Design and principle of operation

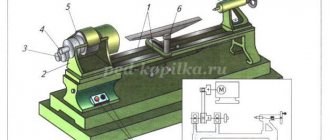

The slotting machine consists of the following structural elements:

- a movable block with clamps for the workpiece;

- frames;

- electric motor;

- chisels.

The electric motor of the machine is pendulum. It provides vertical reciprocating movement of the bit.

A slotting machine should not be confused with a milling machine. The latter can also cut grooves. But he does this according to a different principle - the cutting elements rotate, and do not move from top to bottom and back.

The workpiece is placed in a block with clamps, the chisel is placed at the beginning of the future groove. The unit is started. The chisel is lowered and strikes the wood, gouging out a groove. When the hole is completely cut, the block with the workpiece is moved. The bit begins processing the next area. The workpiece is moved until the groove is completely hollowed out.

Where is it used?

Slotting machines are used for carpentry work. They are most suitable for processing wood when creating furniture products. After all, with the help of the unit you can quickly create an even rectangular groove for assembling an object.

SLOTTING TOOL.

Chisels and chisels are used to select nests, grooves, tenons and other work. The chisel is a trapezoidal steel rod; its lower part ends with a cutter, and its upper part ends with shoulders and a cone-shaped shank for the handle. The chisel blade cuts the wood fibers after hitting the handle with a wooden hammer.

To prevent the handle from being deformed and destroyed, metal rings are put on its end.

The length of the chisel together with the handle is usually 25-30 cm. Chisels with a square rod are used for cutting deep grooves. Typically, chisels have single-sided or double-sided sharpening.

A wedge-shaped chisel has a curved shaft; the wooden handle is hammered into the socket of the upper part; the lower wedge-shaped part of the rod is flattened and ends with a blade. It is usually used to hollow out deep nests and to clear nests of wood debris.

Chisels are somewhat thinner than chisels; they are made of flat steel and are divided into flat, ordinary, universal and semicircular. Woodworkers use chisels with a width of 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 18 mm and 20 mm. All of them have one-sided sharpening.

An ordinary chisel has a flat shaft with one-sided sharpening (sharpening angle - 18-25°) and a width of 12-25 mm

The semicircular chisel has a semicircular shaft with a sharpening angle of 30°. The width of the blade is determined by the straight line between its ends. Semicircular chisels are used when gouging out curved sockets and holes, as well as when processing shaped surfaces.

Rectangular holes and sockets for large volumes of work can be performed using chain slotting machines. The main parts of such a machine are an electric motor and a milling chain. A milling chain of the required width is put on the drive sprocket mounted on the electric motor shaft. The chain moves along a ruler with a roller at the bottom. The milling chain is tensioned, the depth limiter is moved along the guide frame. By turning on the electric motor and pressing the lever device, the electric shaper is lowered down along with the ruler and the tensioned chain, while the chain forms an oblong socket, the width of which is equal to the thickness of the milling chain. For sockets of a certain width, the appropriate chain is selected.

DRILLS AND DRILLING EQUIPMENT

Drilling is the process of forming through and non-through cylindrical and conical holes in workpieces with a drill for tenons, screws, etc. To obtain a smooth surface, it is practiced to drill out knots and then seal them with wooden plugs. The nests are drilled manually using a brace or drill.

Small holes with a diameter of up to 5 mm are drilled with a screw hand drill (drill). To drill deep holes, use a drill, which is a drill with an eye for a handle located in its upper part. Shallow holes for screws are drilled with a gimlet having a diameter of 2-10 mm.

A hand drill with a gear drive is used to make holes of various diameters. Due to the gear drive, a higher drilling speed is achieved (compared to a brace). Depending on the nature and conditions of the work performed, different types of drills are used. Spoon drills are used for drilling holes for bolts and tenons. Such a drill has two sharpened side edges (two blades), which cut wood when the drill rotates in both directions. The drill is deepened into the wood under pressure. The drill is cleaned by removing it from the hole. Unlike a spoon drill, a shell-shaped drill (drill), which has a spiral tip, goes deep into the wood without pressing on it from above and simultaneously pushes the chips out.

An awl-shaped drill is equivalent to a triangular awl; it is used to make holes for screws, turning from left to right when drilling. Using a countersink drill, drill out the top of the holes for the heads of screws and bolts. The working part of such a drill has the shape of a cone with longitudinal grooves running towards the center.

