A self-tapping screw with a press washer is a special screw that has a head that looks like a compressed washer. It has become widespread in many construction and industrial fields. Based on the existing advantages of the product, it is almost impossible to find analogues for it.

Acute

The main material from which they are made is very durable carbon steel. Moreover , during the production process, a small layer of zinc is applied to this tool, which protects it from rust and other negative environmental influences. It turns out that this special tool with a press washer is quite durable, strong and resistant in terms of corrosion protection. The head (that is, the hat) of this device has the shape of a sphere, under which there is a welded press washer. In most cases, his Spitz is cross-shaped.

The most important area of its use is the installation of wooden structures and working with different wood materials. Thanks to the presence of a press washer, the device perfectly presses the sheet material to the working surface, thereby creating an excellent and high-quality connection. The result is a dense and strong structure. And in terms of aesthetics, it looks quite beautiful . It is because of this that a sharp self-tapping screw with a press washer is considered a leader among its competitors.

Self-tapping screws for the bugs profile. Option 2 - self-tapping screws with a press washer

Such self-tapping screws for drywall profiles are used in the same way as bugs. But this type of product has a number of differences:

| Illustration | Description |

| They have a wide cap. It is much lower than that of the first type of product and has a larger width - 10 mm or more. Thanks to this, the element is pressed tightly against the surface and creates less interference when installing sheets. | |

| They can have a length from 13 to 80 mm. But if you use them as self-tapping screws for a drywall profile, then there is no point in screwing in long elements; 13-16 mm is quite enough. | |

| They can have either a sharp or a drill tip. As in the first case, I recommend using sharp fasteners as they are more convenient and provide high strength. In addition, products with a drill are more expensive, so you will incur extra costs. | |

| They can have a galvanized or oxidized coating. Most often, shiny elements are found, but if you come across black fasteners, it’s okay, the quality does not deteriorate from this. |

It’s up to you to decide which screws to use to attach the drywall profile. I will only note that products with a press washer are much more expensive than bedbugs, and there is not much difference in connection reliability.

Below is a table of the ratio of weight and quantity; it contains both options for self-tapping screws for the frame. It will help you make accurate calculations, since fasteners can be sold both by weight and by quantity.

With drill

They are most often created from very high quality steel and are also coated with a small layer of zinc. The head of such a device has a hemispherical shape, and the press washer is located on its back side.

- And if the design of this device may have certain similarities with the first one, then with the area of use it is quite the opposite.

- The main feature that distinguishes this self-tapping screw with a press washer from the rest is the ability to work specifically with a metal surface. The tip of the tool, which is similar in shape to a drill, quickly creates a hole in the steel sheet and the threads go deeper into the material.

- It turns out that self-tapping screws for metal not only create an excellent connection, but also reduce the time required to complete all work several times. In this case, it is not at all necessary to use a drill: if the width of the hole being created is less than two millimeters, the self-tapping screw itself can handle this work. Well, if there is already a prepared hole in the metal sheet, the self-tapping screw will cope with the required task without the help of any other devices.

Like all other devices of this type , these devices are purchased, most often, in bulk. The price for approximately one kilogram of such screws varies from 100 to 150 rubles.

What is a self-tapping screw with a press washer?

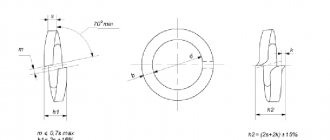

This type of hardware is a self-tapping screw with a diameter of 4.2 mm with a full thread having a large pitch and an enlarged flat head - a press washer.

The difference is that the head has a larger diameter compared to conventional self-tapping screws, to increase the area of the material being pressed. The main purpose is to fasten and press thin sheets of metal, plastic, rubber and plastic parts. The large size of the press washer prevents the self-tapping screw from sinking into the material and provides high clamping capacity.

The tip of the self-tapping screw can be in several designs:

- Sharp

- ideal for use in soft materials: plastic, rubber, wood, sheet metal up to 0.9 mm thick. - With a drill

– has a drill-shaped shape at the end, allowing you to drill holes in metal up to 2 mm thick.

Advantages

A self-tapping screw with a press washer has a serious number of undeniable advantages. The use of these devices helps eliminate the need to first create holes in the surface of the workpiece. This provides huge savings in work time and protects the material from corrosion due to severe exposure. In addition, connections made using such devices are characterized by good reliability and durability. This happens because the self-tapping screw itself is quite resistant to corrosion.

Thanks to the presence of a press washer, it is possible to achieve a tighter fit of the attached materials, and the thread helps to completely eliminate automatic unscrewing of the tool due to any shaking.

A self-tapping screw of this type is a very useful and sometimes irreplaceable device. It is widely used in almost all areas of construction. The reliability of such a product has not surprised anyone for a long time . It is quite convenient to use and is resistant to corrosion that develops under the influence of various precipitation.

In addition, these devices now have no worthy analogues. Thanks to the huge variety of colors, you can very quickly select hardware, the shade of which will match the color scheme of the entire structure. They can be screwed in not only with an electric screwdriver, but also manually using a simple screwdriver.

