The broaching machine is designed for the cleanest possible processing of both the internal and external surfaces of parts of various configurations.

There are all kinds of metalworking devices that differ from each other in certain technological parameters, the main one of which is the purpose of the equipment.

This paragraph implies:

- machines with internal broaching option;

- machines for external broaching.

One of the most common in this family are broaching machines with an internal broaching system. Among all the variety, the most popular is considered to be a broaching machine with a vertical broaching system, used for processing both the external and internal parts of various parts.

The next sign indicating the difference between metal processing machines is the nature of the working movement and its direction.

According to their characteristics, all machines belong to one of the following types:

- with horizontal pulling system;

- with a vertical pulling system;

- a device with a conveyor movement of a rectilinear type, the basis of which is continuity of action;

- a machine that has the option of circular movement of both broaching and the workpiece;

- a machine that has the ability to use various movements of the workpiece and broaching simultaneously, as well as in various combinations.

Horizontal broach

A horizontal broaching machine is used when there is a need to process the internal or external part of a part, the main movement of which will occur in the linear horizontal direction. Correct movement is achieved through special broaches having different profiles.

The working cycle of such a machine is carried out in a strictly horizontal direction. Removal of chips from the entire area of the workpiece during operation is carried out due to the uniform movement of the teeth over the entire length of the existing broach. To ensure that the entire process is fully automated and safe, it makes sense to use a machine for processing and cutting metal with a CNC installed.

Machines with vertical broaching are designed for precision machining of the surfaces of parts of various shapes, made of both ferrous and non-ferrous metals. A vertical configuration broaching machine is used in various industries - mechanical engineering, for the purpose of mass production of parts of all possible shapes.

Why is stretching necessary?

A technological operation such as broaching is considered one of the most effective methods of metal cutting. To carry it out, you need a broaching machine and a special tool, the use of which gives a surface with a roughness of the order of 0.32 microns and an accuracy of geometric parameters corresponding to grade 6.

The tool used to perform broaching metal cutting consists of many teeth. Each is taller than the other when measured in a plane perpendicular to the direction in which the main cutting motion is carried out. Equipping the broach with many cutting blades and placing them in a certain position allows you to use only one such tool in order to remove the entire required volume of chips both during roughing of the surface and during its calibration.

Most broaching machines are set up for processing similar parts

Using broaching machines, as well as specialized tools, it is possible to process both external and internal surfaces of products of various configurations. When broaching, no feed movement is used: all processing is carried out by the main movement of the broach, which can be rotational or translational. The hole punching tool works on a similar principle. Despite the similarity of these technological operations, the fundamental difference between them is that the broaching tool works in compression, while broaching works in tension.

The video below shows the process of processing the inner surface of a pipe using the pulling method.

Broaching, when compared with other methods of metal cutting, has a whole list of advantages, which include:

- the possibility of reducing the cost of operating the equipment used;

- high wear resistance of the broach;

- high rate of minute feed due to the fact that processing is performed by several cutting teeth at once;

- the ability to work on broaching machines even for specialists with a low level of professional training;

- removal of stock from the surface at a high relative speed (this means high processing productivity);

- the ability to eliminate any types of defects in the treated surface;

- high precision processing of metal products.

Schemes of various types of broaching holes and surfaces

The tools that broaching machines are equipped with are made mainly from high-speed steels with a medium alloy level, which are quite expensive. For this reason, its use is recommended for industries that produce their products in large and mass batches.

Meanwhile, broaching machines and broaching can be used for small-scale and single-piece production of metal products, if their geometric parameters are standardized. One cannot do without such a technological operation even in cases where it is the only possible or most profitable method of processing.

Vertical broach

The operating principle of a vertical broaching machine for internal broaching is based on the fact that the main movement is carried out rectilinearly in the vertical direction by the cutting element of the machine while the workpiece of the future part remains stationary. When using the screw broaching method on such devices, which is one of the types of internal broaching, additional rotation is also imparted to both the workpiece itself and the cutting element.

