The production and sale of welding electrodes is a popular activity in Russia. Electrodes are a consumable material that is in demand in construction during the construction of reinforced concrete structures, as well as in those areas of industry where it is necessary to connect metal surfaces by welding. Relatively small financial investments at the opening stage and quick payback (from 1 to 3 years) are the main advantages of an enterprise whose activity is the production and sale of welding electrodes.

Our business assessment:

Starting investments – from RUB 2,500,000. and higher

Market saturation is high.

The difficulty of starting a business is 8/10.

Rod production

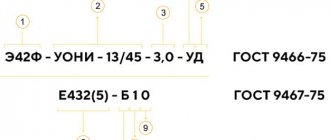

For the manufacture of electrodes, welding wire made of low-carbon, carbon, alloy or high-alloy steel is used. It is necessary to select a material based on the properties of the metal structure being welded.

The production of rods occurs using straightening and cutting machines, on which:

- a wire of the required diameter is bent and then straightened;

- the straightened wire is divided into rods of the required length.

Then the machine operator checks the workpieces and sorts out the defective products.

Equipment for the electrode production workshop

In addition to the line for the production of welding electrodes, which can be located on an area of 30 m2, other equipment will be required:

- three-phase power supply with a power of at least 80 kW;

- a powerful ventilation system, since production involves chemicals that pose a health hazard;

- finished goods warehouse.

Creating a Coverage

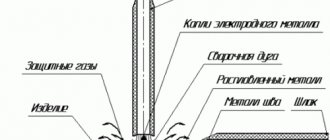

Coating is necessary to protect the weld pool from oxygen, which can have a negative effect on the metal structure. The composition of the coating is affected by the type of electrode. During production, the coating is checked for the presence of main components and impurities.

The coating is prepared according to the following scheme:

- materials are divided into medium and large sized elements;

- They are crushed using disintegrators and ball mills;

- the elements are sifted through a sieve;

- Ferroalloy particles are passivated by aging in air or heat treatment - in the process, a film is formed around the elements, which does not allow the reaction with liquid glass to start;

- materials are dosed in the required proportion and mixed until a homogeneous mass is obtained;

- The binder is prepared and added to the dry mixture.

The result is a thick coating.

How electrodes are produced at the MEZ

Modern production of electrode products is step-by-step and high-tech. It is carried out using sophisticated equipment - not just machines, but automated lines.

At all its stages - from processing of welded wire to packaging - there is multi-stage operational control. It is required for each technological operation:

- incoming inspection of wire and materials;

- production of electrode rods;

- preparation of liquid glass;

- preparation of dry mixture;

- preparation of coating mass;

- heat treatment of electrodes;

- testing of finished products, packaging and packing.

It cannot do without research work - the laboratory controls the granulometric and chemical composition of the components, the characteristics of liquid glass (density, viscosity, modulus), the geometric characteristics of the finished product (humidity, strength, mass coefficient, variation in thickness of the coating), and the formulation of the resulting electrodes is improved.

A welding station has been organized where NAKS-certified welders test electrodes for welding and technological properties and weld samples for mechanical testing of the weld metal and the chemical composition of the deposited metal.

The Magnitogorsk Electrode Plant has exactly such production. The products are manufactured using the best equipment in their class - equipment supplied by the world leader in the industry - the Esab concern. The company operates on the principle of continuous improvement of welding electrode manufacturing technology (certified according to ISO 9001) and attentive attitude towards each client, focused on complete satisfaction of consumer requests.

Applying coating

When performing this stage, presses are used to create the necessary pressure. Application proceeds as follows:

- briquetting of coating mass;

- seal with a special piston;

- the rods are directed into the coating head, where at the same time the coating mass is supplied;

- they pass together through the hole of the calibrating sleeve located in the coating head.

By following a clear algorithm of actions, it is possible to obtain a uniform coating of the rods. The main thing is to install the calibrating sleeve correctly. It is with its help that you can obtain the desired thickness of the coating, which affects the quality of the weld. If the layer is too thick, the coating will crack during calcination work.

