Technology for producing high-strength nodular cast iron

It is known that high-strength nodular cast iron (ductile iron) is produced by modifying liquid cast iron with spheroidizing modifiers containing magnesium, cerium and yttrium. Cast iron subjected to modification must satisfy a number of the requirements below, the fulfillment of which is the task of melting.

Requirements for liquid cast iron.

The most important requirement for the chemical composition of liquid metal when producing high-strength cast iron with nodular graphite is a low sulfur content - up to 0.03%. In this case, a decrease in sulfur content helps reduce the consumption of expensive modifiers.

The technical conditions adopted by VAZ and KamAZ allow a sulfur content of no more than 0.012%. It is almost impossible to create a charge with such a low sulfur content, so the most important task of smelting is desulfurization. In this regard, the use of arc foam with the main lining for melting in this case is justified, despite the high dust and gas emissions and noise.

When laying the main slag, it is recommended to add lime (6 kg/t of metal) to reduce the excess amount of sulfur by 0.001%. The content of demodifiers Pb, Bi, Sn, Sb, As, Ti, Al in cast iron, even in small quantities, prevents the spheroidization of graphite. Taking this into account, careful selection of charge materials is required. The use of scrap of unknown origin is not permitted. In addition to primary materials and return, steel waste from forging and pressing production is used.

The temperature of cast iron during modification should be higher than when modifying gray cast iron, 1480... 1530 °C. This is explained by the fact that the evaporation of magnesium introduced into the melt requires a significant amount of heat (with the introduction of every 1% Mg, the temperature of the cast iron decreases by 80...90 ° C).

Spheroidizing modifiers.

The spherical shape of graphite in cast iron is achieved by using modifiers containing magnesium, cerium and yttrium. Magnesium-based modifiers, in turn, are divided into metallic magnesium and magnesium-containing alloys. Magnesium metal has a density 4 times less than molten cast iron, so when simply introduced into the metal, it floats to the surface and burns with a blindingly bright flame. When it is forcibly immersed in molten cast iron at a temperature of 1400 °C, magnesium evaporates and its vapor pressure can reach 0.7 MPa. Magnesium vapor coming out of the melt causes intense mixing and emissions of the metal. Magnesium vapor burns above the surface of the melt. Typically, no more than 1/10 of the amount of magnesium introduced into it remains in the metal.

To improve the absorption of magnesium by the melt containing alloys , magnesium-silicon-iron, magnesium-nickel, magnesium-copper, magnesium-nickel-copper, etc., are used. Heavy alloys containing about 85% nickel were especially widespread in their time. The density of such a master alloy is higher than that of liquid cast iron, which, combined with a relatively low magnesium content, determines its good absorption and insignificant pyroeffect.

However, nickel is returned to the charge as part of the return and practically does not burn up during the smelting process. Considering that the share of return in the production of ductile iron is at least 40%, the nickel content in the metal increases rapidly from heat to heat if more than 10% return is used in the charge. This creates organizational difficulties associated with the use of excess return of cast iron modified with nickel-magnesium alloy.

Taking into account the bleaching effect of magnesium, secondary modification is carried out with ferrosilicon FS75 in an amount of 0.3 to 1%, depending on the thickness of the casting wall.

Cerium modifiers . The boiling point of cerium is about 3450 °C, therefore, when it is introduced into the cast iron melt, no metal emissions are observed, and, in addition, the temperature of the melt can be lower (1390... 1410 °C). However, to distribute it evenly, forced mixing of the metal is necessary.

Cerium, like magnesium, is an active desulfurizer, but unlike magnesium, it does not form black spots in the structure of castings with high sulfur content in the original cast iron.

To produce high-strength cast iron with nodular graphite, cerium is used in the form of various alloys, such as ferrocerium, mischmetal, cerium mischmetal, siitmish and others, containing about 50% Ce.

Complex modifiers, varied in composition and properties, are currently most widespread. Along with magnesium, which produces a spheroidizing effect and mixing, they usually contain silicon, which prevents bleaching. Cerium and calcium in complex modifiers help bind excess sulfur.

The FCM5 modifier containing 5% magnesium was successfully used in the casting of crankshafts of the Vladimirets tractor. In addition to iron, modifiers of the ZhKMK1 ... ZhKMK10 brands contain Mg, Ca, Si and rare earth elements.

