The equipment has the form of a ring to which a metal threaded rod is welded. It can be screwed into any structure, regardless of its complexity. When performing rigging work, the eye bolt creates a very strong fastening of the parts being connected.

The device is made of carbon, alloy steel. To use the product on marine vessels, the parts are coated with zinc. It forms strong oxides on the surface of the part, which protect the metal from oxidation. This oxide film has high strength. It prevents corrosion of the product.

Scope of application and features

Thanks to its very simple design , the eyebolt product is widely used in various industries. The equipment is considered universal; it can be used for several technological operations:

- Stretching.

- Durable fastening.

This mount is mounted on various types of equipment; the load-carrying capacity of the device depends on the angle of inclination of the bolt. If we take into account the standard size of the product and the angle of the rope relative to the axis, its load capacity will be in the range of 30–20,000 kg. Do not lift the load if the angle of deviation from the vertical exceeds 45 degrees.

Eye bolt GOST 4751-73, production regulations, properties and features

For installation, loading and unloading operations and transportation of goods, special devices are used, which include a GOST 4751–73 eye bolt with an eye for fixing chains, slings, lanyards, mounting brackets, ropes or cables. The design, manufacturing method, operating conditions and dimensional parameters of the hardware are determined by the state standard.

Design and technical specifications

In the design of the device, the main element is a rod with a ring head and a threaded body. The production of hardware is carried out by forging or stamping steel grade Art. 20 and Art. 25.

The state standard imposes increased requirements on the product manufacturing process, since the product is subjected to significant mechanical loads and is operated in different climatic conditions.

According to the technical conditions, the presence of burrs, holes, cavities, cuts, dents and metal scoring is not allowed on the ring and bolt body; special requirements are imposed on the integrity of the ridges and the depth of the threaded groove. The specifications do not allow for the elimination of defects; the restored part has reduced mechanical characteristics. To protect against corrosion, finished products are fired and galvanized.

The dimensional parameters of the mounting socket according to GOST for eye bolts are determined by the following:

- Metal hardness

- Tolerances of perpendicularity of the body axis to the support surface

Lifting capacity

When choosing a device, the main attention should be focused on the technical characteristics of the product in accordance with the weight of the load and the type of work performed.

The lifting capacity of eye bolts is determined by the angle of inclination of the head loop relative to the body of the device.

When transporting heavy cargo, the direction of tension of the sling should be directed along the vertical axis of the eyebolt.

The deviation from the vertical axis to the plane of the bolt and the plane of the hinge should not exceed 450.

If the deviations exceed the permissible value, emergency situations arise due to the failure of the loop head or thread ridges.

Destruction of the integrity of the device can be caused by a discrepancy in the metal grade, or by exceeding the weight of the load beyond the permissible limit stated by the manufacturer.

Types of steel eye fastenings

In addition to their intended purpose, fastenings of a special design are also used in the formation of a non-standard lifting system. Such products are eye bolts with a hinge (swivel), which prevents the rotation of a load with longitudinal rings or rods when lifting heavy, oversized and light objects.

Any innovative design is manufactured according to the conditions of the state standard, ensuring the safety of personnel and the integrity of the cargo.

TU and GOST differ from manufacturer to country, but the main indicator of product reliability is considered to be compliance with the “International Standard DIN 580”, adapted to the interstate GOST 4751−73.

All products must have alphanumeric markings and the manufacturer's trademark on the headband (M8, M16, etc.).

- The technical characteristics of bolts are determined by the manufacturing method:

- The finished product is fired at high temperature.

- The following method is used for marking:

- Stampings

- Impact application.

Each batch of products is equipped with a Certificate of Conformity with the manufacturer’s logo, batch number, number of fasteners, and the result of the examination. Products should be packaged in layers, with oiled paper between layers.

Features and scope

The distinctive qualities of the eye fastening are the steel grade and thread pitch. So, a bolt made from st. 20 with a pitch of threaded ridges M 8 - M 64 should have a hardness rating from 105 HB to 149 HB and a complete absence of scale and traces of rust.

