Updated: 02/01/2021 16:58:31

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

A grain crusher can alleviate the lot of peasants and farmers in feeding poultry or livestock. This equipment quickly grinds grain, root vegetables and grass, and in many models the grinding amount can be adjusted. There are many grain crushers from different manufacturers on the domestic market. To choose the most suitable unit, you need to listen to the advice of our experts.

How to choose a grain crusher

- Design of a grain crusher.

Most often, manufacturers use two options for grinding grains, legumes and root vegetables. - The rotary chopper

is highly reliable . The operating principle is based on the movement of the cutting element inside the working chamber. After grinding with a knife, the product passes through a sieve with a certain perforation and ends up in a container. - A hammer crusher

breaks down the grain that has entered the chamber using hammers that are fixed on the base. The grinding is of higher quality, and the equipment consumes less electricity and is highly productive. - Scope of application

. The choice of grain crusher depends on the size of the livestock or poultry population. - Many farmers who have a small amount of poultry use manual mechanical mills; there is no point in purchasing expensive high-performance crushers.

- If the farm has a pig or a cow, then it makes sense to purchase an inexpensive rotary-type unit. Even with one grinding it will be possible to provide animals with grain for several days.

- Farmers should pay attention to hammer units capable of processing 300-400 kg of grain per hour. In this case, it will be possible to save the time it takes to prepare the feed.

- Power and performance

. These two parameters are closely related to each other. Peasants should not chase devices with high power and productivity. It will operate at 10-15% of its capacity, consuming a large amount of electricity. Therefore, a unit with a 1.0-1.5 kW motor will successfully cope with the assigned tasks (100-200 kg of grain per hour). Farms require higher productivity (200-400 kg/h), therefore the electric motor in the equipment must be more powerful (1.5-2.5 kW). - Weight and dimensions.

The overall dimensions and weight of the grain crusher become important factors when it comes to moving or transporting the device. If there is enough free space on the farm and electricity is supplied to the grinding site, then any stationary model will do. But when you have to grind grain and root crops at different points, you should give preference to light (up to 10 kg) and compact grain crushers.

We have selected 9 of the best grain crushers for review. They are widely represented in the Russian trading network. The rating was compiled taking into account the opinion of the expert community and feedback from peasants and farmers.

5 Cyclone-350

Cyclone-350

A compact electrical device is the domestic grain crusher Cyclone-350. It is intended for household use. The unit is capable of grinding up to 350 kg of grain per hour. This performance was achieved due to a spacious hopper (25 l) and a powerful motor (1.9 kW). The device is sold at the best price, which attracts the attention of zealous owners. The grain crusher body is made of durable sheet steel, grain is loaded from above. The sharp knives rotate horizontally. The simplicity of the design was highly appreciated by both experts and users.

The model is widely used on Russian farms. Among the strengths, consumers in reviews note the reliability and maintainability of the unit. The grain crusher is not without minor flaws, for example, the damper closes on its own during operation. The fixation mechanism is easy to modify on your own.

Rating of the best grain crushers

| Nomination | place | Name of product | price |

| Rating of the best grain crushers | 1 | Zubrenok-Mais | 7 393 ₽ |

| 2 | ZUBR-2 | 7 590 ₽ | |

| 3 | Umnitsa Don KBE-180 2.5 kW | 7 450 ₽ | |

| 4 | Cyclone IZKB-2 | 5 542 ₽ | |

| 5 | FARMER IZE-25M | 4 140 ₽ | |

| 6 | Greentechs IZ-05 (170kg/hour) | 2 950 ₽ | |

| 7 | UralSpetsMash IZ-14 (Farmer 300) | 3 630 ₽ | |

| 8 | Whirlwind ZD-400K | 3 080 ₽ | |

| 9 | Electromash Khryusha 300 kg/h | 2 385 ₽ |

Zubrenok-Mais

Rating: 4.9

The Zubrenok-Mais grain crusher will be an excellent purchase for livestock farmers. The model perfectly combines the qualities of a feed cutter and sheller. Therefore, choosing this expensive model subsequently turns out to be a cost-effective purchase. The manufacturer equipped the equipment with a chopper with a hulling machine, two bins (for grain and corn), two dampers, and two meshes with different perforations. Experts pay attention to the efficiency of the electric motor (1.35 kW), which can grind 140 kg of grain in an hour or peel 800 kg of corn. There will be no problems with moving the grain crusher.

Users are satisfied with the functionality of the unit, quick payback, and ease of use. The model becomes the winner of our rating.