Currently, the most widely used modifiers are FSMg5 and FSMg6, containing 5 and 6% Mg, respectively, and are used for both in-mold and ladle modification.

Spheroidizing modifiers in a crushed state cannot be stored for long periods of time, since their constituent elements are easily oxidized.

Yttrium modifiers have not yet received industrial application.

Methods for introducing spheroidizing modifiers into the melt. Of the variety of methods for introducing spheroidizing modifiers into the melt, only a few methods have been used to date that satisfy safety requirements and ensure a sufficiently high coefficient of modifier assimilation. The method of introducing the modifier is chosen taking into account the scale of production and the cost of the equipment used.

For the purposes of laboratory and research work, as well as for small production volumes, the preferred method of introducing the modifier under the bell in a ladle with a metal lid (Fig. 1, a).

Rice. 1. Methods of introducing spheroidizing modifiers into the melt: a - under the bell; b - in an autoclave; c - in a sealed converter ladle; 1 - bell; 2 - cover; 3 — autoclave body; 4 - ladle with metal; 5—mixer; 6—cavity for modifier; 7— ladle cover; 8 - modifier

A paper bag containing a modifier is placed in a chamotte-graphite or steel bell 1 with holes in the side walls. The package is secured in the bell with binding wire. Cover 2 is put on the bell rod and installed on the ladle. The bell is lowered deep into the metal.

When using heavy nickel-magnesium master alloy, it is widely used to introduce it under the stream into the pouring ladle.

When using metallic magnesium as a modifier, the best results are obtained by using an autoclave (Fig. 1, b). A ladle with metal 4 is installed in the steel body of the autoclave 3 with the lid removed. A sample of magnesium is placed in the cavity 6 of the lid and closed with a stirrer 5. The lid is installed on the autoclave body, the joint between them is sealed. There is also a sealing collar between the cover and the stirrer rod. After air is supplied to the autoclave under pressure P, the pneumatic cylinder lowers the stirrer down, while the modifier falls into the metal, which is mixed during the reciprocating movement of the stirrer.

Sealed Buckets are also widely used, the operating principle of which is shown in Fig. 1, c. A sample of modifier 8 is placed into the side cavity of the ladle. After pouring the metal, the ladle is closed with a lid and turned to a vertical position.

It has been established that the minimum amount of residual magnesium required to obtain a spherical form of graphite in cast iron in any section of the casting must be at least 0.03%. Taking into account the absorption coefficient of the modifier, the amount of magnesium introduced with the modifier should be about 0.4%. When using complex spheroidizing modifiers, the total content of magnesium, calcium and rare earth elements in them should be equivalent to the magnesium content indicated above.

The consumption of the modifier depends on its composition, the method of introduction into the metal, the sulfur content in the metal, the temperature of the metal and other factors and ranges from 0.15% for magnesium metal introduced in an autoclave to 2.5% for alloys when added to a ladle. The necessary and sufficient amount of the introduced modifier can only be determined experimentally.

Ductile iron

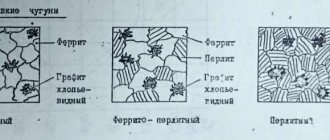

High-strength cast irons are those in which the graphite has a spherical shape. They are obtained by modification with magnesium, cerium, yttrium, which are introduced into liquid cast iron in an amount of 0.02-0.08%. According to the structure of the metal base, high-strength cast iron can be ferritic (up to 20% perlite is allowed) or pearlitic (up to 20% ferrite is allowed). Nodular graphite is a weaker stress concentrator than lamellar graphite, therefore it reduces the mechanical properties of cast iron less (Fig. 8.). Ductile iron has higher strength and some ductility.

High-strength cast irons are marked according to GOST 7293-85 with the letters HF and a two-digit number indicating the minimum tensile strength value in tens of megapascals. For example, high-strength cast iron VCh 40 has a tensile strength of 400 MPa, relative elongation of at least 10%, hardness HB = 1400-2200 MPa, ferrite-pearlite structure. Marking according to the previous GOST 7293-79 provided for an additional indication of the relative elongation in percent, for example, HF 40-10.

Typical composition of ductile iron: 2.7-3.8% C; 1.6-2.7%Si; 0.2-0.7% Mn; £0.02%S; £0.1%R.