Therefore, if you have started a home renovation or are planning to start construction, you cannot do without these devices. But remember, when choosing a screw, pay attention to the instructions! Good luck with your work and shop wisely.

What screws are needed for the profile. Self-tapping screws for connecting profiles and hangers

Let's figure out what screws are needed for the profile? Metal screws are divided into 2 types. Each is different in its technical capabilities and is designed to perform specific functions.

Difference in screw usage

It should be noted here that it is possible to use self-tapping screws with or without a drill. The choice will depend on the quality of the profiles. Screws hold better without a drill, but it’s a little hard to screw them through two profiles, but for fastening hangers it’s perfect.

Self-tapping screws for installing drywall

REPAIR AND FINISHING IN ULYANOVSK - https://www.youtube.com/user/themostfamousMASTER A common problem when installing gypsum boards...

Screw with press washer

Among the craftsmen there are such names for screws as “seeds”, “bugs”. They are small in size, used for fixing profiles to each other and are the most popular.

The self-tapping screw for gypsum plasterboard is coated with either galvanized or oxidized coating. Despite the different tips, the functionality of the fasteners is the same. In order to install these self-tapping screws, no preliminary preparation is required. They are easily installed using a screwdriver or drill. The thin tip quickly makes a hole and by applying slight pressure on the screw, it is tightly fixed in the profile.

To save screws and quickly install, use a profile cutter.

With its help, such self-tapping screws are used to firmly fix the profile to the sheathing or fix metal hangers. It is allowed to work with a screw without pre-drilling holes. The thin tip pierces the base of the material, and the caps tightly fix the screwed elements. The most popular self-tapping screw sizes for fixing structures and conventional profiles with a length of 13-16mm.

Regular self-tapping screw with press washer

Self-tapping screw with drill and press washerDimensions, quantity and weight

Phosphated tapered screws

Distinctive features of the head:

- If the tool comes off on the screw head, it is impossible to get hurt - it is rounded;

- It is convenient to press the self-tapping screw during installation with a screwdriver or screwdriver;

- With such cooking, in some cases it is possible to use a washer or gasket;

- The cylindrical shape guarantees reliable fixation.

Self-tapping screws for corrugated sheets - their types and classification

Self-tapping screws for fastening corrugated sheets are divided into several groups depending on their design, purpose and conditions of use. Self-tapping screws for corrugated sheets can be designed for attaching sheets to a frame made of wood or metal.

Self-tapping screws for corrugated metal have a finer thread and a special tip in the form of a drill. They are usually made from high-strength alloy carbon steel grade C1022 with a zinc protective coating. The presence of such a tip allows them to be screwed into a frame made of metal profiles without pre-drilling holes. So, self-tapping screws for corrugated sheets with a diameter of 4.8 mm can drill through metal 2.5 mm thick.

When attaching a profiled sheet to a wooden frame, self-tapping screws for corrugated wood are used. They have a large pitch cut and a sharp tip. In fact, they are distinguished from a regular screw only by a special head of increased diameter. But thanks to the strength of the steel from which they are made, such self-tapping screws can also pierce sheet metal up to 1.2 mm thick without pre-drilling. Usually this is sufficient for attaching corrugated sheets, since cladding and roofing profiled sheets, as a rule, have a thickness of 0.45 to 1.0 mm.

Self-tapping screws are also distinguished by the design of the head. It can be cylindrical, semicircular, spherical or hexagonal. The heads can also have various slots - asterisk, cross-shaped, figured or straight.

Self-tapping screws with hexagonal heads are designed specifically for fastening using a screwdriver or low-speed drill, since it is much easier to screw screws into corrugated sheets using power tools. In addition, the force needed to screw a self-tapping screw with such a head is six times less than for a self-tapping screw with a regular slot, and one and a half times less than for a self-tapping screw with a cross-head slot.

The type of self-tapping screws used to fasten the corrugated sheet also depends on the area of application of the metal profile. If for interior work and facade cladding you can use self-tapping screws with an enlarged head or press washer, then for roofing only self-tapping screws with an EPDM gasket are used. This is the name given to a special seal made of modified artificial rubber that seals the place where the corrugated sheeting is attached to the roof sheathing.

A gasket made of this material is glued to a spring metal washer and self-vulcanizes upon contact with the surface of the metal profile. This guarantees complete tightness of the attachment point and protects against the slightest penetration of moisture into the joint. At the same time, the gasket retains elasticity throughout the entire service life of the roofing and plays the role of a shock absorber, compensating for the expansion of the metal when the temperature of the roofing changes.

In addition to the sealing gasket, the roofing self-tapping screws along the edge of the hexagonal head have a special protrusion that strengthens the head and facilitates maximum pressing of the washer with a protective seal to the surface of the profiled sheet.

In addition to zinc, self-tapping screws for corrugated sheets can also have a colored protective and decorative coating. This allows you to choose which corrugated sheeting screws to use to attach profiles with different colors. Just like the metal profile itself, the screws are painted in the colors of the standard RAL palette, which allows you not to spoil the appearance of the roof, making its fastenings completely invisible.