Advantages

- good performance;

- ease of use;

- compactness;

- reliability and durability.

Flaws

- not detected.

ZUBR-2

Rating: 4.8

The Russian grain crusher ZUBR-2 has wide functionality. In addition to grinding grains, the model is capable of grinding root vegetables and cutting green mass. The manufacturer equipped its product with a powerful electric motor (1.8 kW), positioning it horizontally. Thanks to this design solution, it was possible to reduce the load on the shaft, which had a positive effect on the durability of the equipment. Experts appreciated the performance of the unit; in an hour it can process 180 kg of grain or 650 kg of root crops. The grinding size is selected by installing a sieve with a cell of 2.5x2.5 or 5x5 mm.

The model takes an honorable second place in the ranking for its versatility and affordable price. Disadvantages include juice getting on the bearing.

Advantages

- multifunctionality;

- affordable price;

- good performance;

- durability.

Flaws

- poor sealing of the chamber.

Umnitsa Don KBE-180 2.5 kW

Rating: 4.7

It is convenient to prepare a tasty feed mixture for pets using the Umnitsa Don KBE-180 grain crusher. The equipment is designed for grinding grains, legumes and root crops. The model is driven by a single-phase electric motor with a power of 2.5 kW. In an hour, the grain crusher is capable of processing up to 200 kg of grain and beans. The user is given the opportunity to select the appropriate grind size by varying the three sieves. Experts note the high build quality and long service life of the equipment. The unit is in the top three of our rating.

Users have positive emotions about the rigidity of the structure, durable paintwork and lack of vibration. As for the disadvantages, the main one will be the high starting current.

Advantages

- great resource;

- good performance;

- robust design;

- ease of use.

Flaws

- high starting current.

Cyclone IZKB-2

Rating: 4.6

The Cyclone IZKB-2 grain crusher has become a popular grinder of feed for poultry and livestock among farmers. The model attracts attention with its affordable price and efficient operation. Not only grain crops, but also root crops are subject to processing. The equipment is driven by a 1.8 kW electric motor. In one minute, the unit grinds up to 5 kg of grain or 11 kg of root crops. Experts liked the design of the feed chopper, where the knife drum plays one of the main roles.

The model stopped one step away from the pedestal of our rating. The position was influenced by feedback from farmers, which pointed out a number of minor shortcomings. For example, during operation the damper closes spontaneously due to vibration. We have to come up with a reliable clamp.

Advantages

- affordable price;

- good performance;

- quality materials;

- reliability.

Flaws

- minor modifications required.

FARMER IZE-25M

Rating: 4.5

The grain crusher FARMER IZE-25M was developed based on the wishes of domestic agricultural producers. The model turned out to be strong and durable; in some farms it lasts about 5 years. The manufacturer offers users several grinding options, starting from 4 mm and ending with 6 mm. Although the equipment is equipped with a small motor (1.3 kW), it has good performance (400 kg/hour). Experts gave the grain crusher the 5th position in the rating.

Users are generally satisfied with the reliability, performance and durability of the unit. It crushes grain efficiently and breaks quite rarely. The model has a number of minor drawbacks. Dissatisfaction is caused by loud noise during grinding, inconvenience of installing the receiving container, and peeling paint.

Advantages

- affordable price;

- reliability and durability;

- high-quality grinding;

- compact sizes.

Flaws

- paint peels off;

- high noise level.

Greentechs IZ-05 (170kg/hour)

Rating: 4.4

The Greentechs IZ-05 grain crusher has an unusual design. The bunker is made in the form of a funnel cut in half. This model is produced at the domestic enterprise ElectroMash. The unit is addressed to peasants with a small number of animals or birds. Only about 5 liters of grain can be loaded into the bunker, and the 1.25 kW electric motor provides a productivity of 170 kg/h. In addition to grains, it is possible to chop any vegetables. Experts liked the compactness and mobility of the grain crusher. With a weight of 7.6 kg and the presence of a convenient handle, moving it to a neighboring area will not be difficult.

The equipment is assembled with high quality, as evidenced by consumer reviews. The only serious drawback that affected the place in our rating was the short electrical cord.

Advantages

- lightness and compactness;

- good performance;

- multifunctionality;

- low price.

Flaws

- short cord.

