We offer to buy long products wholesale in Moscow and Nizhny Novgorod at a competitive price. We cooperate with Russian and foreign manufacturers without intermediaries - this allows us to provide consumers with truly high-quality products.

Main brands:

- 08Х18Н10Т

- 12Х18Н10Т

- 08Х18Н10

- 10Х17Н13М2Т

- 20Х23Н18

- 07Х16Н4Б

- 20Х13

- 30Х13

- 40Х13

- 14Х17Н2

Melting method: gr, vd, vi, w, ei

| Standards | |

| Long-rolled flat products are supplied in accordance with the following Russian standards and technical specifications GOST 2590-88 Hot-rolled round steel products. GOST 2591-88 Hot-rolled square steel. GOST 1133-71 Forged steel, round, square. Assortment. GOST 2879-88 Hot-rolled hexagonal steel. GOST 7417-75 Calibrated round steel. GOST 14955-77 Hot-rolled round steel with special surface finishing. Specifications | Forgings are supplied in accordance with the following Russian standards and technical specifications TU 14-1-1530-75 Forgings of steels and alloys for machine parts. Technical conditions. GOST 26131-84 Forgings made of heat-resistant and heat-resistant alloys. General technical conditions GOST 25054-81 Forgings made of corrosion-resistant steels and alloys. General technical conditions. By agreement with the customer, metal products are supplied with additional requirements “for nuclear power plants”, “Aircraft technical acceptance” (ATP) and with ultrasonic testing. Services Cutting to size with a diameter of up to 600 mm. |

Range of supplied products

| Circle, mm | 8-29 | 30-56 | 58-110 | 115-250 | 200-600 |

| Square, mm | 20-80 | 85-160 | 165-250 | Over 250 | |

| Hexagon, mm | 8-14 | 15-19 | 20-25 | 26-41 | |

Main brands:

- 12Х18Н10Т;

- 08Х18Н10Т;

- 10Х17Н13М2Т;

- 08Х18Н10;

- 20Х23Н18;

- 07Х16Н4Б;

- 14Х17Н2;

- 40X13;

- 30Х13;

- 20X13.

Types of rolled metal

Different types of rolled metal can be distinguished based on the following characteristics:

- production features: hot rolled (produced at temperatures above the recrystallization temperature), cold rolled (produced at temperatures below the recrystallization threshold);

- alloy used: black (from cast iron and carbon steels), non-ferrous (from aluminum, copper, titanium, nickel, cadmium, tin, other metals), stainless;

- surface treatment method: can be matte, mirror, polished, calibrated.

There are also several types of rolled metal based on the type of finished product:

- sheet - sheet steel, tape;

- high-quality - made on special machines, with a cross-section of different shapes (circle, hexagon, strip, square);

- shaped - with a complex cross-sectional shape (rails, channels, angles);

- rolled pipes - welded, cold-drawn, hot-rolled pipes, which can have a round, oval or rectangular cross-section.

Long products: concept and classification

Rolled metal products are metal products united by a common feature: any tangent drawn to the cross section does not intersect it. Profiles are produced on sectional longitudinal roller machines in accordance with GOST 535-2005. Simple geometric profile shapes of this type of product are circle, rectangle, square, hexagon.

Products are most often used as semi-finished products. Rolled metal becomes a blank for the manufacture of products that are more complex in shape and design.

A steel circle is a rod with a round cross-section, which is produced in accordance with the GOST 2590-2006 standard. The main parameter in the production of round rolled metal is the nominal diameter: the standard allows it to vary from 5 to 270 mm. Another important aspect is rolling accuracy, depending on which there are:

- A - high accuracy;

- B - increased accuracy;

- B - normal accuracy.

For metal products with a round cross-section, various grades of steel are used: low-alloy, high-alloy, alloy, carbon. This naturally affects the strength characteristics.

Steel wheels are produced, stored and transported in rods or, for diameters less than 9 mm, in coils. The scope of its use is quite wide and includes mechanical engineering, shipbuilding, construction, the creation of fences and various forged metal structures (fences, window bars).

