Polyamide 6 grade block is a high-strength plastic material; it does not have any specific smell or color. This material also has another name - caprolon 6.

Caprolon is a fairly stable material, it is practically not subject to erasing, and it is also not affected by aggressive substances, such as acids, alkalis or fats. This is an environmentally friendly product and does not release toxic substances during processing or melting.

Features of the material

Caprolon made from polyamide grade 6 is known in such areas as:

- • production of leather goods,

- • food industry,

- • Automotive industry.

In mechanical engineering, this material is used in the manufacture of sliding bearings, gears, and pulleys.

In the countries of the former USSR, this polyamide appeared only in the 80s. It is valued for its high strength and wear resistance. He is not afraid of high and low temperatures.

Caprolon rods are lightweight, they are quite light, but also very durable. The weight of caprolon is 6 times less than steel. Different diameters of the rods allow us to produce bearings of different sizes for transport. They are not subject to oxidation and have a high degree of slip. Such characteristics of caprolon are decisive in the production of impellers for pumps, blades, tension rollers, etc.

In the food industry, cutting boards made of caprolon pa 6 are considered one of the most durable, as they are highly durable, lightweight and easy to maintain.

Areas of use

Due to its properties and technical characteristics, caprolon is successfully used in many industries. It is most common in the following areas:

- electrical engineering. Being a dielectric, caprolon is considered an excellent option for insulating power cables; protective casings for electrical equipment that operate outdoors are also made from it. Due to its low galvanoelectric corrosion, this polymer is used to make terminals, coils, switches and connectors. Resistance to alkaline solutions makes it possible to use the material in contact with various electrolytes;

- mining, shipbuilding and mechanical engineering. Due to its low weight, the use of caprolon makes it possible to lighten the design several times and significantly reduce costs without loss of quality due to the lowest cost of the material compared to similar polymers. The material is used to make sliding bearings, hubs, cuffs, rock crusher drums and much more.

Processing Features

Caprolon processing is possible on milling, turning, drilling and grinding machines. During turning work, it must be remembered that this material has a low melting level.

During long-term machining, it is recommended to use carbon steel tools and tungsten tips.

Caprolon sheets or bushings stored for a long time in the cold cannot be immediately processed on machines. They must be moved indoors for 5 days so that the temperature in the material becomes the same.

It is worth noting that parts made from caprolon have a service life 1.5 times longer compared to parts made from other materials. The cost of producing parts from such polyamide is significantly lower compared to metal parts. Caprolon from polyamide 6 allows the production of parts with low cost, high strength and low labor intensity.

Analogs - external differences between polymers

The closest analogue of a structural polymer in composition is an environmentally friendly fluorine-containing polymer. In many cases, caprolon and fluoroplastic are interchangeable materials, but there are differences:

- In terms of wear resistance, caprolon is ahead of fluoropolymers.

- Fluoroplastic has a dense, uniform structure and boiling white color. Caprolon has a “warm” creamy shade of coffee foam.

- According to tactile sensations, the fluorine-containing material is slippery and smooth, reminiscent of soap, and the second sample is smooth, slightly rough.

- Caprolon is lighter and cheaper than fluorine-containing polymer material.

- The surface of the fluoropolymer is scratched and leaves a mark from pressure. Caprolon cannot be scratched, pressed, or changed in shape.

- If, for comparison, you knock on a workpiece or part, the fluoroplastic muffles the sound, while the other structural sample rings.

Receipt

To obtain high-density caprolon, it is necessary to carry out a low-temperature polymerization reaction, in which aminocaproic acid, alkaline catalysts and activators will take part.

The resulting material can be diluted in phenolic and cresol solutions. This material is considered an excellent dielectric.

According to the state standard, this polyamide must be manufactured in accordance with the requirements of GOST 7850-86. “Caprolon. Technical conditions".

Delivery forms

Most often, sheet caprolon is produced in the form of blanks for the production of numerous parts, including:

The material is mainly supplied in the form of sheets of various widths. The thickness can vary from 6 to 250 mm when these indicators change. It is recommended to select storage spaces with a low level of humidity.

