Cutting sheet and profile metal is required in almost all metalworking and machine-building enterprises, from a small metalworking workshop to a huge factory. Often you have to cut metal in a home workshop or directly on a construction site. Guillotine shears are one of the most convenient machines for cutting and cutting metal. There are several varieties and modifications, which will be discussed in more detail later.

Cutting metal on a guillotine is used when it is necessary to produce parts of a rectilinear configuration of a fairly large size - strips, rectangles, triangles with a side from several centimeters to several meters. The thickness of the metal is in the range of 2-60 mm, the width of the workpiece can reach 2 meters, and the length is practically unlimited.

Main types of guillotine shears

Sample of a German hydraulic guillotine

Industrial workshops, private and home workshops specializing in metalworking are equipped with various types of guillotine shears, which differ in:

- type of drive;

- power;

- type of knives;

- productivity;

- maximum thickness of the metal being cut;

- the range of rental products they can work with;

- size of the processed sheet;

- the number of operations performed.

According to the type of drive, scissors are divided into:

- manual;

- hydraulic;

- pneumatic;

- electromechanical.

Guillotine shears for metal work on the principle of influencing metal simultaneously with a large pressure force and a sharp edge of a knife, operating on the principle of ordinary scissors. The two parts of the knife device are displaced relative to each other. They clamp the sheet or rolled product together and move its adjacent layers, cutting it with a sharp blade.

The guillotine cutting process combines two operations - cutting and breaking.

A good guillotine for cutting industrial metal provides up to 90% of the cut and about 10% of scrap.

Cutting edge with small gap

Cutting edge at optimal clearance

Influence of the gap size on the edge

In this case, the cut is smooth and requires virtually no processing. If the knives are dull or the gap is incorrectly set, then the cut/scrap ratio changes and a sharp protrusion appears on the lower edge - a burr, which indicates poor cutting quality.

The burr can easily cut your hands, especially when working with stainless steel. One of the main safety rules when working with guillotine-type scissors is the use of gloves made of thick fabric or with leather stripes. The appearance of burrs indicates the need to change the settings or sharpen the knives.

Manual guillotine shears for metal

Work related to cutting iron sheets is carried out in almost all enterprises and organizations related to production, equipment repair, mechanical engineering and other metalworking industries. To increase the efficiency of work, it is recommended to buy a guillotine for processing sheet metal. Depending on the volume of metal parts, their thickness, size, as well as batch volumes, various types of guillotine machines are used. One of the simplest, most affordable and quite effective devices is a manual guillotine for cutting metal.

Hydraulic guillotine shears

Industrial machines for cutting metal, equipped with a hydraulic drive system, belong to the most powerful and productive types of guillotines. They are intended for serial or piece production of blanks with straight edges from metal sheets 2-20 mm thick with a cutting length of 1-3 m.

For large engineering companies, hydraulic guillotines are produced with the ability to cut sheets up to 6 m wide and more than 20 mm thick. They are distinguished by their large weight and size and are produced in single copies.

The hydraulic guillotine develops a force on the scissors of ≥ 400 MPa along the entire length of the sheet being cut. The machines are equipped with knives with both direct movement of the upper knife along vertical guides and with an arcuate trajectory (cantilever). The second option allows you to work with thicker sheets of metal or high-strength alloys with less hydraulic power. The cutting accuracy is not reduced.

The gaps between the knives are adjusted according to a special table in manual, semi-automatic or automatic mode. One of the most modern machines is the CNC hydraulic guillotine. Setting it up requires a minimum of time, and switching to the production of one of dozens of types of products is enough to press one button. All information about the settings is stored in the machine memory.

One of the main features of hydraulic shears is their noiselessness - the knives move smoothly, there are no shock effects characteristic of pneumatic and electromechanical guillotines.

Operational safety is ensured by the presence of photo sensors in the work area, protective screens and feed mechanism stroke limiters. Return of the beam to the top point is ensured by springs or gas-accumulating shock absorbers.

Electromechanical guillotine shears

This type of guillotine is widespread along with the hydraulic one. It is practically no different from a hydraulic guillotine in terms of productivity (up to 60 knife strokes per minute) but is noisier - the crank drive mechanism causes rapid movement of the knife and impact on the workpiece.

Electromechanical guillotine

Like the hydraulic guillotine, the electromechanical guillotine is intended for industrial use in workshops where high-performance precision cutting of straight workpieces of large size and thickness is required. However, metal cutting is also carried out using an electromechanical guillotine and in small-scale and artisanal production - a whole series of low-power scissors has been created for this purpose. They take up little space in the workshop and allow you to easily cut galvanized sheet steel, aluminum, copper, plastic and stainless steel up to 2-3 mm thick.

The drive to the upper beam with a knife is carried out using a crank mechanism on the power take-off shaft from an electric motor, which is activated by pressing a pedal or a button. As they rotate, the eccentrics transmit force to both ends of the knife beam, and the cutting force is distributed evenly. At the end of one revolution of the shaft, the beam returns to the upper position, and the workpiece is fed for the next cut.

