Crystal Titanium Bar

Titanium

– lightweight durable metal of silver-white color. It exists in two crystal modifications: α-Ti with a hexagonal close-packed lattice, β-Ti with cubic body-centered packing, the temperature of the polymorphic transformation α↔β is 883 °C. Titanium and titanium alloys combine lightness, strength, high corrosion resistance, low thermal coefficient expansion, ability to operate in a wide temperature range.

- Structure

- Properties

- Reserves and production

- Origin

- Application

- Classification

- Physical properties

- Optical properties

- Crystallographic properties

See also:

Chromium

– structure and physical properties

STRUCTURE

Crystal crystal structure

Titanium has two allotropic modifications. The low-temperature modification, existing up to 882 °C, has a hexagonal close-packed lattice with periods a = 0.296 nm and c = 0.472 nm. The high-temperature modification has a body-centered cube lattice with a period a = 0.332 nm. The polymorphic transformation (882 °C) with slow cooling occurs according to the normal mechanism with the formation of equiaxed grains, and with rapid cooling - according to the martensitic mechanism with the formation of an acicular structure. Titanium has high corrosion and chemical resistance due to the protective oxide film on its surface. It does not corrode in fresh and sea water, mineral acids, aqua regia, etc.

History of discovery

The appearance of a new element is associated with the names of Gregor and Klaproth. Both singled it out almost simultaneously in 1791 and 1795. respectively.

Martin Heinrich Klaproth

In 1805, it was isolated again by Vauquelin from anatase. Moreover, pure titanium was obtained in Holland more than a century after its isolation.

PROPERTIES

Titanium crystals

Melting point 1671 °C, boiling point 3260 °C, density of α-Ti and β-Ti, respectively, is 4.505 (20 °C) and 4.32 (900 °C) g/cm³, atomic density 5.71 × 1022 at/ cm³. Plastic, weldable in an inert atmosphere. Technical titanium used in industry contains impurities of oxygen, nitrogen, iron, silicon and carbon, which increase its strength, reduce ductility and affect the temperature of the polymorphic transformation, which occurs in the range of 865-920 °C. For technical Titanium grades VT1-00 and VT1-0, density is about 4.32 g/cm3, tensile strength is 300-550 MN/m2 (30-55 kgf/mm2), relative elongation is not lower than 25%, Brinell hardness is 1150-1650 MN /m2 (115-165 kgf/mm2). Is paramagnetic. Configuration of the outer electron shell of the Ti 3d24s2 atom.

It has a high viscosity and, during machining, is prone to sticking to the cutting tool, and therefore requires the application of special coatings to the tool and various lubricants.

At ordinary temperatures it is covered with a protective passivating film of TiO2 oxide, making it corrosion resistant in most environments (except alkaline). Titanium dust tends to explode. Flash point 400 °C.

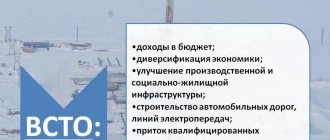

Large deposits

China occupies the leading position, followed by the Russian Federation and North America (Canada). The largest deposit where titanium is mined in the Russian Federation is located on the territory of the Komi Republic and is called the Yaregskoye oil field.

The top ten countries for titanium mining include:

- USA;

- India;

- Australia;

- SOUTH AFRICA;

- Sweden;

- Norway;

- South Korea.

RESERVES AND PRODUCTION

Titanium crystals

Main ores: ilmenite (FeTiO3), rutile (TiO2), titanite (CaTiSiO5).

As of 2002, 90% of mined titanium was used to produce titanium dioxide TiO2. World production of titanium dioxide was 4.5 million tons per year. Confirmed reserves of titanium dioxide (excluding Russia) are about 800 million tons. As of 2006, according to the US Geological Survey, in terms of titanium dioxide and excluding Russia, reserves of ilmenite ores amount to 603-673 million tons, and rutile ores - 49.7- 52.7 million tons. Thus, at the current rate of production, the world's proven reserves of titanium (excluding Russia) will last for more than 150 years.

