Sooner or later, everything forgotten old comes back again. This truth also applies to the home mill for grinding various types of grain crops, which in the past was in almost every home.

A household electric or mechanical mill is an important unit for lovers of a healthy lifestyle and proper nutrition. Using this grain grinding device, you can obtain flour and cereals from wheat, barley, corn and other cereals, and know for sure that the product is made from high-quality raw materials.

The easiest way to have a beautiful front lawn

You've certainly seen the perfect lawn in a movie, on an alley, or perhaps on your neighbor's lawn. Those who have ever tried to grow a green area on their site will no doubt say that it is a huge amount of work. The lawn requires careful planting, care, fertilization, and watering. However, only inexperienced gardeners think this way; professionals have long known about the innovative product - liquid lawn AquaGrazz .

Advantages of manual home mills

The advantages of this device are difficult to overestimate. So, among the main advantages it is necessary to highlight the following:

- ease of operation;

- the ability to select the degree of grain grinding;

- maintaining maximum nutrients;

- saving time;

- a wide range of.

Every housewife who has a manual kitchen mill in her kitchen will say that using the device is simple and convenient. To do this, you just need to install it on the table. Doing high-quality work on grinding a specific product with your own hands is not difficult. Thus, mills from various companies can cope well with salt, poppy seeds, spices, peas, corn, rice, cereals, seeds and nuts.

It is difficult to argue with the fact that a finished product, ground into powder, cannot be compared in quality to a freshly ground one. This is especially true not only for grains, but also for spices, the main value of which lies in their aroma. Therefore, you should not be surprised that even ordinary housewives, and not just professional restaurant chefs, have become friends with mills. It is noteworthy that there are not so many varieties of mills according to their functional purpose, which cannot be said about their design.

Stone hand mills

Types of manual kitchen mills

Let's look at the most common types of hand mills that modern kitchen equipment and appliance stores offer us.

- Disposable mill;

- Manual type burr mill, reusable;

- Electric mill.

A disposable home mill is usually a transparent container made of glass or plastic. It already contains salt, sugar, cinnamon or pepper and peas. The size of the product does not exceed 10 cm. The principle of operation of a disposable mill is that you need to twist the lid, resulting in ready-made freshly ground products. Nowadays, not only a stone home flour mill is available for sale, you can also find elite mills that provide the ability to set and adjust the degree of grinding. Spice grinders may contain one type or a mixture.

Among the advantages of a disposable grinder is a reliable, practical grinding mechanism that allows you to efficiently grind the aromatic spices in the container. Also, when purchasing a complete finished product, you do not need to spend time separately searching for a mill and the required product. This is a great option for people who are constantly busy and value their time.

DIY mill

It is no secret that the disadvantage of such a product is its lack of ergonomics and cost-effectiveness. From time to time you will have to purchase a new flour mill, which can put a significant dent in your pocket. And considering that different dishes may require different spices, your kitchen may be overflowing with a bunch of disposable grinders. You can also notice that the design of disposable mills is very universal and laconic and not everyone likes it.

A manual reusable mill, including a stone one, consists of three parts. It is equipped with a special container into which whole spices are placed, millstones or a high-quality knife, as well as a container into which ready-made crushed spices are placed. These types of flour mills can be:

- equipped with an ergonomic handle;

- equipped with a wheel that must be rotated, or equipped with an upper block;

- universal;

- for a specific type of product, including grain;

- made from a variety of materials, including wood, ceramic, brass, cast iron and plastic.

The main advantage of this type of manual mill for grain and other products is the wide selection of shapes, colors and textures. You can always find an option that best suits your kitchen design. It is noteworthy that this kitchen accessory, including those equipped with stone millstones, often becomes the best present, possessing such qualities as practicality and originality.

