Welded connection of wires is preferable to other methods, because the result of this process is reliable, high-quality contact, ensuring trouble-free operation of electrical wiring for a long time. Welding copper wires is most common, since household wiring involves the use of electrical wires made of copper. Welding of copper wiring is carried out using alternating or direct current (voltage 13-36 V); it is possible to adjust the current with the welding machine.

Inverter welding machine

The inverter device has clear advantages over other devices:

- Small-sized parameters;

- Light weight;

- Adjustment of current parameters;

- The presence of a portable belt (it is convenient to carry out work on a stepladder, in a junction box);

- A stable arc that ignites at low currents;

- Quality of welded joints;

- Less energy consumption without changing the voltage of the household electrical network.

In addition, welding is carried out using transformer devices, devices, stations, devices made independently (if you have certain skills).

The ease of operation of the do-it-yourself electric arc spot welding machine has made it the most widespread. Main parameters of this equipment:

- Electric arc current;

- The mains voltage that forms an arc;

- Type of electric current (alternating, direct).

How to use

Before welding begins, the free crocodile from the negative terminal of the battery is clamped onto one of the workpieces. It will perform the function of mass. The rod will act as an electrode. Its end is briefly touched to the suture site. The electrode gets hot, so it is better to hold it with pliers. The graphite becomes hot and begins to melt the thin metal. To avoid burning the part, the electrode should be moved slowly along the joint line of the workpieces, sometimes interrupting. In the first seconds, the graphite smokes heavily until the remaining electrolyte from the battery burns out.

You can weld with a seam or do spot welding. In the latter case, it is worth pre-drilling holes in the upper part to be connected. This device is also suitable for soldering. It can be used to heat a part and then apply solder to it.

Welding with a battery wears out the battery, so you should not get carried away with this method. It is important to keep the electrode closed for no more than a few seconds at a time. Under the stress of welding, the battery becomes hot and may rupture. The signal for this will be the noise of electrolyte boiling emanating from it. The larger the battery, the larger and thicker the workpieces can be welded. Typically the battery charge is sufficient to operate for several minutes.

Welding technology

Welding work must be carried out using a protective mask, glasses, gloves, and special clothing. There is a possibility of getting burned by hot metal and “catching bunnies.”

Welding of copper wires at home with an inverter is carried out using graphite and carbon electrodes. You can replace the electrodes with the carbon rod of a used battery.

Approximate welding current range:

- 2 cores, cross section of each 1.5 mm² - 70 A;

- 3 cores, cross section of each 1.5 mm² – 80-90 A;

- 2-3 cores, cross-section 2.5 mm² – 80-100 A;

- 3-4 cores, cross-section 2.5 mm² – 100-120 A.

The copper used in the manufacture of electrical wires is of different composition and quality, which determines the welding mode used. Indicators of the optimally selected mode: the electrode does not stick to the welded area, the arc is stable. This combination can be maintained if you have experience in welding.

Welding process:

- The insulating sheath of the copper cable is removed (7-10 cm);

- Stranded wires are twisted;

- The twisted copper wires are trimmed to form an even cut. The remaining twist length is 5 cm;

- A copper clamping mechanism for removing excess heat is placed on the twist, and grounding (“ground”) is connected;

- The twist section is brought to the electrode;

- Welding work is carried out until a molten copper ball appears at the end of the wires, 1-2 seconds is enough;

- After welding of the copper strands stops so that the insulating material remains intact;

- The cooled ends of the wiring must be insulated (insulating tape, heat-shrink tubing).

In addition, it is necessary to promptly change the copper welding tip, which holds the electrode during welding. The main function is to supply electric current to the electrode rod. Its condition determines the quality of the weld: the hole inside the tip should tightly hold the rod, but it quickly loses its properties during the welding process. The copper welding tip wears out and most often requires replacement.

Safety requirements for graphite welding

A graphite electrode allows you to create reliable connections between parts of various types of metal structures, but welding is extremely important to carry out taking into account safety standards.

