The professional path of a home welder is quite simple: the purchase of the first welding machine, the first repair, the first attempts to do the job efficiently, and after a while the first customers. It is at the last stage that the welder needs an estimate. An estimate for welding allows you to thoroughly calculate your expenses and income. In addition, the customer will have more confidence in you, since you will be able to provide him with transparent calculations.

There are many ways to determine the price of welding work: from the “by eye” estimation method to painstaking calculations. In this article we will tell you in detail how to evaluate your welding work so as not to lose money. We will also tell you about the factors influencing the price, valuation methods, and teach you how to perform simple calculations.

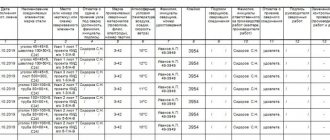

Welding of casing pipes with outer diameter: up to 530 mm

FEDERAL UNIT PRICE FER 04-02-006-10

| Name | Unit |

| Welding of casing pipes with outer diameter: up to 530 mm | 1 welding |

| Scope of work | |

| 01. Preparing the welding unit for work: refueling, starting and adjusting the generator. 02. Preparation of welding cables and electrodes for work. 03. Cleaning the edges before welding from scale, rust, oils and other contaminants. 04. Welding seams and inspecting them. 05. Disconnecting cables and cleaning them after completion of work. | |

The price does not contain overhead costs and estimated profits; accordingly, the direct costs of work for the period 2000

(prices of the Moscow region), which are calculated based on

2009

. For further calculations, this cost must be multiplied by the conversion index to current prices.

You can go to the pricing page, which is calculated based on the 2014 edition standards with additions 1

| Total (RUB) | Workers' compensation | Machine operation | Pay for drivers | Cost of materials | Labor costs (person-hours) |

| 79,66 | 21,13 | 32,02 | 26,51 | 2,33 |

TOTAL PRICE: 79.66 RUR.

Look at this standard in the 2022 edition open page

Look at the resource part of the price in the GESN standard 04-02-006-10

When used in an estimate, the price requires indexation to translate into current prices. The price is based on the GESN-2001 standards, as amended in 2009.

in

2000

.

Source

Cost of welding work

Depending on the thickness of the element:

- Thickness from 1 to 3 mm - from 16 rubles/cm.

- Thickness from 4 to 6 mm - from 21 rubles/cm.

- Thickness from 7 to 10 mm - from 26 rubles/cm.

- Thickness from 10 to 14 mm - from 37 rubles/cm.

- Thickness from 15 to 20 mm - from 53 rubles/cm.

To obtain more reliable data, it is recommended to contact us to coordinate the work, as well as draw up an estimate.

Our company also carries out installation and repair of heating systems. Replacing batteries, for example, will cost around 3,150 rubles, risers - from 3,700. Installation of a backup path for connecting heated towel rails - from 5,250 rubles. The cost of other work on installation of life support systems can be found out by calling our consultants.

Estimated prices for pipe welding

| Specifications | Cost, rub: | ||||

| Nominal diameter, mm: | Outside diameter: | Seam length, cm: | Number of passes: | Price RUR/cm | Price RUR/joint |

| 15 | 21,3 | 6,69 | 1 | 26 | 210 |

| 20 | 26,8 | 8,42 | 1 | 26 | 265 |

| 25 | 33,5 | 10,52 | 1 | 26 | 315 |

| 32 | 42,3 | 13,28 | 1 | 26 | 380 |

| 40 | 48 | 15,07 | 1 | 23 | 420 |

| 50 | 57 | 17,9 | 1 | 23 | 440 |

| 76 | 23,86 | 1 | 23 | 580 | |

| 89 | 27,95 | 1 | 23 | 680 | |

| 102 | 32,03 | 1 | 21 | 735 | |

| 108 | 33,91 | 1 | 21 | 780 | |

| 133 | 41,76 | 1 | 21 | 890 | |

| 159 | 49,93 | 1 | 21 | 1100 | |

| 219 | 68,77 | 2 | 21 | 3200 | |

| 273 | 85,72 | 2 | 21 | 4200 | |

| 325 | 102,05 | 2 | 21 | 5040 | |

Electric arc welding during the installation of one-story industrial buildings: frames in general

FEDERAL UNIT PRICE FER 09-05-002-01

| Name | Unit |

| Electric arc welding during the installation of one-story industrial buildings: frames in general | 10 tons of structures |

| Scope of work | |

| 01. Welding of steel structures. |

The price takes into account the work requirements for 2000

(Moscow prices), calculated according to the GESN model of 2009

. Indexation of translation into current prices must be applied to the cost.

