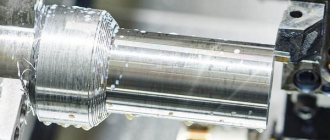

Metal cutting, or turning, is carried out by cutting off a layer of selected thickness from the surface of the workpiece using cutters, drills and other cutting tools. Wrapping the part, in which the metal is cut, is called the main movement. The forward movement of the tool in a straight line, as a result of which turning is performed, is called the feed movement. The selected technological coordination of these two types of movement, as a result of which the process becomes continuous, makes it possible to process cones, cylinders, and form threaded and other surfaces.

Turning is characterized by the use of measuring tools, which are used by turners to measure the parameters of workpieces before and after turning. In small production, micrometers and calipers are used, and in large production, extreme gauges are used.

Types and principle of operation

Using professional equipment you can perform a variety of operations:

- You can make threads of any diameter from the inside of a hollow container or from the outside.

- Turning cylinders to the required size.

- Cutting or grinding ends.

- Drilling holes.

- Formation of grooves on the outer surface.

- Centering.

Also, with any element, you can carry out a procedure to impart the required degree of roughness or, on the contrary, sharpen it to smoothness. In this case, the operating principle is used - due to friction and the action of the cutter, the top layer of metal is removed. You should handle the device carefully, as this is a traumatic operation due to the heating of the chips.

Working on a lathe - what is it, general information

The lathe's equipment is equipped with drills. It has two types of movement:

- the main thing is the rotation of the element;

- Feed – the speed at which the cutter moves.

The specialist must set the correct amplitude, as well as determine in advance the parameters to which the program needs to be adjusted. This set value will be continuously taken from the specified location. The two indicated forces have several actions, so the machine can carry out a wide range of manipulations with cylindrical metal parts, turning them into a cone or thread. At the time of processing, the specialist uses high-precision measuring instruments so as not to remove the excess layer from the surface. These are devices such as micrometers, calipers, bore gauges. The workpiece is secured in advance in a chuck or faceplate. It is important to screw the special die tightly, otherwise it may jump out during rotation. The cutter (drill, reamer or other tool for turning) is also located in a certain socket where it is tightly attached. Metal processing on a lathe is an operation to remove the top layer of a workpiece part in order to obtain a structure of precise dimensions. This procedure is used everywhere both in large factories and in home use, because most materials can be cut well, and also do not break, do not leave scratches, etc. When removing chips, you will notice that they come out different:

- Merged. There can be two subtypes - spiral or tape, depending on the elasticity of the substance. Usually obtained after working with soft alloys and plastics. This is usually an unbroken line.

- Elemental. Accordingly, the residues come out from under the unit in parts, at short intervals. This behavior is typical for hard metals and low rotation speeds.

- With a break when processing a workpiece with low ductility.

- Stepped, that is, monolithic, but with obvious uneven movement.

Before you start the activity, you should choose the right mode. Factors that determine the type of metal turning work:

- Rotational speed. Typically, the harder the surface, the slower it needs to be processed. The most ductile alloys give off the top layer well.

- Type of cutter. It is selected depending on what kind of recess (groove, thread, hole) or cut needs to be made. Also, the density of the scan depends on what material it collides with.

- Feed, that is, how fast the tool will move along the headers. This determines how smooth or rough the outer part will be.

Advantages

Many advantages make this type of turning of parts the most popular at the moment:

- With correct calculations and a good level of skill, it is possible to produce not only classic cylindrical shapes, but also difficult-to-manufacture spheres, balls, and pyramids.

- Even the strongest connections, for example, cast iron or titanium, respond to drills just as well as light and fusible ones - aluminum, bronze.

- The main movement is very fast, so the work is completed in a short time.

- Waste is shavings that can be melted down and reused for workpieces or taken to a scrap metal collection point.

But there are points that, although cannot be called disadvantages, can be called features:

- Operating a machine requires education as a turner or a skill that has been honed over the years, because this is work with increased danger, where it is necessary to accurately monitor the equipment.