It is worth noting that many owners of a manual mill, even if it is a stone flour mill, say that the grinding process itself, accompanied by the creaking of millstones and the pleasant crunch of aromatic spices, has a calming effect. A souvenir hand mill for flour may be fragile, mainly due to the fact that it is equipped with plastic millstones. Therefore, when choosing a product, you should pay attention to the cutting part of the mill. It is best if it is made of metal. Owners of mills with a wooden body say that the design often does not withstand oily seasonings and grains, including garlic, mustard, nuts, star anise, flax and sunflower seeds.

For this product, it is best to choose a mill whose body is made of ceramic or stainless steel. You also need to know that such mills do not provide a choice of grinding degree. It must be emphasized that some of the spices cannot be combined with each other at all, so before grinding the next product, the mill must be thoroughly washed and ventilated. An electric mill is powered by either batteries or batteries. This type of kitchen utensil, like the models discussed above, consists of a special container for spices and other products that require grinding, as well as millstones. Often this type of product has an unconventional design.

Electric homemade mill

An electric homemade mill can produce flour of both coarse, medium and fine grinding. The fraction size is set in the settings. The advantages of a home grain mill are the ability to process a wide variety of raw materials: rice, buckwheat, wheat, soybeans, rye, corn, oats or millet.

The power of the simplest home device will allow you to grind a bucket of corn to a flour-like state in five minutes, and a similar volume of wheat in just two minutes.

Preparing the grains

For future flour, it is better to take unprocessed grains. Sort them thoroughly, remove the spoiled ones. The grain should be washed several times. First with warm water, then cold.

Next, dry the grain on a towel or paper. You should not do this on newspaper - the chemicals from the paint can be absorbed into the grains.

Required materials and parts

Making a mill with your own hands is not difficult if you have all the materials and tools. Before making a mill, it is recommended to study the diagrams and drawings well. You can find them on the Internet on any thematic forum. The drawings will help you understand the principle of fastening parts, electrical components, cutting elements, and avoid many errors in assembly.

The mill structure includes:

- Motor (a motor from an old washing machine will do),

- Motor support,

- Stanin,

- Receiving bunker,

- Rotor and stator,

- Loading hopper.

Materials you also need to have:

- 20 bolts m6,

- Steel corners,

- Sheet steel with a thickness of at least 6 mm,

- Screeds,

- coupling,

- Sheet steel for the manufacture of the lid, at least 3 mm thick,

- 10 m6 screws,

- A pair of bearings, number 203.

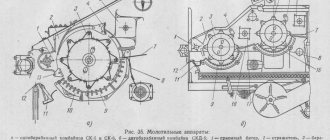

Roller machine design

The machine is equipped with rollers made of two layers of cast iron: gray (internal) and white (external). The surface of the outer layer is corrugated; Moreover, the number of grooves on the grinding roller is twice as large as on the torn roller. An important characteristic is the hardness of the roller material. It varies between 48-55 Rockwell units. Different models differ in parameters: roller diameter, length of the working area, depth of the bleached layer.

The number of rollers and their orientation in space (horizontal, vertical) depends on the model. The rollers rest on bearing supports. On a massive, stable frame, as a rule, there is a connector for removing the rollers.

There are numerous options for technological flour milling lines on the market. They differ in productivity and range of finished products.

Manufacturing process

The design of the grain grinder is very simple. Manufacturing also does not require much effort if you buy all the necessary parts. Some craftsmen prefer to make at home not only the device itself, but also the component parts.

In order to assemble a completely home grain mill, you need experience working with a lathe and drilling equipment.

Rotor assembly

The most important element of an electric mill is the rotor. The process of its manufacture is quite labor-intensive, and before starting work you need to remember several important points:

- The shaft of the rotor being manufactured must be of variable cross-section,

- The shaft is made of round steel,

- The work process is divided into several stages.

The first stage includes the preparation of metal blanks. The workpiece must have several identical holes with a radius of 5 cm. The second stage is erasing the outer layer of the workpiece so that the size of the groove decreases to 10.5 cm. With this size, the working teeth of the future rotor open.

