At all times, products carved from various types of wood have been very popular for interior decoration and the manufacture of individual pieces of furniture. Wood turning has always attracted hobbyists who want to show their creative imagination and skill. Modern turning units make it possible to produce individual furniture parts, interior elements, blanks and parts for folk crafts.

Basic principles of turning

The main principle of turning is the optimal combination of two types of movements. The first is rotational, which is produced through the use of an electric motor and gear system, the second is translational, mainly manual, to supply the necessary turning tools. This operating principle is inherent in all types of lathes. It allows you to work with parts of the most complex configurations. Machining on lathes is carried out with the following types of tools:

- chisels;

- reimers;

- Meislers;

- incisors.

Each lathe has its own mounting system. It can be equipped with additional equipment that expands its capabilities for processing various types of wood.

A special tool rest is used to accurately feed the wooden blank. It allows you to install it in the required position while maintaining the required alignment. Correct and high-quality turning is facilitated by a precisely set angle at the roller.

What kind of cutters will be needed for the job?

There are about 15 types of cutters on a standard machine. Each of them is designed to perform a specific turning technique. You cannot use an unsuitable cutter that performs identical functions. This may give effective results, but will lead to equipment failure.

The cutters are the most important part of the mechanim. In manual and automated machines, they are replaced by a specialist with each stroke. The only exceptions are specialized options that can be configured so that the cutter is automatically changed to the required one a step or two ahead. This feature saves a lot of time. Automatic lathes change the cutter automatically, that is, without human intervention. This is very convenient, since there is no risk of injury, especially when testing functionality, and it also saves significant time and resources.

Specialized machines are equipped with several cutters, since they work with a specific shape and type of part. But universal ones are equipped with dozens of cutters with different sizes. In the largest versions there can be 15 varieties, all of different sizes. Kinds:

- straight cutter;

- thrust mechanism;

- bent through cutter;

- cut-off not passable;

- groove cutter;

- boring mechanism;

- countersink;

- drill;

- cutter for carving;

- scan;

- shaped option;

- tap;

- knurling.

Please note that the knurling cutters have a directional arrow indicating how the tooling moves when the workpiece rotates.

Types of turning equipment

Despite the variety of joinery products, all turning operations can be implemented using the following types of units:

- milling;

- turning;

- thicknesser;

- sawing

Milling is used for cutting out profiles and relief elements. To obtain the required shape and specified relief size, a milling cutter of a specific size is used.

A wood lathe allows you to carry out the entire range of turning, cutting recesses, grinding and polishing operations.

A thickness planer is capable of planing workpieces to a given thickness. In addition, depending on the number of knives on the shaft and the degree of their sharpening, it is possible to obtain a surface with a high degree of accuracy.

A sawing machine is necessary for carrying out work related to the preliminary preparation of flat wooden blanks. Sawing can be done along the installed beam or across it while maintaining the texture of the wood.

All woodworking (including turning) units are divided into three categories:

- industrial (used at large woodworking enterprises, furniture factories);

- semi-professional (used in organizations performing work in small quantities);

- household or desktop (used for individual work in home workshops).

The main differences are performance and weight and size characteristics.

Types of jobs

Such units allow the following types of turning work:

- turning of various types;

- grinding;

- cutting off excess part of the workpiece;

- drilling end holes.

Turning has three types:

- longitudinal;

- transverse;

- corner.

Longitudinal turning involves smooth movement of the cutting tool at a constant speed of rotation of the wooden blank. The turning tool moves at low speed parallel to the axis of rotation. Transverse turning is performed as a result of the movement of a turning tool under a certain force perpendicular to the axis of rotation. Angular turning is used to obtain complex shapes. In this case, the tool is directed at a certain angle to the surface of the workpiece. These methods produce the most complex sample shapes. It should be remembered that in order to properly sharpen a wooden workpiece, you should clarify its density, select the spindle rotation speed and the necessary cutting tool.

To work with one of the types of turning, the following methods of tool placement are used:

- lower;

- top;

- straight (perpendicular or at an angle).

By choosing one of the techniques, you can carve a given shape or make the necessary groove at any angle.

