Many technical devices, as well as most household items, have threaded connections, which humanity began to use since ancient times. The main tools with which the elements of such connections are made include a tap. Its use allows you to quickly and without much difficulty cut precise and high-quality threads on the inner surface of the hole.

Thread taps

Purpose of taps

Taps are used only for cutting internal threads. Completely different tools are responsible for external threads.

- The tool is capable of making new threads in completely different holes or updating an existing one.

- Work can be carried out with different metals, such as brass, copper, similar metals and plastic.

Typically, a set containing three taps is used to make threads. Some cases require up to five taps.

To use it, you need a special tool - a tap holder. The tap fixed in it is inserted into the hole and turned in the desired direction.

How to correctly determine the diameter and cut a thread with a tap manually - table

There are special standards for determining the cross-section. Let's present all the data in the form of tabular values. Let’s say right away that they are not suitable for all tasks, but only for standard ones. These include all nuts on sale that fit the screws. Therefore, if you require a connection with a specific fastener, pay attention to its markings.

| Marking | Turn pitch | Drill diameter | ||||

| 2 | 0,4 | 1,6 | 0,25 | 1,75 | — | — |

| 3 | 0,5 | 2,5 | 0,35 | 2,65 | — | — |

| 4 | 0,7 | 3,3 | 0,5 | 3,5 | — | — |

| 5 | 0,8 | 4,2 | 0,5 | 4,5 | — | — |

| 6 | 1 | 5 | 0,75 | 5,2 | 0,5 | 5,5 |

| 7 | 1 | 6 | 0,75 | 6,2 | 0,5 | 6,5 |

The table can be continued, it is large, but we will not do this within the scope of this article. For more detailed values, we recommend that you refer to the document - GOST 19257 - 73.

These are standard sizes, but there are special purposes, unique connections. For them, everything is very simple to calculate independently. If the thread is marked M10 and the pitch is 0.3, then 0.3 mm must be subtracted from 10 mm. The result will be equal to the hole diameter - 9.7 mm.

If it is made smaller, it will be difficult for the tap to pass, and areas with poor processing will form. And if it is more, then the grooves will be shallow, the screw will wobble inside or even fall out over time.

Let's also imagine the international marking system in inches:

| Designation, inches | External | Interior | Thread, mm | Step |

| G 1/8 | 9,37 | 8,858,8 | 28 | 28 |

| G 1/4 | 13,16 | 11,89 | 11,8 | 19 |

| G 3/8 | 16,66 | 15,39 | 15,25 | 19 |

| G 1/2 | 20,95 | 19,17 | 19,00 | 14 |

| G 5/8 | 22,91 | 21,13 | 21,00 | 14 |

| G 3/4 | 26,44 | 24,66 | 24,50 | 14 |

| G 7/8 | 30,20 | 28,42 | 28,25 | 14 |

| G 1 | 33,25 | 30,93 | 30,75 | 11 |

| G 1, 1/8 | 37,90 | 35,58 | 35,30 | 11 |

| G 1, 1/4 | 41,91 | 25,59 | 39,25 | 11 |

| G 1, 3/8 | 44,32 | 45,00 | 41,70 | 11 |

| G 1, 1/2 | 47,80 | 45,48 | 45,25 | 11 |

| G 1, 3/4 | 53,74 | 51,43 | 51,10 | 11 |

| G 2 | 29,61 | 57,29 | 57,00 | 11 |

| G 2, 1/4 | 25,17 | 62,96 | 63,10 | 11 |

| G 2, 1/2 | 75,18 | 72,86 | 72,60 | 11 |

| G 2, 3/4 | 81,53 | 79,21 | 78,90 | 11 |

| G 3 | 87,88 | 58,56 | 85,30 | 11 |

| G 3, 1/4 | 93,98 | 91,66 | 91,50 | 11 |

| G 3, 1/2 | 100,33 | 98,01 | 97,70 | 11 |

| G 3, 3/4 | 106,68 | 104,3 | 104,00 | 11 |

| G 4 | 113,03 | 110,71 | 110,40 | 11 |

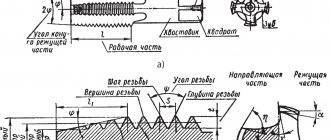

Design and characteristics of taps

The tap is a very simple tool, its design consists of two main parts. The first part is the tail of the tap; it is this part of the object that is fixed in the tap holder or on the machine.

The second part is the main one; there is an external thread on it, which in turn consists of two parts:

- Cutting element. This part of the thread is designed to form thread turns in the hole.

- Calibration element. The second element is necessary for cleaning the newly cut holes and calibrating them.

On the sides of the tap there are special elements called feathers. It is thanks to them that the thread is formed.

How is the operation performed and what is its essence?

The main task of the mechanic is to create a technical hole in the metal thickness with the subsequent formation of hollows from the inside. They need to be made so that the turns fit the bolt, stud or other fastener.