You can go to the pricing page, which is calculated based on the 2014 edition standards with additions 1

| Total (RUB) | Workers' compensation | Machine operation | Pay for drivers | Cost of materials | Labor costs (person-hours) |

| 1333,28 | 442,72 | 439,1 | 451,46 | 35,79 |

TOTAL PRICE: RUB 1,333.28.

Look at the cost of this standard at current prices open page

Look at the resource part of the price in the GESN standard 09-05-002-01

When used in an estimate, the price requires indexation to translate into current prices. The price is based on the GESN-2001 standards, as amended in 2009.

Pipe installation work

| Water and gas pipes: | Electric welded pipes: | ||

| Nominal diameter, mm: | Cost, rub./p.m.: | Outside diameter: | Cost, rub./p.m.: |

| 15 | 147 | 57 | 263 |

| 20 | 158 | 76 | 315 |

| 25 | 189 | 89 | 360 |

| 32 | 210 | 102 | 390 |

| 108 | 420 | ||

| 133 | 495 | ||

| 159 | 525 | ||

| 219 | 840 | ||

| 273 | 1010 | ||

| 325 | 1155 | ||

Also, our company’s employees will quickly dismantle and install metal structures, install a heating system, repair metal fences, weld pipes or cut metal. Our specialists will provide assistance in the development of project documentation, as well as control of the work performed with a subsequent warranty for one year.

Approximate prices for services:

- Manufacturing of metal structures according to customer drawings - from 15,750 rubles.

- The design of metal and reinforced concrete structures without approval depends on the size and complexity of the project.

- Dismantling of metal structures - 2100 rub./t.

- Installation of metal structures (up to 15 meters high) - from 14,200 rubles.

- Installation of metal structures (up to 25 meters in height) - from 17,300 rubles.

- Installation of metal structures (up to 45 meters in height) - from 21,500 rubles.

Manufacturing of metal structures:

| Name: | Cost, rub./t: |

| Floor beams | 15750 |

| Runs | 12600 |

| Links and crossbars | 20475 |

| Beam columns | 15750 |

| Embedded parts | 25725 |

| Flights of stairs | 36225 |

| Rafter and sub-rafter trusses: | |

| - from a pipe | 20475 |

| - from the corner | 22575 |

| Platforms and railings | 57225 |

The price does not include the price of materials. Work can be carried out using the customer’s metal and purchased materials.

Manufacturing of metal products:

- Welded fence with chain-link mesh - from 840 rubles. p/m.

- Welded grilles and gates - from 1,365 rubles/m².

- Warehouse and commercial equipment - from 1365 rubles. p/m.

The cost of manufacturing piece goods is calculated locally, depending on the complexity.

How to calculate the cost of welding work

After purchasing a welding machine from an amateur, sooner or later the first orders from outside will appear. Enough for those you know to know that welding seams have begun to be of acceptable quality, the first people willing to use a welder will appear. And here it becomes necessary to calculate the cost of welding work. The best option is to draw up an estimate. It allows you to accurately take into account all cost items and inspires confidence among customers, since all calculations will be transparent.

There are many ways to determine the cost of services for welding work: from determining the approximate cost by analogy with the previously completed volume to precise verified calculations. Below we discuss all the methods available to the welder, including drawing up an estimate for welding work. The material will help you correctly determine the final cost and avoid unpleasant mistakes.

What determines the cost of welding work?

To competently draw up an estimate, you will need to understand the basic principles of its formation, that is, know what factors influence pricing. There are a large number of objective circumstances that have a direct or indirect impact on the formation of the final cost of services. But at first it is enough to know the basic principles.

The main factor is the volume of work. This is logical, since the longer it takes to complete a task, the higher the cost of the services provided. In addition to volumetric indicators, it is necessary to take into account qualitative ones - the complexity of the work, the type of welding, the quantity and types of consumables that need to be used during the work process.

For example, electric arc welding will be much cheaper than semi-automatic welding using a tungsten rod in an inert environment. Below is a formula that will make it much easier to determine the cost of welding services for metal workpieces. It is great for determining the tariff for a specific type of work or the cost of the entire volume.

But first you need to familiarize yourself with generally accepted valuation methods.

How to estimate the cost of a welder's work

Before proceeding directly to the calculations, you need to familiarize yourself with the options for estimating the cost of work.

It is important to understand that in addition to the mathematical approach, there are other ways to determine cost.

This knowledge is in demand among different categories of specialists: both among home craftsmen and among production site managers who independently determine the cost of services.

There is no single register of all existing methods. But it is worth paying attention to the main ones, which are most often in demand in practice.