A vertical internal broaching machine has almost the same operating principle as a horizontal one, but with some advantages:

- during operation, machines of this class are not likely to sag or bend the axis of the broaching element;

- On a machine of this class, it is not difficult to install additional broaches in case of modernization;

- A vertical broaching machine occupies a small working area. This is due to the fact that the entire working cycle occurs strictly in the vertical direction.

- Machines with vertical broaching not only take up less usable space during operation, but are also more convenient than their horizontal “brothers”. These machines are often used in production where mass processing of light and medium-heavy parts is carried out.

Vertical broaching machines come in both external and internal broaching types. All these types differ in the following characteristics:

- traction force, depending on the machine model, ranges from 50 to 200 kN;

- the maximum maximum amount by which the working carriage extends is in the range from 60 to 160 centimeters;

- the broaching speed during the working cycle can vary from 0.5 to 14 meters per minute.

It is worth noting that both horizontal and vertical broaching machines use a semi-automatic operating principle. The only exception is CNC broaching machines, the entire production process of which is simplified as much as possible and has the highest speed.

Another feature that distinguishes metalworking machines from each other is the number of working carriages available, since there are machines not only with one, but also with several.

The next distinguishing feature is position. The simplest is a single-position design, but the most effective are considered to be machines with a multi-position operating principle, since they contain factory-installed tables with a rotary system in their technological equipment.

Optional equipment

The design of the machine may require the use of additional equipment: machine vices, clamping bars. A transverse key is often used with a flat broach lock; a bracket and a wedge are used for a cylindrical lock. Modern broaching machines involve the use of electronic equipment to control the production process, but this equipment is included in the design of the machine.

A used broaching machine can cost from RUB 2,500,000. For more complex designs the price increases. The maximum price of a broaching machine is 10,000,000 rubles.

Overview of the machine model 7B55

The technical characteristics of broaching machines for working on metal include the following important indicators - the working traction force and the maximum amount of broaching movement. Domestic manufacturers produce various models of broaching machines for metalworking that can satisfy all the necessary needs of the customer. One of these machines is model 7B55.

The technical device of this machine has the following description:

- the main part of the technological equipment is a welded, hollow inside frame, in the middle of which a powerful hydraulic drive is located;

- the drive itself consists of a power cylinder and a rod that moves horizontally along special guide slides;

- a cartridge is installed on the rod where the broach is fixed;

- The machine diagram also has a special auxiliary chuck designed for fastening the end of the cutting tool.

During the working process, the auxiliary cartridge moves along a horizontally located slide together with broaching until it stops. At the end point of movement, their connection is broken using a special spring cam. After the cutting machine has completed the entire cutting operation, the broach returns to its original position and is reattached to the auxiliary chuck.

Like most machines of this class, 7B55 only supports semi-automatic part processing. However, the technical characteristics of broaching machines allow for improvement by installing a CNC, which brings the entire working process to full automation.

Grinding head

The grinding head is located on the bed. A grinding wheel is installed on the grinding head, rotating from a special electric drive. The spindle heads on surface grinding machines are installed in holes in the columns. The main task of this unit is to ensure the operation of the spindle with the grinding wheel, taking into account the following characteristics:

- high rotational accuracy - minimal runout at the front end of the spindle in the radial and axial directions;

- rigidity - correct positioning of the spindle under the influence of centripetal force and resistance force;

- vibration resistance - the ability to dampen vibrations during metalworking;

- durability - long-term maintenance of rotation accuracy;

- minimal heating and temperature deformation;

- quick and reliable fixation of the tool.

When increasing the drive power of the grinding wheel, special attention is paid to the rigidity of the spindle assembly and the design of the joints of the frame units. The rotation of grinding wheels on surface grinding machines is carried out from a built-in electric motor

The spindle of KAMIOKA surface grinding machines is equipped with a labyrinth to prevent moisture and grease from entering the spindle. L&W machine spindles are equipped with high-precision P4 angular contact bearings, providing accuracy down to 2 microns. It also uses a cartridge design that is completely sealed and lubricated to ensure high durability and accuracy. The design of the chuck also makes it sealed and permanently lubricated.