High-strength cast iron is used to make rolling rolls, forging equipment, steam turbine housings, crankshafts and other critical parts that operate under high cyclic loads and wear conditions.

A

b

V

Rice. 8. Microstructure of high-strength cast iron on a ferritic (a), ferrite-pearlitic (b) and pearlitic (c) basis.

Malleable iron

Malleable cast irons are those in which the graphite has a flaky shape. They are produced by special graphitizing annealing (simmering) of castings from white hypoeutectic cast iron. The castings are loaded into special boxes, covered with sand or steel shavings to protect them from oxidation, and heated and cooled according to the scheme (Fig. 9). At a temperature of 950 -1000°C, graphitization of eutectic and secondary cementite occurs (transformation of metastable cementite into stable graphite and austenite). During the second holding at a temperature of 720 - 740°C, the cementite of the resulting perlite is graphitized (sometimes instead of holding, slow cooling from 770°C to 700°C is carried out for 30 hours, during which crystallization occurs according to a stable diagram with the release of carbon in a free state). As a result of prolonged annealing, all carbon is released in a free state.

The usual composition of malleable cast iron is 2.4-2.8% C; 0.8-1.4%Si; ≤1% MP; ≤0.1%S; ≤ 0.2% R. Structure - ferritic or ferrite-pearlite (Fig. 10).

The absence of casting stresses relieved during annealing, the favorable shape and isolation of graphite inclusions determine the high mechanical properties of malleable cast irons.

Malleable cast irons are marked according to GOST 1215-79 with the letters KCH and two numbers, the first of which is the minimum tensile strength in tens of megapascals, and the second is the relative elongation in%. For example, cast iron KCh 45-6 has a tensile strength of 450 MPa, relative elongation δ = 6%, HB = 2400 MPa and a structure of ferrite + pearlite.

Rice. 9. Scheme for annealing white cast iron to ductile cast iron.

Ductile cast iron is used to make high-strength parts that operate under severe wear conditions and are capable of withstanding shock and alternating loads, including valves, couplings, gear housings, crankshafts, etc.

Fig. 10. Microstructure of malleable cast iron on a ferritic (a) ferrite-pearlite (b) basis.

Alloy steels

Simple carbon steels do not always satisfy technical requirements. Alloy steels are widely used in industry, which have high mechanical or special physical and chemical properties acquired after appropriate heat treatment. Alloyed steels are steels in which certain amounts of necessary elements are specially added to obtain the required properties. Chromium, nickel, manganese, silicon, tungsten, vanadium, molybdenum and others are used to alloy steel.

When studying the influence of alloying elements on the properties of steel, it is important to know the interaction of the alloying element with iron and carbon, as well as the influence of alloying elements on the polymorphism of iron and transformations into steel during heat treatment.

Influence of elements on polymorphism.

All elements that dissolve in iron affect the temperature range of existence of its polymorphic modifications.

Most elements either expand the region of existence of the γ-modification (Fig. 2.1a) or expand the region of existence of the α-modification (Fig. 2.1b).

From the schematic diagrams of the state of iron - alloying element (Fig. 2.1) it follows that when the content of manganese and nickel is above a certain amount (c) (Fig. 2.1a), the γ-state exists as stable from the melting point to room temperature. Such iron-based alloys are called austenitic. When the content of vanadium, molybdenum, silicon and other elements exceeds a certain value (d), the α-state is stable at all temperatures (Fig. 2.1b). Such iron-based alloys are called ferritic. Austenitic and ferritic alloys do not undergo transformations when heated and cooled.

Rice. 11. Scheme of state diagrams of iron - alloying element.

Distribution of alloying elements in steels.

In industrial alloy steels, alloying elements can:

be in a free state: lead, silver, copper (if it is not more than 1%) do not form compounds and do not dissolve in iron;

form intermetallic compounds with iron or with each other with a high content of alloying elements, found mainly in high-alloy steels;

form oxides, sulfides and other non-metallic inclusions - elements that have a greater affinity for oxygen than iron. During the steel production process, such elements (for example, Mn, Si, Al), introduced at the last moment of smelting, deoxidize the steel, taking oxygen away from the iron. The amount of oxides, sulfides and other non-metallic inclusions in conventional industrial steels is small and depends on the smelting method;

dissolve in cementite or form independent carbide phases. Carbide-forming elements can be elements that have a greater affinity for carbon than iron (elements located in the periodic table of elements to the left of iron): Ti, V, Cr, Mn, Zr, Nb, Mo, Tc, Hf, Ta, W, Re . These elements, in addition to forming carbides, dissolve in iron. Consequently, they are distributed in a certain proportion between these two phases;

dissolve in iron - most alloying elements. Elements located in the periodic table to the right of iron (Cu, Ni, Co, etc.) form only solutions with iron and are not included in carbides.