Visual assessment

The easiest and fastest way to determine the cost of welding work is “by eye”. This is a relative method and the result largely depends on the master, or more precisely on his vision of the process.

But it is the simplest and does not require any special knowledge other than understanding how to implement the task.

Most often, this method is used by welders to calculate the cost of manufacturing simple structures.

In this case, the specialist takes into account the cost of materials and evaluates his contribution to the project. The final cost depends to some extent on the customer's solvency. If he looks like a wealthy person, then there is a high probability that the price will be somewhat inflated.

Another option is a symbiosis of visual assessment and calculation. Its principle is simple: the cost of work is equal to the cost of materials.

The welder roughly estimates the quantity and price of metal needed for the job. Then the result is multiplied by 2, and the amount is presented to the customer as final for the finished structure.

A fairly primitive method, but at the same time in demand among different categories of welders.

Mathematical calculation

The most common way to determine the cost of welding work. Based on the use of a special formula. Most often, the estimate is calculated by a PC operator who uses a specially developed algorithm (program).

A fairly simple and very accurate method that gives the welder the opportunity to independently determine the price for his services deserves special attention. It consists of breaking the process down into many simple steps that are easy to evaluate. At the very beginning, it is necessary to determine the amount of costs for materials, including consumables. Let these be the main expenses.

The result obtained is summed up and recorded. After this, the complexity of the welding work is determined and the price of the services is determined. The time spent on completing the work should also be taken into account. All this can be called overhead costs.

Now it's time to add up the basic and overhead costs to determine the final cost of the project. In some cases, it is advisable to add the planned profit to the obtained result, as is done in enterprises.

Formula for calculating the cost of welding metal structures

- twork – time spent on work;

- td – indicates the amount of time spent on the road to the object (place of work) and back (the item is not mandatory for calculation);

- ST – rate per hour of work;

- Zmat – the amount spent on consumables;

- Zd - the cost of gasoline or other fuel, a ticket or carrier services spent on arriving at the place of work (facility) - is not a mandatory item for calculation;

- Ао – the amount of expenses associated with depreciation (wear and tear) of the welding machine and auxiliary equipment (equipment).

How much did it cost to renovate a new building?

This calculation method allows you to fairly accurately calculate the cost of the finished metal structure. It can be used both in production and by amateur welders. However, it should be borne in mind that this is not the most detailed and accurate calculation formula. For technologically complex operations, there are more complex calculation algorithms that take into account all the nuances and all types of costs.

Conclusion

Using the above calculation methods, you can determine the cost of most technological operations for welding metals.

It is advisable for novice specialists to use the formula given in the article or the visual assessment method, provided that similar work has already been performed previously.

Well, for those who have been providing welding services for a long period of time, it is best to combine several calculation options so that the final value is as weighted as possible.

Sorted by relevance

| Sort by date

. Dear estimators! A welder in our organization is retiring early. He needs to confirm with documents that he actually performed welding

work

.

The pension fund needs KS-2, but it does not specifically have a working welder.

We lost welding work log If anyone has encountered .

Yulia Ramazanova. What price can be applied for welding

work

to ensure minimum costs?

Calculation formula

Where twork is the time you spent working;

td is the time you spent traveling to your workplace (an optional item in the calculations);

Read also: Do-it-yourself wind generator from a VAZ car generator

ST is your hourly work rate;

Zd - your costs for gasoline (optional item in the calculations);

Zmat - the quantity or cost of your consumables;

AO - depreciation of your welding equipment (depreciation is taking into account the natural wear and tear of the equipment).

This method of calculating the cost of welding work is extremely simple and allows you to evaluate the work for both a production welder and a home craftsman. But keep in mind that this is the simplest formula. With its help, the estimate for welding will be undetailed and primitive.

What influences pricing

To calculate the estimate correctly, you need to understand what factors influence pricing. In simple words, what affects the final cost of your work. There are many factors, but we will highlight the most basic ones that apply to any type of welding.

The first factor is the volume of welding. This is logical; the amount of payment directly depends on the amount of work. But in addition to volumes, the complexity of the welding process, the type of welding chosen and the number of consumables used in welding must be taken into account. Agree, fast arc welding with electrodes is several times cheaper than semi-automatic welding using tungsten rods and gas.

Later we will tell you which formula to use in order to correctly calculate your welding work. Using the formula, you can set the optimal tariff for welding work. In the meantime, let's talk about methods for assessing welding work.

Welding work

To create a permanent connection between two or more metal elements, welding work is performed. Depending on the method of influence, welding can be arc, gas, laser, plasma, electroslag, etc.