Review of the metalworking machine model 7B56

Since 1981, a broaching machine model 7B56 has been produced for the industrial area. They are processed on a broaching machine of this model using the method of correct horizontal broaching through the through holes of the part. The processing itself is rough, and the composition of the processed parts is ferrous and non-ferrous metals, as well as various alloys.

Appearance of the machine 7B56

Broaching machine 7B56

If additional tools were used, it became possible to carry out external processing of parts.

This device had high processing accuracy and sufficiently high productivity to be used on an industrial scale. Below is a description of the design features and characteristics of the broaching horizontal machine 7B56.

Its features include:

- smooth adjustment of the speed of both working and return movement;

- hydraulic drive of the broaching mechanism;

- good quality of the machined surface, associated with increased resistance of the machine to vibrations. This condition was achieved due to an increased level of rigidity and allows for uniform operation over the entire range of traction forces at any speed;

- automatic supply of lubricant to all rubbing surfaces, as well as high-quality filtration of oil in the hydraulic system;

- triggering of the existing alarm when the cutting tool becomes dull;

- the presence of contactless track switches, as well as DC electromagnets, makes it possible to achieve a high degree of reliability and safety of all electrical equipment;

- the possibility of upgrading this machine for subsequent installation on an automatic line;

- the processing accuracy of the horizontal broaching machine 7B56 belongs to the normal class (H);

- the total length of the working stroke of the existing horizontal slides is 160 cm;

- the speed of movement of the broaching mechanism varies in the range of 1.5 – 11.5 meters per minute;

- hydraulic traction force is 200 kN;

- the presence of a powerful 30 kilowatt electric motor that drives the main drive.

Rating of the best edge makers

Having studied the statistics, reviews and technical parameters of the most popular models of edge banding machines, a rating of the best was compiled:

| Manufacturer (model) | Specifications | Description and additions |

| Brandt models Ambition-1200, 1400, 1600 and 1800 | made in Germany, Ambition models - single-sided machines, designed to work with an edge of 0.4-2 mm for gluing it to workpieces of 8-50 mm, operating speed 6m/minute | created for processing (gluing edges) to straight end parts, the adhesive layer is applied evenly with special rollers and pressed tightly using rotating cylinders, the higher the serial model number, the higher the technical parameters of the machines become |

| Company KROM Russian manufacturer offering the best manual edge edging machines | model KROM-750 is a new product in the series of manual machines, ideal for private use and small businesses, works with PVC edges with a thickness of 0.3-3 mm at a working speed of 5 m/minute | The model is distinguished by high build quality and an affordable price, an order of magnitude lower than its foreign analogues, has a built-in reservoir for adhesive mass with a volume of 270 ml, and comes with a repair kit for quickly eliminating minor breakdowns |

| Felder Company The German company presents its customers with edging machines of various levels and classes. | universal (NEW-G320, G460, G330 and ForKa300-s-eco); professional (G500, NEW-G680, NEW-G670 and NEW-G660); Premium (perfect-710x-motion, perfect-608x-motion-plus, perfect-710e-motion, perfect-710x-motion-plus, NEW-perfect812e-motion and NEW-perfect812x-motion-plus); mobile (Felder-ForKa-200) | universal edgers are small in size and work with edges of 0.4-3 mm and workpieces of 10-45 mm; they are used for gluing edges to curved or straight workpieces; professional models are multifunctional edgers designed for rounding corners, jointing, polishing and scraping workpieces at a high level; they work with edge material of 0.4-3 mm and workpieces with a thickness of 8-60 mm; Premium-level machines - devices characterized by high productivity, the most accurate result of work and an almost invisible seam; Mobile edgers are flexible, small-sized, hand-held and very convenient tools, they are designed for additional, auxiliary work for furniture processing |

| Griggio Company Italian manufacturers offering machines of various levels: automatic and manual, designed for gluing straight edges made of laminate and natural wood | small-sized models are designed for facing an edge layer up to 3 mm thick and work with 45 mm workpieces, operating speed 1-4 m/minute | the GB-M model machine, weighing about 8.5 kg, is the smallest and easiest to operate; it has a variable temperature mode and speed adjustment; the rest of the presented models from this manufacturer differ in weight and dimensions, as well as stated power; these are highly professional devices for gluing edges of 0.4-8 mm on furniture pieces measuring 10-60 mm and operating speeds of 1-17 m/minute |

| company CEHISA Spanish manufacturers leading in the wood processing industry | Cehisa edge maker is one of the most popular, it is a one-sided, automatic machine for high-quality gluing of edges made of wood, veneer, laminate and melamine | machines from this manufacturer are in great demand and are actively used in large furniture production, as well as in low-power enterprises |

