Hands from the right place | 03/05/2016

Any technical product consists of individual parts fastened together using fasteners. Although threaded connections were known back in Ancient Rome, China, as well as the Mayan civilization, the tap began to be used as a thread-forming tool only at the end of the Middle Ages (XV-XVI centuries). Before this, the inner spiral of the nut was made by other methods, including using a lathe.

Purpose of taps

Taps are used only for cutting internal threads. Completely different tools are responsible for external threads.

- The tool is capable of making new threads in completely different holes or updating an existing one.

- Work can be carried out with different metals, such as brass, copper, similar metals and plastic.

Typically, a set containing three taps is used to make threads. Some cases require up to five taps.

To use it, you need a special tool - a tap holder. The tap fixed in it is inserted into the hole and turned in the desired direction.

Rating of the best sets of taps and dies for 2022

Manual sets

3rd place: 5545 ERMAK M3-M10

An excellent and inexpensive set of domestic production, perfect for household needs. Although the set of tools is small, it is capable of coping with the most common household tasks. The case is made of plastic and has foam recesses for storing tools.

| Name | Index |

| Number of items | 14 |

| Case material | Plastic |

| Total weight, grams | 600 |

| Manufacturer country | Russia |

| Dimensions, millimeters | 15x20x15 |

| Price, rubles | 1300 |

5545 ERMAK M3-M10

Advantages:

- Budget price;

- Durable tool material;

- Sufficient functionality for everyday tasks.

Flaws:

- Fragile case.

2nd place: Stayer Master 28020-h24

An expanded functionality kit from a foreign manufacturer. It is quite capable of coping not only with household tasks, but can also be used for simple minor repairs of auto parts. Supplied in a metal case, tool compartments are made of plastic.

| Name | Index |

| Number of items | 24 |

| Case material | Metal |

| Total weight, grams | 1200 |

| Manufacturer country | Norway |

| Dimensions, millimeters | 30x20x30 |

| Price, rubles | 2100 |

Stayer Master 28020-h24

Advantages:

- Advanced functionality;

- Adequate price;

- Dual measurement system (inches and meters).

Flaws:

- Inconvenient case.

1st place: “Berger” BG31TDS

In many ways, it is a universal kit, because it can be used for both plumbing and automotive parts. Most dies and taps for standard rifling are present in it. Excellent sharpening quality allows you to avoid using excessive effort when working. The case is made of steel and has a strong locking closure.

| Name | Index |

| Number of items | 31 |

| Case material | Metal |

| Total weight, grams | 1300 |

| Manufacturer country | Denmark |

| Dimensions, millimeters | 30x20x30 |

| Price, rubles | 3400 |

Berger" BG31TDS

Advantages:

- Excellent cutting quality;

- Reliable case;

- Durable tool material.

Flaws:

- In practice, there is no M12x1.25 die (it’s not in the photo, but it’s in the description).

Machine kits

3rd place: ZUBR Professional 28110-H24

Like most professional kits, this one is distinguished by a large number of tools included, a wide range of their applications, and the use of several marking systems at once. All tools are made of high-carbon durable steel and are able to withstand maximum loads when installed in machines.

| Name | Index |

| Number of items | 24 |

| Case material | Metal |

| Total weight, grams | 900 |

| Manufacturer country | Russia |

| Dimensions, millimeters | 30x15x20 |

| Price, rubles | 4700 |

BISON Professional 28110-H24

Advantages:

- Uses two systems - pipe and metric;

- Durable metal tool making.

Flaws:

- Not identified (for its segment).

2nd place: SKRAB 33895

This kit features a convenient arrangement of items in the case – taps on the bottom, dies on top. To hold the tool for internal threads, there is a special collar with embossed handles. A universal die holder for all sizes is also supplied. Users note the high quality of cutting both by machine and by hand.

| Name | Index |

| Number of items | 45 |

| Case material | Plastic |

| Total weight, grams | 1100 |

| Manufacturer country | Taiwan |

| Dimensions, millimeters | 30x20x30 |

| Price, rubles | 9700 |

SKRAB 33895

Advantages:

- Convenient arrangement of items in the case;

- Universal holder for lecterns;

- Equipped with a special collar.