Making cylindrical holes for inserted round tenons, drilling through and shallow holes across the fibers is done with a center drill with a flat head (feather drill). The flat blade cutter cuts the wood horizontally in a spiral shape around the circumference and goes deeper into the wood. However, drilling deep holes with center drills is difficult due to poor chip removal.

For mechanical drilling, a spiral (auger) drill is used, two thirds of which are made in the form of a helical spiral. The cone-shaped screw in the center of the drill bit guides the drill bit into the wood, and the arc-shaped cutters drive the bit deeper into the wood. In this case, short drills are 105-145 mm long. When making sockets with these drills, the holes are clean, since the chips are well removed along the screw grooves.

Helical drills are used to drill deep holes across the grain. The end of these drill bits has a fine thread screw. Based on their shape, they are divided into screw and corkscrew. A corkscrew drill in the form of a steel spiral tape can replace an auger drill.

A plug drill is used to drill out knots. Its working part has the form of a cylinder with a circular cutter; Inside the cylinder there is a diametrical wall - a cutter. A plug drill is used when drilling on machines.

If there are no wood drills, they can be made from metal drills. To do this, metal drills are re-sharpened.

Marking tool.

Tape measure, meter, thicknesser, erunok, malka, comb, compass, bore gauge, ShTs-1, pencil, templates, string is intended for marking a long line, it is rubbed with chalk or painted.

Chisels and chisels are used to select nests, grooves, tenons and other work. The chisel is a trapezoidal steel rod; its lower part ends with a cutter, and its upper part ends with shoulders and a cone-shaped shank for the handle. The chisel blade cuts the wood fibers after hitting the handle with a wooden hammer.

To prevent the handle from being deformed and destroyed, metal rings are put on its end.

The length of the chisel together with the handle is usually 25-30 cm. Chisels with a square rod are used for cutting deep grooves. Typically, chisels have single-sided or double-sided sharpening.

A wedge-shaped chisel has a curved shaft; the wooden handle is hammered into the socket of the upper part; the lower wedge-shaped part of the rod is flattened and ends with a blade. It is usually used to hollow out deep nests and to clear nests of wood debris.

Chisels are somewhat thinner than chisels; they are made of flat steel and are divided into flat, ordinary, universal and semicircular. Woodworkers use chisels with a width of 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 18 mm and 20 mm. All of them have one-sided sharpening.

An ordinary chisel has a flat shaft with one-sided sharpening (sharpening angle - 18-25°) and a width of 12-25 mm

The semicircular chisel has a semicircular shaft with a sharpening angle of 30°. The width of the blade is determined by the straight line between its ends. Semicircular chisels are used when gouging out curved sockets and holes, as well as when processing shaped surfaces.

Rectangular holes and sockets for large volumes of work can be performed using chain slotting machines. The main parts of such a machine are an electric motor and a milling chain. A milling chain of the required width is put on the drive sprocket mounted on the electric motor shaft. The chain moves along a ruler with a roller at the bottom. The milling chain is tensioned, the depth limiter is moved along the guide frame. By turning on the electric motor and pressing the lever device, the electric shaper is lowered down along with the ruler and the tensioned chain, while the chain forms an oblong socket, the width of which is equal to the thickness of the milling chain. For sockets of a certain width, the appropriate chain is selected.

DRILLS AND DRILLING EQUIPMENT

Drilling is the process of forming through and non-through cylindrical and conical holes in workpieces with a drill for tenons, screws, etc. To obtain a smooth surface, it is practiced to drill out knots and then seal them with wooden plugs. The nests are drilled manually using a brace or drill.

Small holes with a diameter of up to 5 mm are drilled with a screw hand drill (drill). To drill deep holes, use a drill, which is a drill with an eye for a handle located in its upper part. Shallow holes for screws are drilled with a gimlet having a diameter of 2-10 mm.

A hand drill with a gear drive is used to make holes of various diameters. Due to the gear drive, a higher drilling speed is achieved (compared to a brace). Depending on the nature and conditions of the work performed, different types of drills are used. Spoon drills are used for drilling holes for bolts and tenons. Such a drill has two sharpened side edges (two blades), which cut wood when the drill rotates in both directions. The drill is deepened into the wood under pressure. The drill is cleaned by removing it from the hole. Unlike a spoon drill, a shell-shaped drill (drill), which has a spiral tip, goes deep into the wood without pressing on it from above and simultaneously pushes the chips out.