Thus, alloying elements preferentially dissolve in the main phases of iron-carbon alloys - ferrite and austenite, as well as cementite or form special carbides.

The influence of alloying elements on ferrite and austenite.

The dissolution of alloying elements in α,g-iron occurs by replacing iron atoms with atoms of these elements. Atoms of alloying elements, differing from iron atoms in size and structure, create stresses in the lattice that cause a change in its period. A change in the dimensions of the α,g lattice also causes a change in the properties of ferrite and austenite. Lattice distortion hinders the movement of dislocations. These factors cause hardening called solid solution.

As an example, Fig. 2.2 shows the change in the mechanical properties of ferrite (hardness, impact strength) when various elements are dissolved in it.

A

b

Rice. 12. Influence of alloying elements on the properties of ferrite a – hardness; b - impact strength

As can be seen from the diagrams, chromium, molybdenum, and tungsten strengthen ferrite less than nickel, silicon, and manganese. Molybdenum, tungsten, manganese and silicon reduce the viscosity of ferrite. Chromium reduces the viscosity much weaker than the listed elements, and nickel does not reduce the viscosity of ferrite.

The influence of elements on the cold brittleness threshold, which characterizes the tendency of steel to brittle fracture, is important. The presence of chromium in iron contributes to a slight increase in the cold-brittleness threshold, while nickel intensively reduces the cold-brittleness threshold, thereby reducing the susceptibility of iron to brittle fractures.

The data given refers to slowly cooled alloys.

Carbide phase in alloy steels.

In steels, carbides are formed only by metals located in the periodic table of elements to the left of iron. These metals have a less complete d-electron band. The further to the left the carbide-forming element is located in the periodic system, the less complete its d-band is. At the same time, numerous experiments show that the further to the left an element is located in the periodic table, the more stable the carbide.

During the process of carbide formation, carbon donates its valence electrons to fill the d-electron band of the metal atom. Only metals with a d-electron band less filled than iron are carbide-forming; Their activity as carbide formers is stronger and the stability of the resulting carbide phases is greater, the less complete the d-band of the metal atom is. In fact, we encounter only six types of carbides in steels:

| M3C | Group I carbides | M.C. | Group II carbides |

| M23C6 | |||

| M7C3 | M2C | ||

| M6C |

where M means the sum of carbide-forming elements.

Carbides classified in group I have a complex crystal structure. The peculiarity of the structure of group II carbides is that they have a simple crystal lattice and usually crystallize with a significant carbon deficiency. Group II carbides are poorly soluble in austenite. This means that when heated (even very high), they may not go into a solid solution. Group I carbides easily dissolve in austenite.

All carbide phases have a high melting point and high hardness. Carbides of group II in this respect are superior to carbides of group I.

The order of dissolution of carbides in austenite is determined by their relative stability, and the degree of transition into solution is determined by their quantity.

Classification of alloy steels.

Alloy steels can be classified according to four criteria: by equilibrium structure (after annealing), by structure after cooling in air (after normalization), by composition and by purpose.

Classification by equilibrium structure

- Hypoeutectoid steels having excess ferrite in their structure.

- Eutectoid steels having a pearlitic structure.

- Hypereutectoid steels having excess (secondary) carbides in their structure.

- Ledeburite steels have primary carbides in their structure, separated from the liquid phase. In cast form, excess carbides together with austenite form a eutectic - ledeburite, which, during forging or rolling, is broken into separate carbides and austenite.

- Ferritic steels.

- Austenitic steels.

Most alloying elements shift points S and E (on the Fe - C diagram) towards lower carbon content, therefore the boundary between hypoeutectoid and hypereutectoid steels, hypereutectoid and ledeburite - in alloy steels lies at a lower carbon content than in carbon steels.

