There are often situations at home when you need to squeeze objects with great force. Here are a few of them:

- Squeezing juice from grapes, fruits and vegetables;

- Pressing or removing silent blocks, bearings and bushings;

- Molding of products using a matrix;

- Bending of durable metal parts;

- Straightening curved objects;

- This list has no end.

These actions require press. The most popular version is hydraulic. The liquid is not squeezed out, so it is enough to equip a hydraulic cartridge for extrusion - stamping, and you can develop almost unlimited force.

These lamps are quite compact. For example, the figure shows a machine less than one meter high that produces a force of up to 10 tons. And it is controlled manually.

Such a press can be purchased at a hardware store, but the price is quite high. If you look closely at the design, you can see that the power element is very similar to a regular car bottle lift. Therefore, you can do it yourself.

Design and diagram of a manual hydraulic pump

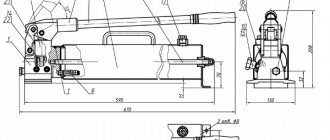

Diagram of a hydraulic hand pump

The manual hydraulic pump consists of two main parts, the pumping unit (1) and the hydraulic tank (2). They are connected to each other by a pin (3). You need to fill the liquid through the hole, having first unscrewed the plug that closes it (4). The handle (6) with the lever (7) drives the plunger (8) of the first and second stages, made as one part. The pumping unit has a two-stage structure. Stage number one, with reduced pressure and higher productivity, serves to accelerate the movement of the hydraulic cylinder plunger. Stage number two, at high pressure and lower capacity, serves to obtain the operating force of the actuator. Overload protection is provided by a safety valve (9). Pressure is released and hydraulic fluid is extracted from the cylinder cavity into the tank using a screw (10).

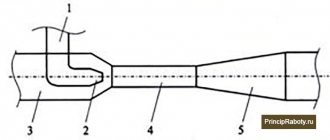

Drawing and concept of a jack press

Power elements are made of steel with a thickness of at least 15 mm or from steel profiles. As vertical struts, you can use a dowel, angle, profile pipe or the same channel. It is preferable to use a threaded rod, as it allows you to quickly adjust the size of the working area.

It is this diagram that we will take as the basis for understanding the design.

Two threaded rods (4) at the bottom (5) and at the top are screwed into the base (7) with a thickness of 20 mm, which allows you to adjust the height of the upper platform.

The pins (4) are made of a steel wheel with a diameter of 30 mm. The upper thread is cut based on the lifting height of the jack rod with a small margin.

The hydraulic jack (6) is installed on the base.

Popular: Homemade pipe bender how to make at home

It would be advisable to fix it there. The bracket is removable to use the lift for its intended purpose.

The lower platform (3) moves vertically on pins.

If the metal thickness is insufficient, the holes can be reinforced with sleeves to prevent tipping. The upper feed platform (1) is bolted with reinforced nuts (2), which are used to adjust the height of the working area.

As a result, the following power structure is created:

This is by no means an axiom; the formula can be anything, especially. Drawings will be developed depending on the availability of material and the type of hydraulic jack used.

The operating principle is as follows: dies (sleeves, punches) or other devices are installed on the platforms, between which the workpiece will change its shape. The jack is lifted in the traditional way - a force equal to the lifting capacity of the jack acts between the platforms.

In industrial construction, a separate hydraulic cylinder and a hydraulic pump are connected to each other by a supply line. This is convenient because it makes the design compact, and the use of a manual pressure pumping system is more convenient.

Working principle of a manual hydraulic pump

Before starting to work with any pump, be sure to inspect the tool and if cracks and chips are found on the surface, do not use it. It is important to check whether the high pressure hose is tightly connected to the hand pump.

Work algorithm:

- We connect the pump to the hydraulic system with a quick-release coupling;

- Turn the valve all the way clockwise.

- Using progressive movements, pump the pump handle up and down. As a result, oil is pumped into the system from the pump. At the same time, pressure builds up in the system, and the piston of the hydraulic tool moves, into which we pump oil.

- In a situation where the working piston of the system into which oil is poured reaches its final position, increased pressure will be created in the system, as a result it will be impossible to pump oil. Then it is necessary to stop the pump to avoid failure of the device.

- In order to lower the pressure in the system, you need to slowly turn the valve all the way counterclockwise. As a result, oil from the system will flow back into the pump. This occurs due to the return of the piston to its original position.

- After finishing pumping oil, you should inspect the hydraulic system for oil leaks, and you should also inspect the pump. If leaks are found, they should be corrected immediately.

Malfunctions and their elimination

- The manual hydraulic pump does not supply pressure. The main reasons for this behavior may be the lack of hydraulic fluid in the tank or the drain valve is not closed. In any case, it is worth checking these versions; if the tap is still closed and there is liquid, then perhaps the reason is that the suction or discharge valve is clogged. Then you will have to disassemble and wash the hydraulic pump valves.

- Oil (hydraulic fluid) is leaking in the gap located between the body and the plunger. In this case, it is highly likely that the O-rings are worn out or damaged. It is recommended to replace them immediately to prevent failure.

- Does not produce the performance specified in the data sheet. Most likely the filter element of the manual hydraulic pump is clogged. It is recommended to thoroughly rinse the filter element.

- Does not develop the pressure specified in the technical data sheet. The safety valve is not adjusted correctly. You need to set the safety valve to the pressure indicated in the data sheet.

Culinary uses of a jack press

At the first stage, an accurate drawing is made, which should include all design elements. Their operational and technical characteristics are taken into account - overall dimensions, steel thickness, load capacity.

