Activities

- Food milk processing industry

- brewing industry;

- production of alcoholic and non-alcoholic drinks;

- juice production, processing of vegetables and fruits, etc.

Geography of work

- Republic of Belarus, CIS countries

- European Union

- Asia

Do you need installation of stainless pipelines? This is what we have been offering to our clients since 2005 until today.

Installation methods

When laying water supply or communications for other purposes using stainless steel pipes, several types of connections are possible, namely:

- welded;

- use of flange type connecting elements;

- crimping.

To connect using water supply and heating networks, you will need not only special equipment, but also a qualified specialist. Such a process is usually carried out, and the welding itself is performed in an inert gas environment. The most modern method that allows high-quality joining of stainless pipes is plasma welding, which also requires the use of special and expensive equipment.

Press fittings provide high-quality connections and quick installation, but are expensive and require special tools

In domestic conditions, it is not always possible to use welding, since for this you need not only to have special equipment at your disposal, but also to attract a qualified specialist to operate it. In this regard, in such cases, threadless flange or threaded fitting connections are used.

Flanges are essentially two ring-shaped elements connected to each other using studs or bolts. To achieve tightness when using flanges, use a special sealing element made of rubber or other soft polymer material. Parts such as flanges, which are quite large in size, are used mainly when pipeline elements need to be periodically dismantled and maintained, spending a minimum of time. The disadvantages of connections of this type are that they react rather poorly to temperature changes and pressure surges in the pipeline.

The service life of fittings for corrugated pipes is practically unlimited; you only need to change the seals, which can last up to 30 years

A more reliable option are fittings, the design of which includes a silicone gasket that ensures tightness. You can dismantle such connections several times without worrying about their reliability.

Grade

The dry numbers speak for themselves: we have before us an exceptionally durable and almost eternal material for water supply distribution. However, we will try to give it as unbiased an assessment as possible, weighing all the advantages and disadvantages of the solution.

pros

- Thanks to corrugation, the pipe is not afraid of water hammer. The high annular rigidity of the walls allows them to withstand high pressure, and their plasticity makes it possible to slightly change the length (and, accordingly, the internal volume) of the water supply pipe during a short-term pressure surge, acting as a damper;

- For the same reason, corrugated stainless steel tolerates freezing and thawing. Ice expanding during crystallization will not tear it, but will only cause it to slightly lengthen;

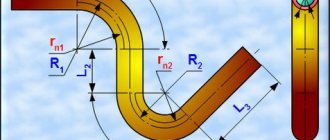

- The pipe bends easily, and the permissible bending radius is equal to its diameter. This feature means that the water supply parts do not need to be precisely adjusted to size, and also allows you to do without fittings at the bends of the water supply system;

The flexible pipe does not need corners: it bends at any angle with a minimum radius

- Stainless steel is sold in coils of 50 meters or more in length, which makes it an ideal material for laying in screeds or grooves;

Let us remind you: when installing water supply, underfloor heating and heating systems, it is highly recommended not to hide collapsible connections. They are the source of the vast majority of leaks.

- Installing pipes on compression fittings is ridiculously easy and does not require complex or expensive tools. To assemble a fitting connection, two wrenches (open-end, pipe or adjustable) are sufficient. For cutting, you can use a roller pipe cutter or grinder;

Specifications

Seamless stainless steel pipes are distinguished by their strength and resistance to rust. The absence of welds guarantees protection of products from heat-affected corrosion.

In comparison with electric-welded analogues, a number of advantages can be identified:

- The pipe does not have a weld, which is the most vulnerable area of the product.

- Has the same strength throughout.

In addition, such pipes are effectively operated at high media pressures and are able to withstand destructive external influences. This makes it possible to use them in conditions of high humidity, high and low ambient temperatures. The threshold temperature for a simple carrier is 800°C, for aggressive chemicals - 350°C.

Other important characteristics include:

- The tensile strength of the material is no less than 529 N/sq.mm.

- The relative elongation indicator is at least 40%.

- The sulfur content in steel is not less than 0.02%.

The permissible curvature of products is also strictly regulated and should not exceed the following values:

- Pipes with a wall thickness of more than 0.5 mm - 1 mm per 1 m of length.

- Products with a wall thickness of less than 0.5 mm and a cross-section of more than 15 mm - 2 mm per 1 m of length.

When purchasing, you should give preference to large hardware stores and products from popular brands. Perhaps the final cost will be slightly higher, but the buyer is guaranteed to receive a quality product with the required characteristics.

Minuses

The disadvantages include the following features:

- Stainless steel is not a cheap raw material, and a corrugated stainless pipe for heating from the best manufacturers costs a decent amount.

- If you plan to design a heated floor, experts recommend using corrugation in a polyethylene braid that protects against contact with chemically active substances. In addition, the concrete screed should be replaced with a “dry” installation method.

- Corrugated pipes have an “industrial” look that will not fit into every design. On sale you can find corrugated polymer shells in different colors, which leaves some room for maneuver.