- The process is very noisy; in a workshop where there are several installations and workplaces, the use of earplugs or special technological headphones is mandatory.

- The machine is very expensive, as are the consumables for it, so it is rarely purchased for personal use. But for mass production it is indispensable and will last for many years.

WE TRUST

An important advantage of working with us is the wide range of metal processing services provided by our plant. Our company has equipment for cutting, chopping, bending sheet and profile products, welding, turning, milling, painting and other operations. CNC turning may be just one of the technological operations required by the customer. By contacting us, you will receive the required set of operations for the production of final products.

Mechanical offers a full range of services:

Apart from the types of lathes that we described earlier, there are other categories based on suitable materials for the lathe. Different lathes are used for wood, metal and glass because they all require certain qualities as well as cutting speed.

When it comes to the profile of the material, square, round, hexagonal blanks, etc. are welcome. Note that having a profile other than round may come in handy if the final part is not round in all areas.

Suitable turning materials include:

- Metal;

- Tree;

- Glass;

- Plastic;

- Wax et al.

Principles and technologies of metal turning

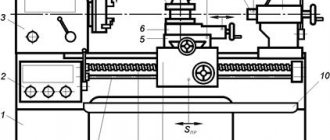

To master the skill of turning, you should familiarize yourself with the structure of the equipment. It consists of:

- The bed is the basis; it is always strong and can withstand heavy loads.

- The headstock and tailstock are clamps that secure the part and are subsequently responsible for its rotation.

- Calipers with a cutter.

These are only the basic elements, but one action of the machine is explained by the coordinated interaction of several nodes at once. The electric motor provides voltage so that all components then move. If the workpiece being processed is small, then it is attached to only one headstock, and if it is large and elongated, then it is clamped on both sides. Fixation occurs using control handles, and the entire structure moves along the lower runners. Also, in addition to the main parts, there are additional devices, they are divided by function:

- cutting tool fastening;

- re-equipment of the device for other technological capabilities for which the equipment was not designed.

The technology for processing workpieces on lathes requires compliance with safety precautions. This is where turner training begins in any educational institution. Otherwise, you can injure your hand, burn your clothes, or get hot shavings in your eyes. TB includes the following rules:

- clothes should be true to size, the shape should fit the body and not bulge;

- the boots have a metal toe cap;

- safety glasses are always put on before manipulation;

- any objects that are not currently related to the work process must be removed from visibility;

- Before each approach, you should make sure that the workpiece and drill are securely fastened;

- You cannot use your bare hands (or gloves) to make movements over the switched-on unit, including removing residues; there is a special brush for this;

- problems may be electrical in nature; it is necessary to check the coolant level and notice in time if the wiring is sparking.

What parts are processed on a lathe?

As a result, the turner can receive:

- nuts;

- shafts;

- bushings;

- pulleys;

- rings;

- couplings;

- gears;

- bearings;

- cylinders, etc.

Everything can also be threaded, grooved or seamed, holes drilled, and an edge can be cut off or the outer surface can be ground with a quick movement of the cutter.

The main stages of manufacturing a part using the turning method

Turning is performed using special cutters: turning chisels. They are equipped with elongated handles, which allows you to hold the tool securely. There are different types of chisels. A semicircular is required for roughing.

- Carrying out the first pass, remove chips to a thickness of 1-2 mm. Use the middle (middle) part of the chisel. All subsequent passes are performed only with side parts.

- Remove chips until 4-5 mm of metal remains for finishing. When moving to it, change the tool to an oblique chisel and place it on the edge.

- By pressing evenly on the tool, finishing is performed. If you need to make an internal hole, use cartridges and face washers.

- Check the accuracy of the work performed using calipers, calipers, micrometers, nutrometers, etc.

Types of tools used

The worker will not be able to perform the intended action if he does not calculate the speed of movement of the drill and the depth of its immersion. Therefore, you should pay attention to the following factors:

- the workpiece must rotate quickly so that there are no delays;

- The fastening of the reamer is checked before starting the activity so that there is no slightest vibration;

- in one pass in one direction you need to remove the maximum possible amount of top metal;

- Every part and component of the machine must be in working readiness, including runners and handles.