Flaws:

- High price.

1st place: Matrix 773110

Maximum professional set of 110 items. Capable of performing absolutely any work, both domestic and industrial. Fully suitable for processing parts made of any materials - aluminum, cast iron, steel and copper. All tools are made of innovative ultra-strong cutting steel 9ХС.

| Name | Index |

| Number of items | 110 |

| Case material | Plastic |

| Total weight, grams | 1500 |

| Manufacturer country | Taiwan |

| Dimensions, millimeters | 50x30x50 |

| Price, rubles | 11000 |

Matrix 773110

Advantages:

- Current price/quality ratio;

- The tool is made of the latest steel;

- Practical versatility and multi-functionality.

Flaws:

- Not found.

Design and characteristics of taps

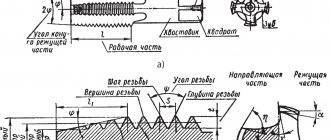

The tap is a very simple tool, its design consists of two main parts. The first part is the tail of the tap; it is this part of the object that is fixed in the tap holder or on the machine.

The second part is the main one; there is an external thread on it, which in turn consists of two parts:

- Cutting element. This part of the thread is designed to form thread turns in the hole.

- Calibration element. The second element is necessary for cleaning the newly cut holes and calibrating them.

On the sides of the tap there are special elements called feathers. It is thanks to them that the thread is formed.

Thread classification

- Metric. The most common fastening thread. The diameter of the parts is measured in mm.

- Pipe. Used in the installation of pipelines and shut-off and control valves (mixers, taps, valves). Diameter is measured in inches and fractions of an inch, which is why it is also called inch.

- Threads on the outer surface of parts: bolts, studs, pipes are called external, and nuts, blind sockets and couplings are called internal.

- The direction of rotation distinguishes between left and right.

- By the number of passes - single and multi-pass.

- The cross-section can be triangular, rectangular, trapezoidal, etc.

- Can be straight (cylindrical) or conical.

Materials

Various materials are used to produce taps, including:

- Alloy steel;

- Tool steel;

- High speed steel.

The most common and optimal option is considered to be high-speed steel. It has many advantages over others:

- High service life;

- Resistance to temperature changes;

- High quality of work performed;

- Ability to work at high speed;

- High strength material.

To work with some materials, special taps with an additional coating are made. This solution increases the service life and efficiency of the tool.

Tool selection criteria

Before purchasing a kit, you should decide on the type and diameter of the tools, which of them are most in demand, and what you should pay attention to:

- If you plan to install a water supply system in a country house, you need to buy a ratchet clamp and pipe dies. The most suitable dies for this type of work will be dies with diameters of 1/2'', 3/4'', 1'', 1 1/4'', 1 1/5'' and 2''. A clamp with a ratchet will make the job easier.

- To repair damaged parts or cut new parts, you will need different sizes of drawers and hand taps. The most popular diameters are considered to be from M3 to M12.

- It is better to select taps of each diameter in sets of two or three numbers, for roughing, medium and finishing. Different numbers are marked by applying ring grooves to the tail section. Rough ones are marked with one ring, medium ones with two and finishing ones with three rings. The rough profile is a truncated cone, the finishing profile has a triangular profile.

- When purchasing kits, you should inspect them carefully. They can slip in two products with the same profile: both rough or two finishing.

- Cutters, as a rule, cut the part in one pass, so they are all finished. Manufactured from high carbon steel. 6. Taps are most often made from carbide materials. Markings indicating the steel grade are applied to the surface of the dies. It can be high-speed or alloy steel.