Russia has the second largest reserves of titanium in the world, after China. The mineral resource base of titanium in Russia consists of 20 deposits (of which 11 are primary and 9 alluvial), fairly evenly distributed throughout the country. The largest of the explored deposits is located 25 km from the city of Ukhta (Komi Republic). The deposit's reserves are estimated at 2 billion tons.

Titanium ore concentrate is subjected to sulfuric acid or pyrometallurgical processing. The product of sulfuric acid treatment is titanium dioxide powder TiO2. Using the pyrometallurgical method, the ore is sintered with coke and treated with chlorine, producing titanium tetrachloride vapor, which is reduced at 850 °C with magnesium.

The resulting titanium “sponge” is melted down and cleaned. Ilmenite concentrates are reduced in electric arc furnaces, followed by chlorination of the resulting titanium slag.

Receipt

A block of crystalline titanium (purity 99.995%, weight ≈283 g, length ≈14 cm, diameter ≈25 mm), manufactured using the van Arkel and de Boer iodide method.

Typically, the starting material for the production of titanium and its compounds is titanium dioxide with a relatively small amount of impurities. In particular, it can be a rutile concentrate obtained from the enrichment of titanium ores. However, the reserves of rutile in the world are very limited, and the so-called synthetic rutile or titanium slag, obtained from the processing of ilmenite concentrates, is more often used. To obtain titanium slag, ilmenite concentrate is reduced in an electric arc furnace, while iron is separated into the metal phase (cast iron), and unreduced titanium oxides and impurities form the slag phase. Rich slag is processed using the chloride or sulfuric acid method.

Titanium ore concentrate is subjected to sulfuric acid or pyrometallurgical processing. The product of sulfuric acid treatment is titanium dioxide powder TiO2. Using the pyrometallurgical method, the ore is sintered with coke and treated with chlorine, producing titanium tetrachloride vapor TiCl4:

TiO2 + 2C + 2Cl2 → TiCl4 + 2CO

The resulting TiCl4 vapors are reduced with magnesium at 850 °C:

TiCl4 + 2Mg → 2MgCl2 + Ti

In addition, the so-called FFC Cambridge process, named after its developers Derek Fray, Tom Farthing and George Chen from the University of Cambridge, where it was created, is now beginning to gain popularity. This electrochemical process allows for the direct, continuous reduction of titanium from its oxide in a molten mixture of calcium chloride and quicklime (calcium oxide). This process uses an electrolytic bath filled with a mixture of calcium chloride and lime, with a graphite sacrificial (or neutral) anode and a cathode made of a reducible oxide. When current is passed through the bath, the temperature quickly reaches ~1000–1100 °C, and the calcium oxide melt decomposes at the anode into oxygen and metallic calcium:

2CaO → 2Ca + O2

The resulting oxygen oxidizes the anode (in the case of using graphite), and calcium migrates in the melt to the cathode, where it reduces titanium from its oxide:

O2 + C → CO2 TiO2 + 2Ca → Ti + 2CaO

The resulting calcium oxide again dissociates into oxygen and metallic calcium, and the process is repeated until the cathode is completely converted into a titanium sponge or the calcium oxide is exhausted. In this process, calcium chloride is used as an electrolyte to impart electrical conductivity to the melt and mobility of active calcium and oxygen ions. When using an inert anode (for example, tin dioxide), instead of carbon dioxide, molecular oxygen is released at the anode, which pollutes the environment less, but the process in this case becomes less stable, and, in addition, in some conditions, the decomposition of chloride becomes more energetically favorable, rather than calcium oxide, which leads to the release of molecular chlorine.

The resulting titanium “sponge” is melted down and cleaned. Titanium is refined using the iodide method or electrolysis, separating Ti from TiCl4. To obtain titanium ingots, arc, electron beam or plasma processing is used.