The cutters differ depending on the degree of processing - rough or final. The former give a rougher version with roughness and irregularities, the latter - a perfectly smooth surface. The geometry of the tool affects which layer is removed in one pass, and the inclination of the cutting head determines which direction the caliper moves. The blade can be narrower than or equal to the wide fastening part, as well as bent to the side. Another classification affects functionality and purpose:

- scoring - with their help you can process the end part, that is, the one that is located at right angles to the axis of movement;

- walk-through – also designed for the end;

- groove - from the name it is clear that they cut grooves;

- shaped – for the production of profiling pipes;

- boring – for drilling holes, through or small;

- threaded - designed for creating screw axes and nut-type cutting;

- cutting - truncation of one side.

The rule for all turners is that after the end of the shift it is necessary to clean the workplace, check all the tools and distribute them in their places. This will allow you not to lose anything and always have what you need at hand.

Equipment and tools

The technology of turning works involves the use of special equipment - lathes. With their help, parts are produced whose shape is a rolling body. In modern production, seven main types of lathes are used:

- turning-turret – designed for the production of small parts in large quantities; equipped with a turret head, which allows you to quickly change the cutting tool and reconfigure the equipment for another type of work;

- screw-cutting lathes – characterized by the ability to combine high rotation speed of the chuck with longitudinal movement of the tool; used for large-scale and mass production;

- rotary lathe – universal machines with a faceplate and a large frame;

- turning and milling – universal equipment for individual, mass and serial production of parts with complex shapes;

- automatic lathes – machines with a large number of spindles, designed for the manufacture of parts with complex geometry of multi-profile surfaces;

- frontal lathes - specialized equipment for working with frontal surfaces; used for piece production of parts, as well as for small series.

When working on a lathe, they use various tools:

- various types of incisors;

- drill;

- taps;

- countersinks;

- dies;

- sweeps;

- threading heads.

Types of lathes

The most common one is screw-cutting. It attracts both individuals and professionals with its simple design, relative cheapness, but at the same time cutting accuracy and ease of use. When purchasing, you should look at the speed of rotation and feed - these are the indicators that determine its performance. More technologically complex and most comfortable are CNC (computer numerical control) equipment. From the name it is already clear that a turner works not at a machine, but at a personal computer. Their advantages in comparison with the timeless classics:

- vibrations are less likely to unbalance settings and disable components from working readiness;

- so that all components do not heat up and cool down, constantly and quickly alternating temperatures, there is an advance heating function;

- even higher rotation speed;

- the ability to connect computer programs for three-dimensional modeling to the CNC, so even the most difficult parts to manually produce can be manufactured with high precision;

- The coordinates of movement are not only horizontal, but also vertical.

Process Features

A distinctive feature of metal turning is the rotation of the workpiece and the stationary fastening of the cutter. This allows the production of shafts and other parts with a large number of cylindrical and conical surfaces.

Turning is a high-performance mechanical processing that provides high dimensional accuracy and good interaction of mating parts.

Processing modes

The metal processed by turning has various qualities: hardness, toughness, ductility. They all require different cutting angles and cutting speeds. Before issuing drawings for work, technologists make calculations of cutting conditions during turning. Based on them, normalization is made according to the time spent on performing each operation. Cutting modes include:

- spindle rotation speed;

- cutting depth;

- innings.

Quality and processing speed are opposite indicators when turning. They depend on the depth of cut and tool feed. The more chips removed in one pass, the greater the dimensional error and surface roughness.

Initially, rough turning is done - a large layer of metal is removed with a through cutter with an edge forming an acute angle to the axis of rotation of the workpiece. Then a tool with a large contact area is placed on the surface to be processed and finishing is done - a thin layer of metal is removed with the side edge of the cutter and at the same time the ridges are smoothed with an edge located along the axis of the workpiece.

The softer the metal, the smaller the sharpening angle - the sharper the cutter. Cast iron and high alloy steels are processed with square plates. For aluminum and bronze, sharpening is done at 30⁰.