The force of lifting an object depends on the angle of fastening of the bolt relative to the plane of the load. The angle of tension of the slings relative to the vertical axis of the fastening is formed by the cargo mass of the object being moved and can range from 30 kg to 20 tons. The safest lifting of heavy loads is carried out by creating a force along the axis of the screw rod.

Hardware made in accordance with GOST 4751–73 from carbon steel is manufactured in different sizes and shapes. In addition to the ring-shaped head, the fastening element can be equipped with a hook. To secure the device to an object, the threaded tip of the product is screwed into a hole on the body of the load, and a sling or cable is fixed in the eye of the bolt.

Dimensions and markings of fasteners

- Steel eye bolts, the dimensions of which are determined by specifications, are subdivided by symbols, their interpretation corresponds to the name and size of the thread:

- Example:

- Eye bolt M 14 GOST 4751–73

- Name - eye bolt

- Thread sizes - 14

- GOST 4751–73 is a regulatory standard.

- For hardware with chrome (01 microns) zinc (9 microns) coating and fine threads, copper plating can be made to order.

https://obrabotkametalla.info/izdeliya/rym-bolt-gost-4751-73

4. TEST METHODS

4.1. Compliance with the requirements of clause 2.3 is checked by external inspection without the use of magnifying devices.

Magnifiers up to three times magnification can be used.

(Changed edition, Amendment No. 2).

4.2. Hardness (clause 2.7) is determined according to GOST 9012 on the generatrix of the supporting part of the ring.

4.3. The threads (clause 2.10) are checked with maximum gauges.

4.4. The deviation from the perpendicularity of the axis of the threaded shank to the supporting surface of the ring (clause 2.12) is checked with an angle gauge or feeler gauge along the clearance between the supporting surface of the ring and the end surface of the control gauge.

4.5. Compliance of eye bolts with the requirements of clause 2.4 is checked by a tensile test with holding under load for 10 minutes.

The load must be applied along the axis of the eyebolt rod.

The application of the load should be smooth, without jerking.

After removing the load, there should be no residual deformation, cracks or tears in the eye bolts.

The absence of residual deformations is determined by checking the dimensions along the axis of the eye bolts before and after testing.

The absence of cracks and tears is checked by external inspection using a magnifying glass with at least four times magnification.

4.6. The thickness of the coating layer (clause 2.15) is checked on the eyebolt ring. Methods for checking the quality and thickness of the coating are in accordance with GOST 9.302.

4.7. (Deleted, Amendment No. 2).

GOST 4751-73 - din 580

NameSelect quantity in pieces

- Eye bolt DIN 580 M 6 zn / GOST 4751-73 (10)

- Eye bolt DIN 580 M 8 zn / GOST 4751-73 (10)

- Eye bolt DIN 580 M 10 zn / GOST 4751-73 (5)

- Eye bolt DIN 580 M 12 A4 / GOST 4751-73

- Eye bolt DIN 580 M 12 zn / GOST 4751-73 (5)

- Eye bolt DIN 580 M 14 zn / GOST 4751-73 (5)

- Eye bolt DIN 580 M 16 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 18 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 20 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 22 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 24 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 27 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 30 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 36 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 42 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 48 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 56 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 64 zn / GOST 4751-73 (1)

- Eye bolt DIN 580 M 80 / GOST 4751-73 (1)

An eye bolt is a metal ring with a skirt and a rod with a thread at the end. With its threaded part, it is screwed into the body of a part, assembly or mechanism, and the ring is used to install cables, chains, slings, carabiners, staples, and hooks into it.

Purpose

An eye bolt is a special type of hardware and is needed for gripping and moving metal structures, mechanisms, machines, units, parts during loading, unloading, assembly, disassembly or transportation.

Since the eye bolt is a lifting mechanism, it is subject to increased demands on materials and workmanship. It belongs to the rigging group and must be periodically inspected for damage or deformation. The following are not allowed on the surface:

- center holes on the ring;

- cuts on the shank;

- burrs;

- dents;

- broken threads on threads.

Welding and eliminating defects in any way is strictly prohibited - such an eye bolt must be disposed of.