The most popular are gas welding works. New interatomic bonds are formed in this case by gas-flame exposure of the metal and heating it to the melting temperature. No less common is electric arc welding with a coated electrode. It allows you to connect both small and large parts into single structures. For operations with stainless steel and non-ferrous metals, argon-arc welding is used on special semi-automatic machines.

| Types of jobs | Unit measurements | Price | |

| Various types of welding (arc, argon, semi-automatic, gas) | cm | from 35 rub. | Order |

| Pipe welding | cm weld seam | from 70 rub. | Order |

| Welded fencing (grids, gates) | p.m. | from 550 rub. | Order |

| Fences (including standard welded, chain-link fences, corrugated sheet metal) | p.m. | from 750 rub. | Order |

| Lattices | m2 | from 1800 rub. depending on the type | Order |

| Decorative fencing | m2 | from 2800 rub. | Order |

| Stairs, railings | p.m. | negotiable, depending on model | Order |

Work evaluation methods

Before you learn how to do the math, familiarize yourself with methods for estimating welding costs. After all, in addition to mathematical calculations, there are other methods. This knowledge will be useful both to home welders who want to make estimates, and to industrial craftsmen who are tasked with independently estimating the cost of their work.

There is no uniform classification of methods. But we will highlight the main ones, which are most common and easy to use.

Visual assessment

The simplest assessment of the cost of metal structures is visual, or “by eye” (as home craftsmen often call it). This is a very unstable and controversial method, but it is the most accessible of all and does not require any knowledge at all. Often, this method is used in their work by beginners or craftsmen who make simple metal structures (for example, greenhouse frames).

In such cases, the master takes into account the time and materials spent, and also evaluates his customer. If the latter looks wealthy, then most likely the master will ask for a higher price.

There is also a hybrid of visual assessment and calculation. Everything is simple here: the cost of the metal (which is often estimated just “by eye”), which was required for the manufacture of a metal structure, is taken and multiplied by 2. Again, a rather primitive method, but quite effective if welding is not your main income.

Mathematical calculation

The most common method. We have already talked about it earlier. To make a mathematical calculation, special formulas are used. The estimate is most often generated on a computer in a special program.

We would like to tell you separately about an interesting technique that allows you to quite simply calculate tariffs for your work. The essence of the technique is to break down all the components of welding so that they can be easily assessed. First you need to determine the cost of the metal and consumables necessary to carry out welding work in an industrial or home environment.

Let's summarize these indicators. We get the amount that needs to be written down. These are our main expenses. Next, we determine how difficult the welding will be (conventional arc welding or resistance welding to be performed, for example). Sets the cost (the more complex the welding, the more expensive it is). The labor intensity of production and the time spent on work are also taken into account. This is overhead.

Now let's sum up overhead and basic expenses. This is the cost of welding. You need to add profit on top or factor it into overhead costs in advance. Calculating the cost using the mathematical method is quite simple and does not require special knowledge.

Next, we will tell you how to calculate the cost of welding using a simple formula.

Varieties

The following types of electric welding are distinguished:

- Manual arc . It is easy to implement and does not require complex technical support. Suitable for welding stainless steel and ferrous metals only.

- Welding using TIG technology . Makes it possible to work with vector non-ferrous metals and alloy steels.

- Semi-automatic . This is a modern and high-quality type of welding. Often used by home craftsmen. The filler material is supplied automatically. The work is simple and of high quality.

- SPOT . It is used in car service centers when carrying out body repairs. Requires the use of sophisticated equipment. It is used extremely rarely at home.

Based on the material being worked with, welding can be:

Depending on the type of equipment used, welding can be carried out using:

- Welding transformer.

- Welding MMA rectifiers.

- Equipment operating using an inverter circuit.

Welding machines can be:

- Ordinary, without additional functions.

- With the “HotStart” option (facilitates initial ignition).

- With the “AntiStick” function (prevents the device from overheating).

- With the “ArcForce” option (prevents the electrode from sticking to metal surfaces).

Depending on the performer, welding work can be carried out:

Factors influencing price indicators

In order for the estimate to be calculated correctly, a clear understanding of the factors influencing the cost is necessary. Everything from the weather to the materials you use can affect the price of welding procedures.

But we will focus on those that really matter for welding.

The first step is to determine the scope of welding tasks. The type of welding chosen is important, as is the volume of consumables.

Arch welding using electrodes will be much cheaper than labor on a semi-automatic machine using tungsten rods and a gas structure.

There is a special formula that can be used to correctly calculate the price of your work. Using it, you will be able to calculate the correct tariff for the customer. It is worth dwelling on the methods that are relevant when assessing welding tasks.