- It is better to buy tools in convenient cases made of plastic or metal. It is more convenient to carry and store than “loose” ones.

- However, the purchase of “placers” cannot be avoided. There are no 100% universal “cases”.

- Sets vary in the number of items. The more there are, the more expensive the purchase will be.

- They produce professional and household tools. Professional ones are distinguished by high quality, better wear resistance and a higher price.

- To determine the profile and pitch, the case must have a thread gauge.

- When purchasing, you should carefully inspect the tool, especially the condition of the cutting edges. Even a beginner will be able to distinguish high-quality products from cheap fakes.

- It is better to purchase products from well-known brands. Czech and German kits are traditionally of good quality. When choosing manufacturers from the Asia-Pacific region, it is better to focus on products from Taiwan. Buying a Chinese kit is like a lottery. You can get quality, or you can get a one-time fake. The kit from Taiwan is always high quality.

Which company is the best kit to buy?

We invite you to get acquainted with some well-known manufacturers:

- Berger Russian brand with production in Taiwan. High-quality, wear-resistant guides and taps. The sets are supplied with a convenient case and holders. The manufacturer provides a lifetime warranty on its products.

- Biber. The German brand is made in China. It is distinguished by good quality and good equipment. There are three numbers of taps of each diameter, which greatly facilitates the process of cutting the workpiece and guarantees good quality.

- Bovidix. The brand belongs to the USA. Production is launched in Taiwan. Bovidix produces tools from the highest quality materials and constantly uses innovation. Consumers leave the best reviews about this brand.

- JTC. The birthplace of the brand and the country of origin is Taiwan. For 33 years, the company has been producing professional instruments that have gained popularity not only in their homeland, but also in Europe and the USA. Always excellent quality, wear resistance, excellent ergonomics.

- Matrix. German brand with production in China. The company is very young. It produces products of good quality and excellent design and ergonomics.

- Rothenberger. The German company is a world leader in the production of equipment for the installation and maintenance of pipelines. Kits from Rothenberger are well-deservedly popular among professionals. If you are planning to build a country house with heating and plumbing, a tool from Rothenberger will be the best solution to problems when installing pipework.

- Arsenal. A Russian brand with production in Taiwan. On the market since 1998. Arsenal produces inexpensive kits of high quality and wear resistance.

- Master. Brand and country of manufacture: Taiwan. Products under the Mastak brand are developed specifically for delivery to the Russian market. Master is a high-quality professional locksmith kit that features outstanding ergonomics, innovation, ease of use and durability.

- Bucovice. Brand and production in the Czech Republic. Leading manufacturer in the Czech Republic and Europe. Bucovice has always been famous for its high quality, durability and excellent equipment.

Not all the best manufacturers are represented here. However, the listed brands are in demand among professional craftsmen. Before you make a purchase, decide on the diameters of fasteners necessary for your activity, find out how much this or that set costs, its functionality, and the popularity of models from different brands. If you don't do this for a living, it's not worth spending money on a professional kit. For your home, you need to choose budget tools at an affordable price. It is advisable to listen to the advice and recommendations of experts. Professionals, on the contrary, should not waste time on trifles. A good and expensive tool will soon pay for itself.

Types of taps

There are a large number of taps that are used to form a wide variety of threaded holes. All of them are divided according to different parameters. The first division of the equipment is its thread type:

- Metric;

- Inch;

- Pipe.

Taps by thread type differ in the profile angle and the number of turns of the future thread. The differences also lie in the slope of the profile, which is necessary for greater reliability of the threaded connection.

In addition, taps can differ in the type of groove:

- Straight groove;

- Helical groove.

Products with screw groove type are divided into left spiral and right spiral. They are designed to create different holes. The first type is used to create threads in blind holes, the second in through holes.

Taps are divided into single-approach and multi-approach. Depending on the type, they are designed to perform work in one or several approaches. For multi-approach products, it is normal to have a set of several taps, each of which must be used to correctly form the thread.

