Today, drywall is very popular. It is used to level walls, create partitions and decorative structures. GKL is mounted on a metal profile lathing, the individual elements of which are fastened with special self-tapping screws. At the same time, their caps sometimes interfere with the tight fit of the plasterboard sheets. To avoid this, a drywall cutter is increasingly being used.

What it is?

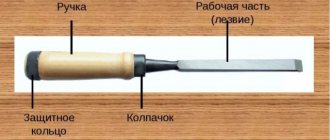

This tool began to be used in construction not so long ago. Most ordinary users and home craftsmen have little idea what a cutter for a drywall profile is, how it works, and on what principle it works.

Externally, the tool resembles pliers: it has 2 handles, one of which has a bracket attached to the end. A cutting element (punch) is installed on the second of them. The principle of operation is also very simple: 2 profiles are combined, the connection point is placed between the bracket and the punch, the handles are pressed, and a hole appears on the metal (it is also called a groove), which holds the profiles in a given position. Some devices on the reverse side press the protruding edges tightly, some do not.

Recommendations from experts

A cutter for connecting profiles is a fairly easy-to-use tool. But there are certain nuances here, knowing which you can not only extend the life of your purchase, but also make it much easier for you to work with it. The list of recommendations given by experts includes the following points:

- immediately buy a set of replacement parts. This will save time on their purchase and subsequent replacement;

- The weak point of the cutter is the rubber covers of the handle. They need to be replaced as they wear out;

- when the springs come out, it is better to contact a specialist to prevent final breakdown;

- do not skimp on your purchase, as repairing the product can cost much more than its original price. A good and expensive tool will last much longer than a cheap analogue;

- It is better to choose models from trusted manufacturers. This way you will definitely buy something worthwhile;

- Take care of the tool, replacing worn parts in a timely manner.

Following these recommendations will help you maintain the functionality of the divider for many years, enjoy your purchase and the results of its work. Knowing what to look for will make it easy to choose a profile cutter. Thanks to him, your repair will be high-quality, convenient and fast.

Types of cutters

There are 3 types of cutters for metal profiles for drywall:

- regular manual;

- reinforced;

- professional.

They are all designed the same, but have some differences. First of all, this is the load for which they are designed and operating conditions.

Manual cutters are small in size. They fit comfortably in one hand. Most often, this type of tool is used by home craftsmen. Their safety margin is quite enough for small repairs in an apartment, and they cost much less than their professional counterparts.

Reinforced cutters are most often purchased by small construction teams. These tools are made from stronger alloys. They also differ slightly in design: they usually have a removable punch, which is easy to change if it gets dull. Thanks to this, the tool will last longer.

USEFUL INFORMATION: Do I need to putty drywall before wallpapering?

Professional tools are usually used for large volumes of work. They are larger and more massive than their analogues, more powerful, and can penetrate thicker profiles. Of course, such a cutter costs much more than its “brothers”. There is no point in purchasing it if you plan to build one partition.

These features must be taken into account when choosing a tool. The most popular at the moment are reinforced cutters.

When choosing a suitable device, you need to pay attention to several more parameters:

- Thickness of the metal being pierced. For example, 0.55 mm is the standard thickness for manual models; a reinforced cutter is capable of making a hole in a profile 1.5 mm thick.

- Hole diameter. Varies from 2 to 5 mm depending on the choice of interchangeable bits that come with the tool.

About plasterboard structures

All plasterboard structures are built from four main types of profiles: rack and guide profiles for plasterboard partitions and guides and ceiling profiles for plasterboard ceilings. In cross-section, the profiles for gypsum craton are shaped like the letter P; accordingly, the profiles have one wall and two shelves. The guide profiles, both for ceilings and partitions, have even shelves. In rack and load-bearing ceiling profiles, the profile flanges have bends to strengthen the structure.

Profiles are connected in two ways:

- Using a special tool called a cutter;

- Using metal-to-metal screws. Self-tapping screws are marked as LN, these are piercing screws and LB drilling screws.

In terms of construction, plasterboard profiles are a technologically advanced material and can be connected in very different ways. Some connection methods can be classified as standard, and they are indicated in the technological maps of profile manufacturers. The second part of the connection methods can be called non-standard.

To purchase pliers for fastening profiles, you need to decide on the types and types offered to us by manufacturers.

- the thickness of the fastened profiles should not exceed one and a half millimeters;

- jerks and impacts during work are unacceptable;

- the center of the punch during installation must be perpendicular to the surface to be fastened;

- moving parts of the tool are regularly lubricated with machine oil;

- It is undesirable to touch the joints of the profile - this will cause nicks to appear on the tool.

Knipex Germany manual models from 6700 rubles;. To purchase pliers for fastening profiles, you need to decide on the types and types offered to us by manufacturers. By design, cutters are as follows: Manual - reliable, ideal for beginners in repair. They look like pliers with a long handle. When the pliers are brought together, a groove is formed - the profiles are fastened together. These pliers are brought together with two hands, less often with one. That is, to work with the tool for a long time, endurance and physical strength are required. Pneumatic are more professional cutters, which are a system of levers that allows you to simultaneously punch several holes. A pneumatic drive is capable of developing quite a large force with little force applied by a person. This type is classified as a desktop cutter (work is performed in a horizontal plane). The main advantage of the models is the availability of a punching kit with diameters from 2 to 10 millimeters (0.1 steps). There are also manual models , more compact and easy to use, for punching one hole in any position (vertical, horizontal). Machine tools – used primarily in industrial production. They are equipped with a pneumatic or electromechanical drive. They can operate in automatic or semi-automatic mode. Also, cutters can be special or universal (punching holes in profiles of different thicknesses).