ORIGIN

Titanium Ore

Titanium is in 10th place in terms of prevalence in nature. The content in the earth's crust is 0.57% by weight, in sea water - 0.001 mg/l. In ultramafic rocks 300 g/t, in basic rocks - 9 kg/t, in acidic rocks 2.3 kg/t, in clays and shales 4.5 kg/t. In the earth's crust, titanium is almost always tetravalent and is present only in oxygen compounds. Not found in free form. Under conditions of weathering and precipitation, titanium has a geochemical affinity with Al2O3. It is concentrated in bauxites of the weathering crust and in marine clayey sediments. Titanium is transferred in the form of mechanical fragments of minerals and in the form of colloids. Up to 30% TiO2 by weight accumulates in some clays. Titanium minerals are resistant to weathering and form large concentrations in placers. More than 100 minerals containing titanium are known. The most important of them are: rutile TiO2, ilmenite FeTiO3, titanomagnetite FeTiO3 + Fe3O4, perovskite CaTiO3, titanite CaTiSiO5. There are primary titanium ores - ilmenite-titanomagnetite and placer ores - rutile-ilmenite-zircon. Titanium deposits are located in South Africa, Russia, Ukraine, China, Japan, Australia, India, Ceylon, Brazil, South Korea, and Kazakhstan. In the CIS countries, the leading places in explored reserves of titanium ores are occupied by the Russian Federation (58.5%) and Ukraine (40.2%).

Being in nature

In nature, titanium is presented in the form of compounds with oxygen. Pure forms do not occur.

Under the influence of meteorological conditions, the structure approaches corundum (a compound of aluminum with oxygen). It is found in marine clay, in aluminum ores with iron and silicon.

Titanium is presented in minerals: titanite, titanomagnetite, rutile. Australian, Brazilian, and Canadian deposits of the latter are known. The mineral is presented in the form of bucrite and anatase.

A widely encountered mineral is iron titanate (ilmenite). Large deposits are represented in Russia and North America.

APPLICATION

Titanium products

Titanium alloys play an important role in aviation technology, where they strive to obtain the lightest structure combined with the necessary strength. Titanium is lightweight compared to other metals, but at the same time can operate at high temperatures. Titanium alloys are used to make the casing, fastening parts, power kit, chassis parts, and various units. These materials are also used in the construction of aircraft jet engines. This allows you to reduce their weight by 10-25%. Titanium alloys are used to produce compressor discs and blades, air intake and guide vane parts, and fasteners.

Titanium and its alloys are also used in rocket science. Due to the short-term operation of engines and the rapid passage of dense layers of the atmosphere in rocket science, the problems of fatigue strength, static endurance and partly creep are eliminated to a large extent.

Due to its insufficiently high thermal strength, technical titanium is not suitable for use in aviation, but due to its exceptionally high corrosion resistance, in some cases it is indispensable in the chemical industry and shipbuilding. Thus, it is used in the manufacture of compressors and pumps for pumping such aggressive media as sulfuric and hydrochloric acid and their salts, pipelines, shut-off valves, autoclave, various types of containers, filters, etc. Only titanium is corrosion resistant in environments such as wet chlorine, aqueous and acidic chlorine solutions, therefore equipment for the chlorine industry is made from this metal. Heat exchangers are made from titanium that operate in corrosive environments, for example, nitric acid (non-smoking). In shipbuilding, titanium is used for the manufacture of propellers, plating of ships, submarines, torpedoes, etc. Shells do not stick to titanium and its alloys, which sharply increase the resistance of the vessel as it moves.

Titanium alloys are promising for use in many other applications, but their spread in technology is hampered by the high cost and scarcity of titanium.

Titanium – Ti

| Molecular weight | 47.88 g/mol |

| origin of name | The mineral got its name in honor of the Titans, characters from ancient Greek mythology, the children of Gaia. |

| IMA status | confirmed in 2010 |

Metal composition

The metal exists in two modifications.