The main parameter for dividing tags into types is purpose. Tools that differ in their purpose:

- Locksmith. The simplest variation of a tap that can be used without special equipment.

- Machine. The difference from a bench tap lies in the shape of the product and the method of its use. Operation is only possible with a special machine.

- Machine-manual. A universal tool that can be used manually and on a special machine.

- Conical. Due to their special shape, such taps are used to form conical threads. Typically used on special machines.

- Cylindrical. An ordinary tap used to form threads in blind holes.

- Nut. It differs from all other models in its elongated tail and the ability to thread several nuts at once.

- Spot. A one-step type of tool that is used to create threads in dies.

- Uterine. The tap is used as an addition to the die tap. It is designed for stripping formed turns.

- Trapezoidal. One-step tool, resistant to high loads. It is used to create trapezoidal shaped threaded holes.

- Grooveless. Taps characterized by a minimum number of grooves in their structure.

- Screw. Such products are designed for quick processing of dead-end holes.

- Combined. Tools that can perform multiple functions at once. For example, a tap-drill.

- Stepped. Ordinary equipment consisting of two parts. Cutting and calibrating.

- Bells. Used to form large diameter threads.

- Chess. Taps that are designed to reduce friction.

- Broach tap. Such equipment is used when it is necessary to form threads in through holes. Slaves are carried out with the machine.

- Rolling tap. Due to the nature of working with the tool, there is no chips or dust.

- Hollow. Taps that are necessary for creating threads in difficult working conditions.

- Candlesticks. Designed for forming threads in spark plug wells of internal combustion engines.

- Fishing Common in the oil and gas industry.

A little history

Fasteners, analogues of modern screws, have been known to mankind since the beginning of our era. Jewelers of Ancient Rome used them to make jewelry, and artisans used them to make medical instruments. The manufacture of fasteners was expensive in those days and was not widely used.

The 15th century has arrived. On the battlefields, warriors in armor and armor clashed, the parts of which were fastened with screws and pins. At the same time, watchmakers assembled their products using screws. But the nuts appeared later, about a hundred and fifty years later. There were no generally accepted standards then. Each master made fasteners at his own discretion. In the 17th century, connections close to modern ones appeared, and the thread pitch was inch.

Metric threads first began to be used in France quite recently, in the 19th century.

Cost of taps

Prices for taps vary from several hundred to several thousand rubles. All this depends on the materials from which the instrument is made and on its type.

Thus, simple taps, such as metalworking, stepped or screw products, are relatively inexpensive, while the cost of fishing taps starts from four thousand rubles.

To form a high-quality and reliable threaded hole, it is important to choose the right tool. The choice depends on what materials will be used and the characteristics of the required thread.

Preparing for Threading

The hole is prepared in several ways before cutting a thread - by sharpening, grinding or drilling the surface of a metal workpiece. For external threads, the diameter must be reduced by 0.1 - 0.4 millimeters. At the beginning of the section where the thread will be, a chamfer is made by sharpening - this is necessary to dull the entry of the thread. And if the hole is bored before threading, its diameter increases to 0.4 mm. The hole for the thread should be slightly larger in diameter than the diameter of the thread itself - this helps prevent breakage of the thread-cutting equipment.

Photos of taps (for thread cutting)

How to remove a broken tap from a hole

The tap may break if the thread is cut into a hole with a small diameter, and chips may become trapped when the tool is removed.

Extraction methods

- 1. The double ends of the rigid wire must be inserted into the grooves of the tap and unscrewed;

- 2. You can weld the handle to the broken instrument and use it to remove it;

- 3. There are special mandrels and countersinks that will help cope with this problem;

- 4. If part of the tap remains outside, you can weld a shank with a square tip to it;

- 5. Drilling with screw drills;

- 6. Burning with electrical erosive machines;

- 7. Etching with dilute nitric acid.