Brief overview of the 7523 machine

Another fairly common machine is the horizontal broaching machine series 7523. This semi-automatic unit is widely used when working with through holes on parts of various sizes and shapes. This modification appeared in 1987, replacing the horizontal broaching semi-automatic model 7B57.

The purpose of this semi-automatic horizontal broaching machine is to process round and slotted holes, as well as keyways.

When processing metal, the cutting machine 7523 has the following parameters:

- normal accuracy class (H);

- the length of the working stroke of the slide located in the horizontal direction is 125 cm;

- the machine has an electric drive with a power of 11 kW;

- the nominal weight of the machine is about 4100 kg;

- The horizontal thrust force is 100 kN.

Types of broaches [edit]

Depending on the type of broaching - external or internal - a distinction is made between external and internal broaches, respectively.

Broaches allow you to process shaped surfaces. The shape of surfaces, which in practice are drawn more often than others, is one of the criteria for classifying broaches, that is, it is customary to divide broaches into keyed, round, splined, square, etc. If a number of typical surfaces are pulled in one working stroke, then the broaching involved is combined.

In accordance with the cutting patterns when broaching, broaches are distinguished by profile (regular), generator (stepped) and group (progressive) cutting patterns.

A type of broaching tool is firmware

, used for processing holes, grooves and other surfaces. Unlike broaching, which works in tension, broaching works in compression and longitudinal bending. Mechanical and hydraulic presses are used to make holes.

There are other types of broaches. Thus, due to the fact that a broach is a cutting tool, some classification characteristics of a cutting tool in general can be used as a basis for the classification of broaches. For example, like many types of cutting tools, broaches are either solid or prefabricated.

Description of the semi-automatic machine model 7534

Another striking representative of its class is the semi-automatic model 7534 horizontal broaching machine.

This metal cutting machine, like the previous model, is used for processing not only round and slotted holes, but keyways of various shapes using the horizontal broaching method.

A special feature of this cutting machine is the ability to install additional equipment, which can be used to process the internal and external surfaces of parts of various sizes and configurations. The broaching machine 7534 can also be equipped with a fully automated system for unloading and loading, which, together with the CNC, allows the work process to be fully automated.

The horizontal broaching machine has the following features:

- an automated lubrication system, the supply of which to the rubbing parts is carried out in doses;

- built-in alarm system that is triggered when the supply of lubricant is disrupted or completely stopped;

- axial - piston pump, which ensures the operation of the hydraulic drive during the working cycle;

- an electrical control system for the degree of purification of the working fluid, which consists of a double degree of filtration using a fine filter;

- an air cooling system for oil located in the hydraulics of a metalworking machine.

The semi-automatic machine series 7534 has the following technical parameters:

- the working stroke of the horizontal guide slides is 160 cm;

- the power of the available traction force is 250 kN;

- the speed of movement of the part during the production cycle reaches 13 meters per minute;

- the maximum external size of the part to be processed is 60 cm;

- nominal weight of the machine is 6250 kg.

Types and design of broaches

Broaches are classified according to a number of parameters. The following types of broaches are distinguished:

- with a cutting part made of high-speed, tool steel or hard alloy;

- solid or prefabricated - depending on the design;

- single- or multi-pass - depending on how many broaches are contained in one working set;

- working using a stepwise, profile or progressive method - depending on how the allowance is removed from the surface of the part;

- with straight and inclined or helical and ring arrangement of cutting blades on the working part.

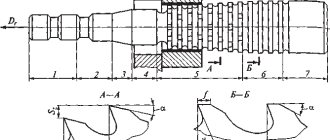

Significant elements of a round broach

Various types of broaches are also distinguished according to their main purpose, and this classification can be called one of the most important. So, depending on this parameter, broaches for external and internal surfaces are distinguished. Using a tool designed for external work, it is possible to process surfaces of various configurations (gears, herringbone profiles, grooves, including T-type, cylindrical shafts, grooves of various shapes, including dovetail, splined shafts, etc.).