- The recesses between the corrugation rings sooner or later fill with dust, which is not so easy to clean out.

Features of connecting seamless stainless pipes

The main competitive advantage of such products is the absence of welds, which are the most vulnerable point of any welded pipe. For this reason, increased quality and reliability requirements are placed on the connection procedure.

Pipes are joined only by welding, and the process can be carried out manually, semi-automatically or automatically. One of the following technologies is used:

- TIG. Welding is performed in an inert gas environment, which protects the treated area from oxidation. The heat source is an electric arc formed between the tungsten electrode and the welding point. If the technology is followed, the seam will be smooth, uniform and not inferior in strength characteristics to the material of the pipe itself.

- HF. A less expensive technology, which, however, does not provide similar strength indicators. Welding is performed using high-frequency current.

- Laser Laser welding is not inferior to TIG technology in terms of seam strength, while making it possible to reduce the melting zone and make the seam less noticeable.

Thus, seamless stainless steel pipes can be safely called one of the most practical, strong, durable and environmentally friendly pipe materials, allowing you to implement any project: from the installation of industrial pipelines to the manufacture of elegant furniture. The only disadvantage of such pipes is the justifiably high cost.

Application and labeling

Stainless steel corrugation is used in the following cases:

- When installing heating systems of private houses, bathhouses, greenhouses (usually a product with a diameter of 20 mm is used). They help connect heating appliances to the heating riser.

- When installing standard water supply pipelines and connecting plumbing fixtures.

- When installing heated floors and varieties (warm walls, baseboards); in heating radiators.

- As cable ducts for protecting electrical cables.

- In fire extinguishing systems as a fire-fighting pipeline.

- When laying communication networks.

- In gas supply systems.

- In internal combustion engines: transports fuel and removes exhaust gases.

Product markings indicate how they can be used:

- With the letter "A". The corrugation is made of unannealed steel.

- With the letter "M". Annealing technology was used.

Connecting a corrugated pipe to a fitting Source prodomostroy.ru

- With the letter "P". The pipe is protected by an additional plastic sheath.

- With the letter combination “El”. For electricians.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Choosing a stainless steel chimney

The stainless steel chimney design includes cylindrical sections 1.0 and 0.5 meters long, as well as numerous additional elements:

- turns at an angle of 90, 120, 135 and 150 degrees;

- adapters for connecting pipes of a different size;

- adapters for connecting sandwich and single-wall pipes;

- tees for connecting junctions;

- gates or internal dampers for adjusting draft;

- clamps for strengthening the joints of pipe sections during installation;

- brackets for attaching the external chimney to the wall of the building;

- transition glasses for crossing ceilings and roof structures with a chimney.

In the delivery set, sellers offer various fasteners for mounting and installing the chimney.

In addition to the above, you must definitely purchase a pipe head or deflector. For solid fuel units, in some cases it is necessary to use a head with a spark arrester.

If the chimney is intended to remove wood combustion products, it can be equipped with a protective cap with a mesh spark arrester

The listed components for the chimney allow you to assemble a channel of any configuration. The following requirements must be taken into account:

The total length of the chimney must be more than 5 meters. Only if this condition is met can you count on normal traction. If it is necessary to install a horizontal transition on the chimney, its length should not exceed one meter. The use of more than two turns at gentle angles in the design is undesirable. This can negatively impact your cravings. When crossing interfloor ceilings and the roof, a fire-proof crossing is required. The design of the roof penetration depends on the angle of inclination of the slope

Here it is important to ensure not only fire safety, but also tightness.

The chimney inside the boiler room is made of single pipes without insulation; all its parts located in the cold room and the external component need thermal insulation, for example, using a sandwich pipe.

When purchasing materials, pipes and components must be checked with a magnet. Suitable quality stainless steel is not magnetic. It belongs to the austenitic class, resistant to heat and aggressive environments. A similar material of the ferritic or semi-ferritic class is susceptible to corrosion, although it belongs to the stainless steel family.

The internal size of the chimney pipe is always indicated in the technical documentation for the heating unit. If a homemade boiler or stove is installed, then the cross-section of the chimney is selected in a ratio of approximately 1:10 to the size of the combustion chamber. In private homes, pipes measuring 140–150 millimeters are usually used.

The data provided will be useful in selecting the material and completeness of the device.

Location rules

Location on the roof

When designing the installation of such combustion product removal systems, take into account the standards provided for by technical standards:

- The roof duct outlet, located on a flat roof or 1.5 m from the ridge, must have a height of at least 0.5 m.

- The chimney, located at a distance of 1.5–3 m from the ridge, reaches its level.

- The edge of the pipe, located at a distance of more than 3 m from the ridge, is flush with a line 10° from the horizon of the ridge line.

- The minimum height of the chimney is 5 m, the maximum length of the horizontal section is 1 m.

- The thickness of the channel walls for solid fuel boilers is 1 mm, devices on

- liquid fuel - 0.8 mm, for gas appliances 0.5–0.6 mm is sufficient.