Towards the creation of coated electrodes and flux-cored wire

Home » Articles » Professionally about welding » Welding in the pastWe recommend purchasing:

Installations for automatic welding of longitudinal seams of shells - in stock!

High performance, convenience, ease of operation and reliability in operation.

Welding screens and protective curtains are in stock!

Radiation protection when welding and cutting. Big choice. Delivery throughout Russia!

At the beginning of the 20th century. humanity had, in addition to the most ancient technologies for joining metals, four more new technologies: arc, contact, gas and thermite welding. Each of these types of welding had its own advantages and disadvantages, which became more and more apparent as the volume of welding use increased. Researchers' efforts were aimed at improving the technological capabilities of existing methods. As for arc welding, its fate depended mainly on the ability of the electrodes to provide satisfactory quality of the weld metal, which was largely due to the design of the electrodes and the compositions of the rods and coatings.

As is known, in the text of Russian privilege No. 11982 dated December 32, 1886, N. N. Benardos did not limit the material and design of the electrode. He proposed not only electrodes in the form of rods, including consumable ones, but also more complex designs, such as “... carbon rods that have metal or an alloy in the form of a rod or powder along the longitudinal axis. In the latter case, flux is sometimes added. Metal electrodes can be in the shape of a cone, circle, sector or spiral. In practice, a carbon pin surrounded by metal rods has proven itself to be a processing electrode: the voltaic arc behaves very calmly and makes it possible to quite uniformly melt the object being processed, onto which molten metal is dripping from the rods surrounding the coal” [21] (Fig. 56).

As for the simple replacement of a carbon electrode with a steel (iron) rod-wire, the process was “difficult”, characterized by large droplet transfer, the seams were porous and uneven. N.N. Benardos tried to solve the problem of improving the quality of weld metal during welding and surfacing with a consumable electrode. He is about [20].

Another principle of consumable electrode welding was to apply current to a metal bar (electrode) through a carbon electrode and melt the bar. Initially, the welding site was heated with a carbon arc, and when a liquid layer of metal had already formed, a metal bar was inserted into the arc by hand so that a carbon rod touched its end, as shown in Fig. 56. The current, passing through the end of the bar, melted it, and as it melted, the coal moved higher, and the bar fell down, supporting the arc.

Thus, when it was necessary to obtain a significant amount of molten filler metal, N.N. Benardos not only introduced the filler metal in the form of a bar into the zone of the arc burning between the carbon electrode and the base metal, but also included the bar in series in the electrical circuit using the indicated technique and excited arc between the metal bar and the base metal, leaving at the same time a significant part of the bar under the influence of current. Thanks to this, the melting rate of the bar increased due to additional heating by the flowing current. The bar in this case was already a metal electrode, melting under the action of an arc and heating by a flowing current.

Obviously, the technique for performing such manual consumable electrode welding techniques was complex. However, Slavyanov’s method, which emphasized the possibility of welding only with automatic supply of the electrode, was even more complex, and was used mainly for repair purposes. Due to the need to make the seam in parts and mold small areas, “electric casting” was not suitable for making vertical and ceiling seams. However, in many welding areas they tried to “tame” the process - replacing the carbon electrode with steel wire when welding using the Benardos method. There have been attempts to patent such a replacement.

In 1907, she applied for a patent in the United States for metal arc welding.

At the same time, another American was also trying to patent metal electrode welding technology. In the patent dispute that arose, the head of the first company argued that his technology was a direct continuation of the Benardos method, and he only replaced the non-consumable electrode with a consumable one, which is what the patent requires. However, a competing company presented a book published in 1888 in Great Britain, which revealed the essence of the same method [10]. As a result, due to lack of novelty, patent protection was denied to both companies. This circumstance opened the way to the unhindered improvement of arc welding with a metal consumable electrode and, first of all, to the creation of new electrodes and generators. Experts guessed that the electrodes, in addition to metal, should contain substances similar to fluxes for forge welding or welding according to the method of N. G. Slavyanov.