Broaching can process surfaces of various profiles

Hole broaching is a more common process operation than external surface broaching. Using a broaching machine and a broach, the following types of internal surfaces can be machined:

- keyways;

- screw type grooves;

- round holes (broaches for round holes);

- holes with different numbers of edges (faceted broaches);

- holes with slots (slotted broaches).

Slotted broach for machining holes

Front This is the guide element. Before processing, the part is fixed precisely on the front part of the tool, which then smoothly transfers the processed surface to the cutting edges of the broach. The nominal cross-section of the front part of the tool and the size of the hole being machined must match, and the choice of the degree of fit is carried out taking into account the required gap between the broach and the walls of the hole.

Shank

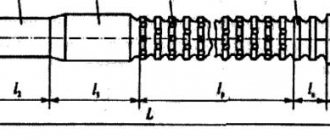

Using this element, the broach is fixed in the chuck of the equipment used. For broaches of both round and flat types, the dimensions of the shanks are strictly specified by the provisions of the relevant regulatory documents (GOSTs 4043-70 and 4044-70).

Standard shank of a splined broach Cutting part This broach element consists of many teeth and is responsible for removing the required allowance from the machined surface. The geometric parameters of the cutting teeth of the broach, starting from its front part and ending with the rear, gradually change. Thus, the front tooth has the shape and dimensions of the hole that is to be processed, and the rear cutting element has geometric parameters corresponding to the characteristics of the finished hole. Due to the fact that the height of the broach teeth gradually increases towards its rear, there is no feed movement during processing, and the allowance is effectively removed from the surface being processed.

Main elements of the cutting part of a keyed broach Support pin This element is equipped with long and heavy broaches in order to ensure their support with the help of a steady rest.

Rear guide part

This part of the broach is necessary so that the workpiece does not become warped when the last cutting tooth leaves its hole.

Calibration part

This element is characterized by fewer teeth than the cutting part of the broach. The shape and dimensions of the teeth located on the calibrating part are completely identical to those of the finished hole.

In order to identify errors, the parameters of the broaches are periodically monitored. The photo shows checking the front and rear angles of the keyway broach

Part processing technology

The description of the processing process on broaching machines is as follows: the part to be processed is fixed to a standard work table faceplate in compliance with all safety measures. A broaching device is passed through the hole of this part, which is fixed directly in the traction chuck. After turning on the start button, oil is supplied into the inside of the cylinder, pressing on the rod, forcing the broaching element to move.

When the moving carriage with its stop element hits a special stop for rearrangement, the limit switch will be activated, resulting in the stop of the working stroke of the carriage. At the next stage of operation, its movement in the opposite direction will occur.

At the final stage, the operator activates the feed idle button, after which it will return to its original position and this will end the working cycle of the device.

The options for fixing the broaching element in the chuck also depend directly on the model of the broaching machine, which can be not only conventional and quick-release, but also fully automatic.

Due to the fact that there is a special thread on the shank of the machine body, the chuck is connected to the working carriage.

General classification

The classification of metal-cutting machines is carried out according to various factors. These are divisions by weight, dimensions, type, accuracy class, degree of automation, and versatility. We need to talk about each of their groups in more detail.

Classification by type

There are 9 types of installations based on the type of equipment:

- Lathes. They occupy approximately 30% of the total mass of metal-cutting devices. The workpiece is clamped in a special clamp. The cutting process begins after installing the cutters, which remove a layer of metal under the influence of rotation.

- Boring, drilling units. They occupy 20% of the total mass of machines. The parts are fixed on the work table. Cutting occurs due to the rotation of the spindle with a drill clamped in the chuck.

- Grinding, grinding, polishing machines. They occupy 20% of the total mass of metal cutting installations. Metal cutting occurs due to the rotation of the abrasive material, which comes into contact with the working surface. The processing speed depends on the size of the abrasive.

