Steel cables are one of the main types of flexible rigging, which is used for various lifting operations. Cables are also used for installing stationary guy wires, suspensions and other fastenings. The peculiarity of steel cable is that it is twisted from many thin threads and is very resistant to stretching in static and dynamic modes. But with high flexibility, the cable is relatively easy to break if the bending radius is less than permissible for a given diameter.

The main way to connect a cable to the hook of a lifting mechanism is through the loop at its end. But a regular loop is not suitable - under high loads it stretches and the bending radius becomes critically low. This will not lead to immediate rupture of the rigging, but some of the threads will be damaged. As a result, the strength of the rigging will decrease, and the service life will decrease by more than 50%.

What are thimbles – let’s explore an important fastening element + Video

A thong is a special fastening element of various shapes, designed to reliably hold ropes and cables made of steel and other materials from lifting and transport devices.

1 Application of thimble in modern construction and GOST standards

The word “koush” originates from the Dutch language and is translated as “metal stocking”. Thimbles of various sizes and compositions are used in many areas of construction, marine and aviation industries. The main purpose of this part is to prevent abrasion and deformation of the metal cable and to obtain a smoother running of the rope during use. The dimensions and strength of the material from which thimbles are made directly depend on the cross-section of the cable.

Metal thimbles

We recommend that you read

Thimbles can be cast, with a bridge and made in various shapes (triangular, teardrop-shaped or round). Regardless of the shape and method of casting, the DIN 6899 thimble made of steel alloy has a special groove along the outer contour through which the steel cable passes without being worn out or deformed during lifting operations. Due to special grooves on the outside, the ropes are firmly held by the thimble even with minor lateral loads. There are several ways to properly use thimbles in construction and production, which differ in the degree of application.

During the construction process, it is important to correctly calculate the correspondence of the diameters of the steel cable and thimble, as well as to monitor compliance with GOST standards, which contain correspondence tables and other recommendations for the use of steel thimbles. Based on the data of the presented standard, the diameter of the metal thimble should be four times the diameter of the main cable. The diameter of the thimble is the diameter of the inner circle drawn between the two extreme points.

It should be understood that GOST 222493 only regulates the use of products for use on various lifting and transport mechanisms under certain temperature conditions, which should not exceed the norm.

If thimbles are used in the aircraft, shipbuilding industries or in the construction of power plants, engineers also take into account the properties of the environment, chemical exposure, temperature changes and other factors that are not specified in the standards of the above GOST.

2 Main types of metal thimbles

Round thimbles. A universal version of a part that has the shape of a ring. When used, the rope loop also takes on a circle shape, which is very convenient in various areas during lifting and unloading work.

Ship thimble. Initially, parts of this type were used in the shipbuilding industry, but gradually the scope of their application expanded significantly. The marine thimble is very durable, as it is made using hot forging technology. Depending on the letter marking on the product (A, B, C), they are intended for use with steel or synthetic cables, and by the marking numbers it is possible to determine the load capacity of the mechanism. For example, the GOST P20 thimble can withstand a maximum load of 2000 tons, while the GOST S300 thimble can withstand loads of up to 300 thousand tons.

Ship thimble

The thimble is cable-stayed. Cable-type products are most often used for stretching, fixing or connecting parts of various mechanisms during construction work. They have a small internal diameter. The cable thimble allows you to achieve high load capacity with minimal loads on the metal part.

Wedge thimble. The part is a device for fixing lifting mechanisms, which consists of several components, a clip, an insert, a fastening pin and a special wedge. During use, when exposed to a certain force, the cable wedges between two equidistant parts of the cage and the insert. When choosing such a part, it is recommended to pay attention to the quality of casting so that the wedge thimble does not have residual pores in the metal, which can negatively affect the operation of the mechanism.

Closed mechanisms. Products made of steel and alloys with closed bead grooves, which are used for synthetic ropes and ropes made from plant materials. The main feature is closed sides, which prevents the rope from slipping through the side during lifting operations.

3 Proper cable attachment

The reliability of the fastening mechanisms also depends on the method in which the loop is created from a rope or cable. The formation of the loop varies according to the degree of load on the cable and thimble. If the production loads are small, then it is enough to use a regular clamp or a simple metal tube using special technology.