Tips for a beginner on how to work on a CNC wood milling machine

The following tips will help beginners quickly master working on a CNC milling machine:

- Purchase several types of high-quality cutters. There is no need to buy entire sets of dubious quality. It is recommended to start with high-speed steel. As soon as you gain experience, it is better to buy carbide cutters.

- Buy a quality vice, a set of parallels and a set of tacks. When processing a part, an important step is securing it. If the part is not properly secured in a vice, it will move during processing. Then the operator will not understand what the problem is.

- If the device does not have coolant, it is recommended to install a fog generator. It's better to take a quality one. It costs more, but will last longer.

- Learn how the CNC controller works. You need to have an idea of what the program does when it starts.

- Work with the axes as much as possible until the work is automated.

- Purchase a cutter measuring tool. Please read the instructions before using it.

- Learn to adjust the vice and the machine itself. It is important to remember that before starting work you need to check the position of the vice.

- Start your work with mild steel; it’s better to leave stainless steel for later.

- Practice on aluminum stepped jaws until the cuts are parallel.

- Explore software. To do this, it is recommended to read not only the help in the software itself, but also study Internet resources.

Beginners in working with CNC machines are recommended to study the instructions in detail and follow only them. Operating such devices is not difficult, but experience is still required. You should pay attention to every error signal. In this case, the machine will last as long as possible.

- November 08, 2020

- 2495

Selection and preparation of workpiece

Wood belongs to the category of ornamental material that allows you to create the most bizarre and spectacular products. The beauty and originality of the crafts made depend on the type of wood chosen, the capabilities of the lathe, the skill level of the craftsman, and the accuracy of the work performed.

Work on a lathe requires careful selection of wooden blanks. Deciduous trees are usually chosen as wood. The most popular are: linden, pear, alder, oak, beech, walnut, and various types of birch. Of the rarest types of wood, red and black are used. However, it should be remembered that the basis of each of the rocks has its own characteristics that must be taken into account when processing. These features include:

- density;

- presence of original texture;

- absence of cracks and knots;

- for coniferous and some deciduous trees, for example, cherry, the absence of so-called tars;

- for coniferous species the presence of external and internal blue.

For beginners, it is advisable to choose for work well-dried blanks that have a solid structure and medium density. They are good for training on the simplest turning equipment. To acquire skills in working with wood, it is advisable to choose a product of simple design.

Wet and dry wood

Wet wood usually processes better. The advantage is not only the simple and quick capture of material, but also the minimal dust formation during operation.

However, the resulting product will undergo major changes over time. Gradual drying can change the shape and size of the object. Rapid drying may even cause cracking.

Unlike fresh wood, when processing dry wood, you can count on stability of shape and final color. However, such turning work is more labor-intensive, but a number of modern devices solve this problem.

The lower availability and higher price of dried wood are also important.

Machine setup

To ensure that the best degree of turning of a wooden blank is obtained, it should be properly configured and the cutting tool should be selected wisely. First of all, you should correctly position the tool rest on a wood lathe. This will optimize the processing process.

Setting up a wood processing machine includes the following operations:

- Secure the prepared blank using the fastening elements of a specific lathe (drive chuck or faceplate).

- Place the tool rest in the center of the workpiece with a gap of about 3 mm.

- For devices with mechanical feed, it is necessary to install a carbon ruler.

- Set the control adjustments to the required position (including spindle speed).

- Select and check the quality of cutting tools.

- Check the serviceability of the external elements of the machine, including the electrical power cable.

- Turn on the machine and check its operation at idle speed.

- If possible, carry out trial processing on a rough workpiece.

The quality of processing and safety depend on the correct configuration and installation of initial modes.

How does a CNC wood cutting machine work?

A CNC machine for wood works according to the following principle:

- First of all, the program intended for processing the object is entered into the control unit of the machine.

- In the main control unit of the device, complete data processing takes place; the control unit prepares all commands for the subsequent movement of the nodes, and then sends them to the drive system.

- The drive controls the movement of the device blocks and the speed of their operation.

- Next, information about the speed of movement of the axes and their position at the moment is recorded. The feedback system is responsible for this. The signal is sent to the control unit.

- In the control block, feedback and initial signals are analyzed and compared. If there are errors, the control unit sends a signal to the actuator, which corrects the operation of the device.

- The control panel and display helps the operator keep track of commands, programs and other important information.

