Owners of housing not connected to a natural gas pipeline often use gas tanks or propane-butane cylinders as a fuel source. The leveling of performance indicators is carried out using special fittings - gas propane reducers, which, if necessary, reduce the pressure in the cylinder and maintain it at a given level.

To ensure that the equipment is in good working order, you should know the rules for calibrating gas cylinder reducers, as well as comply with the requirements for the installation and operation of the devices. Let's consider issues related to the use of propane devices, as well as control over them.

The principle of operation of the gas water heater reducer

By opening the water tap, water enters the reducer, resting against the constricted Venturi nozzle, creating pressure that puts pressure on the membrane.

Water passes at the bottom of the membrane, the pressure is less at the top. The pressure difference bends the membrane upward, which acts on the plate, the plate presses on the rod. The steel rod sends a signal to supply gas and lights the burner. Shutting off the water, the membrane bends down, the rod lowers, the water pressure in the reducer is equalized, and the burner turns off.

The retarder ball is responsible for the gas supply rate. The pressure created by the membrane pushes the ball to the side. Moving along the channel, the ball creates a smooth activation of the burner. When turning off the water, the ball moves to the side without interfering with the passage of water. The rapid outflow of water quickly turns off the gas.

The smoothness of gas activation is additionally regulated by a screw installed inside the plug. By rotating the adjusting screw you can adjust the speed of turning on the gas. Removing the retarder or incorrect manual adjustment will result in the gas suddenly turning on with a pop.

Choosing a boiler for balloon heating

Heating boilers using liquefied gas

Currently, manufacturers do not produce narrow-profile heating boilers using bottled (liquefied) gas. However, equipment designed for natural gas cannot be used without prior modification.

Before purchasing a boiler, you must make sure that the package includes a kit for adapting equipment for propane. The set includes nozzles with a wider nozzle and a kit for attaching them to the burner. The reinstallation procedure can be performed independently only if this is provided for by the design.

There are several types of gas heating boilers using bottled gas, which differ in operational and technical characteristics:

- Burner type - open or closed. It is best to purchase heating boilers using bottled gas with a closed burner. For their operation, air is taken from the street using a coaxial pipe;

- Installation – wall or floor. Most models with power up to 24 kW are wall mounted;

- Number of circuits. To supply heat to your dacha with gas cylinders, you can purchase an inexpensive single-circuit boiler. If you plan to live in the house permanently, it is recommended to buy a double-circuit model with hot water supply.

You can preliminarily calculate the flow rate for heat supply with gas cylinders by reading the technical data sheet of the equipment. However, manufacturers often provide maximum flow rate at maximum equipment power. The lower the burner operating intensity, the less fuel will be consumed.

Gas heating boilers using bottled (liquefied) gas with a cast iron heat exchanger have the best performance indicators. It will last much longer than steel.

Gas reducers for gas cylinder, price and types

Let's try to choose a reducer for gas cylinders, from those popular types that are in greatest demand among consumers. Let’s take a look at the gas appliance market and find out what the price for a gas reducer for a cylinder was at the end of 2017.

Household gas reducer RDSG for propane stabilization

The leading position in the market, and among consumers in the country, is occupied by the RDSG-1-1.2 “Frog” device with a threaded fastening. The RDSG-2 Baltika gearbox equipped with a threadless connection is not inferior in popularity. Both leaders represent the simplest design. As a result, they can offer the lowest possible cost. Specifications: — inlet pressure from 0.7 to 15.7 Bar; — the output pressure lies in the adjustment range from 30 to 32 mBar; — device weight 310 g; — permissible operation in the range from -30 to +45 ±3 °C; — gas throughput characteristic — 1.2 m3/hour. You can buy a gearbox RDSG 2-1.2 Baltika or RDSG 1-1.2 Frog for up to 350 rubles.

How to choose a reducer for a propane cylinder used in everyday life?

The reducer for a propane cylinder is designed for use in temperate climates, therefore its use is permissible at temperatures from -15 to 45 degrees Celsius.

To accurately select a gearbox for a household gas boiler, convector or water heater, you should take into account the technical characteristics of the gearbox:

- Gas consumption.

- Operating pressure.

- Connection method.

The maximum permissible gas pressure at the inlet to the reducer is 25 kgf/cm2, and the maximum operating pressure is 3 kgf/cm2.

For stable operation, the gas consumption of the equipment should not exceed the performance of the gearbox. If the output pressure in the gas reducer is greater than the operating pressure of the gas convector or water heater, the gas burner may go out or the device’s automation may fail.

You can connect the gas consuming device to the cylinder using a regular gas hose. In this case, a gas reducer with a herringbone-type outlet fitting is used. If there are several devices, then you can lay out the gas main using a corrugated pipe. Then you will need a gearbox with a threaded outlet.

Malfunctions. Repair.

If you decide to carry out repairs or adjustments yourself, make sure you have the necessary qualifications. Poor repair of gas equipment can cause a fire, explosion or poisoning. After completing the work and assembly, make sure that the device is tight and operates correctly. The tightness is checked by applying a soap solution to all joints. No bubbling indicates there is no leak. But you shouldn’t delude yourself. The tightness will need to be checked several more times (after a day, three days, a week of operation), and then checked regularly, since a leak may occur some time after the start of operation.

Main malfunctions: the gas pressure at the outlet does not correspond to the nominal value (reason: the spring is broken or deformed), gas leakage (reasons: the membrane is damaged, the tightness of the connection between the membrane and the housing is broken, the float valve is leaking)

Here is a selection of materials:

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, wood, electricity). Do-it-yourself ovens. Coolant, radiators, pipes, heated floors, circulation pumps. Chimney cleaning. Conditioning

If the float bypass valve leaks, then the leak may not occur in the reducer itself, but somewhere further, for example, in a gas stove, since in this case, in zero consumption mode (when the stove or some other consumer is turned off), at the outlet reducer and gas pipes, the pressure can reach the inlet pressure. Gas gradually leaks through the valve, and there is nowhere for it to go. If there is a gas cylinder at the inlet, the pressure can reach 15 bar, which is 500 times higher than the nominal one. Such pressure will definitely lead to leakage. At the same time, it is difficult to detect this malfunction, since when the stove is turned on, the pressure normalizes. There is no sign of overpressure (flame blowout). The fault can only be identified by measuring the outlet pressure in zero consumption mode. It can be no more than 20% more than nominal.

To repair, the gearbox must be disassembled. Only a dismountable gearbox with a spring can be repaired. Sealed gearboxes are not suitable for repair.

In the picture, the membrane is with the bottom side up.