UralSpetsMash IZ-14 (Farmer 300)

Rating: 4.3

Another compact model made it into our rating. This is a grain crusher UralSpetsMash IZ-14 (Farmer 300). It weighs only 7.7 kg and has compact overall dimensions. Thanks to a spacious loading hopper (14 l) and a 1.2 kW electric motor, the unit processes up to 300 kg of grain per hour. According to experts, the advantages of the product include the ability to regulate the degree of grinding. The device can withstand long grinding times; the design includes bottom and side sieves. The knives are made of hardened steel with a thickness of 0.6 mm, and a spare knife is included in the kit.

Users note the independence and mobility of the unit, quickly obtaining the required grinding. As for the shortcomings, there are cases of engine failure.

Advantages

- compactness and lightness;

- affordable price;

- spacious bunker;

- sharp knives.

Flaws

- engines fail.

Whirlwind ZD-400K

Rating: 4.2

The Vikhr ZD-400K grain crusher can process all types of feed grain. It is important that it be dry, be it wheat or oilseed crops. The model was included in our rating for its lightest weight (5.1 kg). At the same time, it is not inferior to competitors in terms of performance. Thanks to a spacious hopper (14 l) and a powerful electric motor (1.55 kW), it is possible to grind up to 400 kg of grain per hour of operation. The manufacturer allows the installation to be used for 6 hours; pauses of 5-10 minutes should be taken every hour.

Users rate the grain crusher differently. Some owners are satisfied with the performance, while others are unhappy with the stops every hour. Another inconvenience is the need to sift the grain before grinding.

Advantages

- light weight;

- low price;

- high performance;

- sustainability.

Flaws

- the receiving hole is clogged with small stems;

- stops are required every hour.

Electromash Khryusha 300 kg/h

Rating: 4.1

The grain crusher Khryusha 300 kg/h produced by Elektromash is sold at the lowest price. But not only this became the main criterion for getting into our rating. The model is in high demand among domestic peasants. With a small mass of the unit (9 kg), it is capable of grinding up to 300 kg of dry grain per hour. To achieve such performance, the product is equipped with a powerful electric motor (1.75 kW). In the standard version, the model has a sieve with 5 mm cells for obtaining medium-ground grains. The device can be used both indoors and outdoors.

Users praise the grain crusher for its compactness, economical energy consumption, durability and low dust content (up to 5%). The disadvantages include a short cord and lack of adjustment of the degree of grinding.

Advantages

- efficiency;

- reliability;

- ease of use;

- low price.

Flaws

- short cord;

- The degree of grinding is not adjustable.

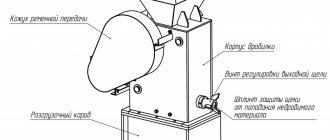

6 Farmer IZE-05

Farmer ISE-05

The Farmer IZE-05 grain crusher has an original body shape. The loading hopper is made in the form of a funnel cut in half. This shape makes loading grain easier. Despite the small volume of the hopper (5 l) and low-power motor (750 W), the unit can grind up to 170 kg of grain in an hour. This performance is achieved due to blunt flanges on the plate-shaped knife and high engine speeds (12,000 rpm). Experts note high-quality manufacturing and reliable protection of the steel structure from corrosion. The flow of supplied grain can be adjusted.

User reviews note the excellent combination of compactness and performance of the device. Thanks to the comfortable handle and low weight, the model is easy to carry. The only drawback that consumers often mention is the short electrical cord. But farmers have no complaints about the quality of crushing.

Types of crushers

Crushers can be divided into several classes:

- Industrial - they are used in large agro-industrial farms.

- Household - they have found their application in household plots.

Another classification option can be given.

The numerous range of crushers can be classified as follows - according to the type of feed processed:

- Plants for root processing. It is used for cutting root vegetables and further mixing with food additives and vitamins.

- Silage processing plants - this equipment is used for crushing grain sprouts, grass or malt.

Installation for processing silage

In addition to the listed installations, the industry also produces universal equipment. It can be used to process all types of feed.

Principle of operation

The machine is extremely effective in crushing forage crops. It makes the food much more attractive; animals and birds eat it with pleasure and grow stronger. The chopper has a simple design, and its operation as a whole is as adapted and simplified as possible. The main element is a durable body. It performs two functions simultaneously: it becomes a receiving chamber and has cutting elements inside. They grind the grain, producing fine flour and grinding.

There are handles on the shredder; they are great for moving and transporting the device. Some modern models are specially equipped with wheels.

Operating rules

The following recommendations will help extend the service life of the grain crusher:

- do not overload the device (uneven grain loading also negatively affects operation);

- for permanent placement, choose a dry, well-ventilated room;

- do not leave the device outdoors unattended;

- clean parts in a timely manner;

- Check the integrity of the sieve before starting work.