An awl-shaped drill is equivalent to a triangular awl; it is used to make holes for screws, turning from left to right when drilling. Using a countersink drill, drill out the top of the holes for the heads of screws and bolts. The working part of such a drill has the shape of a cone with longitudinal grooves running towards the center.

Making cylindrical holes for inserted round tenons, drilling through and shallow holes across the fibers is done with a center drill with a flat head (feather drill). The flat blade cutter cuts the wood horizontally in a spiral shape around the circumference and goes deeper into the wood. However, drilling deep holes with center drills is difficult due to poor chip removal.

For mechanical drilling, a spiral (auger) drill is used, two thirds of which are made in the form of a helical spiral. The cone-shaped screw in the center of the drill bit guides the drill bit into the wood, and the arc-shaped cutters drive the bit deeper into the wood. In this case, short drills are 105-145 mm long. When making sockets with these drills, the holes are clean, since the chips are well removed along the screw grooves.

Helical drills are used to drill deep holes across the grain. The end of these drill bits has a fine thread screw. Based on their shape, they are divided into screw and corkscrew. A corkscrew drill in the form of a steel spiral tape can replace an auger drill.

A plug drill is used to drill out knots. Its working part has the form of a cylinder with a circular cutter; Inside the cylinder there is a diametrical wall - a cutter. A plug drill is used when drilling on machines.

If there are no wood drills, they can be made from metal drills. To do this, metal drills are re-sharpened.

Marking tool.

Tape measure, meter, thicknesser, erunok, malka, comb, compass, bore gauge, ShTs-1, pencil, templates, string is intended for marking a long line, it is rubbed with chalk or painted.

Rating of the best models

Let's look at several current models of slotting machines available on the Russian market.

JET JBM-5 708580M

Compact model designed for processing small volumes of wood. Ideal for those for whom furniture making is a hobby and not a professional activity. One of the cheapest options.

You need to understand that due to its compact size, the unit is not suitable for processing voluminous parts, and due to its low power, it does not penetrate the groove too deeply and interacts poorly with hard types of wood.

Therefore, the model is the best option for those who make small-sized wood products (for example, small crafts or souvenirs).

The unit is small in size. It does not have its own full-fledged frame with a base. But at the bottom of the device there is a clamp that allows you to secure it to a carpenter's table.

There is also no moving block for the workpiece. You will have to move it by hand. Hold it too - since there is no block for the workpiece, there are no clamps that fix it.

For more precise movements of the chisel, a U-shaped guide is attached to the frame holding the electric motor.

The average cost of the model in Russian retail stores is 25,000 – 26,000 rubles. It is unlikely that you will be able to find a slotting machine at a lower price.

| Options | |

| Power, W) | 700 |

| Speed (revolutions per minute) | 1450 |

| Penetration depth (mm) | 120 |

| Dimensions (mm) | 370x350x800 |

| Weight (kg) | 20 |

JET JBM-4 10000084M

A more “advanced” model from the same manufacturer. It also attaches to the carpenter's table. However, the unit has its own base, a movable holder for the workpiece.

Thanks to this, making grooves in wood is much more accurate. This model can already be called “semi-professional” - it is suitable for the full assembly of furniture, although not in production, but in domestic conditions.

The cost of the unit is higher than its simpler counterpart and amounts to 35,000 rubles.

| Options | |

| Power, W) | 550 |

| Speed (revolutions per minute) | 1420 |

| Penetration depth (mm) | 110 |

| Dimensions (mm) | 275x440x640 |

| Weight (kg) | 39 |

Corvette 92

The unit is of domestic production. It has everything necessary for professional woodworking, making it ideal for small furniture production.

The lower part of the device is a metal cabinet in which you can place a chisel or tool. The base of the frame is attached to it with four bolts. Thanks to this, the unit is quite stable. If necessary, the frame can be mounted on another base (for example, on a carpenter's table).

The workpiece area is quite large (40x15 cm) and has its own clamps. This allows you to fasten even a large part, securing it securely.

A massive block with a motor can move along the workpiece. Its location is changed using two rotating knobs. There is also a lever that can move the bit not only from right to left, but also forward and backward. This allows you to hollow out grooves of almost any geometry.

The workpiece platform can also be moved from place to place if desired. Another rotating handle is responsible for its movement.