A steel strip is a rolled metal product with a rectangular cross-section, manufactured in accordance with GOST 103-2006. In production, the main parameters are width (from 11 to 200 mm) and thickness (from 4 to 60 mm). Supplied in rods with lengths from 2 to 12 m.

Of all types of sectional metal products, strip is the most widely used, since it acts as a blank for many other products, including shaped ones. Main areas of application: production of automobile springs, cutting tools, production of steel pipes. The strip can also be used as a structural element of structures, a decorative element of fences and gratings.

Square rolled steel meets the standards of GOST 2591-2006, and the main parameter for its production is the nominal side of the square (from 6 to 200 mm). The form of production is rods, and the raw material base is similar to that used for the manufacture of steel circles. The geometrically correct shape of this type of rolled steel allows it to be used in civil and industrial construction. Examples of products: metal gates, fences, forged grilles, benches.

A hexagon made of steel must comply with GOST 2879-2006, and can be produced with normal or increased accuracy. The main parameter for products with a hexagonal cross-section is the nominal diameter of the inscribed circle (from 8 to 103 mm). Hexagons are produced and supplied in rods from 2 to 6 m long. Such rolled metal is in demand in the automotive industry, as well as the chemical and food industries. It is actively used for the production of bolts, nuts and other types of high-precision fasteners.

In addition to products of simple shape, fittings are distinguished as a separate subtype. It consists of many interconnected elements and is widely used during construction work as an element of reinforced concrete structures. The surface quality allows the reinforcement to be divided into several types:

- 1GP - does not require further processing;

- 2GP - requires hot pressure treatment;

- 3GP - requires cold processing, which involves mechanical cutting.

Characteristics and application of long products

Stainless steel products are represented by a wide range of products that differ in purpose, size and other characteristics.

Rolled stainless steel products are divided into the following types:

- rolled metal of a simple type - small products that do not require specific production technology;

- reinforcement bars - wire products, fittings, mesh;

- shaped rolled products are products of complex shapes that are used mainly in heavy industry (angle profiles and other products).

Taking into account the dimensions, stainless steel bars are divided into the following groups:

- large - products with a round section larger than 80.0 mm, square - larger than 70.0 mm, corner with a shelf larger than 90.0 mm, hexagons up to No. 100;

- medium - round products with a diameter of 35.0-75.0 mm, strips with a width of 60.0-250.0 mm, reinforcement products No. 32-60;

- small - products with a diameter size from 10.0 to 30.0 mm, square products with a section size of 8.0-10.0 mm, corners with shelves 20.0-50.0 mm.

After final surface treatment, calibrated, polished, matte or mirror rolled metal is obtained.

Polished metal, unlike matte, may have traces of surface treatment with abrasive materials.

Hot-rolled products are used if no high demands are placed on the surface of the product.

The main advantages of high-quality stainless steel rolled metal include:

- increased corrosion resistance;

- practicality and long-term operation;

- optimal ratio of quality and cost indicators.

The areas of application of rolled stainless steel are quite wide; such products are in demand in mechanical engineering for the creation of parts and components, in agricultural production, in the mining industries, in the production of reinforced concrete structures, bridges and other engineering structures.

Shaped metal products

Shaped metal products have a complex shape and come in the following varieties:

- Channel is a U-shaped profile in cross section, made by hot rolling. Due to its ability to withstand high longitudinal and transverse loads, the channel is widely used in mechanical engineering, as well as in the reinforcement of reinforced concrete, the construction of metal structures, and anchor posts.

- I-beam (beam) is a shaped rolled product with an H-shaped cross section, made of carbon or low-alloy steel. The shape contributes to high rigidity and load-bearing capacity while reducing weight, which allows the use of I-beams when installing floors and as supporting elements.

- An angle is a metal plate bent lengthwise, used in the automotive industry, carriage building, mechanical engineering, as well as in construction for installing reinforced concrete lintels and connecting metal and wooden products.

Separately, we can highlight rails - a special type of rolled metal that is used in the construction and repair of railways.