- Devices for physical and chemical cutting of workpieces. Least common equipment.

- Devices for processing threads and teeth. Occupies 6% of the mass. Used for threading, manufacturing, and sharpening gears.

- Slotting, broaching, planing machines. They occupy 4% of the mass of metal-cutting equipment.

- Milling machines. They occupy 15% of the total mass. Processing of metal workpieces occurs due to the rotation of cutters of different shapes.

- Split installations. Used to separate reinforcement, profiles, corners.

- Machines for performing various operations related to cutting.

Classification by versatility

A separate division of metal-cutting machines is based on their versatility. There are two groups:

- Narrow profile installations. Used to perform one specific technological operation.

- Universal units. They are large-sized structures that are designed to perform various technological operations.

Classification by degree of accuracy

In terms of accuracy, metal-cutting machines come in several types, each of which has its own marking:

- Increased - denoted by the letter P.

- Normal - designation N.

- High - indicated by the letter B.

- Particularly high - designation A.

- The highest accuracy is indicated by the letter C.

To use units marked B, A, C, you need to prepare the room in advance. It must maintain a constant temperature and humidity level.

Classification by degree of automation

Based on the degree of automation, the following types of metal-cutting machines are distinguished:

- Manual models. The worker needs to clean, prepare workpieces, set up all moving elements independently, and coordinate the work process.

- Semi-automatic machines. The worker needs to change parts independently, turn on and off moving mechanisms.

- Automatic machines are units that process workpieces independently. Used in mass production.

- CNC equipment. The operator sets the required algorithm through the program. The moving mechanisms work independently, select optimal modes, load and unload parts.

CNC machines are gradually replacing other machines due to high processing accuracy and increased productivity.

Metal cutting automatic machine

Classification by weight

Industrial metal-cutting machines are divided by weight. Highlight:

- Lightweight - structures weigh up to 1000 kg.

- Medium - weight starts from 1 ton and ends at 10 tons.

- Large - weight from 16 to 30 tons.

- Heavy - weight from 30 to 100 tons.

- Super heavy - structures weigh more than 100 tons.

Designations are indicated in the technical data sheet.

Safety requirements

When working on broaching machines, it is necessary to strictly observe personal safety measures, which have general principles for all metalworking equipment.

There is a specialized document containing a set of conditions and requirements for broaching machines installed in production. So, for example, safety when cutting on metalworking machines with vertical broaching is ensured by installing a special protective element that protects the operator from injury when the heavy broaching mechanism falls out of the chuck.

During the period of work on horizontal broaching machines, it is mandatory to install a protective folding screen with glass to monitor the process throughout the entire exit area of the broaching element.

It is worth noting that for safety reasons, it is strictly forbidden to install or remove the broach while the metalworking machine is operating.

In the case of using a broach whose weight is more than eight kilograms, the use of a special lift is a mandatory requirement.

Features of operation

Operating personnel are required to place the workpiece in the working niche of the equipment. Next, after launch, the actual processing process begins. A key feature of the functioning of such machines is the fact that the working elements in the form of broaches do not remove chips immediately after cutting, but push them out only after the final exit from the body of the workpiece. Therefore, the range of operator tasks is also expanded due to the need to monitor how correctly machining is performed. On vertical-type broaching machines, the risks of deviations and incorrect cut lines are not so high, since bending of a long workpiece due to its own weight is eliminated.

Specifications

One of the disadvantages of such machines is the dimensions. As a rule, this is an elongated platform in which the workpiece is placed. Dimensional characteristics on average are about 2 m in length, 0.5 m in width and 1.5 m in height. However, the configurations can be different - accordingly, the sizes also differ. The weight is about 500 kg, so before installation it would be a good idea to provide a reliable foundation. From a productivity point of view, the speed of drawing, that is, processing, is also important. For example, a broaching machine from the Flexible Connections enterprise in modification SGP.12.35 provides a working speed of 220 mm/min. In other words, in one minute the equipment can make a cut on an internal surface more than 20 cm long. Here it is also worth considering the maximum processing area, since in most cases, performing the same cutting lines in two approaches is technologically unacceptable. The average length of a single service varies from 4 to 5 m.