- α-Ti - exists up to a temperature of 883 C, has a dense hexagonal lattice.

- β-Ti – has a body-centered cubic lattice.

The transition occurs with a very small change in density, since the latter gradually decreases when heated.

- During operation of titanium products, in most cases they deal with the α-phase. But when melting and manufacturing alloys, metallurgists work with the β-modification.

- The second feature of the material is anisotropy. The elasticity coefficient and magnetic susceptibility of a substance depend on the direction, and the difference is quite noticeable.

- The third feature is the dependence of the properties of the metal on its purity. Ordinary technical titanium is not suitable, for example, for use in rocket science, because due to impurities it loses its heat resistance. In this area of industry, only extremely pure substances are used.

This video will tell you about the composition of titanium:

PHYSICAL PROPERTIES

| Mineral color | Silver gray |

| Stroke color | grayish black |

| Transparency | opaque |

| Shine | metal |

| Cleavage | No |

| Hardness (Mohs scale) | 4 |

| Kink | hackly |

| Strength | pliable |

| Density (measured) | 4.503 g/cm3 |

| Radioactivity (GRapi) | 0 |

| Magnetism | paramagnetic |

Characteristics of titanium

In the periodic table, Titan (Ti) can be found at number 22. This metal and its alloys are tetravalent. Boiling is achieved at a temperature of +3330 °C, and melting at +1168 °C.

There are two types of titanium, which have identical chemical compositions but different structures. This causes differences in their properties. The low-temperature α-modification remains stable only up to a temperature of +882.5 °C; the β-modification can withstand higher temperatures and remains stable up to the melting point.

Titanium and its alloys are paramagnetic. The electrical resistivity of this material is quite high: 5.562*10-7–7.837*10-7 Ohm/m. It has low temperature sensitivity when heated. If the temperature drops to 0.45 K, titanium becomes a conductor. Steel and titanium are very similar in appearance.

VT-metall offers services:

If you compare titanium with aluminum or iron, then its density and specific heat are somewhere in the middle. But it has high mechanical strength, surpassing aluminum in this parameter by 6 times, and pure iron by 13 times. This material can be presented in any form: sheets, plates, pipes and rods.

The mechanical and technical properties of titanium and its alloys, as well as their chemical composition, are determined by the grade of the material. It may include the following elements:

- aluminum;

- molybdenum;

- vanadium;

- manganese;

- chromium;

- tin;

- silicon;

- zirconium;

- iron.

Properties of titanium and its alloys

There are three standard categories of titanium alloys:

- Structural and high-strength titanium alloys. They have a very hard composition, thanks to which an ideal balance of ductility and strength is achieved.

- Heat-resistant titanium alloys. They have a solid composition that includes a certain amount of a chemical compound, which somewhat reduces ductility, but gives high heat resistance.

- Titanium alloys based on a chemical compound. This heat-resistant composition has a low density and can compete with nickel compounds in terms of heat resistance at a certain temperature.

Now Ti is very widely used in construction activities. Even 200 years ago it was considered unsuitable for construction, but time has passed, and at the moment it is one of the most durable and reliable materials with a wide range of other useful properties.

Let's take a closer look at the most popular titanium alloys, their properties and applications:

- VT1-00 and VT1-0.

Technical titan. Semi-finished technical Ti grades VT1-00 and VT1-0 are supplied in large quantities by metallurgical plants. The composition of these grades includes impurities of iron, nitrogen, silicon, oxygen, carbon, etc. At the same time, the VT1-0 variety contains significantly more impurities, which determines its greater strength and lower ductility compared to the second grade. The high ductility of these grades makes it possible to produce the thinnest products, including foil.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

These materials do not have high strength, so cold hardening can be done to increase it. True, this will reduce ductility. Cold hardening is not the optimal method for improving the properties of a given metal, since ductility decreases much more than strength increases. Another disadvantage of technical Ti is hydrogen embrittlement. It is important to ensure that the hydrogen content does not exceed 0.008% in VT1-00 titanium and 0.01% in VT1-0.