Classification by structure after cooling in air

Based on the structure obtained after cooling samples of small thickness in still air, three main classes of steel can be distinguished: 1. pearlitic; 2. martensitic; 3. austenitic.

Pearlitic steels are characterized by a relatively low content of alloying elements, martensitic steels have a more significant content, and, finally, austenitic steels have a high content of alloying elements. The production of these classes of steel is due to the fact that as the content of alloying elements increases, the stability of austenite in the pearlitic region increases, and the temperature region of the martensitic transformation decreases.

Classification by composition.

Depending on the composition, alloy steels are classified as nickel, chromium, chromium-nickel, etc. A classification feature is the presence of certain alloying elements in steel.

Depending on the number of alloying elements:

- low-alloy – the total amount of alloying elements does not exceed 3%.

- medium alloyed - the total amount of alloying elements from 3% to 10%.

- highly alloyed - the total amount of alloying elements is more than 10%, but less than 50%.

High-strength cast irons are those in which the graphite has a spherical shape. They are obtained by modification with magnesium, cerium, yttrium, which are introduced into liquid cast iron in an amount of 0.02-0.08%. According to the structure of the metal base, high-strength cast iron can be ferritic (up to 20% perlite is allowed) or pearlitic (up to 20% ferrite is allowed). Nodular graphite is a weaker stress concentrator than lamellar graphite, therefore it reduces the mechanical properties of cast iron less (Fig. 8.). Ductile iron has higher strength and some ductility.

High-strength cast irons are marked according to GOST 7293-85 with the letters HF and a two-digit number indicating the minimum tensile strength value in tens of megapascals. For example, high-strength cast iron VCh 40 has a tensile strength of 400 MPa, relative elongation of at least 10%, hardness HB = 1400-2200 MPa, ferrite-pearlite structure. Marking according to the previous GOST 7293-79 provided for an additional indication of the relative elongation in percent, for example, HF 40-10.

Typical composition of ductile iron: 2.7-3.8% C; 1.6-2.7%Si; 0.2-0.7% Mn; £0.02%S; £0.1%R.

High-strength cast iron is used to make rolling rolls, forging equipment, steam turbine housings, crankshafts and other critical parts that operate under high cyclic loads and wear conditions.

A

b

V

Rice. 8. Microstructure of high-strength cast iron on a ferritic (a), ferrite-pearlitic (b) and pearlitic (c) basis.

Malleable iron

Malleable cast irons are those in which the graphite has a flaky shape. They are produced by special graphitizing annealing (simmering) of castings from white hypoeutectic cast iron. The castings are loaded into special boxes, covered with sand or steel shavings to protect them from oxidation, and heated and cooled according to the scheme (Fig. 9). At a temperature of 950 -1000°C, graphitization of eutectic and secondary cementite occurs (transformation of metastable cementite into stable graphite and austenite). During the second holding at a temperature of 720 - 740°C, the cementite of the resulting perlite is graphitized (sometimes instead of holding, slow cooling from 770°C to 700°C is carried out for 30 hours, during which crystallization occurs according to a stable diagram with the release of carbon in a free state). As a result of prolonged annealing, all carbon is released in a free state.

The usual composition of malleable cast iron is 2.4-2.8% C; 0.8-1.4%Si; ≤1% MP; ≤0.1%S; ≤ 0.2% R. Structure - ferritic or ferrite-pearlite (Fig. 10).

The absence of casting stresses relieved during annealing, the favorable shape and isolation of graphite inclusions determine the high mechanical properties of malleable cast irons.

Malleable cast irons are marked according to GOST 1215-79 with the letters KCH and two numbers, the first of which is the minimum tensile strength in tens of megapascals, and the second is the relative elongation in%. For example, cast iron KCh 45-6 has a tensile strength of 450 MPa, relative elongation δ = 6%, HB = 2400 MPa and a structure of ferrite + pearlite.

Rice. 9. Scheme for annealing white cast iron to ductile cast iron.

Ductile cast iron is used to make high-strength parts that operate under severe wear conditions and are capable of withstanding shock and alternating loads, including valves, couplings, gear housings, crankshafts, etc.

Fig. 10. Microstructure of malleable cast iron on a ferritic (a) ferrite-pearlite (b) basis.