Next, the rotor is sent for hardening. Hardening occurs in two stages. The first is in an oven at a temperature of eight hundred degrees, the second is in an oil container. It is not recommended to cool the workpiece with cold water: the metal will become brittle. The next step is vacation: the rotor is heated to four hundred degrees and left at room temperature until it cools completely.

The rotor is attached to the shaft with two bearings, which increases the strength of the mill. A small spacer ring is attached to the shaft between the bearings. They allow the bearings to move along the shaft to create more tension.

Stator assembly

It is very difficult to make a stator at home, so it is recommended to buy a ready-made element. Several threaded holes are made in the stator for the bearing caps and the stator itself, as well as for the branch pipe and the loading box. For greater accuracy of the mill operation, you need to correctly set the coordinates on the stator. This is done using several bolts.

Bed assembly

An important part of the mill is the frame. The base is made of thick steel sheet. The stator is attached to the frame with screws, which at the same time will hold the pipe. If a removable pipe is planned, then it must be attached to the opening in the base corresponding to the diameter of the part. The removable pipe is held in place only by friction.

A pipe is made from a section of pipe with a diameter of about 3 cm. The pipe can have either a round or square cross-section. Next, a loading box is assembled from a sheet of iron. The iron sheet is bent into the desired shape, and the seams are soldered. The finished box is installed on the stator and secured with bolts.

Engine mounting

The grain mill is operated by an electric motor. Along with the motor you need to have:

- Capacitor,

- Tumblr,

- Fuse.

- The motor along with its components is installed on a dielectric plate.

An important point: the motor shaft must be coaxial with the crushing rollers, and a coupling is used to transmit the rotating element.

The device is ready for use. All that remains is to pour the grain into the loading hopper and turn on the device.

Homemade grain crusher with your own hands: from a grinder, washing machine or vacuum cleaner

A homemade grain crusher (grain grinder) is a simple and reliable device for grinding grain into flour.

Made from scrap materials, motors for power tools, and household appliances, it will provide livestock and poultry with high-quality compound feed and sufficiently finely ground feed flour. At the same time, the cost of assembling such a grain crusher is 2-3 times lower than that of factory analogues, and the feed obtained with their help is not much inferior to purchased food. This makes a homemade grain crusher a very economically beneficial device.

Grinder grinder

Grinder grinder

You can assemble a grain crusher using an angle grinder (grinder) with a disc size (diameter) of 115 or 125 mm as an engine.

The assembly process of such a device consists of the following steps:

- A rectangular or round base is cut out of waterproof plywood 8-10 mm thick with a jigsaw.

- A round hole is made in the center of the base for the grinder gearbox.

- Diagonally from the central hole on the base, another hole is made for the grain bin.

- The chopper knife is made from hard high-carbon steel 1.5-2.0 millimeters thick.

- If necessary, the knife is released over the fire and a hole is drilled in the center for mounting on the gearbox shaft of the grinder.

- Using sandpaper, the knife is sharpened.

- The grinder is placed on the base, its round protrusion is placed in a pre-cut hole.

- Using a homemade clamp made of metal tape and two screws, the angle grinder is secured to the base.

- A sharpened chopper knife is attached and fixed to the grinder shaft.

- The old pan is cut in half, holes are made in its bottom with a 4 or 5 mm drill;

- The resulting sieve is secured to the base on the knife side using 4 corners, rivets or screws.

- The assembled grain crusher is placed on a capacious container - a bucket or large metal pan. A plastic 5-liter bottle with a cut bottom is inserted into the hole for the grain bin.

During operation, the grinder is connected to the network, and the constant speed of the knife is set with a locking button on the handle. To obtain flour, grain is poured into a homemade receiving hopper - a plastic bottle.

In this case, to regulate the flow of grain, a movable tin valve is inserted into the neck.

