We have been creating our product for more than 5 years, and we strive to make it better every day. We are finalizing the engineering design and improving the quality of the materials used. We have more than 1000 satisfied clients. Our enclosure is not a hut or a box for a generator, but a real home for a gasoline, diesel or gas generator. It can be used all year round due to unique options. A fully thought-out and automated solution for the autonomous use of a generator. Outdoor service life more than 15 years.

Containers for generators of our production are available all over Russia. The microcontainer for the generator can be placed on any flat surface, next to living quarters, and this will not disturb either you or your neighbors.

Our professional team of service center engineers will solve any problems related to pre-design inspection, installation, commissioning and provide service for generators.

A diesel generator in a casing allows it to be placed near a house or cottage; it operates very quietly. Our team has extensive experience in packaging gasoline and diesel generators

The lineup

| Series "Silent" | Series "Super Silent" | Series "Diesel" |

| EK – 1200 Silent | EK-1400 Super Silent | EK – 2100 Diesel |

| EK – 1400 Silent | EK-1500 Super Silent | |

| EK – 1600 Silent |

You can choose your own unique color, or from the popular ones suggested below. The delivery time for a product with “its own” color is from 2 to 7 days.

The winter kit allows you to keep your electrical installation in “hot standby”; it is ready to start at any time, despite the cold. Warm-up time is reduced without compromising engine life.

Where to place the generator in the country? Big problem with choosing a place

Recently, more and more often you can find houses or cottages equipped with power plants. The main advantage of an autonomous generator is that it is possible to provide electricity to an object located at a distance from a populated area. For privacy with nature, many people move to remote areas where there is no electricity or running water. If water can be provided to a family using a borehole or a well, then gasoline or diesel generators are used as a power plant.

Photo: Casing for the generator. Author: Artemy Ivanov

A power plant, like any other internal combustion engine, produces a sound during operation, which not only interferes with constant operation, but can also lead to negative consequences. Unfortunately, an engine that will not make noise during operation has not yet been invented, so options for soundproofing the generator should be considered.

Enclosed generators

This section includes catalogs of the most popular, in-demand models in various categories. All categories include street models. For easy searching, use the tags below. The upper block is “portable electrical units”, the lower block is “diesel generators in a casing”.

| *Gasoline generators in a mini container *Gasoline generators in casing with automatic transfer switch 6-10 kW *Quiet outdoor generators *Ready-made kits with AVR for cottages |

| Diesel engines in casing with automatic transfer switch 6-16 kW DGS with Kubota engine for home Electrical installations for 10-30 kilowatts Low-cost diesel units in a casing |

How to decorate a generator house outside

Despite the small size of the generator room, it also belongs to the small form of architecture. That is why the right solution for you will be high-quality exterior decoration of the house. This includes the outlines of the house, its external design, and the selection of colors, which should be harmonious in relation to the rest of the objects on the site.

To make the generator house fit as harmoniously into the overall atmosphere of the garden or lawn as possible, plant low-growing shrubs around it. It is desirable that their crown be as dense and dense as possible. A good idea is to decorate the walls of the generator room with climbing plants. In addition to decoration, this move will allow you to protect the house from bright sun rays and heat, and also, vine plants will create additional shade for the building. In winter, such plants will provide excellent protection from strong winds and drafts.

If you need temporary storage for the generator, there is an easier way to do this. A simpler construction will suit you. However, do not forget that in such a situation you will need to turn on the generator exclusively in the fresh air.

Installation and installation of the product

To install the electric generator into the casing yourself, you must:

- Mount the battery holder and install it

- Place the electrical unit in the casing and secure it inside, so that the unit does not touch the battery, leaving space between the convector and a place to connect the plugs to the electric generator itself.

- Install a safety temperature sensor on the electrical unit

- Attach the unit to the floor or to special metal crossbars

- Cut a hole for the exhaust pipe and secure it with 3.2*10 mm rivets in the color of the casing (previously cover the area where the pipe body fits with a sealant along the contour)

- Thermally insulate the flexible exhaust pipe (preferably with fiberglass tape for exhaust manifolds), tighten the tape with worm clamps.