How to secure a workpiece

An important element in processing a wooden workpiece is its correct fastening on the machine. To solve this problem, various devices have been developed that provide reliable fixation of almost any blank. Such devices include:

- driving chuck;

- faceplate.

Each of these devices has certain design features that allow you to securely fasten and hold the part during processing.

To secure the future part in the driving chuck, you should drill a small hole in the center of the end of the workpiece. The central tooth of the cartridge is inserted into this hole and then, using a little force, the remaining teeth are inserted. This fastening ensures strict positioning of the blank relative to the axis of rotation.

The faceplate is made in the form of a round metal disk. In the middle of this disk there is a hole through which it is put on the lathe spindle. There are holes made around the perimeter of the washer through which the workpiece is attached to the faceplate using self-tapping screws. To maintain alignment, it is advisable to pre-mark the center of the future part.

How to work on a CNC wood cutting machine?

Operating a CNC machine is not difficult. The main thing is to become familiar with the main stages of processing.

Part design

Special software (CAD) makes it possible to create parts of three-dimensional models (2D or 3D), which will then be completely assembled. CAD is the optimal program for beginners; it is fully automated, in it you only need to set the exact parameters of the parts.

Programming

CAD software allows you to convert parts into g-code. Working with the software is easy even for a beginner. All stages are described and there are pointers. It is almost impossible to make a mistake, since all deviations are reported in the program.

Machine setup

The setup process consists of the following steps:

- Pre-launch. Before starting the device, you need to make sure that the coolant and oil are filled to the maximum in the reservoirs. At this stage, it is important to carefully study the instructions (especially if setting up for the first time).

- Check for foreign objects in the work area.

- You also need to check whether air is supplied to the device and whether the pressure complies with the standards described in the instructions. To do this, the compressor must be turned on.

- Start. Connect the device to the power supply and start it up. The main switch can be found on the rear panel of the machine. The power button is located on the control panel (in the upper left corner).

- Place the necessary tools into the device. The requirements for the order of tool placement are described in the CNC program. If the machine has one tool, you need to install the cutter in the spindle.

- The part is placed in a vice and fixed on the table, their position is fixed.

- The correction indicator is set according to the length of the tool. The tools are moved to the top of the part (their order is also described in the CNC requirements), and then correction values are set.

- The directions of the X and Y axes are corrected. After installing the parts and vice, the workpiece correction is adjusted to find the starting points of X and Y.

- Load the CNC program into the control system. This happens using a flash drive.

Manufacturing of parts

The direct process of manufacturing parts begins after setting up the device. Production includes several steps:

- Trial production. Start the production program in the air (you need to step back approximately 5 cm from the part).

- Start the main program. At this stage, it is important to ensure that the device does not generate error signals.

- After startup, the offset is adjusted according to the CNC requirements. You need to check the details of the part. If necessary, adjust the tool length correction. This step is necessary to check if the part meets the specifications.

- End of work. Once production is complete, the part is removed from the vice and the tools are removed from the spindle. The work area is inspected and cleaned, the machine is turned off and disconnected from power.

Safety precautions at work

Working on a lathe, regardless of experience, requires compliance with established safety rules. It doesn’t matter whether a beginner turner or a sophisticated professional is working. All safety regulations can be divided into the following categories:

- requirements for the workpiece;

- correct fixation of the blank and the procedure for turning on the machine;

- tool preparation;

- preparation of personal protective equipment.

The first category of requirements includes:

- check the integrity of the workpiece;

- no obvious defects;

- humidity level;

- compliance with the requirements for the shape of the blank (this will eliminate runout of the part).

The second list is related to work rules. Before turning on the turning unit, you must read the instructions. It describes the sequence of preliminary work, the order of switching on, operating rules and possible malfunctions. In addition, the instructions, depending on the installed fixing device, contain recommendations for the correct installation and fastening of the blank. The main requirements for turning work are:

- securely fix the blank;

- check the integrity of the power cable (it supplies high voltage to the engine);

- serviceability of the grounding cable;

- all controls must be set to their original positions;

- there should be no debris or unnecessary objects on the bed and surface of the machine;

- During turning operations, chips should be removed gradually in a thin layer (it is necessary to avoid deep penetration of the tool into the workpiece, otherwise it may be destroyed, which will lead to fragments getting on your hands and eyes);

- It is advisable to press the elbow tightly to the body (this will create additional support, allowing for improved fixation of the instrument).