Grain crusher from a washing machine

Grain crusher from a washing machine

You can make a simple and productive grain crusher from an old vertical type activator machine (Oka, Volga, Fairy) as follows:

- The squeezing device is removed from the machine.

- With the washing machine on its side, unscrew the fixing (locking) screw or bolt on the activator pulley.

- Having installed the machine in the working position, the activator is removed along with the shaft.

- A plate of galvanized sheet metal of the appropriate size and shape is attached to the activator niche.

- The shaft is unscrewed from the activator.

- A trapezoidal knife is cut out of an old circular saw and rapid blade, the diameter of which is slightly smaller or the same as that of the removed activator.

- The knife is sharpened using sandpaper and secured to the shaft using two nuts.

- The shaft with the attached knife is inserted into the hole in the tank and secured in the pulley with a locking screw.

- To collect the final grinding product - flour - the drain hole at the lowest point of the tank is widened using a hammer and chisel, a piece of steel pipe is inserted into it and brought out at an angle.

- To prevent large particles from getting into the final product, a fine-mesh steel mesh or a sheet of galvanized sheet with holes 4-5 mm in diameter is installed in front of the hole for collecting flour at an angle of 60-700.

- To load grain into the removable lid of the machine, widen the existing hole and insert a 5-liter plastic bottle with a cut bottom into it.

The advantage of such a homemade grain crusher is that its assembly does not require drawing up a drawing or making a base for the engine.

In addition, it has good stability, has a spacious tank (up to 30-40 l) and low electricity consumption.

Grain crusher from a vacuum cleaner

Grain crusher with motor from Raketa vacuum cleaner

To make a simple and reliable grain crusher, working but unused Soviet vacuum cleaners such as “Raketa” and “Saturn” are used.

The production of such a grain crusher is carried out as follows:

- The motor in the housing is removed from the vacuum cleaner.

- The chamber with the suction impeller is removed from the motor shaft.

- A round base is cut out of thick sheet steel.

- A hole is cut out in the center of the base for the motor shaft, and a hole is made on the side for the grain bin.

- The motor housing is secured to the base using screws and brackets.

- A trapezoidal pre-sharpened knife is attached to the motor shaft.

- A sieve made from an old saucepan with 4- or 5-mm holes in the bottom is attached under the knife.

For convenient operation of such a unit, it is attached to the container with special clamps and short self-tapping screws.

Important! The hole into which the grain bin is inserted and through which raw materials are supplied for grinding must be located in the rotation zone of the chopper knife. If the rotation zone of the knife does not completely cover the feed hole, not covering 1 centimeter or more, most of the grain will spill out and not be crushed, thereby clogging the sieve.

Types of grain grinding machines

Types of grain grinding machines

Depending on the grinding method, design and location of the working parts, there are 4 types of grain crushers:

- Rotary – crushing of grain in such devices occurs due to a rotor located horizontally and moving at high speed.

- Hammer crushers - the design of such grain crushers includes a rotating vertical drum and stationary hammers located in a circle, against which the grain is crushed. When grinding in this way, the finished flour is poured down and, passing through a sieve, ends up in a container placed under the deck of the housing.

- Roller crushers crush grain due to 2 rollers located in one chamber, rotating towards each other. At the same time, the gap between them is so small that the incoming raw material is not simply crushed, but, due to high speed, is crushed into dust. The advantage of such devices over others is the ability to crush grain with high humidity.

- Millstones are grain crushers in which grain is crushed when it gets between two discs (millstones) located with a small gap. In this case, one disk rotates at high speed, and the second is stationary.

Among these varieties, the most common are rotary and hammer ones - they are more productive, reliable, and easier to repair and maintain.

Crushers for home use

"Whirlwind ZD-350K"

Among factory-made grain crushers, the following models are most suitable for private farms:

- "Whirlwind ZD-350K";

- "Zubr-2";

- "Three Little Pigs 350";

- "Farmer ISE-05";

- "Cyclone-350";

- "Bison 400";

- "NIVA IZ-250".