Attaching the cable to the thimble

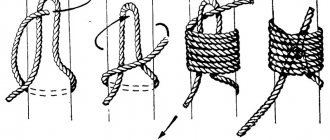

At higher loads, more complex fastening schemes are used. In this case, you can, for example, use double braided cable technology. This means that the ends should be spread out to a length of 20-25 centimeters. Next, the two loose ends are installed crosswise on the thimble and connected by a common cable. To give additional reliability, the braided connection should be reinforced with metal clamps.

Regardless of the fastening method, it is important to choose the right metal cable, which must withstand the maximum load and have a sufficient service life. Steel ropes differ from each other only in the way they are weaved (single, double, triple), and the main selection criterion is the tensile strength indicator, which can be calculated using a special table of coefficients before using the rope in conjunction with the selected thimble.

tutmet.ru

How to make a thimble with your own hands.

Sometimes in everyday life there is a need to

make a clamp with your own hands

. Making your own clamp is not at all difficult. For this purpose, a small piece of aluminum pipe of suitable diameter into which the two ends of the cable could be inserted would be quite suitable.

The pipe must be bent in an arc at a distance of at least 120 mm. A cable is inserted into this arc, the ends of which are covered with aluminum brackets and secured with bolts and nuts. If you need to increase the cable, the diameter of the pipe is selected so that both pieces of the cable can be inserted into it.

When using homemade clamps, reliability and wear resistance will, of course, be lower than that of factory products.

Therefore, it is better not to use them under heavy loads, but for domestic needs their use is quite justified. Tweet

Cable thimble - photos, main types, methods of fixation

A thimble for a steel rope or cable is a frame made of high-strength carbon steel, which can have various shapes: round, triangular or teardrop-shaped. It is assumed that such a useful device as a thimble was originally used to equip ship ropes and cables. The name of this device, which is actively used in the construction industry today, has Dutch roots and means “stocking” (kous). It’s no wonder that the Dutch are also considered the authors of this device.

Throat DIN 6899B

Using a thimble to improve the reliability of cables

The looped ends of the cables and ropes (ogons) are put on the thimble and securely held on it due to the shape of its section, which has the configuration of a gutter. Depending on the scope of application, the size of the fire and the loads experienced, the thimble for ropes or cables can have different sizes. Some models of thimbles for ship ropes, for example, can weigh up to 40 kg, and devices used in the construction industry and everyday life are small in size and weight. The main technology used in the production of thimbles is forging.

The choice of thimble size is mainly influenced by the diameter of the cable for which it will be used. The dimensions of such a device include its diameter, equal to the maximum diameter of the circle that can be inscribed in its inner part, as well as the radius of the groove of its groove, measured in the cross section of the thimble.

There are generally accepted recommendations, according to which the diameter of the thimble should be 4 times the diameter of the cable itself, and the radius of the groove of the groove should be chosen so that the cable in such a groove is buried by 2/3 of its diameter.

Types of thimbles

According to their design and scope of application, thimbles are divided into round, cable-stayed, marine, acid-resistant, and wedge sockets. Let's take a closer look at their features.

- A round cable thimble is a galvanized product shaped like a solid ring. When using such products, the cable loop has the shape of an even circle.

Round cable holder

- The ship's thimble, which has a teardrop shape, is produced by hot forging. Such products are divided into two main types: for use in conjunction with steel ropes (type C) and thimbles used with ropes made from plant materials (type P). In the marking of such thimbles, in addition to designating their type, the value of the maximum load that such fasteners can withstand is also given. A ship's thimble, the marking of which contains, for example, the number 400, is capable of withstanding a load of 40 tf.

- The cable thimble, characterized by a small internal diameter, is today used not only for ship ropes, but also in the construction industry for fixing and securing various mechanisms and metal structures.

- Acid-resistant thimble, which has a shiny surface, is used in production enterprises where there is a high risk of contact with an aggressive environment. Such products are made from steels that are highly resistant to corrosion and acids (M1-M12).

- Semi thimbles are products designed for large diameter cables used for lifting and towing loads.