An inspection will show if there are defects in the membrane or a broken spring. A torn membrane can be replaced. But it’s not worth it, it’s better to buy a new gearbox, since it’s quite difficult to hermetically connect the new membrane with the washers. A broken spring can be replaced. Most often, the spring does not break, but simply compresses a little over time. As a result, the outlet pressure becomes lower than nominal. This malfunction can be easily corrected by placing a gasket between the housing and the spring. Read about this below in the section on transferring to another pressure.

Membrane - top view.

If you have diagnosed problems with the bypass valve, then you need to inspect it. It is a tube with a thin hole. A piece of hard rubber mounted on a rocker arm is pressed against the end of the tube. The valve may not close for the following reasons: Firstly, the mobility of the rocker arm is impaired. Move it with your hands, make sure it moves freely. If there are problems, grind or replace the hinges. Secondly, a piece of rubber was worn out and torn. It can be removed with a sharp knife and replaced by gluing another one of the appropriate size in its place. Thirdly, the end of the inlet tube may not be smooth, with damage and roughness. This prevents a tight seal. The end can be sanded with fine sandpaper.

Very often, a leak occurs due to a leak in the seal between the membrane and the lower part of the housing. Troubleshooting is easy. You need to lubricate the edge of the lower part of the case where the membrane fits with silicone sealant, let it dry a little (10 minutes), install the membrane, assemble the gearbox and let it dry a little more (2 hours).

During disassembly and subsequent reassembly, it is quite easy to break the tightness of the membrane. If you have disassembled the gearbox, then during reassembly in any case, even if there was no leakage, use silicone sealant. This will improve reliability.

Disadvantages of the device

They are not particularly numerous, but significant:

1. First of all, you need to pay attention to the fact that such devices may leak gas.

2. Use of force when installing the gearbox. In addition, it must be connected correctly. Otherwise, the gas may gradually escape from the container, filling the building. Naturally, in this case an explosion may occur.

3. Relatively high cost. For an 18-liter cylinder you can pay about 1,800 rubles.

4. You cannot independently control the pressure in the container.

To ensure that these shortcomings do not complicate your life, you need to choose, store and connect the device correctly. Only in this case will the gas cylinder for the dacha work for a long time and properly.

Problems with standard electrical equipment and gas wiring

The range of faults here is extremely wide, but most often the problems are associated with a failed MAP sensor or gas pressure sensor. In this case, the ECU does not receive impulses about the presence of gas, its pressure and temperature, so the car automatically switches to gasoline mode.

A common cause of MAP sensor failure is that the basic filter in the LPG system is unable to clean the fuel; we recommend installing a reinforced filter with a sump.

By the way, problems also occur after poor-quality installation of gas equipment. Any breaks or short circuits in the wiring, associated with careless connection or insulation of the wires, mislead the gas “brains”, so the system immediately switches to the main fuel.

Reverse type

When gas enters the working chamber from the cylinder, the valve contracts, which prevents the flow of fuel. The flow can be adjusted with a special screw, which, when turned out, compresses the pressure spring and bends the membrane. In this case, the transfer disk is pressed against the return spring, the valve is lifted and gas penetrates into the working chamber. How is the working pressure adjusted automatically?

Simultaneously with the increase in pressure in the gas pipeline, the pressure in the working chamber also increases, as a result of which the membrane is straightened under the action of a compressed spring. In this case, the transfer disk is lowered, which acts on the return spring, which, in turn, presses the valve into the seat. As a result, the supply of gas from the cylinder or gas pipeline to the working chamber is reduced, and accordingly, when the gas pressure in the pipeline decreases, a reverse reaction is triggered.

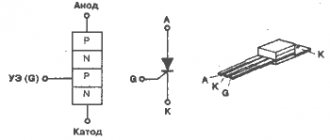

Scheme of operation of the reducer for direct (a) and reverse (b) gas. 1. Closing spring 2. Valve 3. Pusher 4. Diaphragm 5. Pressure disk 6. Spring

Why is the reducer on a gas cylinder humming: what to do if the gas pressure regulator is noisy

The reducer is a mandatory component of the connection diagram for tanks with liquefied and compressed gas mixtures. They are installed on gas tanks, single cylinders and cylinder installations to stabilize and bring to standard values the gas pressure entering household equipment, welding torches and heaters.

It happens that during operation the device for ensuring stable pressure begins to make noise. We will tell you why the gearbox on a gas cylinder hums, and we will analyze why the sound appears. We will show you how to eliminate malfunctions in the operation of the device, which can be determined “by ear”.

The article we presented describes in detail the types of gas pressure stabilizers and their design features. Methods for restoring full functionality are given. Our recommendations will help home craftsmen cope with the repairs themselves.

Advantages

A gas cylinder for a summer residence has some advantages:

— Easy to use and replace.

— Mobility

. Naturally, there are certain rules for installing the device, but in general it is not limited to one place, like a boiler.

— Various types of containers.

Depending on the purpose for which the device will be used (cooking, heating), you can purchase one or another cylinder (5, 16, 18 or 50 liters).

— Possibility of refilling the container

.

As you can see, even in the absence of centralized heating, a gas cylinder in the country can make life comfortable and convenient.

The gas reducer is airy - why and what to do about it?

First of all, it is necessary to exclude the fact that gas cylinder equipment does not correspond to a specific engine. If the gearbox freezes and becomes airy immediately after installing the gas equipment, it can be assumed that the problem is due to the fact that the gearbox simply cannot cope with its task. In this case, you should replace the gearbox or install an additional pump.

The second point is a crack in the cylinder head or block, a breakdown of the cylinder head gasket. If the cause of the air lock is related to a crack in the head or block, as well as the cylinder head gasket, you will experience the corresponding symptoms. The antifreeze will change color, may become dirty or rusty, and bubbles may appear in the expansion tank while the engine is running. In addition, the exhaust will become more abundant and blue or white in color.

Before venting the LPG reducer, you need to make sure that all the above-mentioned malfunctions are absent, otherwise all your efforts will be in vain. And the air plug itself forms again.

There are several ways to remove an air lock from an LPG gearbox.

If a problem is discovered on the road or during a trip, you can try to solve the problem yourself. To do this, you can try to “blow out” the gearbox. This is done this way: remove the upper pipe, then press the gas pedal a couple of times until water flows out. This will allow you to get to your destination and begin a deeper study of the problem.

You can ventilate the gearbox in another way. We start the engine using the main fuel and wait for the fan to turn on, that is, for the coolant to warm up sufficiently. Slightly loosen the clamp on the coolant outlet pipe from the gearbox and bleed the air, trying to ventilate the gearbox

It is important to follow safety precautions and be careful. Everything may take about half an hour.