Long products: main types and purpose

Long products are billets for various types of production, having an elementary cross-sectional shape. On the metal rolling market it is represented by squares, circles, stripes, hexagons and other shapes.

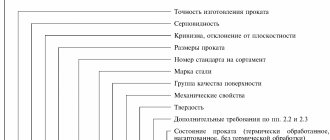

Different types of long products may differ in materials, dimensions, precision and other parameters. The main classifier is the quality of the surface, by which rolled products are distinguished:

- ready for use without processing;

- intended for hot processing under pressure;

- for cutting.

The scope of application of long products depends on its shape.

Steel circles are one of the most popular products from this line. They are produced in different diameters from carbon and low-alloy steel, less often from high-alloy raw materials. The scope of application is wide: heavy engineering, construction, shipbuilding, production of fences, nets and reinforcement, and sometimes forging.

Steel square is a rolled product that is only slightly inferior in demand to the previous one. This is a rod with a square cross-section with the same raw material base that is used to produce steel circles. Used to create precise structures of all kinds.

Steel strip of various dimensions with a rectangular cross-section. It is hardly possible to list all the possible applications. Such a strip can perform any function: from a blank for the production of tools to a basis for complex structures.

Beams are H-shaped profiles. They are characterized by high strength and can withstand very high vertical and horizontal loads. They are used as connecting and strengthening elements of structures, the basis for door and window openings. They are also used in the construction and installation of overhead tracks, shafts, balconies, and bridge structures.

Corners are L-shaped profiles that are used in installation and construction: during the construction of structures, strengthening ceilings and walls. They are also used in machine and carriage building. More often, corners have equal cross-sectional sides; unequal angles are less common. There are angles of normal and increased precision rolling.

Reinforcement is rolled products designed to increase the rigidity and strength of reinforced concrete structures. The fittings are made of hardened and low-carbon steel. It is used in reinforced concrete structures of any type and purpose, and its technical characteristics are determined, first of all, by the grade of steel and the diameter of the product.

Wire is a product in the form of a thread, usually with a round cross-section, although it can also be trapezoidal, oval, square and hexagonal. The diameter can vary: from fractions of a millimeter to several centimeters. Wire is used to create marks, springs, electrodes, wires, and cables. They produce heat-treated and untreated, coated and uncoated, galvanized and ungalvanized wire.

Channel is a rolled product with a U-shaped profile, which is used to create frames and structures. Suitable for covering roof purlins. It is often used in concrete buildings, since the result is a durable structure that can withstand various types of stress.

Features and application of other types of rolled metal

The two remaining types of metal products, sheet and pipe, are also widely used for a variety of purposes:

- hot-rolled sheet is a metal product that is used in the manufacture of pipes and bent profiles, decking, fencing, as well as in boiler building;

- Cold-rolled sheets have a better surface quality than hot-rolled sheets and are used in the automotive and mechanical engineering industries;

- round seamless pipes perform the function of transmitting a liquid or gaseous medium at high temperatures and pressure, and are also used for the manufacture of metal structures;

- round electric-welded straight-seam pipes are needed for organizing engineering systems (heating, water supply, gas supply);

- profile welded type of pipe cannot be used for pipelines due to its rectangular cross-section; it is used in frame construction (sheds, gazebos, greenhouses), and stairs and fences are made from it.

A huge variety of metals and product forms allows it to be used in almost every industry.

Why you should contact our company

Our company has its own warehouses in Nizhny Novgorod and Moscow, which constantly have a large supply of metal products - this allows us to ensure fast and regular deliveries to our customers. Stainless steel products are delivered by road, sea and rail to all regions of Russia.

Our regular clients are enterprises in the oil and gas, oil refining and chemical industries, nuclear and fuel energy, mechanical engineering, aircraft and shipbuilding, military-industrial complex, food industry, agriculture and construction throughout Russia. Our advantages:

- Professional consultations with clients on all emerging issues.

- We supply only high-quality stainless steel bars, which is confirmed by certificates of quality and conformity.

- Individual approach to every customer.

Call us at + or leave a request in a special form on the website to find out the cost of your order and get advice on any other issues.