- Wedge sockets or clips are devices with which cables are fixed in lifting mechanisms. Such a thimble consists of several structural elements: a clip, an insert and a wedge, due to which the rope is jammed between the insert and the cage body.

- There are also thimbles that are used only for cables made of synthetic materials. The design feature of such products is that the side part of its gutter is completely closed, which prevents the lightweight synthetic cable from slipping out of it.

Synthetic rope thimble

Methods for fixing the cable to the thimble

Rope or cable thimbles will be useless if the fire itself is not reliable enough. Loops can be formed at the ends of cables in various ways. If the loads on the cable are insignificant, then a loop can be formed using a regular clamp or a metal tube, which is flattened after it is used to form a loop at the end of the cable. You can see the details of such a simple technological operation in the photos, which are not difficult to find on the Internet.

In order to make a more secure loop at the end of the cable, you will need to unravel it into two parts, approximately equal to each other in thickness and number of fibers. It is necessary to unravel the end of the cable to a length of approximately 30 cm. This procedure should be performed with gloves so as not to injure your hands with steel fibers. The two unraveled halves of the cable are placed crosswise in the thimble groove and connected to the unraveled part of the cable. The most important thing is to ensure such a connection is highly reliable. To do this, each half of the loose part is passed between the turns of the unloose part, for which a screwdriver is used, with which the turns are moved apart, and the loose part is passed into the resulting gap. For greater reliability, the resulting braided connection can be further strengthened with clamps, a flattened tube or wire twists.

One of the ways to fix a cable with a thimble

The importance of choosing ropes and cables

Choosing and securing the rope thimble correctly is only half the battle. An equally important procedure is the selection of the rope itself, which must withstand the loads placed on it. The basis of the design of any steel rope or cable is the wire, which is wound in a certain way onto the core. The core can be made of metal or organic material, which is additionally impregnated with a lubricating compound that significantly reduces friction between the metal fibers of the cable.

A serious difference between steel ropes and others lies in the method of laying their fibers, which can be single, double or triple. Single lay, which is characterized by the greatest rigidity, involves a spiral entwining of the core with individual wires. This type of laying is performed in several layers, with each layer being wound in opposite directions. With double and triple lay, not individual wires are wound around the core, but strands of them. These types of lays differ only in the scheme of their implementation.

The main parameter that should be followed when choosing a steel cable is the maximum breaking force that it can withstand. This parameter directly determines whether the cable you choose can perform the tasks that you are going to solve with its help.

Article rating:

Share with friends:

met-all.org

Using a thimble to increase cable reliability

The lights in the form of a loop are located on the thimble. Reliability is ensured by a special cross-sectional shape made in the form of a gutter. The dimensions of the thimble vary according to the scope of application, the size of the fire and the loads. Large product versions reach 40 kg and are used for ship ropes. Those options that are common in everyday life and the construction industry are smaller in size.

When choosing, it is necessary to take into account the diameter of the cable so that the size of the product matches. The main indicators of the thimble size are the internal diameter and the radius of the groove.

There are certain recommendations, according to which the diameter of the product should be 4 times larger than the diameter of the cable used. The groove should also be one third larger than the cable.

KOUSH is... What is KOUSH?

- KOUSH - male, marine ladle, an iron ring with edges curved outward, for tying it with rope. Splash the ladle. Dahl's Explanatory Dictionary. IN AND. Dahl. 1863 1866 ... Dahl's Explanatory Dictionary

- koush - noun, number of synonyms: 2 • kous (1) • clip (12) ASIS Dictionary of Synonyms. V.N. Trishin. 2013 ... Dictionary of synonyms

- thong - earring - [Ya.N.Luginsky, M.S.Fezi Zhilinskaya, Yu.S.Kabirov. English-Russian dictionary of electrical engineering and power engineering, Moscow, 1999] Topics of electrical engineering, basic concepts Synonyms earring EN thimble ... Technical Translator's Guide

- koush - thimble Kausche, Kauscheneinband - part of a hanging structure, the shape of the K. is round, long-lasting and in... Girnichy encyclopedic dictionary