Alloy steels

Simple carbon steels do not always satisfy technical requirements. Alloy steels are widely used in industry, which have high mechanical or special physical and chemical properties acquired after appropriate heat treatment. Alloyed steels are steels in which certain amounts of necessary elements are specially added to obtain the required properties. Chromium, nickel, manganese, silicon, tungsten, vanadium, molybdenum and others are used to alloy steel.

When studying the influence of alloying elements on the properties of steel, it is important to know the interaction of the alloying element with iron and carbon, as well as the influence of alloying elements on the polymorphism of iron and transformations into steel during heat treatment.

Influence of elements on polymorphism.

All elements that dissolve in iron affect the temperature range of existence of its polymorphic modifications.

Most elements either expand the region of existence of the γ-modification (Fig. 2.1a) or expand the region of existence of the α-modification (Fig. 2.1b).

From the schematic diagrams of the state of iron - alloying element (Fig. 2.1) it follows that when the content of manganese and nickel is above a certain amount (c) (Fig. 2.1a), the γ-state exists as stable from the melting point to room temperature. Such iron-based alloys are called austenitic. When the content of vanadium, molybdenum, silicon and other elements exceeds a certain value (d), the α-state is stable at all temperatures (Fig. 2.1b). Such iron-based alloys are called ferritic. Austenitic and ferritic alloys do not undergo transformations when heated and cooled.

Rice. 11. Scheme of state diagrams of iron - alloying element.

Distribution of alloying elements in steels.

In industrial alloy steels, alloying elements can:

be in a free state: lead, silver, copper (if it is not more than 1%) do not form compounds and do not dissolve in iron;

form intermetallic compounds with iron or with each other with a high content of alloying elements, found mainly in high-alloy steels;

form oxides, sulfides and other non-metallic inclusions - elements that have a greater affinity for oxygen than iron. During the steel production process, such elements (for example, Mn, Si, Al), introduced at the last moment of smelting, deoxidize the steel, taking oxygen away from the iron. The amount of oxides, sulfides and other non-metallic inclusions in conventional industrial steels is small and depends on the smelting method;

dissolve in cementite or form independent carbide phases. Carbide-forming elements can be elements that have a greater affinity for carbon than iron (elements located in the periodic table of elements to the left of iron): Ti, V, Cr, Mn, Zr, Nb, Mo, Tc, Hf, Ta, W, Re . These elements, in addition to forming carbides, dissolve in iron. Consequently, they are distributed in a certain proportion between these two phases;

dissolve in iron - most alloying elements. Elements located in the periodic table to the right of iron (Cu, Ni, Co, etc.) form only solutions with iron and are not included in carbides.

Thus, alloying elements preferentially dissolve in the main phases of iron-carbon alloys - ferrite and austenite, as well as cementite or form special carbides.

The influence of alloying elements on ferrite and austenite.

The dissolution of alloying elements in α,g-iron occurs by replacing iron atoms with atoms of these elements. Atoms of alloying elements, differing from iron atoms in size and structure, create stresses in the lattice that cause a change in its period. A change in the dimensions of the α,g lattice also causes a change in the properties of ferrite and austenite. Lattice distortion hinders the movement of dislocations. These factors cause hardening called solid solution.

As an example, Fig. 2.2 shows the change in the mechanical properties of ferrite (hardness, impact strength) when various elements are dissolved in it.

A

b

Rice. 12. Influence of alloying elements on the properties of ferrite a – hardness; b - impact strength

As can be seen from the diagrams, chromium, molybdenum, and tungsten strengthen ferrite less than nickel, silicon, and manganese. Molybdenum, tungsten, manganese and silicon reduce the viscosity of ferrite. Chromium reduces the viscosity much weaker than the listed elements, and nickel does not reduce the viscosity of ferrite.

The influence of elements on the cold brittleness threshold, which characterizes the tendency of steel to brittle fracture, is important. The presence of chromium in iron contributes to a slight increase in the cold-brittleness threshold, while nickel intensively reduces the cold-brittleness threshold, thereby reducing the susceptibility of iron to brittle fractures.

The data given refers to slowly cooled alloys.

Carbide phase in alloy steels.

In steels, carbides are formed only by metals located in the periodic table of elements to the left of iron. These metals have a less complete d-electron band. The further to the left the carbide-forming element is located in the periodic system, the less complete its d-band is. At the same time, numerous experiments show that the further to the left an element is located in the periodic table, the more stable the carbide.