- Install the pipe and tighten it with power clamps on both pipes.

- Insert the cable (control, power, auxiliary needs), put it in the corrugation, make the connection, fix the cable inside the casing (if the ATS is built into the casing, insert the corrugation into the cable glands and tighten).

Precautionary measures

The battery terminals should not touch metal parts or the fan housing. The fastening must be on the reverse side of the terminals. It is better to mount the unit and the battery holder inside the product using 5-6 mm exhaust nuts. The gas exhaust tape will burn in the first 15-30 minutes, do not be alarmed by the smoke from it, it will soon stop. The cables and convector should not touch the gas exhaust, the temperature of the exhaust gases reaches 400 Celsius.

Attention! Do not store oil, fuel, watering cans, rags, etc. in the casing. For comfortable refueling of the power station, use a compact fuel pump with outlet. Do not refuel the unit while it is running!

Where to start building a generator house

You should start building a generator room by choosing a location for the future house. It is advisable that it is not too far away, but not too close to a residential building in order to avoid unforeseen situations.

Before starting construction, we recommend finding a 2x2 meter site. Why? Because practice shows that for your convenience, the generator room should be slightly larger than the generator itself by about 70 cm in each direction. That is, as a result we will get dimensions of approximately 2x2 meters. As for the height of the room, it should not be more than 2 meters.

Once you have decided on the location for the future generator house, you can proceed directly to its construction. A rough outline of this process should be organized as follows:

- Remove 10 meters of the top layer of soil to form an even pit.

- Pour sand into the resulting depression and compact it thoroughly.

- Lay 2-3 layers of roofing felt on top of the sand. It will provide reliable protection to the house from excessive moisture penetrating inside.

After this, proceed to laying the foundation. If you have a mini-power plant, you will need to make box-shaped formwork from the boards. Install reinforcement inside it, and then lay concrete. The height of such a slab should be from 12 to 15 cm.

If you have a diesel power plant with a power of 10 kW or more, then you will have to use reinforced concrete for the foundation (its mass must be at least 1.5 times the mass of the unit itself).

Such a foundation will be able to dampen vibrations of the generator during its operation. And that is why it is recommended to securely fasten the latter to a concrete slab in any way convenient for you. Also, do not forget to place anchors in the foundation. In the future, you will attach the frame of the house to them.

Advantages

| For convenience and safety, the top cover of the product is held by gas lifts, with a slight tilt forward. When refueling or servicing, this is especially important, as it prevents a gust of wind from closing it. To open, you need to lift the lid about 30 degrees, then it opens by itself. The gas exhaust pipe is supplied with the product and can be installed anywhere in the housing, depending on the configuration of the electric generator. The pipe is painted with temperature-resistant paint, and a seal is installed along the contour. The shape of the insert pipe works as a thermal compensator, preventing excessive heating in the areas adjacent to the body. |

| For models of the “Silent” series, there is an internal compartment for installing an automatic start unit. The compartment has a high degree of protection. On the outside it is protected by a door with a seal; on the inside, the cables are inserted through sealed inputs. In this configuration, the unit performs the function of an energy module. Allows you to make a connection directly on the street from a pole or at the place where cables enter the house. Since the main operating mode is automatic, for monitoring and control it is not necessary to constantly access the unit, but only to switch modes when refueling or servicing. |

| Powerful ventilation is the key to long-term operation of the generator in the casing. The fan serves to remove the heat generated by the unit. All outdoor products use high-performance BLAUBERG fans, starting from 2350 m3/hour. For single-cylinder models that do not have an oil pump, when operating for more than 4 hours without effective heat removal, the oil dilutes almost to the state of water and falls under the inlet valve. After the electrical installation cools down, the deposit hardens and will not start without removing the valve cover and cleaning the valve. |