Some motorists, when the gearbox becomes airy, recommend a simple solution to the problem. According to those who understand, it is possible to expel air from the LPG gearbox quite simply; to do this, it is enough to properly “spur” the car at high speeds along the highway. Due to high pressure and temperature, the air lock will come out on its own through the valves provided for this.

If none of the options work, you will have to go to a specialist

It is important to discover the true reason why an air lock has formed in the gearbox. Simply removing it is not the solution, as the problem may happen again!

The main causes of gearbox hum

So what could be causing the gearbox hum, and is it dangerous? Now that we understand the principle of operation of the device, this question can be answered as follows:

- With the membrane moving from its working position. Most often, this malfunction occurs when the membrane is installed incorrectly; it can be treated by simply overhauling the gearbox;

- With wear on the rubber parts of the valve. A problem that can be unpleasant when the reducer continues to release portions of gas into the working area, and if the gas equipment is not sealed, gas contamination may occur in the room;

- With a membrane rupture. The most common cause of hum, a secondary symptom is a discrepancy between the output pressure and that declared by the manufacturer. Corrected by replacing the membrane with a new one;

- With a hose split at the inlet fitting. The problem is solved by replacing the hose. The main danger is depressurization of equipment;

- Poor quality fuel. This is also one of the reasons when an unpleasant hum may be observed in the gearbox area. As a rule, it occurs immediately after refueling. It is recommended to change gas station;

- With incorrect installation of the gearbox in the car. It should not touch the body, otherwise a hum will be heard in the cabin. It can be eliminated by reinstalling the gearbox, or installing a damper gasket between the body and the gearbox.

Any kind of extraneous sounds from the gas reducer should be treated with special attention, because in some cases this can lead to dire consequences. Periodically check the equipment for leaks, drain the condensate from the reduced pressure chamber and do not forget that any gas equipment has a potential fire and explosion hazard, so contact the appropriate services to prevent incidents.

HBO 3rd generation

The engine does not develop full power

— The gas filter is clogged; — Gas lines are clogged; — The gearbox is faulty; — The stepper gas supply regulator is faulty; — The lambda probe is faulty; — The system adjustment is broken (can be corrected by software).

Failure" when the throttle valve is opened sharply

— The throttle position sensor is faulty; — The system adjustment is broken; — The mixer is not selected correctly.

The engine does not switch to gas power after reaching the “transition” temperature designated by the software.

— The gearbox temperature sensor is faulty; — There is no engine speed signal (tachometer).

Popping sounds in the intake manifold when the throttle valve is opened sharply

— Leaning of the mixture due to incorrect adjustment of the system; — Leaning of the mixture due to incorrect operation of the stepper gas supply regulator; — “Air leakage” into the engine due to a leak in the intake tract; — The ignition system is faulty; — The engine gas distribution mechanism is faulty; — The adjustment of the thermal clearances of the timing valves is disrupted.

Increased gas consumption

— The air filter is clogged; — The ignition system is faulty; — The gearbox adjustment is broken; — Reduced engine compression; — The gearbox is faulty; — Poor heating of the gearbox with coolant; — The stepper gas supply regulator is faulty; — The lambda probe is faulty. — The adjustment of the lambda control system is broken.

Gas connection

This part of the work is performed by gas workers.

Even if you are a professional, but you performed the tie-in without the appropriate permission and on your own, you face administrative liability. If you are an amateur, your actions can lead to a serious accident.

What you should pay attention to when connecting to the gas supply:

- installation of shut-off valves - a gas tap that will shut off the supply;

- a gas filter is installed behind the tap according to the relevant standards;

- A strictly metal pipe from the boiler is connected to the main line through the filter. It is preferable to use a flexible corrugated stainless steel pipe for this purpose;

- the pipe is connected to the corresponding boiler pipe using a union nut with a paronite gasket;

- the joints of the elements must be hermetically sealed. To seal these areas, tow and paint or their modern analogues are used. Synthetics are excluded.

To check the tightness of the gas connection, the connections are moistened with a soap solution and see if any bubbles appear.

About air jams

What to do if the gas reducer freezes for this reason?

If this mechanism freezes, it is necessary to carry out special prevention: dry the gas before it penetrates the reducer. Also, oxygen is preheated to 60-70 degrees.

Oxygen is dried this way: it is passed through an element that acts as a moisture absorber, for example, calcined vitriol. This is a drying component. It is placed in a dryer, which runs between the gas tank and the reducer. The ROK-1 apparatus is often used.

After this operation, the reducer hose is removed. The gearbox itself is purged. Moisture is removed from it.

If an air lock still occurs in the gas reducer, it means:

- All connections have weak sealing.

- A powerful funnel appeared when antifreeze was added or replaced. As a result, air does not leave the system. The reason for this is a strong stream of liquid. Because of it, the air does not escape. Therefore, it is better to fill it with a very weak stream.

- The air valve is not working properly. Thermal changes in the engine occur. And the air is concentrated in the cooling system.

- The fiber and seal in the pump do not work well. Because of them, air is pumped up.

- OS leaks in hoses and heating radiators. The volume of liquid decreases, and the air develops. The radiator core becomes clogged and the engine overheats.

- Head gaskets burn out. Antifreeze ends up in the crankcase of the power unit or exhaust mechanism. Its volume is decreasing. It boils due to the huge volume of air. In the first case, the OS level test will determine that it exceeds the maximum value. In the second, white smoke will follow from the chimney.

A logical question arises - how to remove the air lock in the gas reducer?

First you need to determine its cause.

Design features and maintenance

According to their design, gearboxes differ into direct and reverse acting devices. The differences between them are in the design details, the performance characteristics are identical.

Design of gearboxes for a gas cylinder

In addition, gas reducers are used in single-stage and two-stage types. In single-stage, the pressure is reduced in one stage. In a two-stage reduction, the reduction is carried out in two steps. Balloon single-stage reducers are most widely used due to their reliable design and ease of use.

The structure of the gas reducer and its principle of operation

Such mechanisms may differ in color, body, and have individual features, however, the basic structure and principle of operation are the same.

The main parts of this equipment are:

- locking spring;

- membrane;

- reducing valve.

On the one hand, the spring tends to close the valve, interrupting the gas supply, and on the other, the membrane acts on the valve, trying to open it. At the same time, the membrane is counteracted by a reduced gas with operating (low) pressure. As soon as the operating pressure drops below normal, the force of the membrane on the valve exceeds the force of the shut-off spring, and it opens.