Thanks to the maximum chiselling depth of 76 mm, it is able to process even fairly large workpieces.

The machine costs from 55,000 to 60,000 rubles. This is not a very high price, so the unit can also be purchased for use on a personal plot.

| Options | |

| Power, W) | 1500 |

| Speed (revolutions per minute) | 1450 |

| Penetration depth (mm) | 155 |

| Dimensions (mm) | 650x550x2030 |

| Weight (kg) | 220 |

720HD

Professional unit. Designed for processing large-scale workpieces. It has good performance, so it can be used in furniture production.

The block with the workpiece moves in any direction horizontally. The frame with engine and bit has hydraulic shock absorption. This allows you to move it very smoothly and thereby achieve high precision chiselling.

The model costs about 150,000 rubles.

| Options | |

| Power, W) | 750 |

| Speed (revolutions per minute) | 1400 |

| Penetration depth (mm) | 76 |

| Dimensions (mm) | 560x480x830 (without cabinet base) |

| Weight (kg) | 108 |

STALEX B5013

Professional level slotting machine. Ideal for medium-scale furniture production. It has great power and the ability to process large workpieces. Thanks to this, it has high performance and is practically universal.

The unit has an electric motor with a chisel at the end, which can only move in a vertical plane. But the workpiece board can also move horizontally. And not only left and right, but also back and forth.

You can change its location very quickly - just make a few turns of the rotating knobs that are responsible for it. The bit is lowered and raised using a spring-loaded lever.

The device has a powerful steel base, which makes it as stable as possible. If desired, the unit can be fixed to the floor. For this purpose, there are holes in the base for bolt fastening.

The cost of the machine ranges from 180,000 to 200,000 rubles.

| Options | |

| Power, W) | 1100 |

| Speed (revolutions per minute) | 1650 |

| Penetration depth (mm) | 125 |

| Dimensions (mm) | 1090x1120x790 |

| Weight (kg) | 330 |

The best metal slotting machines

Models of this type are characterized by high performance and power. Metal slotting machines are used to form keyways, grooves, and splines.

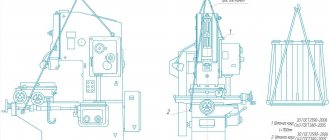

StankoGomel GD200-01

5

★★★★★

editorial assessment

99%

buyers recommend this product

The rotating cutting head of this model allows chiselling at an angle of up to 90°. The stroke length of the cutter can be adjusted by rotating the crank handle shaft.

The unit table has three modes of movement: transverse, longitudinal and circular. This provides maximum convenience during operation.

The dimensions of the machine are 1900x1270x2175 mm, the power of the main drive is 3.6 kW. A quick-release guard protects against injury from chips.

The lathe chuck installed in the center of the working surface guarantees reliable fixation of the part. The standard package includes lubrication and lighting systems, and a set of tools.

Advantages:

- powerful engine;

- workpiece fastening;

- 12 table positions;

- adjusting the stroke of the cutter;

- ease of maintenance.

Flaws:

- large dimensions.

StankoGomel GD200-01 is intended for use in mass production, where it is necessary to process complex parts.

Stalex B5012

5

★★★★★

editorial assessment

97%

buyers recommend this product

The model is equipped with an emergency engine stop button, the use of which ensures operator safety. Robust design and powerful motor guarantee stable operation of the machine under high loads.

The table movement mechanism allows you to fix it at the desired height. Equipment dimensions - 1000x650x1000 mm.

The maximum chiseling depth is 120 mm. Lubricating fluid is supplied to the guide columns manually, which facilitates maintenance of the unit. The holder can be adjusted depending on the size of the workpiece. The device is controlled from the keypad.

Advantages:

- ease of maintenance;

- simple controls;

- long service life;

- powerful engine;

- high performance.

Flaws:

- not a small price.

Stalex B5012 is worth purchasing for processing flat and shaped metal surfaces. A universal solution for both production and home workshops.

Kommunar 7A420

4.9

★★★★★

editorial assessment

95%

buyers recommend this product

A special feature of the model is the ability to rotate the frame with the cutter at an angle of up to 90°. Thanks to this wizard, it is possible to process an inclined plane without changing the position of the part. The table can be moved either manually or mechanically.

The diameter of the working surface of the table is 500 mm, the drive power is 3 kW. To quickly stop it, an emergency braking device is provided. Interlocked handles make operation easier.