In the USA, several companies began developing materials for arc welding. Work on improving electrodes began (1908), Westinghouse (1909), General Electric (1912), Wilson Welder and Metals ( 1914) etc.

At this time, Elektrika Svetsnigsaktien Bolaget, founded in 1904 by marine engineer Oskar Kjellberg (Sweden), was active in Europe. His attention was drawn to an interesting observation by welders who noticed that the quality of the weld improved in cases where the electrodes or areas to be welded were “stained” with slaked lime, which clogged the welding sites after producing acetylene from calcium carbide. The same effect also occurred from contamination remaining on the surface of the wire after drawing it, which was carried out using lime [152]. The challenge was to use arc welding at the Gothenburg shipyard to ensure high-quality and cost-effective ship repairs. It was necessary to weld the rivet head and weld the edges (instead of chasing). In this case, welding had to be performed in all spatial positions.

The rods were dipped into the paste. It is a mixture of mineral powders diluted in water. The coating was dried at room temperature.

In 1907, O. Kjellberg received British patent No. 16952, and in June 1908, patents from Germany and France. The inventor defended the idea of coating metal electrodes with “second class conductors” in the form of oxides, hydroxides and silicates of zirconium, magnesium, calcium, potassium, boron, manganese, etc. [153].

O. Kjellberg conducted research on the coating of electrodes, selecting its thickness and composition so that the coating melted with a lag behind the melting of the metal core. With a sufficiently thick layer of coating, a “case” was formed, in which part of the arc was located, due to which the process of its combustion was stabilized and directional transfer of droplets was ensured (Fig. 57). This to a certain extent facilitated welding in the ceiling position and on a vertical plane. There was a positive effect. At the time, it was attributed to the presence of a gas flow similar to that which protected the pool and filler metal in oxy-acetylene welding.

O. Kjellberg performed welding in the ceiling position with straight polarity, knowing that in this case less heat was generated on the electrode and the danger of dripping was reduced. In other cases, the inventor proposed working with reverse polarity. He believed that by significantly heating the electrode, the risk of it “freezing” to the bath decreases. Practice has shown that Kjellberg's coating ensured satisfactory quality of the weld metal, especially in the case of reverse polarity, in which most of the work was performed.

O. Kjellberg continued to further develop coating compositions, trying to reduce the formation of slag and increase the toughness of the weld metal. Thus, in 1912, he patented electrodes with several layers of coating, as well as tubular electrodes, taking a step towards creating flux-cored wire.

The compositions of electrode coatings developed by O. Kjellberg will be improved for many years to come; electrodes with the OK brand will be used for decades, as will pastes and fluxes produced by. But already the first inventions of coated electrodes significantly improved the quality of the weld metal. Both the ever-increasing number of welding firms and industrialists strived for this. Moreover, on the eve of the First World War and with its outbreak, industry required faster and simpler connection methods than the common mechanical ones (rivets, bolts), which were almost unsuitable for repair.

In 1918, Lloyd's Register tested samples of welded joints made with OK electrodes. Although the strength and ductility indicators were not so high compared to modern indicators, the performance properties of the butt weld exceeded the properties of a rivet joint of equivalent thickness. Manual arc welding with a consumable electrode and the electrodes themselves were certified by Lloyd's Register as “experimental”, which opened the way to legitimate practical application. Vigorous research continued into the composition of electrode coatings and the scientific understanding of the results obtained.