The principle of operation is presented in the context of the gearbox

In addition to the basic parts, the gas reducer device may have a pressure gauge and valve, which perform the function of monitoring the input/output pressure and additionally adjusting the output gas supply.

Here is a video that shows the principle of operation of the gas reducer:

Checking pressure gauges on gas cylinders

When they talk about checking gearboxes, they actually mean checking pressure gauges on household gas cylinders. Let's reveal a secret: gearboxes are not listed in the state register of measuring instruments of the Russian Federation, but pressure gauges are present. And when specialists arrive, they check the operation of the flow meters - just like they check gas meters.

But it is also necessary to monitor the functioning of the gearbox, since these two devices work in conjunction. A malfunction of one of the elements will immediately affect the operation of the entire system.

Design and purpose of the flow meter

Pressure gauges that meet the requirements of GOST 2405-88 are installed on household gearboxes . The main purpose of the devices is to control the pressure in the gas system. To accurately set operating parameters, two devices are used - at the input and at the output.

The design of flow meters consists of the following elements:

- durable metal case, covered with glass on one side;

- scale with units of measurement – Pa, MPa, kgf/cm²;

- arrow painted in bright color;

- a sensitive element located inside the housing and driving the pointer.

The element responsible for rotating the arrow may differ. For low-pressure environments, membrane devices are used, but for gas networks spring models are more often used - the arrow moves due to the contraction or straightening of the spring.

To make it easier for the user to navigate and adjust the parameters as needed, a red line is placed on the scale - just opposite the working pressure marks.

Some installation and operation rules:

Liquefied gas, which is used to fill cylinders for subsequent use, is always under increased pressure. To lower it, it is necessary to install a special type of shut-off and distribution valves on the cylinder - a propane reducer. Subsequently, the reducer automatically maintains the specified level of gas pressure. According to safety regulations, the device is always painted bright red - the same color as propane cylinders.

Schematic diagram of a gas reducer

Such a common problem in the operation of gas cylinders, such as the hum of the gearbox, is fraught with several reasons that can lead to such an interesting effect. But first, let's look at the design of the reverse gearbox, as the most common one today. This will help us further understand the nature of the characteristic noises and, possibly, troubleshoot problems ourselves:

- The housing is the first thing the gearbox starts with. It consists of two halves;

- At the bottom of the housing there are inlet and outlet fittings;

- The inlet fitting leads us to a seat with a rubber ring necessary for a tight fit of the valve;

- Next comes the main pressure reducing valve. A rubber gasket ensures a tight fit to the saddle;

- The clamping force of the valve is provided by a lever that has a removable connection with a membrane - a rubber gasket, on one side having a solid metal washer with a lever mechanism, and on the other - a washer against which the gearbox spring, located in its second part, rests.

- Everything that is behind the membrane is called a reduced pressure chamber. When it rises beyond the working limits, the membrane under pressure goes inside its half of the body, moving the lever, which closes the main valve.

Depending on the gas that will be reduced and the type of equipment, a huge number of devices can be distinguished, from reducers for propane-butane, methane, hydrogen, oxygen, and other gases to complex technical devices designed for network, ramp or cylinder equipment.

What is a propane reducer?

The design of the gearbox is simple. There is a membrane inside; the device is connected to a gas cylinder with a special nut. There is a key (screw), with which the pressure is adjusted to the required level. There is a pressure gauge on the gearbox, which displays the operating pressure level. On the other side of the reducer, a hose is put on to connect to the gas-consuming device. Propane cylinders are painted red, so the reducer should be the same color. Reducers for other gases have a different color. The gearbox weighs about 0.5 kg.

Propane reducer markings include:

- manufacturer (must be a trademark of the enterprise);

- gearbox brand;

- year of issue.

In addition, the gearbox is supplied with certificates of conformity and safety regulations.

Overpressure protection

Compliance with safety standards is one of the main components of the gas supply system. Exceeding pressure levels several times higher than the nominal value can create an emergency situation with any possible consequences. In order to prevent an accident, some models are equipped with an additional safety valve, which releases excess gas if the nominal values are exceeded by 2.5-3 times.

When organizing gasification based on a group cylinder installation, it is advisable to equip each unit with a similar device. For more information about the principle of operation and compliance with safety precautions in an autonomous gas supply system, read the article: autonomous gasification - gas cylinder installations.

This is how the reducer is connected in a cylinder installation

Classification depending on the scope of application

In general, all automatic pressure control devices can be divided into reducers for inert gases (nitrogen, argon, helium, etc.) and flammable gases (hydrogen, propane, methane, etc.). To avoid confusion, gearboxes are equipped with different threads.

Thus, reducers for flammable gases have a left-hand thread, and reducers for inert gases (including oxygen) have a right-hand thread.

- Oxygen reducers are used in work related to cutting, soldering and gas welding. Also used in medical institutions and for scuba diving.

- Acetylene gearboxes are used for cutting pipelines and gas welding. In addition, they are actively used in auto repair shops and service stations when carrying out body repairs.

- Propane reducers are used when carrying out work related to gas welding, cutting and heating. In addition, they are used to organize a high-quality supply of gas from cylinders to gas stoves, as well as in construction, in particular, when installing roofs using bitumen shingles.

- Air reducers are used to reduce air pressure in networks and various air communications; they are also in demand on submarines.

4th generation HBO malfunctions

Gas equipment may well fail. Do not be alarmed if this trouble occurs: with timely diagnosis, repairs will not take much time and money. In this article we will look at the main malfunctions of the 4th generation HBO and find out the reasons for their occurrence.

The technician determines the reasons for the failure of gas equipment by studying the characteristic symptoms, so it is important to know exactly what factors lead to problems with gas equipment.

Causes of malfunction of 4th generation HBO.

Unfortunately, the main culprits for breakdowns of gas equipment are the drivers themselves, who do not try to understand the mechanism of operation of the gas equipment and carry out timely maintenance of the system.

Gas equipment components also fail under the influence of such negative factors as the use of contaminated gas or debris entering the device. Failure to follow operating instructions and installation errors can also cause malfunctions of the 4th generation gas equipment.

The most common problems with HBO.

Many drivers, when problems arise with the internal combustion engine, immediately turn to LPG. This is the wrong approach: interruptions in the operation of a car engine can be associated not only with improper operation of gas equipment. You need to check all the engine parts, alternately starting it on gasoline or gas.

Jumping engine operation and floating speed can be caused by the following negative factors:

- Poor ignition performance due to exhaustion of spark plug life.

- Low compression in the engine compartment.

- Valves not adjusted properly.

- The lambda probe has failed or is on the verge of shutting down.

