encounter another malfunction of the automation unit responsible for water pressure - periodic clicking.

If the reason is not related, as described above, to a breakdown in the water supply system itself (usually airing) or lack of pressure in the hydraulic tank (ruptured membrane), then the problem is in the automation.

Having summarized numerous opinions on this problem on engineering forums, we can conclude that there is only one possible solution to it - try to eliminate the frequent operation of the automation (clicking) by increasing the difference in the relay response thresholds.

If this does not solve the problem, then the only option is to replace the unit.

It just doesn't work

The relay may not close to turn on for the following reasons:

- Insufficient voltage in the network - automation is demanding on this parameter.

- Oxidation of the contact group - it is necessary to disassemble the device and clean the contacts.

- The automatic shutdown pressure limit is set too high.

- Lime and other deposits in the five-pin fitting with a pressure gauge connecting the relay to the pump (five-pin), or the hole in the membrane compartment is clogged - you need to remove the relay and clean the part.

- Sand gets into the membrane part of the block, which interferes with the action of the diaphragm on the piston. The latter is often observed if the pump has pumped sand. It is necessary to disassemble the relay, carefully clean and rinse everything.

How to properly install a pumping station

In order to less often wonder why the pump does not pump water from the well or supplies it incorrectly to the system, serious attention must be paid to the installation of pumping station elements. Correct installation of water supply systems with submersible pumps is no less important, since repairing a deep-well pump or replacing it is also an expensive procedure.

So, when installing pumping stations, you must strictly follow the following recommendations:

- avoid bending and deformation of pipes used for installation;

- ensure absolute tightness of all connections made to prevent air leaks into the system;

- be sure to place a check valve and a filter element on the supply pipe;

- immerse the lower end of the inlet pipe in water in a well or well at least thirty centimeters (in this case, the distance of the end of the pipe to the bottom of the water supply source must be at least twenty centimeters);

- with a significant depth of the water supply source (more than 4 m) and, if necessary, to pump water over a significant distance, increase the design diameter of the pipes used for installation;

- use a water flow sensor and a pressure switch to equip the pumping station;

- locate the pumping station, which is installed on a hard and level surface, next to the water supply source;

- after installing the equipment and connecting it to the water supply system, draw water into that part of the suction pipeline that is located between the pump and the well or well.

How to ensure stable operation of the water supply system

In order for the plumbing system to function successfully, it is necessary to provide a certain level of pressure and water pressure. When there is no access to centralized water supply, this problem is easily solved using a pumping station. It usually consists of:

- pump;

- membrane storage tank;

- automatic control unit (pressure switch, pressure gauge, etc.).

The pump pumps water, which enters the tank. When the pressure in the tank reaches a certain maximum level, the pump turns off. Gradually, the water from the tank is consumed for various needs and the pressure drops. At a minimum pressure level, the pump turns on again and water flows into the tank. The process is controlled automatically.

With the help of such a unit, you can provide water supply to a house, bathhouse and other buildings located on the site. Having studied the principle of operation, you need to begin studying possible breakdowns and ways to eliminate them.

Having studied the principle of operation and the design of the pumping station, you can repair it yourself

Causes of breakdowns

Even if the operating instructions for the pumping station (hydrophore) are strictly followed, no one is immune from equipment breakdowns. Thus, any malfunctions in the operation of the station, from improper operation to complete shutdown, are most often caused by one of the listed reasons or a combination of them:

- no power is supplied to the station;

- there is no water in the system;

- breakdown of pumping equipment;

- malfunction of the membrane tank;

- breakdown of the automation unit, etc.

The best mobile application for experienced players has appeared and you can have a phone with all the latest updates and discover sports betting in a new way.

Since all pumping stations for water supply to a private home have a fairly simple and uncomplicated design, you can eliminate minor faults and breakdowns on your own. In some cases, it is enough to disassemble the hydrophore and replace the worn part, in others, sealing a crack in the hydraulic tank will help, and sometimes the hydrophore does not turn on due to lack of power.

If the causes of the breakdown are not known to you, and you cannot fix the problem yourself, you will have to contact a specialist. Next we will look at frequent breakdowns of the hydrophore for water supply to a private home, their causes and methods of elimination.

DIY repair

Let's look at the stages of some repair work.

Replacing the hydraulic accumulator bulb

Repairs are often made by replacing the membrane. To do this, the hydraulic accumulator and the sealing element itself are dismantled:

- The flange is removed.

- The membrane is removed.

- The tank is washed.

Replacing the membrane in the pumping station

After this, the new membrane is installed in its place. The final stage of repair is assembling and installing the expansion tank in its place.

Adjusting the pressure switch

Unfortunately, this part cannot be repaired; it can only be replaced or adjusted. There are two steering wheels on the sensor body. The large one serves to increase the pressure in the system. The small one regulates the pump activation interval. By tightening them, you select the operating range of the device.

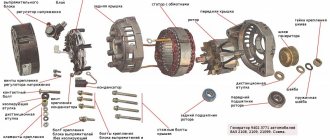

Impeller restoration or replacement

- To replace the impeller, it is necessary to separate the motor and the water supply chamber by unscrewing several bolts on the flange.

- The impeller is mounted on a rod and pressed with a nut.

- Unscrew it and remove the disk.

- We reassemble in reverse order.

Replacing the hydraulic accumulator

- The expansion tank has the form of a metal barrel with a sealed body. Inside the bulb there is a rubber bag into which water flows when the pressure in the system increases.

- If the diagnostics revealed a breakdown in the hydraulic accumulator, it must be removed by unscrewing the locknut on the hose leading to the pump.

- The parts that are replaced in the tank are the air inflation nipple and the rubber water bag.

- Replacement occurs by unscrewing the back cover of the bulb.

Replacing the oil seal

- Following point 3, we disassemble the pump.

- Having removed the impeller, we get to the oil seal.

- You can remove it by heating or melting it with a gas burner or a hair dryer.

- We clean off any remaining dirt or rust and press in a new oil seal.

Bearing replacement

- Following the instructions indicated above, we perform a step-by-step complete disassembly of the device.

- We pull out the engine armature through the rear cover.

- There are two bearings on the shaft, at both ends of the rod.

- To remove them, the shaft will have to be heated with a burner.

We put new rings on the old place, having first cleaned the rod from rust.

Connect the use of hydraulic accumulator

Hydraulic accumulator for pumping station 50 liters

Connecting the pumping station involves the use of hydraulic accumulators. Typically this is a 50-liter capacity (membrane tank for water supply systems). A natural question arises: why such difficulties? I would like to note that this scheme is used in all “cool” water supply systems in Europe and Russia.

The main job of a hydraulic accumulator is to save energy and the service life of the pumping unit. How does this happen? The design of the hydraulic accumulator itself is a temporary reservoir of water pressure. Usually, any owner needs to briefly open the tap in the kitchen or bathroom (wash hands, wet a rag, etc.). In a stationary pipeline, a short-term opening of the tap does not affect the start of the pumping unit.

Under conditions of such operation of the pump, it always turns on briefly. The pressure in the pipes will in any case immediately drop below 4 bar. As a rule, any start of the electric motor of a pumping station consumes more power, and accordingly, electricity consumption increases. Frequent switching on also affects the service life of all parts of the unit.

To maintain the required pressure in the system for a long time, special expansion tanks are used. Now, when you briefly open (use) a tap or mixer, the station will not start up again. When the water level in the tank drops after frequent switching on, the pump will naturally turn on until a certain pressure is created again, and so on in a circle.