Eye bolts are simply irreplaceable when carrying out unloading and loading operations, installation of machine tools, engines and other equipment. It is widely used in mechanical engineering, construction, cargo transportation and many other industries.

- In our company you can purchase:

- domestic eye bolt GOST 4751;

- foreign analogue - eye bolt DIN 580.

- The main difference is that domestic eye bolts have a longer threaded shank.

- Features of operation

- The load capacity of the same eye bolt may vary when performing different jobs and depends on:

- direction of the cable relative to the axis of the eyebolt;

- position of the cable relative to the plane of the mounting ring.

The maximum lifting capacity is allowed only if the cable is aligned with the eyebolt. If there is a deviation of up to 45 degrees from the axis and plane of the ring, then the load capacity is reduced accordingly. When the angle between the axis of the eye bolt and the cable exceeds 45 degrees, the use of the eye bolt is not permitted.

Materials

Eye bolt GOST 4751-73 is made by stamping or forging from carbon structural steel 20 and 25. This steel is used for the manufacture of fasteners and parts with increased requirements for surface hardness. They tolerate high temperatures well and are not subject to temper brittleness.

Eye bolts DIN 580 are made of C15 steel. This is a German-made carbon structural steel, an analogue of domestic steel 15, from which bolts, screws, hooks and other parts are made that operate at high temperatures and have high surface hardness and low core strength.

Products can be manufactured uncoated or coated, at the discretion of the manufacturer. Of all the anti-corrosion coatings, the most common is zinc, as it is the most practical and inexpensive.

Marking, symbol

An eye bolt is a very important product, so each of them is marked. It contains the thread designation, load capacity and manufacturer's mark. Some bolts are small and cannot be marked with all the required markings. This product is equipped with a special tag on a cable, which contains all the necessary information.

Each batch of eye bolts is accompanied by a document indicating the manufacturer, symbols, number of products and, of course, the results of control tests.

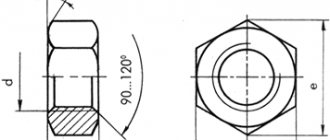

Eye nut

The eye nut is not a fastener like the others, but belongs to the rigging devices. The eye nut is not suitable for creating long-term threaded connections, but serves solely for lifting loads. Eye nuts are used to safely lift and move large parts and mechanisms during loading, unloading, transportation, installation and repair of equipment.

Eye nut DIN 582 is available with metric threads from M6 to M56. The eye nut DIN 582 is made from C15 steel, which is used to create high-strength products.

To increase service life, the eye nut DIN 582 has an anti-corrosion coating. The most common is zinc protective coating.

In addition, the eye nut can be made of stainless or acid-resistant steel.

eye nuts as lifting mechanisms that undergo appropriate checks by technical supervision services. Our company provides all the necessary certificates and reports with the results of inspections and tests from the manufacturer for the supplied products.

On products such as eye nuts, GOST requires that the load capacity, thread size and manufacturer's markings be indicated. In that case. If the eye nut is small in size and there is no place to put the markings, then the manufacturer, using a cable, attaches a plate to it indicating all the necessary parameters.

The eye nut GOST should not have external damage on the ring such as:

- dents;

- cuts;

- cracks;

- damage or wear of threads.

If there is any damage, welding or eliminating defects in any other way is not allowed. such eye nuts to be removed from service and disposed of.

buy eye nuts on our website; to do this, you need to fill out an application, indicating the size and quantity. Eye nut DIN 582 is sold both in batches and individually.

We offer GOST eye nuts manufactured at domestic and foreign factories in accordance with all current standards. If you decide to buy eye nuts from us, we guarantee the quality of each unit supplied. If you need a ring nut, buying it from us will not be difficult.