On some models, the sieve can be turned over if one side begins to collapse.

Device Features

The grain crusher cannot be called special, but different models have enough features. True, they usually concern small and insignificant details, which do not greatly affect its performance, but they definitely make the device more convenient - it becomes much easier to use.

Accordingly, the work goes faster, the grinding becomes better, and the saved time and effort can be spent on any other useful things that can always be found on a farm where the use of a crusher is necessary.

Grain crusher

Any grain crusher, be it Bumblebee, Bison, Piggy, Cyclone, or Spike, is similar in principle to a coffee grinder, only with the exception that grain crushers are much more powerful.

- Whole grain is poured into a special compartment called a “hopper”.

- Passing through the department with knife-hammers, it is crushed to the required fraction.

- Depending on what exactly needs to be obtained at the output, different hammers are used, because in a grain crusher you can grind just grain, or whole ears, along with the stems on which it grew.

This applies to both wheat and other grain crops, including barley, corn and buckwheat. Thanks to this, you can prepare a variety of food for all poultry and animals. Also, grain crushers can grind oily products, such as sunflower meal.

It is fundamentally different from dry grain because it has much greater viscosity and when crushed, the resulting grain is much larger. Just as in the case of grains and oilseed crops, a grain crusher can grind root vegetables, whole ears of corn, hay and grass.

But given that this is not the direct purpose of the inventory, such actions are the exception rather than the rule. In order to please livestock with a salad of fresh vegetables garnished with hay, it is better to use a feed chopper.

Also, regarding working with a household grain crusher, there are some rules for farms and households that must be followed at all times and special attention must be paid to them.

Since the operation of the device is based on knives - hammers, which carry out chopping thanks to centrifugal force, it is worth pouring the grain evenly and in small portions. In large quantities, it can jam the mechanism, which will lead to instant damage to the engine or shaft.

This problem can be solved with the help of a feed valve, which, although installed in many models, is still missing in some.

Never, under any circumstances, should you leave a crusher connected to the mains unattended, especially if there are children nearby.

Moreover, children should not be allowed to work with it without supervision - the grain crusher has a lot of open moving parts. Also, it is highly undesirable to start a grain crusher that is already preloaded - in most cases the engine will not be able to start.

In general, in terms of engine load, grain crusher, feed cutter, grass cutter, and household feed choppers are very demanding. When the device is turned on, it must be under a payload at all times - idle operation does not benefit it. It should only last a few seconds.

The duration of continuous operation is also limited. In order not to overload the device, it must be turned off approximately every hour - the hammers and the motor must cool down at this time. If you follow these simple but very important rules, your equipment will last a very long time.

1 Whirlwind ZD-350K

Whirlwind ZD-350K

Domestic pet owners are showing great interest in the Whirlwind ZD-350K grain crusher. This Russian development is produced in China. The model turned out to be light, comfortable, has a pleasant appearance and a collapsible design. The hopper with a capacity of 10 liters can be quickly dismantled to simplify the transportation of the product. In an hour, the unit is capable of grinding up to 350 kg of wheat, barley, rye or other fodder. Crushed fractions can be mixed with other feeds, allowing you to choose your own recipe for each animal. A powerful motor (1.35 kW) at high speed (12,000 rpm) rotates sharp knives, so when crushing you can get a fraction in the form of flour.

Judging by user reviews, they have no special complaints about the grain crusher. The unit does an excellent job of grinding grain, combining affordability and high performance.

What does the market offer?

The modern market of technical devices gives domestic models a place of honor. Chinese units cannot cope with the loads and quickly fail. The leaders are grain crushers of the “Khryusha” and “Farmer” brands. In terms of price, the first models save the budget, while the second are distinguished by their reliability and high build quality. In any case, it's up to you to decide.

Ground feed has always been a complete source of nutrition for animals, so purchasing a grain crusher is an important task for all owners of farmsteads.

Crushing methods

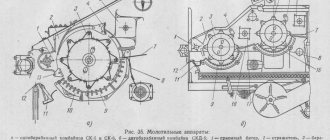

The crushing device is not complicated. Main structural elements: body and cutting parts. For ease of transportation, the grain crusher can be equipped with handles and removable wheels. Different types of grain crushers differ from each other in the way they crush grain.

The most popular varieties include the following:

- Rotary.

- Hammer.

- Roller

The most common ones on the market are rotary and hammer grain crushers. The quality of work of both types is approximately the same, but the differences in design result in different parameters and characteristics.

The main components that make up the structure of electric grain crushers:

- Frame. Can be made of plastic or metal. The grain intended for grinding is poured into the housing.