- Lack of injectors, incorrect adjustment of injectors, as a result of which either too little or too much gas is injected.

- Wear of the engine timing system.

If the power characteristics of the motor suddenly decrease, the reasons should be sought in the following:

- Unadjusted gas injectors, malfunctions in their operation.

- Due to insufficient heating, the gas reducer begins to malfunction, producing pressure that is insufficient for normal engine operation.

- Lambda probe wear.

- Debris getting into the gas filter or fine filter.

- Poor flow of gas through system pipes due to their clogging.

Automatic petrol/gas switching does not work: reasons.

- Failure of thermometers that determine the gas temperature in the gearbox and engine.

- Gas pressure sensor failure.

- Lack of required voltage in the battery.

- Loss of tachometer signals.

- Oxygen enters the gearbox heater, causing the gearbox to remain cold.

Unregulated fuel consumption.

- Wear or failure of the gearbox, drop in pressure in the system.

- Debris in air filters.

- Insufficient heating of the gearbox, its misalignment.

- Damage to injection nozzles.

- Abnormal compression in the engine.

- Lambda probe wear.

Why do failures occur during re-gassing?

- Incorrect gas injector calibration.

- Clogged gas filter.

- Pressure drop in the reducer.

- Clogged gas pipes.

We can talk about malfunctions of the 4th generation gas equipment if the engine begins to work intermittently. If this problem occurs, you need to change the fuel to gasoline and drive it until all negative factors are established.

Please note that it is impossible to repair gas equipment yourself without the appropriate knowledge and skills. Moreover, such repairs can lead to more serious consequences.

Repairs should be carried out by professionals who thoroughly understand the features of gas equipment.

Malfunctions and repair operations

We examined the structure of typical models of gas reducers and made sure that there are no technically complex components in the design. Everything is so elementary that to repair devices it is not at all necessary to contact a gas specialist. Simple repair operations can be easily performed by yourself.

You just need to figure out in advance what to do so that the reducer on the gas cylinder stops humming.

Image gallery

Photo from

In order to independently determine the cause of the malfunction of the liquefied gas pressure regulator, the device will need to be disassembled

Often the cause of noise in the gearbox, which appears due to deformation or displacement of elements, can be eliminated in the process of a simple overhaul and cleaning

Parts of the regulator that have received serious damage, cracks, chips, breaks must be replaced using repair kits from the same manufacturer as the gearbox

To replace the gearbox membrane, a similar element can be cut out of rubber-fabric material with exact dimensions and shape

Disassembling the gas pressure regulator

Cleaning and replacing sealing elements

Broken thread on the gearbox tube

Damaged gas reducer membrane

The causes of noise in the reducing device include:

- Deformation and damage to the elastic working element (membrane) of the device, which is often caused by excess pressure of the gas mixture at the outlet of the cylinder or gas tank.

- Incorrect operation. Most often, due to careless and illiterate actions in the process of self-adjustment, the spring or membrane is damaged.

- Preparation for supplying low-quality, poorly purified gas mixture to gas appliances.

Often, in the initial stages of noise appearing in the gearbox, it is enough to simply adjust the factory settings. However, it is an unregulated device and will have to be repaired in any case. Repairs are made by simply replacing damaged parts: a membrane, the end of a bypass valve or a spring.

How to change the membrane?

To replace the membrane, it is better to use a repair kit commercially produced by the gas reducer manufacturer. This elastic element belongs to the abrasive and periodically worn category, which is why manufacturers of expensive gearboxes supply replacement parts for sale.

In order to competently carry out repairs and replace damaged parts, you need to thoroughly study the device using the technical documentation attached to the product.

If you do not have a membrane for your brand of gearbox, then you need to find out the following characteristics:

- Dimensions of the rubber-fabric diaphragm (membrane).

- The thickness of the oiled elastic fabric from which the membrane is made.

- Location of fixation points around the membrane circumference.

The data can be found in the technical documentation for the device or obtained as a result of banal measurements.

One of the typical reasons for a malfunction of the gas pressure regulator from a cylinder is loss of tightness in the area of contact of the membrane or damage to it itself

It happens that the sound in the gearbox does not appear due to a broken or deformed membrane, but due to a loss of tightness between it and the housing.

In this case, the gearbox can simply be rebuilt. Before reassembly, the parts of the body in contact with the membrane must be lubricated with sealant, then the components must be connected, ensuring a perfect fit of the diaphragm to the rigid base.

How to fix a reducing spring?

The process of replacing a spring that presses a valve or membrane is no more difficult than installing a new membrane. In the design of gearboxes used in circuits with gas cylinders, reduction springs of the first degree, Ø 15.5, with a number of turns of 12-14 pieces are used.

Springs are used in the designs of all types of gas reducers. They are found in elementary unregulated “frogs” and in more complex devices with adjustment devices

During operation, a spring can simply crack, lose its elasticity and elasticity, and stretch. Due to any of the listed malfunctions, the membrane and inlet valve will not be able to balance their force, i.e. control over the flow of gas into the reducer will be lost.

If the spring breaks, it is replaced with an absolutely similar part. If it is simply stretched somewhat, the problem is solved by installing a gasket. The thickness of this seal is selected based on the situation, measuring the actual distance required for reduction.

How to change the pressure reducing valve?

This work is more serious than previous actions. An important functional part of the gearbox is associated with a control screw, the position of which determines the gas pressure. It is pressed by a spring, which can easily be damaged if too much force is applied.

In addition, the valve may not cope with its duties due to damage or deformation of the end of the tube abutting against it. The movement of the rocker arm may be disrupted, the movement of which is hampered by any displaced or damaged part. Valve malfunctions are also observed due to wear of the gasket.

In the design of pressure regulators for compressed gases, used in everyday life mainly for gas welding and metal cutting, similar structural elements are used

Naturally, to restore the valve's functionality, you will have to disassemble the gearbox housing. Mobility of the rocker is ensured by replacing displaced parts. If necessary, grind the edge that interferes with free movement.

It often happens that all problems in the operation of the valve are associated with just a leaky gasket. Because of it, the elements of the device slightly change their position, but even fractions of millimeters affect the functionality of such a sensitive device. “Cureable” by installing a new gasket.

If the end of the tube is damaged, you just need to sand it. If the tube or rocker arm is seriously damaged, it is better to replace them. Replacement is carried out using repair kits produced for the maintenance and repair of gas fittings.

Malfunctions. Repair.