An original solution to the problem of creating welding electrodes was found by A. Stromenger [26]. As a chemist and organizer of an analytical laboratory in London, he knew well the properties of various materials and proposed testing steel rods with a braid of blue asbestos containing iron compounds. Such asbestos was often sent to him for analysis from South Africa. The experiments exceeded all expectations. The asbestos braid ensured high quality weld metal and stable arc burning even on alternating current. Stromenger, together with Professor S. P. Thomson from the University of London, began to study the processes of melting and evaporation during welding and came to the conclusion that they supposedly occur as a result of the influence not of a simple arc, but of a “quasi-arc”, acting not only in the axial direction, but also in the radial. In accordance with this idea, Stromenger proposed placing an electrode between the edges, connecting it to the positive pole of the generator, and the product to the negative (Fig. 58). The asbestos coating served as an insulator. The arc excited between the ends of the electrode rod and the edges also melts the asbestos, thereby protecting the welding area. To obtain long seams, Stromenger used several electrodes 300-400 mm long, laying them sequentially one after the other. The glassy slag that formed at the weld during cooling was easy to separate.

A. Stromenger received a UK patent in 1911, in which he noted that the advantage of the invention is the release of heat at a very close distance from the surface being welded, as well as the formation of slag, which serves as a “secondary conductor” capable of regulating and distributing this heat. In 1911, a company was created, named (though not immediately) “Quasiark Welding”, which began producing electrodes with a blue asbestos braid impregnated with sodium silicate. A. Stromenger continued to improve the design of his electrode, proposing to additionally wind a thin aluminum wire around the rod (up to 2% of the volume of the total metal); Thanks to aluminum, the process of steel deoxidation went better. Later, he made some more improvements, in particular, he began to add manganese salts to the coating of electrodes for surfacing rails, and began to wind uranium wire for welding high-strength steels. A. Stromenger also proposed welding with a beam of electrodes, which melted alternately.

Already in 1911, with the help of Stromenger electrodes, trams and ships began to be repaired in London. Connections were made not only with a recumbent electrode, but also in its usual position. A. Stromenger recommended using transverse vibrations of the end of the electrode; This achieved high quality welding of thick-sheet (up to 10 mm or more) structures, and he also proposed X- and K-shaped edge cutting and multi-pass welding.

In the UK, interest in Quasiark welding was significant, as this method had good technical performance. In addition, there was also a political-economic factor at work - the desire to reduce the import of carbide necessary for oxy-acetylene welding.

In 1918, at the Richborough shipyard, she built the world's first all-welded ship, 38.4 m long and 5 m wide. In February 1920, an even larger all-welded ship, Fullagar, was launched in Birmingham. These successful works had a significant impact on the fate of electrodes with special coatings.

A. Stromenger's company entered the international arena not only as a manufacturer of electrodes, but also as a manufacturer of welding generators and auxiliary equipment.

In October 1914, a UK patent was issued to E. G. Johnson, who proposed applying a coating consisting of three parts crushed slag and one part lime silt mixed with sodium silicate. The coating was “pressed” onto a wire rod under pressure. Three years later, Johnson developed the design and composition of another electrode: a cord of white asbestos or cotton was wound with a large pitch onto a nickel-plated steel rod-wire, and the whole thing was covered with a paste of lime and fluoride slag bound with sodium silicate (Fig. 59). In 1922, E. P. Johnson organized, which began to compete with.

The phenomenon of stabilization of arc combustion when using steel electrode rods “stained” with lime, used by Kjellberg, formed the basis of another technology for applying ferrite-calcium coating. Its essence was as follows: steel rods were moistened with water to obtain a layer of iron hydroxide (rust), then they were immersed in milk of lime and dried at a temperature of 150 ° C. This coating, however, did not protect the welding zone well. This problem was solved in 1916 by O. Andrus and D. Stresau using paper. Several layers of paper were wound around a steel rod, then immersed in a solution of sodium or potassium silicate and calcined in an oven. The welding zone was protected by cellulose decomposition products. These were the first organic-coated electrodes. Subsequently, many inventors returned to the idea of using cellulose in one form or another as a coating composition. Electrodes with paper winding began to be produced in the USA in large quantities from the beginning of the First World War instead of the English Quasiark electrodes. produced them until it entered the American market with its electrodes in 1924.