Caprolon should be used with some caution due to its smoothness, elasticity and tendency to slip. When striking with a hammer or sledgehammer, specialists, observing increased safety precautions, first secure it on a flat surface. To avoid injury from sharp edges, wear protective gloves.

Which caprolon is better?

The technical characteristics of different types of caprolon are slightly different, since this material can be produced in different ways. The most popular types of caprolon are:

- • caprolon made by extrusion (kapron),

- • injection molded (sheet caprolon),

- • casting method with the addition of solid lubricants,

- • by casting method with the addition of polyethylene,

- • extrusion with fiberglass,

- • heat resistant,

- • food.

Products made from caprolon, which are produced by casting, are the most common in Russia. They are easy to shape and also have high anti-friction properties.

Rod caprolon, which is produced with the addition of solid lubricants, is widely used in heavy industry. It is used on production belts, in mechanical engineering, etc. Bushings made from such caprolon have high durability and wear resistance. The use of rod caprolon is also due to the fact that this material reduces the noise level during friction.

Extruded caprolon 66 grade without filler is able to withstand temperatures above 100 o C.

Graphite-filled caprolon has the ability to absorb moisture, so it is used in mechanical engineering.

The production of grade 46 caprolon reduces the need for heat-resistant parts, since this material can withstand temperatures up to 259 oC.

Technical specifications

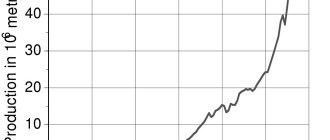

Despite the relative youth of the material and recent use (no more than 30 years), its scope of application is expanding, and its popularity is growing , largely due to its properties and characteristics.

Caprolon, technical characteristics:

- density (g/cm3) from 1.135 to 1.16 depending on the brand and modification;

- tensile strength (MPa) from 70 to 100;

- the maximum permissible temperature range for long-term operation is +110 degrees, and for short-term operation it can reach +150 degrees;

- subject to melting at a temperature of 225 degrees.

Just a small part of the technical parameters shows the high strength and wear resistance of caprolon.

Is it possible to compare fluoroplastic and caprolon?

What is better - caprolon or fluoroplastic? These materials are considered one of the most durable polyamides. Their physical characteristics are practically the same. But it is worth noting that fluoroplastic is not as durable as caprolon. It can be cut, but caprolon cannot be cut.

Also, many manufacturers of the well-known caprolon can call it armadid, technamid, zaytel, tekamir.

Interesting facts about the properties of caprolon

According to the results of scientific research on harmful substances in plastics, caprolon is not toxic and toxic substances are also not released during combustion. If the processing mode is violated and the material is overheated to +290, then the process of its decomposition and the release of CO (carbon monoxide), CO2 (carbon dioxide) and NH3 (ammonia) begins. The level of ammonia concentration in the production area should not be more than 20 mg/m3.

In our store you can buy sheet caprolon, as well as caprolon rods.

Manufacturers and cost of polyamide 6 block

It can be sold by weight, as it is manufactured in the form of sheets, sleeves, rods, circles or blocks. Caprolon varies in diameter and thickness. The average price of 1 kg of caprolon is 300-400 rubles. But it is worth noting that the final cost of a finished product or blank made from this material can be much higher.

Well-known production companies that specialize in this material in the Russian Federation are:

- • PP MTR-Service,

- • LLC PromResurs,

- • LLC PKF YuHK,

- • LLC EnergoTehProm-NN,

- • LLC Continent,

- • APEX-PLUS LLC.

General information

Kaprolon represents the Russian name for the famous polyamide - polycaproamide. There are also analogues of this material on the market.

The product belongs to the category of fairly new products, which have been produced since the end of the last century. The technical characteristics and properties of caprolon are unique, including increased strength and wear resistance. A product made from caprolon, left in an open space for up to several years, will have its original properties absolutely unchanged.

Created in the recent past, the material has a white tint with a yellowish tint and is odorless. It is prone to changeability due to additives during the production of all kinds of coloring preparations. In terms of strength, the polymer resembles steel.

The extended range of temperatures used makes it possible to work in areas with varied climates, including extreme conditions. Anti-friction properties favor its use for bearings or gaskets.

