The paint for the barbecue must be resistant to fire and high temperatures. Heat-resistant paint is suitable for exhaust pipes, ovens, grills and barbecues, and can be used to repair surfaces exposed to fire. High temperatures promote surface degradation and corrosion. The surfaces of barbecues and stoves deteriorate and become discolored, so you need to purchase heat-resistant paint and paint it.

Fresh paint on the surface of the grill Source domdacha.su

Application of heat-resistant paint

Fireproof barbecue paints and wet painting solutions are suitable for objects exposed to high temperatures:

- barbecues;

- pipelines;

- ovens;

- grills;

- engines;

- boiler facades;

- barbecue and grills;

- steel structures;

- metal fireplaces;

- landing valves;

- hydrants

- chimneys of fireplaces.

Heat-resistant solutions make it easy to spray paint and control the painting process.

Painting a barbecue with spray paint Source ytimg.com

Preparatory work

Thermal paints are applied only to a clean, dry surface. It is recommended to remove the old coating layer before applying heat-resistant paints. A smooth metal surface is sanded before painting. The base with rust is subjected to sandblasting and shot blasting. Traces of metal corrosion (down to the smallest particles) are removed using sandpaper or a special product (rust converter).

After cleaning, it is recommended to degrease the surface (acetone, solvent, xylene, solvent) and dry thoroughly.

Heat-resistant paint for barbecue

To paint the grill you can choose:

- heat resistant;

- heat-resistant paint.

According to the composition they are distinguished:

- epoxy-phenolic +200 ºC+;

- acrylic +100 ºC;

- ethyl silicate +450 ºC;

- powder +400-500 ºC;

- epoxy ester +450 ºC;

- epoxy +200 ºC;

- silicone +600 ºC;

- organosilicon +650 ºC;

- composite with many polymers +750 ºC.

Painted metal grill Source stroy-podskazka.ru

See also: Catalog of companies that specialize in paints and varnishes and related work

Well-known brands that are distinguished by durability and reliability in practical use:

- Termal;

- Certa;

- Kudo;

- Hammerite;

- Hi-Temp;

- Thermal KO-811;

- Elcon;

- Rust Oleum.

One-component paints, unlike conventional ones, do not fade, but can withstand heat of + 400 degrees. By adding metal powder to heat-resistant paint, a high level of flame protection and high heat transfer are achieved, which creates a thermal barrier and fire protection.

Heat-resistant paints based on silicone resin have been created for painting metal barbecues. When painting metal with a thickness of 30-100 microns, the normal condition is + 650 ºC.

Variety of paints for painting Source gidpokraske.ru

Fire-resistant silicone paint does not melt at temperatures above 650 degrees and is often used in painting old barbecues.

Peculiarities:

- corrosion resistance;

- excellent adhesive properties;

- fire protection.

Thanks to its unique composition containing composites and heat-resistant glass, heat-resistant paint is resistant to temperature changes. Binder particles, special pigments and fillers determine the temperature range that requires attention to preliminary surface preparation and adherence to painting technology. If it contains zinc powder, the painted surface will withstand + 500 degrees. And if it contains titanium dioxide, then the maximum exposure rate is + 1000 °C.

Criterias of choice

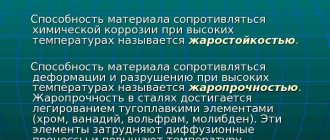

Heat-resistant paints are often called fire-resistant. This characteristic indicates resistance to specific temperatures.

The paint, intended for treating surfaces exposed to temperatures up to +650 degrees, is produced on the basis of heat-resistant glass and composites. Heating to temperatures below +1000 degrees is usually typical for barbecues, stoves, barbecues, fireplace grates, and various home radiators.

Heating from +1000, more than +1200 degrees is typical for industrial production, and involves the use of especially durable paint and varnish compositions, which are applied in any available way.

Video description

This video shows what materials to gather for painting and how to paint a grill.

Many of these heat-resistant paints emit gases that are designed to minimize the spread of fire to nearby areas and surfaces. And other fire-retardant paints create a protective charred coating that covers the main material of the grill for a limited period of time. The choice of product and paint depends on the required level of safety and the material from which the surface is made.

Factors to consider when choosing fireproof paint

What factors need to be taken into account:

- intended purpose;

- compound;

- metal operating conditions;

- temperature Range;

- color stability;

- application characteristics.

Attention! Application characteristics should be the main factor when choosing heat-resistant paint for a barbecue. These coatings require a relatively thin film to remain intact at high temperatures without cracking.

A well-painted grill looks very impressive Source psk-remont.ru

How to paint and why won’t regular dye work?

The paint must be heat-resistant, i.e. withstand high temperatures (up to 600-1000 degrees Celsius), while not losing the aesthetics of appearance, not melting, not cracking, not flaming. To do this, special components are added to it, which give the coating protective properties when in contact with fire or other hot substances.

Conventional dyes do not have such advantages, so it is not rational to use them. When such paints are exposed to fire or high temperatures, the color of the coating will change. It may crack or completely come off the surface being treated.

Interesting: heat-resistant paints for metal are completely safe. When exposed to high temperatures, the dye does not release harmful substances. In this case, the coating remains the same as it was originally.

Painting a barbecue in 5 stages

The grill can be painted with heat-resistant paint in 1 day in 5 stages:

- Cleaning from contaminants, wash with water and detergents.

- Dry and wait until completely dry.

- Choose the optimal place, protected from rain and wind.

- Paint the grill using paint on the outside. It is advisable to use an aerosol.