A threaded element may be needed in everyday life for the most durable connection of two parts. Here it is necessary to achieve absolute cleanliness - so that there are no shavings, deformations, or broken threads left. It is also very important to follow GOST standards for the size of the device. The diameter should match the screw that will go inside.

Many parameters are important - the type of material, its density, as well as condition, for example, temperature, the presence of corrosion. First you need to prepare the workpiece - remove excess dirt. Then you need to choose the right tool, and only then begin metalworking in two or three stages - from roughing to finishing.

Several parameters are significant:

- hole diameter;

- cutting depth;

- number of threads (these are entries, the most common is the presence of three cavities);

- pitch, that is, the distance between two furrows.

Materials

Various materials are used to produce taps, including:

- Alloy steel;

- Tool steel;

- High speed steel.

The most common and optimal option is considered to be high-speed steel. It has many advantages over others:

- High service life;

- Resistance to temperature changes;

- High quality of work performed;

- Ability to work at high speed;

- High strength material.

To work with some materials, special taps with an additional coating are made. This solution increases the service life and efficiency of the tool.

Types of taps

There are a large number of taps that are used to form a wide variety of threaded holes. All of them are divided according to different parameters. The first division of the equipment is its thread type:

- Metric;

- Inch;

- Pipe.

Taps by thread type differ in the profile angle and the number of turns of the future thread. The differences also lie in the slope of the profile, which is necessary for greater reliability of the threaded connection.

In addition, taps can differ in the type of groove:

- Straight groove;

- Helical groove.

Products with screw groove type are divided into left spiral and right spiral. They are designed to create different holes. The first type is used to create threads in blind holes, the second in through holes.

Taps are divided into single-approach and multi-approach. Depending on the type, they are designed to perform work in one or several approaches. For multi-approach products, it is normal to have a set of several taps, each of which must be used to correctly form the thread.

The main parameter for dividing tags into types is purpose. Tools that differ in their purpose:

- Locksmith. The simplest variation of a tap that can be used without special equipment.

- Machine. The difference from a bench tap lies in the shape of the product and the method of its use. Operation is only possible with a special machine.

- Machine-manual. A universal tool that can be used manually and on a special machine.

- Conical. Due to their special shape, such taps are used to form conical threads. Typically used on special machines.

- Cylindrical. An ordinary tap used to form threads in blind holes.

- Nut. It differs from all other models in its elongated tail and the ability to thread several nuts at once.

- Spot. A one-step type of tool that is used to create threads in dies.

- Uterine. The tap is used as an addition to the die tap. It is designed for stripping formed turns.

- Trapezoidal. One-step tool, resistant to high loads. It is used to create trapezoidal shaped threaded holes.

- Grooveless. Taps characterized by a minimum number of grooves in their structure.

- Screw. Such products are designed for quick processing of dead-end holes.

- Combined. Tools that can perform multiple functions at once. For example, a tap-drill.

- Stepped. Ordinary equipment consisting of two parts. Cutting and calibrating.

- Bells. Used to form large diameter threads.

- Chess. Taps that are designed to reduce friction.

- Broach tap. Such equipment is used when it is necessary to form threads in through holes. Slaves are carried out with the machine.

- Rolling tap. Due to the nature of working with the tool, there is no chips or dust.

- Hollow. Taps that are necessary for creating threads in difficult working conditions.

- Candlesticks. Designed for forming threads in spark plug wells of internal combustion engines.

- Fishing Common in the oil and gas industry.

Types of threads to be cut

Using taps of different categories, as well as different types of dies, it is possible to form threads of various types on the internal surfaces of parts. Depending on the type of thread being cut, taps are divided into the following categories.

Metric

These are taps that are used to cut metric threads. The cut thread element in such cases has the shape of an isosceles triangle, and all its parameters are measured in millimeters. The markings of such taps contain the letter “M”. To select metric taps and the diameter of the preparation hole, a special reference table is used.

Inch

The working part of such taps has a conical shape. The diameter of inch tools is measured in inches, and the pitch is measured in the number of threads per inch (25.4 mm). The slope of the average surface of taps of this type is 1°47'24".

Pipe

This includes cylindrical and conical taps used for cutting threads in pipe fittings.

Table 1. Tap parameters and thread hole size

Taps can be used to make holes with both right-hand and left-hand threads. Taps for left-hand threads, when compared in reality or from photos with right-handed tools, differ from the latter only in the direction of the rise of the helical line of their cutting part.

Cost of taps

Prices for taps vary from several hundred to several thousand rubles. All this depends on the materials from which the instrument is made and on its type.

Thus, simple taps, such as metalworking, stepped or screw products, are relatively inexpensive, while the cost of fishing taps starts from four thousand rubles.

To form a high-quality and reliable threaded hole, it is important to choose the right tool. The choice depends on what materials will be used and the characteristics of the required thread.