During the process of carbide formation, carbon donates its valence electrons to fill the d-electron band of the metal atom. Only metals with a d-electron band less filled than iron are carbide-forming; Their activity as carbide formers is stronger and the stability of the resulting carbide phases is greater, the less complete the d-band of the metal atom is. In fact, we encounter only six types of carbides in steels:

| M3C | Group I carbides | M.C. | Group II carbides |

| M23C6 | |||

| M7C3 | M2C | ||

| M6C |

where M means the sum of carbide-forming elements.

Carbides classified in group I have a complex crystal structure. The peculiarity of the structure of group II carbides is that they have a simple crystal lattice and usually crystallize with a significant carbon deficiency. Group II carbides are poorly soluble in austenite. This means that when heated (even very high), they may not go into a solid solution. Group I carbides easily dissolve in austenite.

All carbide phases have a high melting point and high hardness. Carbides of group II in this respect are superior to carbides of group I.

The order of dissolution of carbides in austenite is determined by their relative stability, and the degree of transition into solution is determined by their quantity.

Classification of alloy steels.

Alloy steels can be classified according to four criteria: by equilibrium structure (after annealing), by structure after cooling in air (after normalization), by composition and by purpose.

Classification by equilibrium structure

- Hypoeutectoid steels having excess ferrite in their structure.

- Eutectoid steels having a pearlitic structure.

- Hypereutectoid steels having excess (secondary) carbides in their structure.

- Ledeburite steels have primary carbides in their structure, separated from the liquid phase. In cast form, excess carbides together with austenite form a eutectic - ledeburite, which, during forging or rolling, is broken into separate carbides and austenite.

- Ferritic steels.

- Austenitic steels.

Most alloying elements shift points S and E (on the Fe - C diagram) towards lower carbon content, therefore the boundary between hypoeutectoid and hypereutectoid steels, hypereutectoid and ledeburite - in alloy steels lies at a lower carbon content than in carbon steels.

Classification by structure after cooling in air

Based on the structure obtained after cooling samples of small thickness in still air, three main classes of steel can be distinguished: 1. pearlitic; 2. martensitic; 3. austenitic.

Pearlitic steels are characterized by a relatively low content of alloying elements, martensitic steels have a more significant content, and, finally, austenitic steels have a high content of alloying elements. The production of these classes of steel is due to the fact that as the content of alloying elements increases, the stability of austenite in the pearlitic region increases, and the temperature region of the martensitic transformation decreases.

Classification by composition.

Depending on the composition, alloy steels are classified as nickel, chromium, chromium-nickel, etc. A classification feature is the presence of certain alloying elements in steel.

Depending on the number of alloying elements:

- low-alloy – the total amount of alloying elements does not exceed 3%.

- medium alloyed - the total amount of alloying elements from 3% to 10%.

- highly alloyed - the total amount of alloying elements is more than 10%, but less than 50%.

Describe the production of ductile and ductile cast irons

Malleable is the name given to cast iron in castings made from white cast iron and subjected to subsequent graphitizing annealing, as a result of which cementite disintegrates and the resulting graphite takes the form of flakes. Ductile iron has better damping properties than steel and is less sensitive to notches, and performs satisfactorily at low temperatures. The mechanical properties of malleable cast iron are determined by the structure of the metal base, the number and degree of compactness of graphite inclusions. The metal base of malleable cast iron, depending on the type of heat treatment, can be ferritic, ferritic-pearlitic and pearlitic. The highest properties are possessed by malleable cast iron, which has a matrix with a granular perlite structure; they can replace cast or forged steel. In cases where increased ductility is required, ferritic ductile cast iron is used. To intensify the graphitization process during heat treatment, ductile cast iron is modified with Te, B, Mg and other elements. Malleable cast iron is used mainly in automobile, tractor and agricultural machinery manufacturing. There is a tendency (especially in the automotive industry) to replace ductile cast iron with high-strength spheroidal graphite in order to increase the strength of castings, reduce the duration of the technological cycle and simplify manufacturing technology.