- Checking the results and correcting errors.

It is necessary to paint in sunny weather, away from bodies of water and precipitation. Before painting, select paint, check the expiration date and functionality of the aerosol device.

Attention! Experts recommend using silicone and multipolymer enamels for painting metal barbecues.

Oxidation or bluing

An alternative method to protect the grill from corrosion is oxidation, also called bluing. Its essence is to apply a special chemical composition to the surface of the fryer, as a result of which the metal acquires a rich black color and the ability to resist rusting.

Brazier

This procedure requires the following components:

- caustic soda (caustic soda);

- 5% sulfuric acid solution;

- laundry soap.

Rust cannot be oxidized, so before starting work, a previously used grill is cleaned using a drill with a brush attachment and polished. Then the structure is disassembled, a container of sufficient volume is filled with a 5% sulfuric acid solution and the fryer parts are immersed in it. Massive and non-removable barbecues can only be processed in this way in industrial conditions.

The product parts are left in the acid for 5 minutes. Meanwhile, dissolve laundry soap in water at the rate of 50 g per 1 liter and bring it to a boil. Once removed from the acid, the fryer is immersed in soapy water and boiled for 10 minutes. To complete the burnishing, the grill must spend 1.5 hours in a solution of caustic soda (proportion 50g/1l of water) brought to a temperature of 140 °C. Then the metal is thoroughly washed and the structure is assembled.

Important! Don't forget about safety measures. Before final rinsing, parts should not be handled with bare hands; in addition, protective clothing must be used during the oxidation process to prevent burns.

Useful tips for using heat-resistant paints

When choosing black heat-resistant paint for a barbecue, you need to know the material of the surface to be painted. The special properties of different paints help protect not only metal coatings, but also concrete, brick, asbestos and plastered structures. The heat resistance of a coating is related to the maximum permissible temperature at which the dried paint retains its protective properties against weather influences for a long time. This information is usually found on packages and cans.

The color palette of heat-resistant substances also depends on the temperature range. For example, black, graphite and silver heat-resistant paints are suitable for painting barbecues and fireplaces. Gray and white heat-resistant paints are designed for piping and metal fireplaces. The service life of the protective coating depends on compliance with the application technology specified in the manufacturer's instructions.

Protection of brick structure

Nowadays, it is fashionable to make not just metal barbecues, but brick or stone braziers. In addition to the fact that it is made of fire-resistant bricks, heat-resistant impregnation will not harm it, plus it will help protect it from bad weather. The treated surface is easy to clean from soot, grease and soot with your own hands.

A cheap option would be to use KO 85 varnish, but it can crack due to frost. An option that combines price/quality combination would be the use of impregnation for stoves and fireplaces. This composition is not afraid of frost because it contains an oil component. The downside is the need for re-processing every other season.

Another practical composition is a silicone water repellent for ovens. The mixture is endowed with water-repellent and antifungal characteristics and perfectly protects brick walls from grease. Moreover, it retains all available properties even at high temperature loads.

In the following video, the master uses aerosol varnish for a DIY barbecue:

Application of heat-resistant paint for barbecues

The resistance of the coating to temperature changes directly depends on the thickness of the layer of gray heat-resistant paint.

Resistant paint lasts 1-2 years and does not deteriorate due to weather influences Source pechiexpert.ru

To achieve a positive result, 1-3 thin layers are enough. A thick coating provides reliable protection against corrosion, but reduces the temperature range. Therefore, you can use a specialized anti-corrosion primer and coat the surface of the grill with heat-resistant paint. Apply the composition with a roller, brush or spray, avoiding the appearance of stains and carry out the painting yourself in compliance with safety rules.

Processing of products with non-metallic components

Combined structures, in which a metal brazier is used in tandem with a brick casing, also require additional protection. Heat-resistant and moisture-resistant varnishes can be used here; the only vulnerability is their inability to withstand low temperatures.

Fat impregnation based on an oily substance exhibits excellent frost-resistant properties. Such a solution is not afraid of temperature changes, but during operation it gradually becomes thinner and needs regular renewal.

Briefly about the main thing

The paint for the barbecue is selected in accordance with the materials of the barbecue and must be resistant to weather conditions. The main goal when choosing paint is to extend the life of the fryer and improve the appearance of the device. The choice of paint must be approached responsibly; among the variety of coloring substances, you can easily make a mistake and make a bad purchase. And most importantly, take care of safety; the paint must withstand temperatures of 600-700 degrees. Therefore, you need to carefully explore the possible options and purchase a quality product for painting your barbecue.

Safety precautions when painting

If you want to achieve the perfect effect when painting a structure, use the recommendations and safety rules. So, remember the following:

- It is better to paint with an aerosol when there is no wind outside.

- It is necessary to paint the grill from the outside.

- After cleaning the surface from dirt, you can rinse it and let it dry completely.

- When painting, it is necessary to create such conditions so that when drying, dust particles do not fall on the surface. Otherwise, you will be disappointed with the result of your work.

In conclusion, it should be noted that the process of painting a barbecue is not as tedious as it might seem. But it should be taken seriously. You need to choose a suitable coloring agent that meets all the main requirements. Then, prepare the surface itself. Apply a couple of layers, first allowing them to dry completely. That's all!

Follow the rules so that your grill looks beautiful and does not deteriorate for a long time. The paint for the barbecue must withstand almost any temperature and protect parts from corrosion and burning. The choice of coatings is huge, each has its own characteristics. When purchasing, proceed from your needs, and also find out more information about your model in advance.