Price list

Welding work

PRICES FOR WELDING WORKS

Prices for welding services are approximate. The final price is determined by the master after a conversation with the customer, and depends on the complexity of the work, the materials used, and the volume of work.

PRICE LIST FOR WELDING WORKS

from 1500 rub. from 3000 rub. from 3500 rub. from 4000 rub.

| № | TYPE OF WORK | DESCRIPTION | UNIT. | PRICE |

| Metal welding | ||||

| 1 | Welding work including materials | – argon – arc – gas – semiautomatic. | cm | from 20 rub. |

| 2 | Pipe welding | by any method | joint | from 150 rub. |

| 3 | Make a garage 4x6 sheet 2mm, roof 2x pitched, gate 2x2.5 The whole structure is bolted. Wicket, iron door, size 2.05×0.80 steel 2mm is paid separately. | from 57,000 rub. | ||

| 4 | Manufacturing of metal structures (cost per finished product) | Prices are indicative. The final price is determined by the master and depends on the complexity, materials, volumes | ||

| 4.1 | Welded fences | gates, bars | p.m. | from 600 rub. |

| 4.2 | Fence | chain-link mesh, welded | p.m. | from 1100 rub. |

| 4.3 | Trade and warehouse equipment | shelving, racks, furniture | p.m. | from 1800 rub. |

| 4.4 | Metal products / metal structures | according to customer drawings | ton | from 45000 rub. |

| 4.5 | Change house (frame) | from 6000r | ||

| 5 | Manufacturing of fences | |||

| 5.1 | Simple metal welded | m2 m.p. | from 800 rub. negotiable | |

| 5.2 | From mesh | m2 l.m. | negotiable | |

| 5.3 | From corrugated sheet | m2 l.m. | negotiable | |

| 6 | Manufacturing of gratings | |||

| 6.1 | Simple welded | m2 | from 2000 rub. | |

| 6.2 | Swing | m2 | from 4000 rub. | |

| 6.3 | Inflated | m2 | from 3000 rub. | |

| 6.4 | Forged decorative | m2 | from 8000r. | |

| 7 | Manufacturing of fences | including installation | ||

| 7.1 | Simple welded | m2 | from 1500 rub. | |

| 7.2 | Non-standard decorative | m2 | from 3000 rub. | |

| 7.3 | Simple portable | m2 | from 1300 rub. | |

| 8 | Manufacturing of stairs, railings, canopies | The price includes installation. The final price is determined by the product model | ||

| 8.1 | External stairs | – frame – painted steel fences – stainless steel fences | ||

| 8.2 | Technical stairs | -vertical – marching – transitions – platforms and areas | m.p. | |

| 8.3 | Stainless steel railings | m.p. | from 3500 rub. | |

| 8.4 | Wooden railings | m.p. | from 8000r. | |

| 8.5 | Canopies over the entrance | m2 | from 7000 rub. | |

| 8.6 | Polycarbonate canopies | m2 | from 2500 rub. | |

| 9 | Field work of a welder at the customer’s premises | with an order amount of 6000 rubles. | ||

Let's sum it up

Using our article, you can find out how to find out the price of welding work and estimate its volume. Using an easy formula, you will be able to read the price of any type of welding: both arch and contact.

Are you just starting to understand welding? Then a visual assessment and a mathematical formula for calculation will be enough.

But if you weld professionally, then we advise you to combine all existing methods and select them individually. You will be able to determine how much your welding work costs. We wish you success!

Where, how and from whom to order?

If you need to make a welding seam, you should decide whether to do the work yourself or contact a specialist. It will be cheaper to do everything yourself. But for this you need to have electric welding equipment, skills and experience working with it. You can borrow the device from neighbors or friends for a while. It is important to follow safety precautions.

If you have no experience in carrying out electric welding work, then it is better to seek help from professionals. You won't be able to learn welding techniques quickly. Without knowing and not following the technology, you can easily make a serious mistake.

The choice of a welder must be approached responsibly. It is recommended to inquire about the following:

- Does the person have special education and supporting documents?

- How much experience in electric welding does the master have?

- What equipment does the specialist work with?

- What types of welding does the master know?

- Does the master give a guarantee of the quality of the service provided?

- Does the person have regular customers?

- How do customers respond to the welder?

Methods for assessing the welding process

Before performing mathematical calculations, it is necessary to define methods that differ from numerical characteristics. In addition to formulas, there are other methods that will allow you to better understand the entire welding process.

Information is needed not only by those who prepare estimates for their home. When working in production and independently calculating the price of your work, the information described in this article will be useful.