If you decide to carry out repairs or adjustments yourself, make sure you have the necessary qualifications. Poor repair of gas equipment can cause a fire, explosion or poisoning. After completing the work and assembly, make sure that the device is tight and operates correctly. The tightness is checked by applying a soap solution to all joints. No bubbling indicates there is no leak. But you shouldn’t delude yourself. The tightness will need to be checked several more times (after a day, three days, a week of operation), and then checked regularly, since a leak may occur some time after the start of operation.

Main malfunctions: the gas pressure at the outlet does not correspond to the nominal value (reason: the spring is broken or deformed), gas leakage (reasons: the membrane is damaged, the tightness of the connection between the membrane and the housing is broken, the float valve is leaking)

Here is a selection of materials:

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, wood, electricity). Do-it-yourself ovens. Coolant, radiators, pipes, heated floors, circulation pumps. Chimney cleaning. Conditioning

If the float bypass valve leaks, then the leak may not occur in the reducer itself, but somewhere further, for example, in a gas stove, since in this case, in zero consumption mode (when the stove or some other consumer is turned off), at the outlet reducer and gas pipes, the pressure can reach the inlet pressure. Gas gradually leaks through the valve, and there is nowhere for it to go. If there is a gas cylinder at the inlet, the pressure can reach 15 bar, which is 500 times higher than the nominal one. Such pressure will definitely lead to leakage. At the same time, it is difficult to detect this malfunction, since when the stove is turned on, the pressure normalizes. There is no sign of overpressure (flame blowout). The fault can only be identified by measuring the outlet pressure in zero consumption mode. It can be no more than 20% more than nominal.

To repair, the gearbox must be disassembled. Only a dismountable gearbox with a spring can be repaired. Sealed gearboxes are not suitable for repair.

In the picture, the membrane is with the bottom side up.

An inspection will show if there are defects in the membrane or a broken spring. A torn membrane can be replaced. But it’s not worth it, it’s better to buy a new gearbox, since it’s quite difficult to hermetically connect the new membrane with the washers. A broken spring can be replaced. Most often, the spring does not break, but simply compresses a little over time. As a result, the outlet pressure becomes lower than nominal. This malfunction can be easily corrected by placing a gasket between the housing and the spring. Read about this below in the section on transferring to another pressure.

Membrane - top view.

If you have diagnosed problems with the bypass valve, then you need to inspect it. It is a tube with a thin hole. A piece of hard rubber mounted on a rocker arm is pressed against the end of the tube. The valve may not close for the following reasons: Firstly, the mobility of the rocker arm is impaired. Move it with your hands, make sure it moves freely. If there are problems, grind or replace the hinges. Secondly, a piece of rubber was worn out and torn. It can be removed with a sharp knife and replaced by gluing another one of the appropriate size in its place. Thirdly, the end of the inlet tube may not be smooth, with damage and roughness. This prevents a tight seal. The end can be sanded with fine sandpaper.

Very often, a leak occurs due to a leak in the seal between the membrane and the lower part of the housing. Troubleshooting is easy. You need to lubricate the edge of the lower part of the case where the membrane fits with silicone sealant, let it dry a little (10 minutes), install the membrane, assemble the gearbox and let it dry a little more (2 hours).

During disassembly and subsequent reassembly, it is quite easy to break the tightness of the membrane. If you have disassembled the gearbox, then during reassembly in any case, even if there was no leakage, use silicone sealant. This will improve reliability.

General information.

Propane gas, which is naturally found in petroleum gases and is released during oil refining, is used by people for a variety of needs - both at home and at work. According to its chemical composition, propane is a saturated hydrocarbon, colorless and odorless.

Propane is used:

- for gas welding works;

- for space heating;

- in construction;

- for gas household appliances;

- as one of the types of fuel for cars (considered cheaper and more environmentally friendly than gasoline and diesel fuel).

But since gas is a flammable explosive substance, special cylinders are used to store it in a compressed state. In the middle of the cylinder, the gas is under high pressure, and in order to release it outside, you need to regulate the gas pressure at the outlet of the cylinder. This function is performed by a reducer for a propane cylinder. .

In addition, the reducer maintains a stable level of operating pressure.

Malfunctions. Repair.

If you decide to carry out repairs or adjustments yourself, make sure you have the necessary qualifications. Poor repair of gas equipment can cause a fire, explosion or poisoning. After completing the work and assembly, make sure that the device is tight and operates correctly. The tightness is checked by applying a soap solution to all joints. No bubbling indicates there is no leak. But you shouldn’t delude yourself. The tightness will need to be checked several more times (after a day, three days, a week of operation), and then checked regularly, since a leak may occur some time after the start of operation.

Main malfunctions: the gas pressure at the outlet does not correspond to the nominal value (reason: the spring is broken or deformed), gas leakage (reasons: the membrane is damaged, the tightness of the connection between the membrane and the housing is broken, the float valve is leaking)

Here is a selection of materials:

IN

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, wood, electricity). Do-it-yourself ovens. Coolant, radiators, pipes, heated floors, circulation pumps. Chimney cleaning. Conditioning

If the float bypass valve leaks, then the leak may not occur in the reducer itself, but somewhere further, for example, in a gas stove, since in this case, in zero consumption mode (when the stove or some other consumer is turned off), at the outlet reducer and gas pipes, the pressure can reach the inlet pressure. Gas gradually leaks through the valve, and there is nowhere for it to go. If there is a gas cylinder at the inlet, the pressure can reach 15 bar, which is 500 times higher than the nominal one. Such pressure will definitely lead to leakage. At the same time, it is difficult to detect this malfunction, since when the stove is turned on, the pressure normalizes. There is no sign of overpressure (flame blowout). The fault can only be identified by measuring the outlet pressure in zero consumption mode. It can be no more than 20% more than nominal.

To repair, the gearbox must be disassembled. Only a dismountable gearbox with a spring can be repaired. Sealed gearboxes are not suitable for repair.

In the picture, the membrane is with the bottom side up.

An inspection will show if there are defects in the membrane or a broken spring. A torn membrane can be replaced. But it’s not worth it, it’s better to buy a new gearbox, since it’s quite difficult to hermetically connect the new membrane with the washers. A broken spring can be replaced. Most often, the spring does not break, but simply compresses a little over time. As a result, the outlet pressure becomes lower than nominal. This malfunction can be easily corrected by placing a gasket between the housing and the spring. Read about this below in the section on transferring to another pressure.

Membrane - top view.

If you have diagnosed problems with the bypass valve, then you need to inspect it. It is a tube with a thin hole. A piece of hard rubber mounted on a rocker arm is pressed against the end of the tube. The valve may not close for the following reasons: Firstly

, the mobility of the rocker arm is impaired.

Move it with your hands, make sure it moves freely. If there are problems, grind or replace the hinges. Secondly

, a piece of rubber was worn out and torn.