It is enough to visit our office or warehouse in St. Petersburg or contact our managers on or via the Internet.

https://krep-torg.ru/gost-4751-73—din-580/

3. ACCEPTANCE RULES

3.1. The manufacturer must conduct acceptance tests of eye bolts. During acceptance tests, eye bolts are checked:

before machining:

- for compliance with the requirements of clause 1.1 in terms of dimensions obtained by die forging or forging and clauses 2.3, 2.4: in the case of production by free forging in backing dies - each eye bolt; in the case of production by volumetric stamping - 5% of the batch, but not less than 5 pieces;

— for compliance with the requirements of clauses 2.5 and 2.6, each eye bolt;

— for compliance with the requirements of clause 2.7 10% of the lot, but not less than 5 pieces;

after machining:

— for compliance with the requirements of clause 1.1 (dimensions , and and ) clauses 2.8-2.14 each eye bolt;

— for compliance with the requirements of clause 2.15 — according to GOST 9.301.

Note. The batch consists of eye bolts of the same size, made of steel of the same grade, and heat treated together.

(Changed edition, Amendment No. 1).

3.2. If unsatisfactory test results of eye bolts are obtained according to at least one of the indicators, repeated tests are carried out on a double number of samples taken from the same batch, according to the full program. The results of repeated tests are final and apply to the entire batch.

(Introduced additionally, Amendment No. 2).

GOST 4751-73 | eye bolt, eye bolt, ring bolt

High-strength fasteners, manufactured in accordance with GOST 4751-73 , have a characteristic shape that distinguishes them from other products. Eye bolts have a design in the form of a shank with an external thread and a metal ring. Fasteners are made of stainless and carbon steel.

An additional galvanizing coating helps improve bolt performance and prevent corrosion. The high strength shoulder and ring eye bolt has metric full threads. Its nominal diameter ranges from 6 to 100 mm and has a thread tolerance of 8g.

The most common fasteners in use are with a diameter of 48 mm.

Fasteners in accordance with GOST 4751-73 are made from steel (carbon grades 20 and 25, stainless) using stamping or forging methods. Standardly produced in unprocessed form.

At the request of the customer, taking into account the operating conditions, they can additionally undergo treatment using thermal diffusion galvanizing or galvanic galvanizing techniques.

Eye bolts are produced with markings that contain the manufacturer’s trademark, thread designation, regulatory standard (GOST 4751-73).

It is permissible to mark only the trademark; the remaining data is indicated on a special tag attached to the consignment of goods.

It indicates the symbols, the number of fasteners manufactured and the results of control tests.

Features of operation of eye bolts with eyes according to GOST 4751-73

This type of fasteners is used for lifting machine components and heavy parts. They are convenient for assembling and disassembling structures and transporting them. Thanks to the presence of a special ring instead of a head, the process of gripping units and parts is greatly facilitated.

Eye bolt, eye bolt, bolt with ring in accordance with GOST 4751-73 are also used in the creation of rigging devices, devices for non-cargo and cargo purposes, and installation work.

Fasteners are designed not only to lift and lower products, but also to hold them suspended.

The GOST 4751-73 establishes different levels of load-carrying capacity of fasteners.

They, first of all, depend on the location of the sling relative to the plane of the ring and its direction in relation to the vertical axis.

If the vertical axis of the product and the direction of the sling coincide, the eye bolt has maximum load capacity. In case of deviations in the above indicators, the load capacity is reduced.

Eye bolts have special requirements regarding mechanical properties. Any defects are unacceptable (chips, cracks, burrs, cuts on the shank, etc.). Additionally, the hardness of the fasteners and the perpendicularity of the thread axis with respect to the supporting plane are checked. The size of the seat and its design must be free of breaks and other defects.

An eye bolt, a bolt with an eye, a bolt with a ring in accordance with GOST 4751-73 have a special technical design and a strict purpose. It makes it easy to move various parts by hooking them onto a lifting hook. Based on this, eye bolts are rightly called mounting bolts. They are widely used in construction, production and even in everyday life.

https://xn—-jtbaeggiethskfo2f3c.xn--p1ai/gost-4751-73-rym-bolt

this site

- home

- Hardware

- Rigging

- Eye bolt DIN 580, GOST 4751-73

To lift/lower and move cargo from place to place during installation and rigging work, a type of fastening hardware such as an eye bolt (bolt with a ring eye) is widely used.

The most popular in the Russian consumer market is the eye bolt DIN 580

(meets the requirements of GOST 4751-73). Its rod has an incomplete large-pitch metric thread, and the head is made in the form of a ring (eye). A cable, chain, or other rigging is threaded into the hole in the ring.