- Alloy VT5 (VT5L).

To alloy the VT5 (VT5L) alloy, only aluminum was used, which is the most common alloying agent. The special properties of aluminum have led it to a leading position among all alloying additives:

- aluminum is a natural material that is easy to find and inexpensive;

- the lower density of aluminum compared to Ti allows one to significantly increase the specific strength of the resulting composition;

- the more aluminum in the composition, the more heat-resistant the joint is, and the creep resistance of the joint also increases;

- the inclusion of aluminum in the composition improves the elastic modulus;

- Increasing the volume of aluminum in a compound reduces their hydrogen embrittlement.

Compared to technical Ti, the VT5 grade is characterized by such properties as greater strength and heat resistance. An improvement in these properties leads to a decrease in the technological plasticity of Ti. The VT5 connection in a hot state can be stamped, forged and rolled, which allows the production of profile, rod and stamping products. But the main area of application is shaped casting (VT5L brand), and not metal in a deformed state.

- Alloy VT5-1.

The VT5-1 connection is included in the Ti-Al-Sn system. The technological properties of titanium and its alloys with aluminum are improved by tin. This leads to a decrease in oxidation processes and an increase in creep resistance. The strength properties of this titanium alloy make it possible to classify it as a medium-strength compound. At the same time, VT5-1 is not susceptible to cuts, its endurance limit is with sufficient reserve, the level of heat resistance reaches +450 °C.

From a technological point of view, VT5-1 is more preferable (compared to VT5). Main scope of application: forgings, sheets, profiles, plates, stampings, pipes, wire and other types of semi-finished products produced under pressure.

The connection is formed by welding. In this case, the base material and the welded joint have the same strength. Exposure to high temperatures does not increase the strength of VT5-1.

If it is necessary to work at cryogenic temperatures, then it is necessary to control the content of impurities in the material, since exceeding the permissible threshold can lead to an increase in cold brittleness. The VT5-1kt marking indicates a composition with a reduced content of impurities.

In European countries, the Ti-5A1-2.5Sn compound is used in two ways: for standard purposes and for operation at cryogenic temperatures. The composition for cryogenic work is labeled Ti-5AI-2.5Sn ELI and the level of impurities is also monitored to maintain its properties.

- Alloy OT4-0.

A high-tech connection with low strength is labeled OT4-0. Under pressure as a result of hot processing, manganese can improve the manufacturability of the composition. It is a pseudo-α-grade titanium alloy with a small amount of β-phase. Not subject to thermal hardening. Scope of application: forgings, sheets, rods, strips, stampings and strips. Easily takes the desired shape during cold and hot processing. Even stamping at room temperature is allowed. The properties of the material are ideal for welding work.

- Alloy OT4-1.

Among the most technologically advanced is the titanium alloy OT4-1. It has the following properties: low-strength, low-alloy pseudo-α-class Ti-Al-Mn system, perfectly deformable. This titanium alloy can be reshaped either hot or cold. Scope of application: forgings, sheets, profiles, plates, strips, rods, strips and pipes.

Cold stamping is mainly used for sheet stamping, which does not require a complex shape. If it is necessary to produce a part with a more complex shape, it is advisable to heat the material to +500 °C. The properties of OT4-1 allow it to be used for welding work in any way. In this case, the base metal and the welded joint will have the same strength and ductility.

For complete annealing, a temperature of +640...+690 °C is required (suitable for the manufacture of sheet semi-finished products and their derivatives) and +740...+790 °C (for the manufacture of forgings, rods, stamping, etc.).

For incomplete annealing, a temperature of +520…+560 °C is sufficient. Among the properties that reduce the value of this alloy are low strength and excessive hydrogen brittleness (to maintain optimal properties of the metal, a hydrogen content of no more than 0.005% is required).