Equipping electromechanical CNC guillotines allows you to turn them into one of the most accurate and productive machines for cutting and chopping metal. They are easy to maintain, have a reliable kinematic circuit and are cheaper than hydraulic ones. If you wish and have plumbing qualifications, you can make a guillotine cutter with an electric drive yourself in a home workshop or in a small production environment.

Scope of application and price

A manual lever guillotine is used both for cutting metal (there is a significant limitation on thickness) and for a number of other flat materials (plastic, rubber, plexiglass, etc.). It is advisable to buy a manual guillotine when performing small-scale work. The popularity of the product and low cost make it possible to quite often find such an installation in the personal household of a home craftsman or in the garage of a private owner. Small construction companies engaged in roofing work can also buy the unit. Often, the purchase of guillotine cutting equipment of this type is carried out in car services, repair shops, small enterprises and organizations working in the housing and communal services sector, mechanical engineering, and other industries related to metalworking.

Having purchased a product with this drive, you have an advantage, since the price of manual lever guillotine shears for cutting sheet metal is significantly lower compared to other types of machines used for processing rolled metal.

It is important to choose and buy the right type of knife and that the price is low. The quality of cutting or chopping the sheet will depend on its strength, reliability and durability. As a rule, high-strength steel alloys are used, and in some cases, knives based on chrome alloys. The most common knife sizes:

- length: from 100 mm to 3.0 m

- width: 50 – 220 mm

- thickness: 10 – 120 mm

Pneumatic guillotines

A guillotine for cutting metal with a drive powered by compressed air exceeds hydraulic ones in productivity and is approximately equal to electromechanical ones. For its operation, a compressor or a central line with compressed air is required. Pneumatic guillotines are used in large metalworking shops for the production of large-scale parts.

Like electric and hydraulic machines, pneumatic guillotine shears belong to the stationary type of equipment. They are equipped with large work tables, retractable containers for collecting products and automated feeding mechanisms. Most pneumatic shears are equipped with CNC control - the speed of the pneumatics in combination with electronic control allows you to produce a large number of high-precision parts in a limited time.

Manual guillotine for metal

Mechanical guillotine shears driven by a lever or pedal are undoubtedly the most common type of metal-cutting machines. With restrictions on the thickness of the metal being processed and its types, manual guillotine shears can be found in every workshop or workshop where work with sheet metal, fittings or rolled profiles is expected.

Mechanical guillotine machine

The mechanical guillotine cutter is equipped with two knives. The lower one, like a hydraulic or electric guillotine, is stationary. And the top one can move vertically downwards along guides, like in industrial installations, or rotate around an axis. The rotation point is located at one end of the knife beam, and the handle is at the other.

A manual mechanical guillotine can be equipped with a gearbox, which allows you to develop significant force on the knife, allowing you to cut sheets more than 1 mm thick and stainless steel. The foot guillotine is operated by a pedal, while the manual guillotine is operated by a lever. A combined drive is also possible. A mobile guillotine for cutting metal is installed on any flat surface that ensures the stability of the machine, and is used on construction sites, for example, for cutting roofing steel or corrugated sheeting.

In the second case, a manual saber-type guillotine, equipped with an arched knife, is most often used. In this case, the cutting point will be smoothly mixed by the cutting path and will not damage the metal of a complex profile. The manual saber guillotine is used for both transverse and longitudinal cutting of workpieces made of steel, aluminum, and stainless steel.

Guillotine cutting on manual machines is also possible when working with reinforcement, angles and profiles. If sheet cutting on a guillotine is possible on all types of machines, then a mini guillotine for metal for working with shaped steel must be equipped with a gearbox.

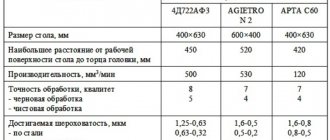

Table of characteristics of guillotine knives

Design features of guillotine shears

A manual guillotine for rolled metal is one of the types of cutting devices. There are also foot, mechanical, electromechanical, hydraulic guillotine machines. Each of these devices has its own advantages and features of use when processing metal workpieces.

Structurally, this is a fairly simple device, which, nevertheless, effectively performs the assigned functions - namely, cutting sheet iron (steel, stainless steel, non-ferrous rolled products) into blanks of a certain shape and size. By purchasing this equipment at a low cost, you will be able to produce high-quality metal products without additional costs (workshop rent, electricity, etc.).

Lever guillotine shears consist of the following main elements:

- frame, bed with a working surface of a certain size

- upper cutter

- bottom cutter

- limiting devices

- clamping mechanism

- graduated stop

The simplest type of units at reasonable prices is guillotine shears. The mechanism is driven by the muscular strength of the hands. Externally, the design of the machine looks like a regular table on which the cutters are mounted, and the control (laying the metal workpiece on the table top, marking the cutting line and, finally, the process of cutting the sheet itself) is done manually. When deciding to buy a manual guillotine for cutting metal sheets, you should consider a number of features:

- when cutting sheet metal, it will be necessary to apply a certain mechanical force, which will increase in direct proportion to the thickness of the sheet and the length of the cutting line;

- the thickness of the workpiece will be small compared to other types of machines, but you can buy this mechanism at an affordable price;

- In addition to thin sheet steel, the guillotine bed can process workpieces made of plexiglass, plastic, and rubber