Copper welding diagram using a graphite electrode.

Let's describe them in detail:

- the current supplied to the welding cables must be turned off before starting work in order to protect yourself from electric shock;

- operations using a welding machine should be performed only in special clothing, shoes and using personal protective equipment that will help protect the eyes, hands and skin of the body from burns;

- the work site is cleared of flammable items, which will avoid the risk of fire;

- after welding one twist, it is important to wait until it cools down, and only then proceed to work with the next one;

- excessive haste and unwillingness to wait until the first twist cools down can lead to a burn on the welder’s body;

- the twists are insulated after welding using heat-shrinkable tubing and electrical tape.

If you do not adhere to the safety requirements described above when performing welding work with graphite rods, you can get a burn to the skin, retina, etc.

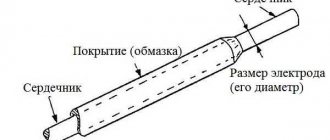

Electrodes for welding wires

The choice of the appropriate type of electrode determines the quality of the work done. It is necessary to select welding tools that optimally meet the parameters of the upcoming process. The general classification of these tools used in the welding process includes electrodes for:

- Alloy steel;

- High-alloy steel with non-standard parameters;

- Metal surfacing (applying a metal alloy or metal to the surface of an object by fusion welding);

- Non-ferrous metals;

- Structural steel;

- Cast iron.

The electrode coating defines the following typology:

- A – acid coating (oxide of iron, silicon, manganese);

- B – basic coating that allows welding with direct current of alternating polarity. Contains calcium carbonate, calcium fluoride;

- C – cellulose spraying creates gas protection during welding (flour, compounds of organic origin);

- R – rutile (rutile, organic, mineral components) provides a low percentage of metal splashing and gas protection.

Electrodes for welding wires:

- Coal – electrical coal;

- Graphite – crystalline carbon.

Process Features

Electrodes made from coal differ from metal ones in that they are infusible. This means that during welding they act as a conductor of electricity, but do not become part of the weld pool.

During operation, the carbon rods heat up to very high temperatures. And if you continue heating, then almost immediately they will go from a molten state to a boiling state (by the way, coal boils at a temperature of 4200 ° C).

Due to the characteristics of the material, only direct electric current of straight polarity can be used in the welding process. Accordingly, the minus (cathode) here should be on the electrode, and the plus (anode) on the metal surface of the product.

When working with carbon electrodes, the welder usually requires filler elements. In this case, welding can be done in two ways:

- from left to right (in this case, the additive is behind the electrode);

- from right to left (there is an additive in front).

Interestingly, when welding from left to right, thermal energy is used more efficiently, and this allows you to increase the speed of work. However, in practice you can often find the “right to left” technology - it is more familiar.

In some situations, you can do without an additive, for example, when flanging thin metal products or when welding corner joints . Moreover, if you use a carbon electrode without additives to join metal sheets with a thickness of up to 3 mm, then the productivity will be an order of magnitude greater than when welding with other electrical conductors.

Graphite electrodes for welding

Composition – graphite, a carbon substance of dark gray color with a metallic sheen. The soft material makes it easy to cut elements. Graphite electrodes for welding show better results compared to carbon electrodes.

Peculiarities:

- The graphite electrode remains intact during the welding process;

- The cost is lower than coal;

- Suitable for inverter welding machines equipped with current regulation;

- The connection of wires by welding a graphite rod is durable and reliable;

- Welding with a graphite electrode ensures the metal's resistance to oxidation.

- Low consumption during welding due to the high melting point (four times higher than copper);

- When welding wires with a graphite electrode, it is possible to replace it with improvised graphite products (graphite rod, brushes of commutator motors, battery rods);

- The absence of copper plating of graphite substitutes is solved by using an alligator clip for the electrode instead of standard holders, and an alligator clip is also used to connect the mass.

- Do-it-yourself welding of wires in a junction box with these clamps is more convenient due to their smaller dimensions.