Before this, you need to choose the optimal set of tools and consumables. To process and weld metal structures, you will need a welding machine, a powerful drill, and a set of bolts and nuts. Blanks for a manual hydraulic press can be formed using a self-generator or an angle grinder. In order to secure the unit, holes will need to be made in its base.

Recommendations for assembling the machine:

Frame. The frame consists of 6 channels. The connection is made in two ways: welding and mechanically using screws;

auxiliary table. The optimal design is to install two channels with a gap between them;

How to choose the right hydraulic manual pump?

Choice

Three main selection factors:

1. The hydraulic pump tank must be larger than the hydraulic cylinder capacity.

2. Manual hydraulic pumps come in two types: single-acting and double-acting, pay attention to this parameter.

3. The pressure level should match what you need for work. Select a hydraulic pump with a pressure equal to or greater than the maximum pressure of the hydraulic cylinder.

Is it worth making a manual hydraulic pump yourself?

At the moment, hand-made pumps are almost never found. Despite this, you can make a hydraulic pump with your own hands. We will need a steel tank. The body will be made from it. To control the pressure in the tank you need a valve. It needs to be secured at the top with a washer. A lever is installed to control the closing valve. A cast iron pipe may be suitable. Use a pressure gauge to monitor pressure. In the end, you will end up with a device that will not withstand pressure of more than 4 atmospheres. With all this, a homemade hydraulic pump will take up a lot of space and be inconvenient to carry. The disadvantage of homemade hand pumps is their low efficiency; quite a lot of force will be required to activate the pump. Also, homemade devices are very unreliable. And if you take into account all the disadvantages, then spending resources on creating a homemade manual hydraulic pump is very ineffective. That is why they are not common.

Tools and materials

If you are going to make a hydraulic press with your own hands, then you will need the following tools, consumables and equipment:

- welding equipment;

- electrodes;

- metal hacksaw or grinder (angle grinder).

In addition, you will need the following elements that will make up your future garage press: a hydraulic jack, two springs that will pull the movable platform to its original state. If you find an old bridge fungus in your garage left over from a renovation, it can be used as an element of a pulling device for homemade presses with a lower jack. In this case, the fungus is put on the jack rod, the upper part of the springs is attached directly to it, and the lower part is fixed to the frame.

The type and quantity of materials required to build a press greatly depends on the chosen design option.

In order to make a press from a jack, you will need the following rolled metal:

- channels (no less than 8 numbers), rectangular or square pipes (with dimensions no less than 40x40), corners with a shelf width of no less than 50 mm;

- a steel sheet with a thickness of at least 8 mm, which will be used as a reliable foundation for the entire structure;

- a piece of steel strip 10 mm thick - for the manufacture of guides and stiffeners, if necessary;

- a piece of pipe - for making sockets for the head of the jack rod.

Manual hydraulic pumps NRG

NRG hydraulic pumps are very reliable devices and are very common here in Russia as they are produced here. The NRG line of pumps contains devices with distributors. The letter “P” is usually placed at the end of the designation of such instruments. This letter means that the tool can work with double-acting hydraulic devices. Let's consider several models of NRG manual hydraulic pumps:

NRG pumps

- Model nrg-7020R. Creates a maximum pressure of 700 bar. And it has a nominal tank volume of 2 liters. The kit includes a hydraulic distributor that allows you to work with both single- and double-acting devices.

- Model nrg-7007. Also creates a pressure of 700 bar. The nominal tank volume is 0.7 liters. The advantages of this model are the presence of a safety valve, minimal force on the handle, and two stages of oil supply. This tool is designed for single-acting hydraulic tools with a spring return rod.

- Model nrg-67016R. The nominal tank volume is 14 liters. Handle force 55 kg. Pressure maximum 4 MPa. Capacity is 115 cubic cm. Such a device weighs as much as 30 kg and is quite large. Suitable for a small car service.

Purpose of manual models

The main purpose of using pump-type equipment is to pump water from a source to certain points: to a residential building, bathhouse, garage, garden. In suburban areas, the source most often is wells and wells, less often - ponds and other bodies of water.

All residential or country houses can be divided into three categories: permanent, seasonal and periodic residence. Not all of them have electricity, and some are supplied irregularly.

If we summarize all these factors, we can draw the following conclusions:

- in permanent residences, electricity is used by default, so the main equipment for pumping water is an electric pump, and the manual model is a spare backup unit;

- if the cottage is used only in the summer and power lines are connected, then the energy-dependent option is also ideal, and the manual device plays a secondary role;

- a summer cottage without electricity most of all needs manual equipment.

To irrigate 2-3 flower beds, you can still draw water with buckets, but to ensure complete and daily watering of beds, greenhouses and lawns, a pump is needed. This is where a model that requires a pair of hands to operate comes in handy.

You can make a simple speaker yourself by using the skills of welding and assembling metal or plastic parts.

An example for making your own model can be a factory product assembled from durable cast iron or steel parts, with a comfortable handle for use

Some craftsmen build reliable equipment for wells and wells that serves well for years. We present an overview of homemade products, for the manufacture of which scrap materials were used.

Summary, pros and cons of hydraulic hand pumps.

Pros:

- Easy to use;

- Do not require any additional energy source;

- High maintainability;

- Have high mobility;

Minuses:

- Low performance;

- Muscular strength of the operator is needed, therefore, additional load on the operator;

Bottom line, it is reasonable to use a manual hydraulic pump in small workshops and mobile services, where there is no need to pump in large volumes of oil and build up significant pressure. In general, hand pumps are very convenient, and most importantly, they are mobile since they do not depend on any energy sources.