At the same time, in Europe, welders followed the path of using electrodes with protection consisting entirely of mineral materials. Thus, the French inventors R. Sarazin and O. Moneyron developed a method of coating metal rods with a thick layer of coating, which included compounds of alkali and alkaline earth metals (zerspar, marble, chalk and soda). They have low ionization potential. Therefore, when using electrodes with such coating, it is easier to excite and maintain an arc (It is known that N.N. Benardos used carbon electrodes with a “wick”, that is, electrodes whose core was filled with sodium and potassium salts).

In 1926, in Switzerland, a coating composition for electrodes was developed from a mixture of iron oxide, ferromanganese and ferro-silicon. An electrode coated with this composition with the addition of graphite turned out to be suitable for cold welding of cast iron. Later she received a patent for a “thermite” electrode. Aluminum powder (50%) was introduced into its coating, which, reacting with iron oxide, provided additional heating of the welding zone. Van der Willigen and Moerman (Eindhoven, the Netherlands) proposed coatings with a high content of iron powder. However, the introduction of iron powder into the coating was used back in 1920 in Glasgow, UK. In this case, the thickness of the coating exceeded the diameter of the rod by 20 /°: such electrodes were called “heavy”. It is interesting to note that this coating turned out to be electrically conductive, and an arc was often excited on it.

In 1918, low-hydrogen coatings were developed based on calcium spar, calcium carbonate and limestone, which produced carbon dioxide in the arc, which provided effective protection of the welding zone [154]. In the 1920s Other electrode coating compositions have been proposed both in Europe and the USA. At that time, ilmenite, alumina, silicon dioxide, many metals (including uranium), and a number of organic substances were tested for suitability as coating components.

A significant contribution to improving the technological properties of electrodes and their manufacturing technology was made by J. J. Chail, who worked for several decades at. In 1924, he developed a composition and organized mass production of electrodes with a cellulose coating applied by crimping. The coating also included titanium oxide and ferromanganese. Chail and others successfully solved the problem of manual arc welding of high-strength and corrosion-resistant steels.

Already in the 1920s. began to distinguish between types of coatings depending on their chemical and metallurgical properties: basic, acidic, neutral, etc. [155]. Consumers were increasingly interested in the performance qualities of electrodes: arc stability, the ability to make seams in a ceiling position, on a vertical wall, with deep penetration, etc. [156, 157].

In Russia, where since 1890 carbon arc welding using the Benardos method has found widespread use, and the repair of castings (surfacing) was carried out with a consumable electrode using the Slavyanov method (i.e., flux), no attention was paid to the improvement of consumable electrodes for a long time. Until 1914, high-quality electrodes were used only by some companies associated with Western European companies, AEG, etc.). Such electrodes were supplied mainly from Germany and Sweden. In the early 1930s. in the Soviet Union, the All-Union Electrotechnical Trust developed electrodes with a slag-forming and deoxidizing coating (VET-26, etc.). At the Orgametal welding plant (Moscow) during 1934-1937. A series of electrodes, called OMM, with a slag- and gas-forming coating were created for welding various grades of steel with both direct and alternating current. Among them were electrodes that were widely used in the USSR for more than 20 years: brand OMM-3 (A. A. Erokhin), which made it possible to sharply increase the productivity of the welder, and brand OMM-5 with ilmenite coating (K. V. Lyubavsky), suitable for welding in all spatial positions [158].

In the same years, in Kyiv, at the Institute of Electric Welding, V.I. Dyatlov developed thin-coated electrodes of the UAN series, suitable for welding various steels, including alloyed ones. They were used for surfacing rails, wheel tires and other wear-intensive products and machine parts. The AN-1 coating, having the following composition (in percent by weight): titanium concentrate - 86.4, manganese ore - 10.9, potash - 2.7, provided the melting coefficient of the electrodes (28...30) * 10-4 g/ (Ac), while for chalk electrodes this coefficient did not exceed (14...17)*10-4g/(Ac) [7, 159]. This was probably the last thinly coated electrode in history, providing sufficiently high mechanical properties of the weld metal, economical in composition and production.