Using an inverter

Copper wires, most common in residential buildings, are connected in several ways, but welding is considered the most reliable. As a result of this connection, a homogeneous conductor is obtained, which ensures complete fire safety.

Welding is carried out with direct or alternating current voltage from 12 to 36 V, and the welding current must be adjusted. Most welding inverters meet these requirements.

They produce a special apparatus for welding copper wires, which is used by electricians. It has a power range of 1-1.5 kW and welding current adjustment in the range from 30 to 120 A.

Unlike conventional inverters, the equipment has less weight and dimensions; in addition, the ends of the welding cables are equipped with a special holder for carbon electrodes and a clamp with a large clamping surface for the conductors.

If the farm already has an inverter welding machine, then you don’t need to buy a special device for welding copper wire.

For convenience, pliers and an electrode holder are welded to the welding cables or attached through a bolted connection. Any powerful clamp can play the role of a carbon electrode holder. Its handles must first be insulated.

The pliers are attached to the ground wire. They will hold onto the twist of the copper conductors being welded, while they will perform the important function of heat removal. This is necessary to protect the insulation from exposure to high temperatures.

Autonomous welding from batteries with your own hands!

The welding machine uses a fairly low (tens of volts) voltage and high current to create an arc, which actually melts the metal. What if you use for this purpose not mains voltage with a bulky transformer, but... batteries? Unexpected, right? But nothing is impossible here. Conventional batteries provide almost the same voltage that is needed for welding, only lower - 12 Volts.

Theoretically, you can get an arc from one 12-volt battery, but it will be so short that cooking with it is a real hassle. For reliable and convenient operation, you will need three 12 Volt lead batteries, which in total will give 36 Volts. It is best to take car ones - their current is enough even for thick electrodes (4 mm), but you can also use batteries from uninterruptible power supplies or motorcycle ones. In this case, you will have to limit yourself to thin electrodes (no thicker than 2 mm), and the welding itself will take more time.

Scheme

Three 12-volt batteries are connected in series to obtain a voltage of 36 volts sufficient for welding.

The circuit is simple, but pay attention to the following subtleties:

- all connections must be very good, since at low voltage heating and losses increase greatly due to poor contact (it is best to use conductive paste);

- The cross-section of the wires between the batteries and from the batteries to the terminals should not be less than 16 square meters. mm (better - 25 square), of course, only copper will do;

- it is not the minus that is connected to the part (that is, the ground clamp), but the plus - accordingly, the minus is connected to the electrode, and welding must be done with “blue” electrodes (for example, MP-3S);

- if the electrode is stuck, try to tear it off, since long-term operation in short circuit mode is harmful to batteries - they do not have built-in protection (see also below);

- to protect the batteries from overheating in the event of a strong “sticking”, connect a short piece of wire of 2.5 squares between the batteries, preferably on a screw terminal so that it can be easily changed: if there is a strong overload, it will burn out and prevent the batteries from overheating.

Varieties and their properties

A carbon electrode is a consumable material made from hard coal. It contains additives that determine the characteristics of the welding rod. To ensure that the composition holds its shape and can be used in work, resin is added to the mixture.

Carbon electrodes are suitable for working with all metals, from refractory to materials with a low specific gravity and a large number of pores. The diameter of the rods varies over a wide range of values - from 1.5 to 25 mm. They are also very different in length. The shortest electrode is only 25 mm in length, and the longest is 300 mm. Consumables of such long length are in demand for welding seams in hard-to-reach places. The electrodes also differ in shape. They are round, rectangular, hollow or semicircular.

For work, specialists most often use round and semicircular ones, which are the optimal choice for forming a welded joint of a standard configuration. Rectangular ones are an ideal option when you need to eliminate flaws on a metal surface. Using hollow electrodes, you can create a U-shaped groove at the junction.

In addition to the usual ones, welders also have copper-plated carbon electrodes in their arsenal. They are used to impart strength to the welded joint and create a copper coating on the joint surface in the form of sputtering. The remaining performance indicators of these consumables are no different from the usual ones.