"Zubr-2"

Important! The average cost of a factory installation, depending on power, performance and brand, ranges from 2000-2300 to 6200 rubles. Assembling a homemade device if you have an unnecessary working washing machine, an old vacuum cleaner, or an angle grinder will cost only 500-1000 rubles.

"NIVA IZ-250"

Grain crusher performance

Productivity is the most important characteristic of grain crushers, which indicates the amount of grain they grind per hour (kg/h).

For homemade and factory models, the average is:

- Homemade units - up to 150-200 kg / h;

- Factory models - from 180 to 400-500 kg / h.

Moreover, in most cases, the productivity of factory crushers cannot be increased, while for any home-made unit this characteristic can be significantly improved by changing the power unit (engine) to a more powerful one.

Conclusion

A homemade grain crusher, with some minor costs for its production, very quickly pays for itself.

It is useful not only for private owners of large households, but also for medium and small farmers, individual entrepreneurs and companies engaged in the production of premixes and animal feed.

Hand mill

A do-it-yourself mechanical mill is much lighter than its electric counterpart, and its productivity is quite high. It consists of two parts - a millstone and a frame with a handle.

Millstones for the mill

For a productive mill, it is very important to find good millstones. The subsequent grinding and durability of the crusher depend on the quality of the stones. Usually suitable stones can be found in special workshops, or found on the river bank and processed independently. Processing of future millstones is carried out using a grinder with a diamond disk of at least 23 cm in diameter. A powerful drill is needed to make holes in the center of the stones. The optimal diameter of the finished millstones is 22-24 cm, and the height is 10-12 cm. You can make larger millstones, but smaller ones are not advisable. The greater the weight of the stones, the better the grinding quality of the flour.

A hand mill should consist of two millstones and a base. The upper millstone is called the runner, and the lower one is called the nizhnyak. The runner is usually made lighter, since after each cycle of operation it is raised to remove the remaining flour. A hole must be drilled in the runner to reach the center of the grain. It is better to drill with a special drill with a diamond coating, and during the process, cool the drilling site with cold water.

The next step in making a home grain mill is cutting the notches on the millstones. They should have the shape of grooves with a triangular cross-section, about 10 mm wide, at least 2 mm deep and at least 4 mm in the lower part and runner, respectively. In the center of the runner, four large grooves are made, eight millimeters deep and fifteen millimeters wide. It will be easier to understand the location of the notches and holes if you find a finished project or drawings of a burr hand mill.

Making the frame

A home grain mill should have a durable wooden frame. It serves as a support for the lower millstone and centers the runner. A small cutout is made at the bottom of the wooden frame for flour. The hole can be closed with a sieve with a cell of the desired size - the flour will sift on its own and will not require additional processing. A metal clamp is attached to the slider, to which the handle is attached.

A do-it-yourself mill made according to this scheme will last for many years and is capable of grinding a wide variety of types and types of grain.

Principle of operation

The mill must include a receiving hopper. The grain from it is fed to a torn system, the rollers of which are distinguished by large grooves.

After the first stage of processing on a tattered system, particles of different sizes are fed into a basement bunker, and from there to a mill sieving machine. In installations there are up to three torn systems, where the grinding cycle is sequentially repeated .

At the same time, sorting is carried out into fractions: flour, bran, other products (cereals, duns). These sieves are fed to a roller machine with fine cutting grooves. Here the product also goes through three stages of grinding, during which flour and bran are again separated from the mixture.

The next stage is knockout. The grinding product arrives here via pneumatic transport. This type of transportation creates air currents that favor better aspiration. At the same time, the flowability of the product increases by reducing its temperature. Another advantage of using pneumatics is the absence of condensation on the internal surfaces and rollers of machines, on gravity feeds and sieves.