The plunger pump supplies lubricant through the filter, which guarantees ease of maintenance and increases the life of the unit.

Advantages:

- high performance;

- large table area;

- ease of control;

- durability;

- operator safety.

Flaws:

- complex installation.

The Kommunar 7A420 will be useful in small-scale production or a repair shop. The machine is designed for the production of splines, grooves, keyways.

Arsenal S315TGI

4.9

★★★★★

editorial assessment

93%

buyers recommend this product

The model is distinguished by wide readjustment capabilities and is capable of processing large and heavy workpieces. Installing a device for pulling outer surfaces also expands the range of applications of the unit. The guide slides are equipped with a rotating device for tilting the surface at an angle of up to 45°.

The table can be quickly moved in the desired direction thanks to special handles. The machine's automatic stop function ensures operator safety.

Performance can be adjusted through frequency modulation. The package includes an installation kit, lubrication system and lighting package.

Advantages:

- cast iron construction;

- powerful engine;

- automatic stop;

- convenient control;

- durability.

Flaws:

- high energy consumption.

Arsenal S315TGI will be useful for chiseling shaped, flat surfaces, making grooves, grooves - an excellent choice for small-scale production.

READ ALSO

12 Best Jackhammers

How to do it yourself

As can be seen from the short review above, the cheapest slotting machine costs from 25,000 rubles, which is a lot. What to do if there is no opportunity or desire to give that kind of money? You can make the unit yourself. Let's talk about what is needed for this.

Materials and skills

First of all, we need a “donor” from which we can take an electric motor. It is important that it performs not rotational, but reciprocating movements.

Of course, you can make a pendulum. But this is difficult and not everyone can do it. Therefore, we will take the path of least resistance and take a ready-made solution. The power unit from a jigsaw is ideal for its role. After all, the file moves vertically.

Expert opinion

Levin Dmitry Konstantinovich

For work, it is better to take a jigsaw with adjustable saw stroke. If it is not there and the movements of the cutting part are too frequent, the slotting machine may damage the workpiece.

You will also need:

- iron clamps (we will use them to secure the power unit);

- steel pipes (will hold the workpiece);

- metal profile (we will make guides from it);

- carpenter's table (we use it as a base).

Skills required include the ability to use welding. Without it, alas, you won’t be able to assemble a slotting machine yourself.

Work process

Here's what you need to do to create an aggregate:

- Draw a drawing . At least a simple one. It will help you navigate the work process.

- Secure the power unit . Everything is simple here: using clamps made from strips of sheet iron, we attach the jigsaw (you can directly in the body) to the carpenter’s table. In this case, the mount for the file should face the opposite side of the table.

- Changing the holder . We remove the file holder from the jigsaw, and in its place, using a clamp or welding, attach another one for the chisel.

- We attach the profile to the carpentry table . We screw the transverse strips onto the bolts, and two longitudinal ones onto them.

- We are preparing a frame holder . We make it so that it moves freely along the longitudinal guides on the carpentry table. Don't forget about the clamps. They should be both where the frame “rides” along the guides and where it holds the workpiece. We fasten the clamps for the workpiece on a separate frame, and we mount it on the main one through vertical stands with wine, which allows us to move the wood closer and further away from the cutting part.

As a result, we get an analogue of a factory machine, but with one difference: the engine is mounted horizontally.

What are the savings?

The costs of assembling such a unit will be as follows:

- inexpensive Chinese jigsaw - about 2,500 rubles;

- metal profile – 1,500 – 2,000 rubles;

- wood for assembling a carpentry table - about 1,500 rubles.

Even taking into account the costs of electricity, clamps and bolts, the total cost will be no more than 10,000 rubles. This is more than half the price of the factory model.

Which wood slotting machine would you choose?

PurchasedHomemade

The best wood slotting machines

These models are designed to work with soft materials. Wood slotting machines are widely used in carpentry shops, furniture factories, and in the production of windows and doors. With their help, you can select grooves, grooves, and sockets.

Griggio G 550 S

5

★★★★★

editorial assessment

100%

buyers recommend this product

The electric welded frame ensures the strength and stability of the machine when working in intensive mode. The front clamp reliably holds the workpiece during operation. The carriage and spindle head are made of cast iron and are highly durable.