High-strength cast iron, characterized by a spherical or similar shape of graphite inclusions, is obtained by modifying liquid cast iron with additives Mg, Ce, Y, Ca and some other elements (in pure form or as part of alloys). Nodular graphite weakens the metal matrix to the least extent, which leads to a sharp increase in the mechanical properties of cast iron with a purely pearlite or bainitic structure, bringing their properties closer to the properties of carbon steels. A purely ferritic matrix (in a cast or heat-treated state) provides an increased level of ductility. High-strength cast iron has good casting and technological properties (fluidity, linear shrinkage, machinability), but in terms of concentrated volumetric shrinkage it is close to steel. This cast iron is used to replace cast and forged steel parts (engine crankshafts, compressors, etc.), as well as parts made of malleable or ordinary gray cast iron. High-strength cast iron containing so-called inclusions. vermicular graphite (when viewed under an optical microscope - thickened curved plates with rounded edges), in properties they occupy an intermediate position between cast iron with nodular and cast iron with flake graphite. This cast iron has good technological properties with low volumetric shrinkage and high thermal conductivity (almost the same as gray cast iron). Cast iron with vermicular graphite is used in diesel production and other areas of mechanical engineering.

Malleable is the name given to cast iron in castings made from white cast iron and subjected to subsequent graphitizing annealing, as a result of which cementite disintegrates and the resulting graphite takes the form of flakes. Ductile iron has better damping properties than steel and is less sensitive to notches, and performs satisfactorily at low temperatures. The mechanical properties of malleable cast iron are determined by the structure of the metal base, the number and degree of compactness of graphite inclusions. The metal base of malleable cast iron, depending on the type of heat treatment, can be ferritic, ferritic-pearlitic and pearlitic. The highest properties are possessed by malleable cast iron, which has a matrix with a granular perlite structure; they can replace cast or forged steel. In cases where increased ductility is required, ferritic ductile cast iron is used. To intensify the graphitization process during heat treatment, ductile cast iron is modified with Te, B, Mg and other elements. Malleable cast iron is used mainly in automobile, tractor and agricultural machinery manufacturing. There is a tendency (especially in the automotive industry) to replace ductile cast iron with high-strength spheroidal graphite in order to increase the strength of castings, reduce the duration of the technological cycle and simplify manufacturing technology.

High-strength cast iron, characterized by a spherical or similar shape of graphite inclusions, is obtained by modifying liquid cast iron with additives Mg, Ce, Y, Ca and some other elements (in pure form or as part of alloys). Nodular graphite weakens the metal matrix to the least extent, which leads to a sharp increase in the mechanical properties of cast iron with a purely pearlite or bainitic structure, bringing their properties closer to the properties of carbon steels. A purely ferritic matrix (in a cast or heat-treated state) provides an increased level of ductility. High-strength cast iron has good casting and technological properties (fluidity, linear shrinkage, machinability), but in terms of concentrated volumetric shrinkage it is close to steel. This cast iron is used to replace cast and forged steel parts (engine crankshafts, compressors, etc.), as well as parts made of malleable or ordinary gray cast iron. High-strength cast iron containing so-called inclusions. vermicular graphite (when viewed under an optical microscope - thickened curved plates with rounded edges), in properties they occupy an intermediate position between cast iron with nodular and cast iron with flake graphite. This cast iron has good technological properties with low volumetric shrinkage and high thermal conductivity (almost the same as gray cast iron). Cast iron with vermicular graphite is used in diesel production and other areas of mechanical engineering.

Claim

1. A method for producing high-strength cast iron from initial cast iron with a sulfur content above 0.04%, including melting the charge in a melting unit, bringing the melt temperature to 1420-1460 ° C, primary modifying it with a master alloy containing rare earth metals and silicon to obtain cast iron in the structure vermicular graphite on the fracture of the control sample and secondary modification, characterized in that during primary modification the alloy is uniformly fed onto the metal stream through a dispenser when pouring the metal into the transfer ladle, and during secondary modification, together with the secondary alloy, an additional primary alloy is added to the cast iron melt in an amount of up to 0.5% by weight of liquid cast iron and placing them on the bottom of the ladle to obtain cast iron with nodular graphite.

2. The method according to claim 1, characterized in that a preliminary estimate of the amount of primary alloy is made based on the sulfur content in the original cast iron.

3. The method according to claim 1, characterized in that after primary and secondary modification, the molten cast iron is kept for 4÷6 minutes and 0.5÷1.0 minutes, respectively, for the slag to float, which is removed from the surface of the liquid cast iron.