- Work zone. Knives, hammers or rollers are located here, depending on the design of the grain crusher. The grain grinding process takes place here.

- Electric motor. Activates elements located in the working area.

- The container where the crushed grain goes.

Grain crushers for domestic use are divided into various models depending on the type of drive used. The simplest is a manual chopper, which operates mechanically. A pneumatic grinder does not require much physical effort and produces smaller grain fractions at the output. The main advantage of an electric shredder is its high performance.

Rotary grain crusher

A rotary grain mill grinds grain using moving knives. Sharpened on both sides, the knives are mounted on rotating shafts.

This machine has many advantages:

- high productivity;

- low energy costs;

- small dimensions;

- reliability during operation.

The parts of the rotary grain crusher are made from materials that have particularly high strength. The rotary chopper is a grain crusher with adjustable grinding. The level and size of the grain depend on the setting of the rotation speed of the shafts with knives. The output is finely ground grain. The downside is that the resulting pieces have different sizes and shapes.

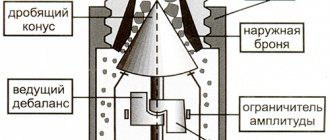

Hammer grain crusher

For better crushing, a grain hammer crusher is used. The design consists of several units: a drum, a sieve and a deck. Grinding occurs when the drum with hammers attached to it rotates. The size of crushed grains is adjusted by choosing gratings with cells of different sizes. Thanks to this, it is possible to obtain the desired dimensions of the final product.

The crushed grain obtained after processing in a hammer machine is considered to be of higher quality than after processing in a rotary machine.

This result is due to the large amplitude of movement of the hammers. They are able to grind all grains, including those located far away. When deciding which grain crusher to choose - rotary or motor, you should take into account that a rotary grinder consumes much less electricity, while having more power. In addition, its productivity is higher than that of a hammer one, and it takes less time to process. The rotary machine has a lower price and is cheaper to maintain.

Both rotary and hammer grain crushers have both advantages and disadvantages. Therefore, which grain crusher to choose can be determined correctly by understanding for what purpose it is going to be used.

If you have large birds and cattle on your farm, a rotary grain crusher is suitable. In the presence of small birds and small or young individuals, the hammerhead will be preferred.

We should not forget that different models of the same type have their own characteristics.

Roller grain crusher

The peculiarity of a roller grain crusher is that it can not only crush grain, but also grind it. This is explained by its design. The main detail is the grooved rollers. As grains pass through them, grinding occurs.

A good result is obtained only after pre-soaking the grain.

A grain roller crusher can process not only grain, but also malt used to make beer. If flat teeth are installed, then not only crushing is carried out, but also flattening. In this case, the grain remains intact, but is cleared of its shell.

The product after processing by a roller grain crusher can be obtained in various types. This depends on the machine settings and the shape of the teeth installed on the rollers. It is possible to set different speeds at which the rollers will rotate. The size of the gap between them is also subject to adjustment. After correctly setting all the parameters, the product can be obtained with the required degree of grinding, suitable for feeding different animals.

Mini grain crushers

Mini grain crushers are widely used on private farms. They save time and significantly solve the problem of feeding pets, even with a small number of them. For a low cost you can get an excellent helper in the household.

Despite the simple design of mini crushers, you should read the instructions for use before use.

How to make a grain crusher with your own hands - learning the algorithm

You can make a grain crusher from an ordinary grinder. This will help save a considerable amount of money and produce a reliable design capable of processing large amounts of grain in the shortest possible time.

Before you make a grain crusher with your own hands, you will need to prepare the tools. You will need:

- Pliers;

- Drill with attachments for working with metal and wood;

- Vise;

- Spanners.

Before work, you should also study the drawings, which indicate the installation locations of the unit elements.

Having carefully studied all the diagrams, you can begin to work. The entire algorithm of actions looks like this:

- First you need to take a sheet of high-quality plywood, which will serve as the basis of the unit;

- Make several holes in the plywood. You need to insert a grinder into one of them, and the second hole will serve as a place for feeding grain;

- Secure the body of the angle grinder with bolts and brackets;

- Remove the grinder disc and install metal knives instead, each side of which must be sharpened with high quality;

- Install and secure a special mesh underneath the plywood, which will act as a sieve;

- A plastic barrel with a volume of 5–10 liters can act as a bunker for processed grain.

Be sure to test your homemade device. Remember that the grinder engine requires regular lubrication, otherwise it will become unusable due to abrasion of the main parts.