The size of the desktop is 600x110 mm, the dimensions of the model are 1000x800x2100 mm. An automatic lubrication system and a chain tensioner simplify maintenance of the unit. The working surface can be rotated at an angle of up to 45° for ease of chiselling parts of complex structures.

Advantages:

- reliable fastening of the workpiece;

- convenient control;

- ease of maintenance;

- robust design.

Flaws:

- high price.

Griggio G 550 S is designed for horizontal or vertical chiselling of grooves for hinges, locks, and sashes. Used in medium and large-scale production of window blocks, furniture or doors.

Powermatic 230V 719T

5

★★★★★

editorial assessment

98%

buyers recommend this product

A spacious cabinet is included with the unit. The owner can store tools and other equipment necessary for work in it.

For quick commissioning and maintenance of the device, the kit also includes spare structural elements, flywheels, and mandrels for installing cutters of various diameters.

The spindle speed is 1400 rpm. The dimensions of the machine are 540x550x1880 mm, control is carried out using only two buttons. The depth of chiselling is adjustable by the operator, which guarantees the accuracy of processing parts. The end stop and axle travel limiters are also adjustable.

Advantages:

- rich equipment;

- ease of maintenance;

- long service life;

- small dimensions;

- long control handle.

Flaws:

- complex installation.

Powermatic 719T is recommended for making grooves at angles up to 35°. An excellent choice for professional use.

Jet 719 AS 708572KM

4.8

★★★★★

editorial assessment

93%

buyers recommend this product

One of the design features is a long hand lever with rack and pinion gear and gas stop. With its help, the operator can not be distracted from the workpiece while making grooves. Special rotating handwheels and a graduated scale provide quick adjustment of the surface position.

The motor power is 1300 W, the spindle speed is 1450 rpm. The fixing device allows you to securely fasten the part before starting. The depth stop and travel limiters along the axes can be adjusted. The table is made of cast iron and equipped with a wooden overlay, which guarantees strength and resistance to heavy loads.

Advantages:

- robust design;

- reliable fixation of the workpiece;

- stop adjustment;

- high performance;

- Ease of use.

Flaws:

- narrow table.

Jet 719 AS is designed for making longitudinal and transverse grooves. A reliable solution for professional use.

Encore Corvette-92

4.8

★★★★★

editorial assessment

90%

buyers recommend this product

The unit is equipped with a vice with a quick-release mechanism and clamps. Their use facilitates the installation of the workpiece, ensures reliable fastening and increases the accuracy of processing.

Feed pulleys with rotating handles ensure easy table movement. A pneumatic shock absorber compensates for the weight of the moving headstock.

The motor power is 750 W, the working surface size is 400x150 mm. The model is equipped with a magnetic starter, the use of which eliminates the possibility of spontaneous activation during power outages. A special ruler makes it easier to control the distance between holes and the length of the selected groove.

Advantages:

- small dimensions;

- reliable fixation of the workpiece;

- careful processing;

- long service life;

- ease of installation.

Flaws:

- small chiseling depth.

The Encore Corvette-92 is worth purchasing for installation in a garage or home workshop. An affordable choice for processing wood and plastic products.

READ ALSO

12 best hammer drills

FDB Maschinen MS361D

4.7

★★★★★

editorial assessment

87%

buyers recommend this product

This machine has a dovetail type slide equipped with a stroke adjustment mechanism. The absence of play ensures smoothness of both longitudinal and transverse movement of the work table. Clamps guarantee reliable fixation of the part in a horizontal or vertical plane.

The motor power is 550 W, the spindle speed is 2800 rpm. The sampling depth and longitudinal feed limiters ensure accurate and precise processing.

The unit is small in size and weighs only 62 kg. The simplicity of the design facilitates maintenance and repair.

Advantages:

- convenient control;

- easy installation;

- accuracy of work;

- easy movement of the table;

- low price.

Flaws:

- high energy consumption.

FDB Maschinen MS361D will be useful in a home workshop or small production. Economical choice for making rectangular holes, pockets and slots.

Analogs

The difficulty of self-assembling a slotting machine is that the jigsaw engine:

- travel speed is too high;

- too little power.

As a result, it does not always work satisfactorily. What to do? Assemble a milling machine instead of a slotting machine. The algorithm of actions and materials will be the same. The only difference is that instead of a jigsaw we use an electric drill with a milling attachment.

The main difference between a milling machine is that it does not produce a rectangular groove, but a hole with slightly rounded edges. However, in most cases it will do for household purposes.