| All locks: side doors, top cover and door to access the control unit are closed with one key. The delivery set includes 2 sets of 2 keys. The door hinges have hidden fastenings. Along the contour of the openings, a reinforced wear-resistant rubber seal is installed, like in cars. Cable entry is carried out through holes in the bottom. There are two of them, dimensions 40*60 mm. One at each end, located at the edge of the bottom on the front side. The legs have holes for fastening to a concrete platform. |

| Sound insulation consists of two parts - top and bottom. The bottom is made of compressed mineral wool, 35 mm thick. The top is made of non-flammable material K - FLEX (rubber). The latter has high noise-attenuating properties and a porous structure, which, unlike foam rubber impregnated with non-flammable chemicals, retains its properties at any temperature and will not catch fire even after contamination with machine oil or other fuels and lubricants. The noise level of the electrical unit in such a product is 12-15 dB lower, depending on the model. The quietest of the Silent series is the EK-1400 model. |

Generator house design

Uninterrupted operation of the generator room will be possible only when you can constantly maintain the temperature inside not lower than +5°C. It is considered optimal for high-quality and uninterrupted operation of the unit. That’s why it’s so important to insulate the building.

Frame

For the frame of the generator room, we recommend that you use a steel angle. It can be attached to the anchors that we mentioned earlier and which you should have secured while laying the foundation.

A profiled metal sheet is welded to the internal and external posts with a distance of 10 cm between each. Afterwards, fill the resulting free space with high-quality heat-insulating material. Mineral wool, which is comparable in thermal characteristics to brickwork, is a good choice.

You will also need angle steel for the roof frame. It is necessary to lay metal sheets on its shelves, and put insulation on top of them. The roof itself should be made of metal tiles.

Door and platform to the generator

The width of the door to the generator room should be between 60 and 70 cm wide. Make the area between the doors and the generator itself 1x2 m in size. Between its other sides the distance can be smaller - from 50 to 60 cm.

Inside, be sure to finish the walls with special paint that will prevent the metal sheets from rusting. This way you will not only achieve a pleasant interior design, but will significantly extend the life of the house itself.

Ventilation

Any generator room must have a good ventilation system. The easiest way to do this is to take a pipe out of the house (we recommend a 10 cm galvanized iron pipe). If your power plant is air-cooled, you will need a forced ventilation system. Such a fan will need to be mounted either into the wall or directly into the air duct. In this case, the fan can perform quite different functions:

- blow on the engine of the unit;

- remove excess hot air.

If the power of your installation is below 6 kW, you will need to install at least 2 fans (each with a capacity of 1000 m3/h). They should turn on and off automatically during the start and end of operation of the generator engine.

Don’t forget about “bottom” ventilation, which is formed due to the leaky connection of the wall to the floor. This way, the exhaust gas, which will contain an excessive amount of carbon dioxide, can easily “leak” out of the generator room. The same applies to gasoline vapors, the accumulation of which can cause a fire or even an explosion. As you may have guessed, this is precisely the main reason why you should not “immerse” the generator house too much in the ground.

Additionally, you can hang shelves in your building where you will store your tools or containers with additional fuel. The brackets for them can be safely mounted on the wall of the structure.

Note! In addition to the process of building a generator house itself, it is very important to provide you and the specialists with the opportunity to comfortably service the generator. Therefore, here are a couple more points that should not be forgotten.

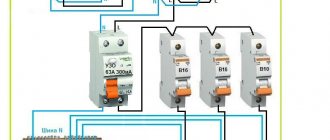

1. Switch

Before turning on the generator, the switch must disconnect the house from the main network. Therefore, it should be in a convenient place and preferably in your sight. Do not forget also about its careful isolation from metal surfaces and other objects.

2. Automation

Almost any generator can be equipped with automation (if it is not provided for during production, of course). Such an automatic reserve input device will independently respond to power surges in the network. This will prevent your generator from running idle.