Comparison with fluoroplastic

Caprolon is one of many polymers used to replace metals. Of all analogues, it is most often compared with fluoroplastic and polyurethane. Technical characteristics of fluoroplastic and polyamide in comparison:

- Thermal resistance is better with fluoroplastic. It can withstand temperatures up to 200 °C.

- Both materials are slightly susceptible to chemical corrosion. The difference is that fluoroplastic parts are more often used in diluted acids, and caprolon parts are used in alkalis.

- The specific density of caprolon is significantly less than that of fluoroplastic. They can be distinguished by their weight. Fluoroplastic is almost twice as heavy

. In places where the weight of the product plays an important role, polyamide-6 is more often used. - In terms of compressive strength and deformation upon impact, fluoroplastic is superior to caprolon.

Fluoroplastic is a soft and flowable polymer, not suitable for use under high loads. The service life of fluoroplastic is higher than that of polyamide-6, and in terms of strength characteristics, fluoroplastic has better performance

However, caprolon is more affordable, and this often determines the choice of manufacturers in its favor.

. More information about fluoroplastic F4 can be found here.

Polyurethane is used to replace rubber, traditional plastics, and sometimes metals. It is indispensable in the manufacture of various gaskets and seals.

Thanks to the use of new polymer materials, manufacturers of various types of mechanisms have the opportunity to significantly lighten and reduce the cost of structures. This brings significant economic benefits and often increases the service life of products.

Among the wide variety of modern polymer materials, fluoroplastic and caprolon stand out, and this is not surprising, because both of them are widely used in almost all industries. What properties do both materials have, how do they differ, and in what areas are fluoroplastic and caprolon used?

Types and their applications [edit | edit code]

- Grade “A” is used for the manufacture of critical aircraft parts.

- Grade “B” is used for the manufacture of structural parts for mechanical engineering.

- Brand "MG" - modified with graphite, anti-friction.

- The MDM brand is modified with molybdenum disulfide and has increased dielectric properties.

Caprolon PA6 can be produced colored using pigments in any colors upon request of the consumer.

The color of natural caprolon PA-6 is from white to cream,

The color of PA6-MG and PA6-MDM is from gray to black.

Material characteristics: comparison table

| Properties | Fluoroplastic | Kaprolon |

| Density | 2100–2200 kg/m3 | 1150–1160 kg/m3 |

| Working temperature | -269…+300 °С | -40…+100 °С (short-term -100…+170 °С) |

| Melting temperature | 327 °C (transition to fluid state) | 220–225 °C |

| Coefficient of thermal conductivity | 0.25 W/m×°С | 0.3 W/m×°С |

| Compressive strength | Up to 700 MPa | Up to 2100 MPa |

| Tensile strength | 20–30 MPa | 80–90 MPa |

| Compressive strength | 12–15 MPa | 100–110 MPa |

| Elongation at break | 350 % | 600 % |

| Brinell hardness | 30–40 MPa | 160–180 MPa |

| Impact resistance | Up to 10 MPa | Up to 14 MPa |

| Yield strength | 11–14 MPa | 70–80 MPa |

| Hygroscopicity in 24 hours | 0 % | 1,5–2 % |

| Maximum hygroscopicity | 0% (does not even absorb water vapor) | 6,0–7,0 % |

| Electric strength | 50 kV/mm | 30–35 kV/mm |

| Dielectric constant at 1 MHz frequency | 0,002 | 3,3 |

| Dielectric loss tangent at a frequency of 1 MHz | 0,2–03 | 0,015–0,025 |

| Specific surface electrical resistance | not less than 1017 Ohm | 1×1012–1×1013 Ohm |

| Specific volumetric electrical resistivity | 1×1017–1×1020 Ohm×m | 1×1013-1×1014 Ohm×m |

| Coefficient of sliding friction on steel in lubricant | 0,02 | 0,06 – 0,08 |

| Coefficient of sliding friction on steel without lubrication | 0,02 | 0,2 – 0,3 |

| Abrasion resistance | high | very high |

| Flammability | Does not burn | Lit |