It can be removed with a sharp knife and replaced by gluing another one of the appropriate size in its place. Thirdly

, the end of the inlet tube may not be smooth, with damage and roughness. This prevents a tight seal. The end can be sanded with fine sandpaper.

Very often, a leak occurs due to a leak in the seal between the membrane and the lower part of the housing. Troubleshooting is easy. You need to lubricate the edge of the lower part of the case where the membrane fits with silicone sealant, let it dry a little (10 minutes), install the membrane, assemble the gearbox and let it dry a little more (2 hours).

During disassembly and subsequent reassembly, it is quite easy to break the tightness of the membrane. If you have disassembled the gearbox, then during reassembly in any case, even if there was no leakage, use silicone sealant. This will improve reliability.

What is better: exchange or refill?

There are two ways to obtain a cylinder of gas necessary for the operation of a gas boiler, stove, outdoor lighting lines, etc.: fill your container or exchange it for another that has already been filled. In the first case, the cylinders are left at the station for 1-2 days, the consumer receives his full container.

In the second - a quick exchange of an empty container for a filled one. Consumers can make their own choice about which method to use. The second method is faster, but you get someone else's equipment, which may not be the newest. The cost depends on the type and volume of gases. Standard case: 200-300 rubles.

How to drain condensate from a gas reducer?

After switching from gasoline to gas, many motorists mistakenly believe that installing LPG is all that is required of them in order to forget about gasoline prices and start really saving. However, it is not. In fact, in order for everything to work properly, it is necessary to regularly monitor the condition of gas equipment and timely replace certain elements.

One of the most important “commandments” when operating gas equipment is the timely replacement of filters and, of course, the timely draining of condensate from the gas reducer. Unfortunately, not everyone knows about this, and some know, but simply ignore this rule.

In this article I will talk about why to drain condensate, when it is necessary to do this work, and also how to do it correctly.

In fact, this important procedure should be performed regularly or after a certain mileage. If you ignore it, then very soon you may have troubles in the form of a decrease in engine power, tripping, or other unpleasant phenomena associated with unstable operation of the power unit.

The most important thing in this matter is not to fall into despair, and not to come up with different versions as to why the engine began to behave this way, that is, in other words, don’t overwhelm yourself. The first step is to check what may be related to the problem, and it is very easy to check. Next, you should remember the rules for operating gas equipment, which the installers should have told you.

Those who installed gas equipment on your car could not help but tell you that you will have to regularly drain the condensate. This nuance is very important, so it is unlikely that you were not told about it; most likely, you yourself forgot about it, without attaching much importance to it. This, by the way, also happens, for example, it is also recommended to check the oil in the engine or gearbox regularly, almost every day before leaving, but does anyone do this? Only a few, hardly...

Draining condensate from the gas reducer, as well as checking the oil level, should become a regular occurrence, which you make it a rule to do once a month or once every two months. In principle, opinions on how often it is necessary to drain condensate from the gearbox often differ; some say that at least once a month, others say that it is enough to drain condensate every 10 thousand km.

How to choose

One of the most common choices in this class of devices remains the RDGS-1 device, the main advantages of which are its affordable cost and simplicity of design. RDGS-1 is produced in Russia and Belarus; below are the main characteristics of the device:

- Input pressure value 0.07 – 1.6 MPa

- Output pressure 2950 – 3300 Pa

- Gas consumption 1.2 m3/hour

- Weight 310 g

- Operating temperature range -30°С +45°С

Reducer RGDS-1

Instead of the time-tested gearbox RDGS-1, the price of which is 150-200 rubles, you can buy a more modern model. For example, the Italian device m714, which costs a little more (about 250 rubles).

Typically, this reducer is supplied complete with a Pullover1 gas heater, but it can also be purchased separately. The gearbox is equipped with a gasket made of elastic material, which has a five-time use life. The input pressure of m714 is in the range of 0-20 Bar, and the output pressure is 30 mBar.

Often, to connect composite cylinders to burners, a German-made GOK model costing about 500 rubles is used. However, there are also more expensive models.

Thus, the N240 gearbox, which costs more than 1000 rubles, has the following characteristics:

- Inlet pressure up to 18 bar

- The output pressure can be adjusted within the range of 20 – 60 mbar

- Productivity – 4 l/hour

- Operating temperature range -20°С +50°С

Gearbox N24

Another type of gearbox, called miniature, has become widespread among gas cutters. A prominent representative of this class can be considered the BPO-5 general purpose gearbox, the main technical characteristics of which are:

- Input pressure value up to 2.5 MPa

- Output pressure value up to 0.3 MPa

- Weight 0.65 kg

It must be remembered that purchasing and installing a reducer for a gas cylinder is a serious and responsible step. Not only the quality of operation of gas appliances, but also the safety of everyone who will use this appliance largely depends on the correct choice.

Central heating, unfortunately, is not available everywhere. In this case, either a stove or a gas cylinder can save you. For a summer residence, this option is optimal. However, this device also has its own characteristics.

Pressure gauge markings

In principle, each pressure gauge can be used with a variety of media, but there are gases for which there are restrictions.

Thus, for acetylene, you cannot use devices with copper parts, since their contact can lead to the formation of explosive substances.

And for installation on oxygen equipment, it is also necessary to use special pressure gauges, and it is imperative to degrease them to remove possible oil residues.

Therefore, pressure gauges that must be used in specific conditions must be marked accordingly. So the O2 sign should appear on the scale of the oxygen pressure gauge.

In addition, by analogy with painting cylinders, the pressure gauge body should also be painted:

- Oxygen - blue.

- Flammable gases - red.

- Acetylene is white.

- Ammonia is yellow.

Requirements for pressure gauges

Due to the fact that pressure gauges are designed to operate in high-pressure systems, they are subject to a number of stringent requirements.

So, when is it prohibited to use pressure gauges:

- All pressure gauges must be tested at certain intervals in special laboratories, where their performance, serviceability, and accuracy of readings are determined. After performing maintenance, a corresponding mark or seal is placed on the device.

Thus, oxygen pressure gauges are checked once a year, and in some cases (use in breathing equipment) after 6 months the readings are compared with the control pressure gauge. It is prohibited to operate devices that have not passed verification.

- If the arrow does not return to o by more than the permissible error, operation is not allowed.

- If the glass or housing is damaged, the pressure gauge cannot be used.

Remember that any malfunction of the pressure gauge leads to incorrect display of information about the pressure existing in the system, and this can lead to emergency situations. Therefore, before installing the pressure gauge, be sure to check its serviceability and the possibility of its use in a given gas environment at the expected pressure.