Please note that when you switch the generator, the voltage in the network will most likely drop briefly. During this period, it is advisable to provide particularly sensitive devices with an additional power stabilizer (computer, telephone, etc.). It will just allow you to maintain the correct voltage level required for the operation of electrical appliances for several minutes.

You can use a classic UPS as a stabilizer. In addition, any uninterruptible power supply, in principle, will become a good protector during voltage surges in the network in your country house.

Spot sound insulation method

As a rule, the generator has several points of contact with the surface. It is through these areas that vibration occurs, which can be transmitted even through hard surfaces: metal, concrete and other surfaces. As an alternative solution, each element that produces vibration can be silenced using soundproofing devices. Currently, some manufacturers offer ready-made soundproofing structures. By placing the device inside the structure, an additional noise insulation barrier is created, as a result of which noise and vibration are significantly reduced. It is important to carefully study the design characteristics so that difficulties do not arise during operation.

conclusions

We talked about the basic principles of constructing a container for a generator and the features of its operation. If you approach the matter wisely and with straight hands, then, on your own, you can make a box that is in no way inferior to factory models and, most importantly, cheaper. If you still have questions, we recommend that you go to the topic Mini container for a generator and ask them to the author of the box. The topic also presents several more models of homemade containers for gas generators.

Articles that will be useful:

Ventilation device

Good ventilation must be ensured in the generator room. To do this, in the simplest case, you can extend a galvanized iron pipe 0 10 cm outside the roof. But houses built for air-cooled electrical installations require forced ventilation. The fans are installed in the air duct or

built into the wall. Their functions are different: some blow on the running engine of the power plant, others remove hot air from the room.

So, for a portable installation with a power of 6 kW, it is advisable to install two fans with a capacity of 1,000 m3/h each. They turn on only when the generator starts and turn off automatically when the engine stops.

It is also necessary to make “bottom” ventilation - a leaky connection between the walls and the floor.

This is necessary so that exhaust gases with a high content of carbon dioxide, which are heavier than air and therefore accumulate below, “flow out” through these leaks from the room. The same applies to gasoline vapors, the accumulation of which can lead to an explosion and damage to all equipment.

From the above, it is clear that the structure for the generating set should not be buried in the ground, since this can lead to the accumulation of exhaust gases and gasoline vapors in the room.

In the generator room you can place shelves for storing tools and additional fuel containers. The brackets supporting the shelves are attached directly to the walls of the house.

An important detail is the switch that disconnects the cottage from the main network before turning on the generator. It should be placed in a visible place on the wall and well insulated from metal surfaces and objects. This safety measure will protect those who maintain the power plant from unexpected power resumption.

Global methods of sound insulation

To suppress the noise level of a running generator at an enterprise, it is necessary to use a separate room. The thing is that the generator power produces high noise, which interferes with operation. An existing structure can be used as a room for the generator or a new structure can be erected. The main requirement of the constructed structure is effective sound insulation. Sip panels, mineral wool or basalt slabs can be used as insulating material. Today the market offers a large selection of soundproofing materials, among which you can choose exactly what you need.

Photo: The generator can be placed outside, isolating it in a special box. Author: Artemy Ivanov

If an existing structure is used, then high-quality noise insulation of the generator must be installed in it. Interior wall decoration is made using sound-proofing and sound-absorbing materials. To decorate the walls of a room you can use: fibrous, porous materials and sip panels. A generator installed indoors will create much less sound.

Power plant noise level

As you know, sounds are transmitted in two ways: through air and vibration. When airborne noise enters the house, a person hears a roar from the engine and exhaust system. As for vibrational sound, it can be transmitted through solid bodies, creating discomfort in the room.

Photo: Sound-absorbing box for the generator. Author: Artemy Ivanov

According to experts, the noise level from a power plant is 100 dB; to make it easier to understand, you should consider which sounds are equal to what.

Loud sounds in the room can not only lower your mood, but also prevent you from resting, and as a result, this problem can lead to diseases of the nervous system. Today, with the help of soundproofing and noise-absorbing materials, you can create ideally comfortable conditions.