In 1938 in Leningrad, K.V. Petran developed a series of electrodes with a thick base coating of the UONI-13 type (deposition coefficient equal to (25...30.4)* -4 g/(Ac), intended for welding structural steels. These electrodes turned out to be one of the best in the world welding technology and are still widely used in the production of metal structures [158].

In addition to searching for compositions and optimal designs of electrodes, inventors also worked on the technique of using electrodes. Thus, in 1924, J. Bethenot proposed a “double” electrode, consisting of two coated electrodes of a semicircular cross-section. The rods, insulated from each other, were connected to one pole and two power sources (the second potential to the product), and welding was carried out with two arcs. When manual welding, up to 15% of the time is spent on changing electrodes and cleaning the crater before igniting the arc of the next electrode.

At the end of the 30s. in the USSR, methods of welding with lying and inclined (Silin’s method) long (up to 900 mm long) electrodes have found practical application (Fig. 60). In the mid-1930s. In the USSR, due to the ongoing competition, a welding method that increased labor productivity became popular - welding with the simultaneous use of several electrodes. Electrode beam welding was widely used by Stakhanovite workers. This technique was used by S. T. Nazarov (Moscow Mechanical Engineering Institute) to improve the quality of cast iron welding. He managed to avoid oxidation and eliminate porosity of the weld metal during “cold” (without preheating) welding of cast iron, using electrodes made of steel, copper and brass rods instead of electrodes made of copper, nickel and Monel metal, which could only prevent the formation of carbides. Thanks to his electrodes, S. T. Nazarov performed unique work. However, the electrode beam welding method, including the one improved in the 1950s. V.S. Volodin, turned out to be ineffective compared to welding with a solid single electrode of the same diameter, since the costs of manufacturing several electrodes of small diameter and arranging them into a bundle are much greater than the costs of manufacturing one electrode.

As for welding cast iron abroad, electrodes were the best here. Since the mid-30s. this company also produced electrodes for welding high-strength steels, tool and self-hardening steels, aluminum and its alloys. developed "synthetic electrodes" with a low-carbon steel rod coated with asbestos and ferrochrome, which were widely used for welding corrosion-resistant steels. For welding copper, an electrode with a copper rod and four layers of coating was proposed.

In the 1930s New electrode designs continue to be created. Thus, the British branch developed an electrode with a metal rod having grooves into which the coating is placed [160] (Fig. 61).

In another embodiment, it was proposed to wind a metal braid over the electrode coating. In cases where the braid was in contact with the rod, current could be supplied through the rollers or mouthpiece [159].

E. M. Kuzmak and N. P. Doronin proposed applying a second layer of coating to the spiral [158]. The spiral melts due to the additional heat of the arc. The deposition rate of electrodes of this type increases to (41.6...55.6) * 10-4 g/(Ac). However, the technology for manufacturing braided electrodes was complex. A more practical way to increase the deposition rate was the idea proposed in several countries to introduce metal powder into the coating composition (for electrodes with a steel rod - iron). The coating becomes electrically conductive, part of the welding current is shunted through it, which can be increased, and part of the heat is removed. However, electrodes with iron powder coating have been created and become widespread since the 1960s. Electrodes for welding alloy steels almost simultaneously began to be developed by alloying the deposited metal through the coating, using alloyed wire. In the Soviet Union in the early 1930s. The problem of welding corrosion-resistant steels began to be dealt with at the All-Union Institute of Aviation Materials (VIAM-25 electrode) and at Orgametal (OMH electrode, L. K. Ershov). One of the most successful electrodes for welding austenitic chromium-nickel steels were electrodes of the TsL type (I.A. Lipetsky) with a X19N9 rod (with or without titanium) [158, 159]. In solving the problem of creating electrodes for arc welding, their manufacturing technology was of no small importance. Winding asbestos cord, winding paper tape, immersion in solutions with binders and techniques could not be immediately mechanized. In 1920, she mechanized the production process of her electrodes. In the USA, the first to apply coating using the pressing method was . The use of this method caused changes in the design of electrode coatings: asbestos, cellulose, metals and all other components were added to the coating composition only in powder form. Bulky and low-productivity machines for immersing rods were replaced by presses with mechanical and pneumohydraulic drives. All other operations of the production cycle were also mechanized. Preparation for coating materials, primarily of mineral origin, was carried out centrally [160].