- COUCH - a round or oval steel clip with a groove on the outside, inserted into the cable loop to protect it from abrasion. A bracket with a block for lifting a load, a hook, and another cable (or bolt) for fastening are threaded through the hole in the cable... ... Big Polytechnic Encyclopedia

- Koush - This term has other meanings, see Koush (meanings) ... Wikipedia

- thimble - 3.10 thimble: A metal loop clip at the end of the halyard at the point where it connects to the carabiner. Source: GOST R 12.4.184 95: System of occupational safety standards. Safety belts ... Dictionary-reference book of terms of normative and technical documentation

- A thimble is a rigging device in the form of a steel cage with a groove on the outside. The thimble is inserted into the loop of the cable to protect it from abrasion; a bracket or roller is inserted into the thimble for connection to a block or other cable. Source: Directory... ... Construction Dictionary

- KOUSH is a type of European halberd ... Encyclopedia of weapons

- A thimble is an iron ring that has a groove around the circumference of the rim, corresponding to the thickness of the rope into which the ring is spliced (embedded). K. protects the rope passing through it from friction with the rope into which it is inserted... Encyclopedic Dictionary of F.A. Brockhaus and I.A. Ephron

dic.academic.ru

Where to buy steel thimbles?

Despite the emergence of high-strength polymers, steel remains the main material for making thimbles. The excellent performance characteristics of steel thimbles determine the high demand for slings made of wire ropes. TD "Stropkomplekt" sells a wide range of professional equipment for rigging work in St. Petersburg, Leningrad region, with delivery to any region of Russia at a reasonable, affordable cost. You can find out more details and place an order by calling toll-free 8 (800) 550-93-95 or by mail

The word KOUSH - What is KOUSH?

The word koush in English letters (transliterated) - koush

The word koush consists of 4 letters: k o u sh

Meanings of the word koush. What is a thimble?

Koush

Koush (Dutch kous (eye)) is a drop-shaped, round or triangular frame made of metal with a groove on the outside. The thimble is embedded in a cable loop (ogon) to protect it from abrasion and breakage. The loop is smoother.

en.wikipedia.org

KOUSH (from the Dutch. kous) - a round or oval steel cage with a groove on the outside. The cable is inserted into the loop of the cable to protect it from abrasion; a bracket or roller is inserted into the cable to connect the cable to a block, hook or other cable.

Big Encyclopedic Polytechnic Dictionary

A thimble is a metal ring with a groove along its outer surface. Thimbles: - are embedded in ogons, which serve to connect or fasten the main ends of the cable to the butts and eyes...

glossary.ru

KOUSH, an iron elongated ring, which on ships often ends the rigging gear, braiding the cable around the K.K. is grabbed by other gear using a hook or connects. staples, or sometimes the tackle passes through K’s point.

Military encyclopedia. — 1911—1914

A thimble is an iron ring that has a groove around the circumference of the rim, corresponding to the thickness of the rope into which the ring is spliced (embedded). K. protects the rope passing through it from friction with the rope into which it is inserted.

Encyclopedic Dictionary F.A. Brockhaus and I.A. Efron. — 1890-1907

Russian language

Koush, -ah, TV. -em (tech.).

Orthographic dictionary. — 2004

- cat

- Cooper

- hammer

- thimble

- cofactors

- cofactors

- coffee maker

wordhelp.ru

Types of thimbles

According to their design and scope of application, thimbles are divided into round, cable-stayed, marine, acid-resistant, and wedge sockets. Let's take a closer look at their features.

Round cable holder

Synthetic rope thimble

KOUSH is... What is KOUSH?

polytechnic_dictionary.academic.ru

Thimble - how to choose the right one and seal or braid a cable on it

A cable thimble is currently an integral and irreplaceable part of most lifting, tensioning, holding, towing, fastening and many other similar machines, mechanisms and structures used in a wide variety of areas of production and human activity. It is quite rightly believed that thimbles (kous) were first used to equip ship cables and ropes with them by Dutch sailors, which is confirmed by the translation of this word from the native language of Holland - “stocking”.

Koush is... What is Koush?

dic.academic.ru

Koush and GOST 2224-93 - how to use the salting device? + video

The thimble for steel ropes, which is now regulated by GOST 2224-93, appeared when critical loads were increasingly under threat of breaking a frayed loop of the cable. So how did you solve the problem of metal wear on bends?