All tools that are planned to be used during work must be in good condition. Handles should not have cracks or obvious defects. The cutting edge must be sharpened according to the rules.

Before starting work, you should take care of personal protective equipment. These include: a protective gown, a hat and safety glasses. Having personal protective equipment will help avoid injuries.

Lathe cutting tool

The efficiency that distinguishes work on a lathe is determined by a number of parameters: cutting depth and speed, the amount of longitudinal feed. In order for the processing of a part to be of high quality, it is necessary to organize the following conditions:

- high rotation speed of the workpiece fixed in a chuck or faceplate;

- stability of the tool and a sufficient degree of its impact on the part;

- the maximum possible layer of metal removed during the passage of the tool;

- high stability of all machine components and maintaining them in working condition.

The cutting speed is selected based on the characteristics of the material from which the workpiece is made, the type and quality of the cutter used. In accordance with the selected cutting speed, the rotation speed of the machine spindle equipped with a lathe chuck or faceplate is selected.

Using various types of cutters, roughing or finishing types of turning work can be performed, and the choice of tool is mainly influenced by the nature of the processing. By changing the geometric parameters of the cutting part of the tool, you can adjust the size of the removed metal layer. There are right cutters, which move from the tailstock to the headstock during the processing of the part, and left cutters, which move, respectively, in the opposite direction.

Main types of turning tools

According to the shape and location of the blade, cutters are classified as follows:

- tools with an extended working part, the width of which is less than the width of their fastening part;

- straight;

- bent.

Cutters also differ according to their purpose of use:

- scoring (processing surfaces perpendicular to the axis of rotation);

- pass-through (turning flat end surfaces);

- groove (formation of grooves);

- shaped (receiving a part with a certain profile);

- boring (boring holes in the workpiece);

- threaded (thread cutting of all types);

- cutting (cutting off a part of a given length).

The quality, accuracy and productivity of processing performed on a lathe depend not only on the correct choice of tool, but also on its geometric parameters. That is why in lessons in special educational institutions where future turning specialists are trained, a lot of attention is paid to the geometry of the cutting tool.

Turning tool angles

The main geometric parameters of any cutter are the angles between its cutting edges and the direction in which the feed is carried out. These angles of the cutting tool are called leading angles. Among them are:

- main angle – φ, measured between the main cutting edge of the tool and the feed direction;

- auxiliary – φ1, located, respectively, between the auxiliary edge and the feed direction;

- the angle at the tip of the cutter is ε.

The angle at the tip depends only on how the tool is sharpened, and the auxiliary angles can also be adjusted by installing it. As the main angle increases, the apex angle decreases, and the part of the cutting edge involved in processing decreases; accordingly, the tool life also becomes shorter. The smaller the value of this angle, the larger part of the cutting edge is involved both in processing and in removing heat from the cutting zone. Such cutters are more durable.

Practice shows that for turning not too rigid workpieces of small diameter, the optimal main angle is the value of which is in the range of 60–90 degrees. If you need to process a workpiece of large diameter, then the main angle must be selected in the range of 30–45 degrees. The strength of the tip of the cutter depends on the size of the auxiliary angle, so it is not made large (as a rule, it is selected from the range of 10–30 degrees).

Particular attention in turning lessons is paid to how to choose the right type of cutter depending on the type of processing. Thus, there are certain rules according to which the processing of surfaces of one type or another is carried out using a cutter of a certain category.

- Conventional straight and bent cutters are necessary for processing the outer surfaces of the part.

- A thrust tool will be required for end and cylindrical surfaces.

- A parting cutter is chosen for making grooves and trimming the workpiece.

- Boring cutters are used to machine previously drilled holes.

A separate category of turning tools consists of cutters, with which you can process shaped surfaces with a generatrix line length of up to 40 mm. Such cutters are divided into several main types:

- by design features: rod, round and prismatic;

- in the direction in which the product is processed: radial and tangential.

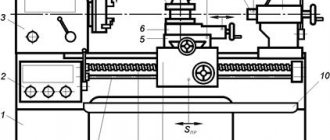

Screw-cutting lathe 1V625MP