Technical examination - cylinder

Technical examination of cylinders includes inspection of the internal and external surfaces of cylinders; checking mass and capacity; hydraulic test.

Technical inspection of cylinders, with the exception of those discussed below, is carried out at least once every 5 years also at filling enterprises or at filling stations. At the same time, the internal and external surfaces are inspected, a hydraulic test is carried out and the weight and capacity of the cylinder is checked. Acetylene cylinders are subjected to external inspection, pneumatic testing and porous mass testing.

Technical inspection of cylinders is carried out in accordance with the Rules for the Design and Safe Operation of Pressure Vessels and paragraphs.

Technical examination of cylinders is carried out in accordance with the Rules for the Design and Safe Operation of Pressure Vessels of the USSR State Mining and Technical Supervision and IV-B - 165 - IV-B - 172 of these Rules.

Technical inspection of cylinders, as mentioned above, is carried out once every 5 years at a gas distribution station or a special point.

Technical examination of cylinders is carried out in accordance with the Rules for the design and safe operation of vessels operating under pressure and liquid.

The results of technical inspection of cylinders with a capacity of more than 100 liters are entered in the cylinder passport. In this case, stamps are not placed on the cylinders.

The results of the technical examination of cylinders with a capacity of more than UL n are entered in the cylinder passport. In this case, the cylinders are not stamped.

The results of technical inspection of cylinders with a capacity of more than 100 liters are entered in the cylinder passport. In this case, the cylinders are not stamped.

The results of technical inspection of cylinders with a capacity of more than 100 liters are entered in the cylinder passports. In this case, stamps are not placed on the cylinders.

The results of the technical examination of cylinders with a capacity of more than 100 liters are entered in the cylinder passport. In this case, the cylinders are not stamped.

The results of technical inspection of cylinders with a capacity of more than 100 liters are entered in the cylinder passport. In this case, the cylinders are not stamped.

The results of technical inspection of cylinders with a capacity of more than 100 liters are entered in the cylinder passport. In this case, stamps are not placed on the cylinders.

The results of technical inspection of cylinders with a capacity of more than 100 liters are entered in the cylinder passport. In this case, the cylinders are not stamped.

The results of technical inspection of cylinders with a capacity of more than 100 liters are entered in the cylinder passport. In this case, stamps are not placed on the cylinders.

Cases when using a pressure gauge is prohibited.

If the pressure gauge does not have a seal or stamp, the verification period has expired, or the gearbox pointer does not return to the initial mark, by an amount greater than half the permissible error when turned on, then it is prohibited to use such a pressure gauge.

In addition, it is not allowed to use a device that has broken glass or other damage that could affect the accuracy of the readings.

In conclusion, we note that a working pressure gauge can serve as a guarantee of safety when working with gas welding equipment.

Measuring instruments and tools require control using metric meters. Pressure gauges that analyze the pressure of liquids and gases are installed on heating boilers, gas cylinders, and used on production units. To obtain correct readings from the device and to protect company employees, pressure gauges should be checked periodically.

Mandatory requirements for vessels subject to inspection

Technical requirements for vessels that are presented for the next inspection are established by the relevant governing documents. For propane-butane cylinders, this document is RD 03112194-1094-03, and for methane equipment - RD 03112194-1095-03. Both documents were approved by the Ministry of Transport of the Russian Federation in 2002.

Before submitting a car cylinder to a specialized inspection point within the prescribed period, you must perform an independent inspection and make sure that it meets the requirements of the governing documents:

- the regulatory expiration date has not expired;

- the outside of the cylinder is cleaned of oil and other contaminants;

- the type of vessel and its design are in accordance with regulatory requirements;

- the automobile cylinder is equipped with standardized filling, consumable and other fittings provided for by design; the tee has the necessary plugs;

- cylinders do not contain gas residues;

- all valves are closed.

RD 03112194-1094-03 and RD 03112194-1095-03 allow cylinders to have parts and fittings of different designs, but only within the limits of changes made by the manufacturer during the period that a particular product was in production.

Removal of vessels from residual gas motor fuel must be carried out at specially equipped sites. The rules do not allow the presence of excess gas pressure in cylinders. If there is excess pressure, the cylinder is not allowed for inspection and is unconditionally returned to its owner.

The basis for refusal to carry out an examination is the presence of cracks, bruises, various types of cavities, scratches on the outer part of the body, exceeding 10% of the structural thickness of the wall. Also, cylinders that are missing all or part of the passport data, have expired the designated certification period, or have expired are not subject to testing.

The inspection of cylinders is accompanied by marking in compliance with the standards governing the rules for applying inscriptions. The stamp of the point that carried out the inspection, the date of the inspection and the scheduled date of the next inspection are applied to the marking plate of the manufacturer using the embossing method. The mark is applied in one line in Arabic numerals, the height of which should not be less than 8 mm. The appointed date for the next inspection can be duplicated in white inscription on the outer part of the cylinder pre-painted with red enamel. In addition, white warning notices must be applied to the outer part of the cylinder.

Fire extinguishing system testing

The program and methodology for testing gas fire extinguishing systems is regulated by the following regulatory documents:

- GOST R 50969-96;

- GOST R 51057-200;

- GOST R 53281-2009.

During testing, the following is checked:

- Volume of gas and degree of filling of the cylinder;

- Duration of supply of gas fire extinguishing mixture;

- Remaining mixture in container;

- Efficiency of eliminating the source of ignition;

- The strength and completeness of all elements of the installation after start-up and the vibration that accompanied the operation, the readiness of the structure for repeated loading;

- Information component:

- Reception and control device recall speed;

- Generating a notification to the central security console and deciphering its information content;

- Timely submission of all commands on the loops.

The element subjected to the greatest dynamic loads during testing is the pipeline. Increased demands are placed on its strength and reliability.

Testing of pipes and connecting fittings is carried out according to the following regulations:

- Visual inspection of all external parts of the pipeline;

- All spray nozzles (except the last one) are covered with plugs.

- They block access to the cylinders or distribution manifold.

- Fill the system with water through the last nozzle and turn it off;

The test pressure of gas fire extinguishing systems is 1.25 of the working pressure, but pressure is pumped into the system in stages:

- 0.05 MPa;

- 0.5 from the worker;

- Operating pressure ;

- 1.25 from working pressure;

- Between periods of rise, a holding time of 1-3 minutes is performed. at this time, using a pressure gauge, determine whether a leak has started;

- The system is maintained at maximum pressure for 5 minutes.

- After testing is completed, the liquid is drained and the pipelines are intensively purged with compressed air.