The eye bolt is screwed into a mounting hole with threads of similar parameters located on the surface of the object being moved.

These hardware are indispensable when towing vehicles, loading and unloading, installing/dismantling machine tools, building structures, various engines, and moving other heavy loads inside and outside buildings.

Eye bolt DIN 580

can have a thread diameter ranging from M6 to M100 with a tolerance range of 6g. The parameters of the inner diameter of the ring vary from 16 to 180 mm. The temperature range in which the products can be operated is very wide and ranges from -200 to +200°C.

If the axes of the bolt and the sling coincide, the load capacity of the product will be the greatest, amounting, depending on the dimensional parameters, 0.14 - 8.60 tons. If an angle is formed between the axis of the bolt and the sling, the load capacity decreases. The limit value of such an angle is 45°; if it is exceeded, rigging work is unacceptable.

Eye bolts DIN 580 are manufactured by forging or upsetting (stamping). The starting raw materials are carbon steel C15E with or without a protective zinc coating, as well as stainless steel grades A2/A3/A4/A5.

Name Price for Up to 30,000 rub. Up to 60,000 rub. From 60,000 rub. Buy, quantity

| M6 Eye bolt DIN 580, ZINC (50) (packing 50 pcs. 3 kg) | 1 pack | 916.59 RUR | 872.94 RUR | 831.37 RUR | 0 3 In cart: 0 kg (pack) |

| M6 Eye bolt DIN 580, ZINC (50) (packing 50 pcs. 3 kg) | 1 pack | 916.59 RUR | 872.94 RUR | 831.37 RUR | 0 3 In cart: 0 kg (pack) |

| M6 Eye bolt DIN 580, ZINC (1) (packing 1 pc. 0.055 kg) | 1 PC | 18.33 RUR | 17.46 RUR | 16.63 RUR | 0 0.055 In basket: 0 kg (pack) |

| M8 Eye bolt DIN 580, ZINC (50) (packing 50 pcs. 4 kg) | 1 pack | 933.18 RUR | 888.74 RUR | 846.42 RUR | 0 4 In cart: 0 kg (pack) |

| M8 Eye bolt DIN 580, ZINC (500) (packing 500 pcs. 26.32 kg) | 1 pack | RUB 9,331.82 | RUR 8,887.45 | RUB 8,464.24 | 0 26.32 In the basket: 0 kg (pack) |

| M8 Eye bolt DIN 580, ZINC (1) (packing 1 pc. 0.054 kg) | 1 PC | 18.66 RUR | 17.77 RUR | 16.93 RUR | 0 0.054 In basket: 0 kg (pack) |

| M10 Eye bolt DIN 580, ZINC (30) (packing 30 pcs. 3.3 kg) | 1 pack | 913.53 RUR | 870.03 RUR | 828.60 RUR | 0 3.3 In the basket: 0 kg (pack) |

| M10 Eye bolt DIN 580, ZINC (30) (packing 30 pcs. 3.3 kg) | 1 pack | 913.53 RUR | 870.03 RUR | 828.60 RUR | 0 3.3 In the basket: 0 kg (pack) |

| M12 Eye bolt DIN 580, ZINC (20) (packing 20 pcs. 3.6 kg) | 1 pack | 863.12 RUR | 822.02 RUR | RUR 782.88 | 0 3.6 In the basket: 0 kg (pack) |

| M12 Eye bolt DIN 580, ZINC (20) (packing 20 pcs. 3.6 kg) | 1 pack | 863.12 RUR | 822.02 RUR | RUR 782.88 | 0 3.6 In the basket: 0 kg (pack) |

| M14 Eye bolt DIN 580, ZINC (15) (packing 15 pcs. 2.85 kg) | 1 pack | 663.02 RUR | 631.45 RUR | 601.38 RUR | 0 2.85 In cart: 0 kg (pack) |

| M14 Eye bolt DIN 580, ZINC (1) (packing 1 pc. 0.184 kg) | 1 PC | 44.20 RUR | 42.10 RUR | 40.09 RUR | 0 0.184 In basket: 0 kg (pack) |