1 Where and for what is the thimble used?

Today, thimble is classified as a fastener. Most often, it has the shape of a drop, this allows it to be placed in a loop exactly along the contour, as a result it fits tightly to the rope and protects against abrasive loads, taking them upon itself. The outer part has a groove, so the cable does not slip out even with a slight lateral load. Such protection will only be successful if you choose the right thimble for steel ropes, based on the diameter of the latter. Tables by which this can be done without errors can be found in GOST 2224-93; probably, every fastener store is armed with them.

We recommend that you read

True, this document does not cover thimbles that will protect the cable from damage under prolonged and active loads at nuclear power plants, in aircraft and shipbuilding, rigging in sea and river transport and other critical areas. The scope of this GOST extends to lifting transport mechanisms in various temperature conditions, but humidity or chemical effects of the atmosphere are not taken into account here.

2 Thimble for steel ropes - types and their purpose

In addition to the usual drop-shaped thimble that caught our attention, there are many more types used in various conditions and areas. For example, a locking product has two more screw clamps on either side of the groove into which the rope is pulled. The wedge thong is also reliable for steel ropes; fixation there is carried out using a wedge. Its design is quite simple, and a simple law of physics helps to hold the cable many times stronger. Thus, the wedge mechanism has a concave part opposite the jamming section, at the top of which there is a pressing element.

There are also ship's thimbles, which in terms of load capacity and resistance to atmospheric phenomena correspond to the scope of application. If you need a small loop diameter, then the cable-stayed version of the product is suitable for you. To use such a fuse for a steel cable in acidic environments, you also need to find a special thimble with appropriate protection. If the rope has a very large radius, then it is hardly possible to make a full-fledged loop from it, then the bend is equipped with a half-throat.

And these are not all the varieties that can be found on the shelves of modern stores; each of them has its own standard (GOST or DIN), and therefore summary tables and production requirements. This variety of fasteners also differs in the way they are used. How to properly tighten a rope into a thimble can be learned in the appropriate instructions that are included with purchase, or in the technical process at the place of their use.

Thimble for steel ropes - an argument against breaking + Video

It should be assumed that the first thimble (both the term and the device itself) appeared in maritime affairs, and since the word is from the Dutch language, the Dutch can also be considered the inventors of this product useful for construction. By the way, “kous” is translated as “stocking”!

Throttle for steel ropes and cables - a reliable fire

Externally, a rope thimble is a triangular, teardrop-shaped or round frame, which is made by forging or casting from high-strength carbon steel. The products are inserted inside the loop - the fire, and do not slip out thanks to the groove running along the outside. The dimensions of such a product as a thimble can be impressive - some forged marine examples weigh almost 37 kg on their own and are capable of withstanding enormous loads. Of course, smaller specimens are used in construction and everyday life - it all depends on the diameter of the rope or cable that needs to be secured at the bend of the loop.

So, with a rope diameter within 2.5 mm, you will need a thimble with a diameter of 10 mm and a groove radius of 1.5 mm. The diameter of the thimble in this case refers to the distance between the two outermost points of the circle inside the product. If the thickness of the rope is 10-12 mm, you will already need an option with a diameter of 40 mm and a groove radius of about 7 mm. That is, whatever cable or rope you choose, according to the requirements, the diameter of the inner circle of the thimble must be 4 times larger, and the groove must be of such a size that the product “sinks” almost 2/3 into it. Thanks to this, you will ensure maximum safety during work and extend the life of the cable.

There are marine, round, cable-stayed, steel and acid-resistant thimbles, as well as wedge sockets.

- Marine cable thimbles are usually made by hot forging and have a teardrop shape. There are two types of marine products - type C is used for fastening steel ropes, while type P is intended for plant ropes. Both types can be made from either carbon or low-magnetic steels. The largest representative of type C is designed for a cable with a thickness of 66.5 mm in diameter. The numbers in the marking after the letter indicate what load the fastener can withstand, for example, C400 can withstand a load of 40 tf, and P20 can withstand a load of 2 tf.