To purchase pliers for fastening profiles, you need to decide on the types and types offered to us by manufacturers.

Manufacturers and prices of cutters

The following brands of cutters for connecting profiles are very popular among builders:

- Tsentrinstrument (Russia) – manual models from 300 rubles;

- Matrix (China) - average cost 614 rubles (simple manual model);

- Topex (Poland) - the average cost of manual models is from 1100 to 1470 rubles;

- Knipex (Germany) – manual models from 6,700 rubles;

- Stanley (USA) - a reinforced model from the leader in the production of hand tools with the ability to squeeze with one hand costs 7,500 - 9,200 rubles.

Despite the differences in price, the cutters are the same in operation. The choice mainly depends on the preference of the company and financial capabilities. More expensive professional models, of course, are more durable than their cheap counterparts. Buyer advice:

- If you plan to use it regularly, it is better to purchase a professional model.

- For a one-time repair, a cheap model from a lesser-known manufacturer is quite suitable.

The cutter is easy to use—spread the handles apart and sharply close them together. The hole is ready.

Benefits of using a cutter

Installation of profiles using a cutter is noticeably different from the classical method, which involves the use of self-tapping screws. The advantages that this type of fastening has:

- savings on consumables - self-tapping screws;

- no additional tools (drill, screwdriver) are required for installation;

- profiles are not deformed;

- there is no risk that the screw will go too far;

- no need to waste time on marking;

- a hole is punched much faster than a self-tapping screw is screwed in;

- the holes have smooth, neat edges, nothing sticks out of them;

- no dents on the frame;

- does not consume electricity;

- The connection is reliable, but if necessary, it can be quickly and easily disassembled.

Many builders, after working with a cutter, abandon self-tapping screws, since the process of assembling a metal frame is significantly accelerated and simplified.

Advantages and disadvantages

Using a cutter during installation of a metal profile for plasterboard has a number of advantages:

- Speed . If you make holes with a drill or by screwing screws into the profile, it takes quite a lot of time. Using a cutter reduces the time it takes to make one hole to a fraction of a second.

- Accuracy . The tool allows you to make a neat, even hole without deforming the profile. Often this cannot be achieved when using a drill or screw. The hole deviates from the required position and becomes slightly inclined. Metal often wrinkles (especially true for soft aluminum profiles).

- Evenness . The front side of the metal profile frame remains absolutely flat. When connecting with screws or bolts, this cannot be achieved - the head always remains on the surface.

- Economical . Using a drill or screwdriver involves the consumption of electrical energy. The cutter is a completely mechanical tool. This allows you to save on electricity. There is also a saving in the absence of the need to purchase additional fasteners (for example, screws).

- There is no need to hire an assistant . Often, when assembling large structures made of metal profiles, a second person is needed to hold the material while drilling. When using a cutter, the need for it practically disappears - all the necessary actions can be performed alone.

Despite the large number of advantages, the tool has one significant drawback. The connection made using it is not as reliable as installation using screws. The fact is that the thread of the screws better resists the tensile load. An absolutely smooth connection made with a cutter is much less reliable. Due to insufficient fastening reliability, the cutter is used as a temporary solution or in combination with screws. Especially if the drywall will experience significant loads. For example, when covering a wall, it is recommended to fasten the main connections with screws, and use the cutter only on the transverse ones.

In general, installing the frame in this way is quite simple; you practically do not need to use self-tapping screws, since all products are firmly snapped onto the profiles. You can use a screwdriver in cases where you find it expedient to additionally strengthen the assembly using hardware. You need to insert it up to the special stops on the connecting element:

for fixation with crabs and side connectors, the jumpers are shortened by 5 mm. Published on October 31, 2017 in the category Building materials // 1 comment // Author: Admin

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Drywall is a universal material that is actively used to create smooth surfaces, original decorative elements, niches, and shelves. In order for such structures to be durable and last a long time, it is necessary to install a reliable frame. It is this that allows you to fully realize high-quality insulation, sound insulation and disguise various types of communications - pipes, wires. Properly installed sheathing requires the exact size of the profiles and calculation of the installation density of individual elements. This article will describe how to attach drywall profiles to each other.

How to use the tool

Using a cutter for a metal profile for drywall will not require any special skills or special abilities from its owner. The frame elements are connected very simply:

- profiles are aligned relative to each other and fixed in the desired position;

- the handles of the cutter are moved as far as possible in different directions;

- the ear is placed so that the connection point is between the lip and the cutting element;

- the handles are squeezed sharply, as a result the punch makes a hole in the profile;

- the handles are again moved apart and the tool is moved to the side or removed.

USEFUL INFORMATION: How to make plasterboard shelves with your own hands (video)

Thus, the profiles are connected to each other.

Tips for use

A cutter is a very simple and undemanding tool, however, it also requires proper care and compliance with certain rules:

- most cutters are designed for a total profile thickness of no more than 1.5 mm;

- you can’t make breakthrough breakthroughs;

- hitting is also prohibited;

- The cutter must be placed strictly perpendicular to the plane of the profiles being pierced;

- you cannot make a breakdown in the place where the profile is built up or joined;

- The hinges need to be lubricated periodically.

A profile cutter for drywall is a simple and convenient tool. Even a beginner can assemble a frame with its help.