In the 1920-1930s. Dozens of types of presses were created in different countries. The first manual presses designed by F. Wertmann with a gear drive appeared in Germany and Switzerland (Fig. 62). Their productivity was up to 50 electrodes per minute [162]. In 1924, R. Mauchna (Belgium) organized the production of electrodes up to 5 thousand per day.

In 1935, R. Sarazen proposed a method and machine for continuous coating of electrodes [162, 163]. In accordance with his invention, the wire from the coil was unwound when the wheel rotated (Fig. 63). At the same time, it was straightened in rollers and entered an extrusion press, after which it was cut into individual electrodes and conveyed for drying. The mechanization of electrode production and the increase in press power contributed to an increase in the production volume of this important type of welding materials. Thus, in the USA in 1932, 8.2 thousand tons of electrodes were produced, in 1936 - 30 thousand tons, and in 1940 - 120 thousand tons. In the USSR, centralized production of electrodes for welding ordinary steels reached the following indicators: in 1932 - 19 thousand tons, in 1934 - 32 thousand tons, and in 1937 - 42.7 thousand tons [6].

The intensive growth in the production of electrodes indicates that manual arc welding in a short time overtook gas welding, which held the lead in terms of application volume for more than a decade, and became equal to it in such indicators as versatility and quality of the weld metal.

As if summing up the intense struggle between gas and arc welding (primarily for the quality of the weld metal and versatility of application), engineer S. Sandelowski in the “Proceedings of the Third All-Union Autogenous Congress” about [164]. As an example of developments that have expanded the capabilities of manual arc welding, one can cite the creation by the team of the Electric Welding Institute named after. E, O. Paton electrode coating made of synthetic slag, providing AC and DC welding of horizontal and vertical seams. This coating could also be applied to wire for automatic welding (an aqueous solution of glycerin was added to the coating to achieve elasticity) [165].

Researchers in different countries have periodically tried to place protective and doping substances inside the electrode. This search was started by N. N. Benardos. However, the cost of manufacturing flux-cored wire was higher than that of coated electrodes, so its use for manual welding was not profitable. In the late 30s. They returned to work on compositions and welding techniques in connection with solving the problem of arc welding automation.

In 1938, in the laboratory (Leningrad), V. E. Sakhanovich was engaged in developing manufacturing methods and studying the nature of melting and properties of weld metal deposited with flux-cored wire. The main goal was to find principles for zone protection when automating arc welding. At that time, such principles were developed to ensure protection of the welding zone as coating the wire with coatings, supplying shielding gases and supplying flux. Placing the charge (coating) inside the wire solved the problem of current supply and welding in all spatial positions. Initially, electrodes were made from ready-made tubes into which the charge was driven. To compact the charge, the tubes were cased. As a charge, we used crushed coating of existing piece coated electrodes in an amount sufficient for the slag to completely cover the bath. As one of the options for the industrial production of flux-cored wires, V. E. Sakhanovich proposed feeding the strip from a coil into rolling rollers, bending it into a groove and filling it with flux poured from a hopper. With further movement, the strip is rolled into the wire in rollers and pulled through dies or rolled to the required diameter [166].