- Cable-stayed options also came to us from the marine theme, but now they are more often used in the construction industry in various kinds of braces, supports, telescoping and for connecting parts of mechanisms and metal structures. A distinctive feature of cable-stayed products is their smaller internal diameter.

- Acid-resistant elements are made of corrosion- and acid-resistant steel M1-M12. This provides additional reliability of fastenings in production. Such products are easily recognized by their shiny surface.

- Semi thimbles - used to prevent wear and tear of large diameter ropes at small bending radii, which is typical when lifting or towing loads.

- A round galvanized thimble is a solid round product, thanks to which an even circle is formed inside a loop of a cable or rope.

- Wedge options are clips for securing steel ropes in lifting mechanisms. The device consists of a clip, an insert and a wedge, which jams the rope between the walls of the clip, the insert and the wedge itself.

- The thimble for synthetic rope is characterized by the fact that its groove on the sides is closed, which prevents the soft synthetic material from slipping out.

Weaving a cable onto a thimble - proven methods

By itself, this simple device will not create a strong fire; you also need to skillfully braid the cable. If the expected loads are small, then you can get by with a special clamp clamp or an ordinary flattened tube. The process of creating a loop is as follows: pass a loop into the tube so that the required area for the thimble looks out from one edge, and both ends of the cable come out from the other side. From this edge you should clamp the tube with the cable in a vice, pass a metal strip into the thimble for convenience and tighten the tube. The main thing is not to overdo it, so as not to damage the cable itself.

A reinforced clamping clamp will allow you to fire even faster, but the finished structure does not look the most aesthetically pleasing, and even when working with such a cable you will cling to everything. A cable braided in a special way will look much more aesthetically pleasing and strong. To do this, you need to unravel the cable into two parts by about 30 cm, with the same number of fibers in each part. Don't forget to wear protective gloves, as metal fibers can easily damage your hands. If there is a core not made of metal fibers inside, it can be cut off - we don’t need it.

We try on the resulting halves to the thimble - it is important that they fit tightly to it and that it does not dangle after weaving is completed.

You can secure them with wire or mark the required length so as not to get lost, since rarely does anyone succeed in making a loop correctly in this way, and having achieved the result, you are unlikely to want to redo everything again. We need to knit the two halves by crossing them in such a way that the fibers on the main part intertwine with the loose fibers. Having wrapped the loose part once by hand around the main part, use a screwdriver or a metal rod to pry up the fibers and turn them deeper, mixing them with the fibers of the main part.

It is possible that not all the fibers will “settle down” at once; in this case, turn them again with a screwdriver. Do the same on the other side until you end up with a braided cable. Nothing prevents you from additionally clamping the cable in the tube or putting on a clamp; in extreme cases, simply tie wire around the base of the loop. In a word, it is still necessary to secure the fibers in some way. After which the product with fire will be ready for use! Fire can be done in this way on fairly thick cables, but you may need someone's help.

Not just a thimble - we select the cable for its intended purpose

Along with the thimble, you also need to select a modern cable for its intended purpose. This product in most cases consists of wire wound around a core. The more fibers there are for the same thickness of cable, the more flexibility it will have. Both organic and metal materials can be used as a core. Organic cores are often soaked in a special impregnation, which is gradually released during the operation of the rope and reduces friction between individual strands and fibers in the rope itself, thereby extending its service life.

According to the type of construction, steel ropes have many differences that are not noticeable to the eye. For example, there are only three types of lay: single, double and triple. In the case of a single lay around a central wire or core, the steel wires are twisted in a spiral in several layers, and if the first layer is curled in one direction, then the subsequent layer is curled in the other. When double laying is done, the wires are first twisted into strands, and these strands are curled into a cable; with triple laying, the process is even more complicated. Single fibers have the highest rigidity, but they wear out faster as a result of increased friction between the fibers.

When choosing, it is very important to take into account the maximum breaking force that a particular rope can withstand. For example, galvanized products with a diameter of 2.2 mm have a tensile strength of up to 300 kg, while a three-millimeter rope almost doubles this figure. Products with a diameter of 5 mm can withstand tensile forces of up to 1800 kg!