- The joints of the structure do not fall on the floor.

- The passage through the roof of the sandwich pipe has a gap of 13 cm, through the ceiling - 20 cm.

- The permissible number of turns of smoke exhaust channels is 3. The diameter of the pipe is not less than that of the outlet pipe.

Our advantages

Our company has chosen the installation of stainless pipelines as its main activity. The highest demands are placed on such work, and we fully meet them. We have everything necessary to carry out high-quality installation, namely:

- a permanent staff of qualified specialists who hone their professional skills by installing stainless steel pipelines at numerous sites both in the CIS and abroad;

- modern high-tech equipment designed for the installation of process pipelines made of stainless steel, which meets the high requirements of the market;

- the desire to become the best among competitors;

- confidence that our many clients, having appreciated the installation of stainless steel pipelines produced by our company, will turn to us again and again, and will also recommend us to their partners.

Customers often face a dilemma: to install a stainless pipeline using a company that has extensive successful experience in such work, or to entrust the work to a little-known company that is also ready to perform this work at a slightly lower price. At the same time, Customers should not forget that by entrusting the installation of a stainless steel pipeline to unqualified performers, they risk encountering serious problems during the commissioning of the equipment and during the production of the final product. Therefore, we recommend entrusting such responsible work to companies whose specialists have real experience in installing process pipelines.

Another confirmation of the company’s high professionalism is the number of its staff. Our company, unlike some of our competitors, has its own large and permanent staff. This confirms our focus on the high professional training of our specialists, who are always ready to install stainless pipelines for you with high quality and in the shortest possible time, regardless of the amount of work, the remoteness of the site and the complexity of the tasks.

Our goal and main priority is the Customer’s satisfaction with the result of cooperation with PUE “RViMA”. Installation of stainless pipelines, carried out at a high professional level, is the key to positive feedback about our work and contributes to the dynamic development of our company.

Why contact us

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

- non-ferrous metals;

- cast iron;

- stainless steel.

When completing an order, our specialists use all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

In order to bring the workpiece closer to the sketch submitted by the customer, our specialists use universal equipment designed for jewelry sharpening of tools for particularly complex operations. In our production workshops, metal becomes a plastic material from which any workpiece can be made.

The advantage of contacting our specialists is compliance with GOST and all technological standards. Strict quality control is carried out at every stage of work, so we guarantee our customers a conscientiously completed product.

Thanks to the experience of our craftsmen, the output is an exemplary product that meets the most demanding requirements. At the same time, we start from a strong material base and focus on innovative technological developments.

We work with customers from all regions of Russia. If you want to place an order for metalworking, our managers are ready to listen to all the conditions. If necessary, the client is provided with free specialized consultation.

Installation of stainless pipelines

Stainless steel pipes are widely used in the food industry, due to the strength and resistance of the material used to corrosion, even in aggressive environments. Installation of stainless pipelines is in demand on the market. Such pipes are used for the production of any food products, since the steel meets all sanitary and hygienic requirements

And it doesn’t matter how long ago the pipeline was installed, because the stainless steel will not interact with the product, and any penetration of substances from the pipeline system into the raw materials is excluded. Such products meet all toxicological requirements, do not require painting or other additional processing and retain a neat appearance.

The manufacturing enterprise Region LLC carries out a complex technological complex of works on the installation of stainless steel pipelines

Our company’s specialists pay special attention to the correct connection of individual pipes into a common system

Thanks to this approach, we can guarantee stability and reliability of operation and, importantly, process control over the quality of the resulting product. This level can only be achieved by professional workers who use suitable tools and comply with the rules and regulations for such work.

This level can only be achieved by professional workers who use suitable tools and comply with the rules and regulations for such work.

Stainless steel pipes are perfectly formed and easily welded, which allows you to assemble non-standard pipelines according to your ideas.

carries out installation work of any complexity:

— high-quality installation of stainless pipelines;

— installation of platforms and overpasses for further installation of dairy equipment and laying of pipelines;

— installation of stainless steel containers;

— manufacturing of equipment according to drawings;

— all types of insulation work necessary when laying a pipeline;

— preparation of commissioning works of installed dairy equipment.

Additionally we offer:

— Departure of a team of installers to any region of the country.

— Installation of technological equipment for the dairy industry requires special responsibility and high professionalism from the workers carrying out this process. Therefore, our installation specialists regularly improve their skills and have all the necessary certificates allowing such work to be carried out.

Installation of dairy equipment by Region LLC specialists includes:

— Guarantee for work performance;

— Full compliance of installation work with approved standards of the Russian Federation;

— Ensuring proper setup and subsequent maintenance of equipment, as well as training of personnel to work on it;

— Certification of installation specialists for work in food production;

— Guaranteed delivery of the facility to Rostechnadzor authorities.

If you have purchased expensive technological equipment for dairy production, then do not skimp on installation. Hire specialists who can perform the installation professionally and guarantee subsequent long-term operation of the equipment.