In 1939, in the USSR (NIAT), flux-cored wire was used as an additive for welding aluminum. The charge (mainly chloride and fluoride salts of sodium and lithium) was poured into an aluminum (12.0 * 0.5 m) tape while passing it through the point of a drawing mill or through rollers. The resulting workpiece was placed in a seamless tube 8 * 2 and drawn to a diameter of 3.15 mm, the diameter of the internal channel filled with flux was 1.6 mm. The welding process proceeded stably, and microstudies showed that the weld was dense and pore-free [167].

Source: Kornienko A.M. “Welding history. XV-mid XX century.”

See also: Welding and surfacing materials - history of development

Drying and calcination

The next stage of how electrodes are made is drying. It can occur directly after crimping in special ovens. It is performed if rutile coating is used, where temperatures up to +200°C are required.

If the main coating is selected, then the products first go into drying racks, where they remain for several hours at a temperature of +30°C. After this, they are sent to a heating furnace, where they are heated to +400°C.

After calcination, products are selected for testing, and the electrodes are accepted and packaged. They are packaged and stored.

Risks

The electrode manufacturing business can become successful. It will develop if the business is properly organized and an advertising campaign is carried out. To do this, you need to distribute advertisements in the media and on the Internet. You can distribute leaflets or try to contact direct suppliers. It must be taken into account that business depends on seasonality. Peak sales occur between March and November. Make sure you have enough finished products. In winter there is a decline. Taking this factor into account, it is necessary to plan the launch of the production workshop.

Control at production stages

In the manufacture of electrodes, every stage from the production of rods to storage is important, since strict adherence to all steps affects the quality of the weld and the reliability of the structure. To ensure proper product quality, Magnitogorsk Electrode Plant (MEZ):

- uses high-quality equipment at all stages of production;

- uses materials that comply with standards;

- carries out quality checks during product manufacturing;

- tests finished products, which helps to avoid defects.

As a result, this makes it possible to obtain reliable welding electrodes. Their quality is confirmed by the availability of appropriate certificates.

Manufacturing of electrodes by crimping method

But the coating method used at home is not suitable for the manufacture of electrodes on an industrial scale. It is unlikely that large companies in need of large quantities of welding material will buy “handicraft” products without a certificate and accompanying documentation, even if they are of good quality.

Therefore, in an enterprise that has plans for further development and expansion, it is preferable to use electrode production technology using the crimping method. Since the product obtained in this way maximally complies with modern requirements and standards for welding materials.

Crimping is the production of welding electrodes using special presses, where they are exposed to high pressure (from 300 to 650 kgf/sq. cm). The process consists of pulling a metal workpiece (electrode wire) through the holes located in the installation cylinder, which is filled with a coating solution.

Finished products are checked for defects and the ends are cleaned. Only after this are the electrodes labeled and packaged. The waste remaining after the operation of the scrap cleaning machine is sent for processing and then put into production of the next batch of products.

To organize a mini workshop, you need a line for the production of medium-power electrodes, including:

- rod feeder;

- GEP – hydraulic electrocoating press;

- stripping installation.

Additional devices:

- MPE – electrode supply mechanism;

- MZT – stripping and transportation mechanism;

- Ballast – automatic straightening and chipper, equipped with a receiving hopper and a wire unwinder;

- BP – briquette press;

- MOB (10) – a mechanism for cleaning raw defective electrodes;

- MS (50) – wet mixer.

The price of equipment for electrodes varies from 6,800,000 to 8,000,000 rubles.

It should be noted that the coating is a necessary component of the electrode, facilitating uniform melting of the metals being welded. And the slag crust formed during the welding process blocks the access of oxygen to the connecting seam, which avoids rapid loss of temperature on the surfaces being welded. The result is a perfectly smooth seam, without bubbles and microcracks.

More to read:

What kind of machine should I buy for the production of masonry mesh?

How to open a plant for the production of fiberglass reinforcement?

We are opening our own production of profile pipes.