| M16 Eye bolt DIN 580, ZINC (10) (packing 10 pcs. 2.85 kg) | 1 pack | 647.08 RUR | 616.27 RUR | 586.92 RUR | 0 2.85 In cart: 0 kg (pack) |

| M16 Eye bolt DIN 580, ZINC (10) (packing 10 pcs. 2.85 kg) | 1 pack | 647.08 RUR | 616.27 RUR | 586.92 RUR | 0 2.85 In cart: 0 kg (pack) |

| M16 Eye bolt DIN 580, ZINC (1) (packing 1 pc. 0.294 kg) | 1 PC | 64.71 RUR | 61.63 RUR | 58.69 RUR | 0 0.294 In basket: 0 kg (pack) |

| M20 Eye bolt DIN 580, ZINC (10) (packing 10 pcs. 4.5 kg) | 1 pack | 888.56 RUR | 846.25 RUR | 805.95 RUR | 0 4.5 In cart: 0 kg (pack) |

| M20 Eye bolt DIN 580, ZINC (1) (packing 1 pc. 0.448 kg) | 1 PC | 88.86 RUR | 84.63 RUR | 80.60 RUR | 0 0.448 In cart: 0 kg (pack) |

| M24 Eye bolt DIN 580, ZINC (10) (packing 10 pcs. 8.7 kg) | 1 pack | RUB 1,958.59 | RUB 1,865.32 | RUB 1,776.50 | 0 8.7 In the basket: 0 kg (pack) |

| M24 Eye bolt DIN 580, ZINC (1) (packing 1 pc. 0.904 kg) | 1 PC | 195.86 RUR | 186.53 RUR | 177.65 RUR | 0 0.904 In basket: 0 kg (pack) |

| M24 Eye bolt DIN 580, ZINC (5) (packing 5 pcs. 4.35 kg) | 1 pack | 979.29 RUR | 932.66 RUR | 888.25 RUR | 0 4.35 In the basket: 0 kg (pack) |

| M24 Eye bolt DIN 580, ZINC (20) (packing 20 pcs. 17.4 kg) | 1 pack | RUR 3,917.18 | RUB 3,730.65 | RUB 3,553.00 | 0 17.4 In basket: 0 kg (pack) |

| M36 Eye bolt DIN 580, ZINC (1) (packing 1 pc. 2.65 kg) | 1 PC | 587.26 RUR | 559.30 RUR | 532.66 RUR | 0 2.65 In cart: 0 kg (pack) |

https://www.zitar.ru/metiz/rym_bolt_din_580_gost_4751_73/

INFORMATION DATA

________________ * See note from FSUE “STANDARTINFORM”

1. APPROVED AND ENTERED INTO EFFECT by the State Committee of Standards of the Council of Ministers of the USSR dated May 10, 1973 N 1169

2. Inspection period - 1993, frequency - 5 years

3. INSTEAD GOST 4751-67

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 9.014-78 | 5.6 |

| GOST 9.301-86 | 2.15, 3.1 |

| GOST 9.302-88 | 4.6 |

| GOST 515-77 | 5.3 |

| GOST 1050-88 | 2.1 |

| GOST 1759.0-87 | 2.15 |

| GOST 2991-85 | 5.3 |

| GOST 7505-89 | 2.3 |

| GOST 9012-59 | 4.2 |

| GOST 10549-80 | 2.10 |

| GOST 14192-96 | 5.8 |

| GOST 15150-69 | Introductory part |

| GOST 16093-81 | 2.10, application |

| GOST 24705-81 | 2.10, application |

5. Tested in 1988. The validity period was removed by Decree of the USSR State Standard of December 16, 1988 N 4162

6. REISSUE (June 1998) with Amendments No. 1, 2, 3, 4, approved in May 1979, January 1983, December 1988, August 1990 (IUS 7-79, 5-83 , 3-89, 11-90)

Reprint (as of April 2008)

This standard applies to eye bolts intended for lifting, lowering or holding products by weight during installation and rigging work for all operating conditions in accordance with GOST 15150.

(Changed edition, Amendment No. 4).