The range of rolled metal products produced by modern industry is so large that it is easy to get confused. The number of state standards regulating the production of various metal products exceeds the number of their varieties several times. In order to simplify the search for the required information, directories of rolled metal products are created.

In this material we will talk about the most popular types of products, indicate the main state standards related to them, and lightly touch on the parameters that influence their choice.

Rolled metal assortment: popular types of products and weight calculation algorithms

Being in a high-rise building, on the deck of a ship, on board a liner, few people evaluate the strength of the structure - comfort is important. But without a metal base in the form of a frame, sheets, channels, and reinforcement, these structures simply would not exist. You can’t do without processed metal products in everyday life: roofing, communication pipes, gratings, etc. The range of rolled metal products is numerous and varied. What rolled metal and how to choose products of the right size will be discussed in the article. Metal corner: range, weight, characteristics, GOST standards (read more)

A range of rolled metal products is a list of products classified by type.

Advantages and disadvantages

Rolled metal has the following advantages:

- High strength characteristics, wear resistance, long service life - the use of rolled metal allows you to create reliable and durable buildings, structures, machines and mechanisms.

- Ease of processing - working with rolled products is facilitated by the use of welding, cutting, bending, and drilling.

- Compatibility with other materials = concrete, wood, plastic, which allows the production of products with high consumer characteristics.

- Standardization - the characteristics of rolled products are regulated by GOSTs, which facilitates product quality control and simplifies engineering calculations.

- Wide assortment - a large number of types of rolled products and their standard sizes allows you to select products for any application conditions.

The disadvantages of rolled metal include a tendency to corrosion and relatively high weight. The first disadvantage is minimized by the use of protective coatings, the second by the correct choice of types, standard sizes of rolled products and the use of construction equipment.

Definition of rolled metal: what does the metal assortment include?

The word "assortment" is of French origin. True, the sound is somewhat distorted (French - assortir), but the essence is identical: select, sort. Consequently, an assortment is a list of any selected products, combined by variety, type. Most often this concept is used in the metallurgical industry to designate a set of rolled metal products. To understand how the range of metal products is formed, it is necessary to understand the question of what rolled metal is.

The range of rolled metal products is formed according to three indicators: size, section shape and characteristics.

The metal passes through rolls on a special device (mill) and acquires a certain size and shape. This process is called rolling.

There are three rolling methods:

- hot;

- warm;

- cold.

They vary depending on the presence and degree of thermal effect on the metal. There are several types of rolling mills: pipe rolling, sheet, crimping, for special types of rolled products, billets.

Based on the above, we can define the range of rolled metal products. A range of rolled metal products is a list of rolled profiles that contains a description of their qualities and sizes.

The product range is divided into three main groups: long and packaged products, sheet and pipe products.

When forming the assortment, three indicators are taken into account:

- section shape (profile);

- dimensions;

- chemical and physical characteristics.

There are three main groups of rolled products:

- rolled sheets;

- long and shaped rolled products;

- pipe products.

To summarize information about the types of products and their characteristics, directories of rolled metal products are created. It is there that the consumer can get acquainted with the full list of products and their qualities and choose the desired option.

To familiarize yourself with the entire list of products, you need to study the rolled metal directory.

What is most valued on the market

In the world of modern technology, the counter is overflowing with an abundance of parts, but the most in demand are:

- sheet metals;

- beams;

- pipes;

- corners.

The buyer always carefully chooses the manufacturer. After all, price, quality and warranty periods depend on the reputation of the enterprise. Products from China are not always durable; they attract some customers only with a price (below the market price). But after purchasing, you may encounter the problem of low-quality goods and lost money.

What to do to buy high-quality rolled metal of the correct classification

It is necessary to contact trusted companies.

Products must comply with all established norms, standards and GOST requirements. All of them are certified according to the following parameters:

- size, length, assortment;

- chemical composition of steel, alloys;

- compliance with technical conditions during production.

So, what is rolled metal, types of rolled metal, their grade classification, photos and pictures you found in our article.

Contact Rosta LLC if you decide to buy devices for industrial use. We have manual and semi-automatic band saws in stock and on order, as well as pendulum, vertical and two-post units. To clarify the information you are interested in, contact the managers by phone;; 8 (800) 707-53-38. They will answer all your questions.

Characteristics and features of pipe products

Pipes are a fairly common category of rolled products. Main characteristics of these products:

- total length;

- wall thickness;

- internal and external diameters;

- type of material;

- preparation method.

Most pipe products are round, but square and flat pipes are also produced. There are several manufacturing methods:

- rolling;

- pressing;

- casting;

- welding.

The main part of metal pipe products has a round cross-section.

Depending on the specifics of the manufacturing process, pipes can be seamless or welded. Seamless ones are used for transporting gases and liquids under pressure above 1 MPa. Welded pipes are created by folding a strip (rolled strip), laying it end-to-end and overlapping, and welding the seam. These products are used to move gases and liquids at low pressure.

Steel pipe: GOST, diameter, weight, wall thickness (read more)

Requirements for pipe products are regulated by the following documents:

- GOST 10705-80 – electric welded pipes;

- GOST 10704-91 – straight-seam products;

- GOST 8732-78 – seamless pipes;

- GOST 3262-75 (TU) – water and gas pipelines;

- GOST 8645-68 – rectangular profiles;

- GOST 8639-82 – square profiles.

Pipes are used in the gas and oil industries, mechanical engineering, and construction. They are used for laying various pipelines, for the manufacture of industrial cylinders and vessels.

GOST 10704-91 (Long-seam electric-welded steel pipes)

Home->Directory->GOSTs, TUs and OSTs of rolled metal products->GOSTs

GOST 19903-74 (Hot rolled sheet products. Assortment) GOST 9583-75 (Cast iron pressure pipes manufactured by centrifugal semi-continuous casting methods. Technical conditions)

>

STATE STANDARD OF THE USSR UNION

| ELECTRIC-WELDED STRAIGHT-WELMED STEEL PIPES Assortment Electrically welded steel line-weld lubes. Range | GOST 10704-91 |

Date of introduction 01/01/93

1. This standard establishes the range of steel electric-welded straight-seam pipes.

2. The dimensions of the pipes must correspond to table 1.

3. According to the length of the pipe, they are made: of unmeasured length:

with a diameter of up to 30 mm - at least 2 m;

with a diameter of St. 30 to 70 mm - at least 3 m;

with a diameter of St. 70 to 152 mm - at least 4 m;

with a diameter of St. 152 mm - not less than 5 m.

At the request of the consumer, pipes of groups A and B according to GOST 10705 with a diameter of over 152 mm are manufactured with a length of at least 10 m; pipes of all groups with a diameter of up to 70 mm - a length of at least 4 m;

measured length:

with a diameter of up to 70 mm - from 5 to 9 m;

with a diameter of St. 70 to 219 mm - from 6 to 9 m;

with a diameter of St. 219 to 426 mm - from 10 to 12 m.

Pipes with a diameter over 426 mm are manufactured only in unmeasured lengths. By agreement between the manufacturer and the consumer, pipes with a diameter of over 70 to 219 mm can be manufactured from 6 to 12 m;

a multiple length of at least 250 mm and not exceeding the lower limit established for measuring pipes. The allowance for each cut is set to 5 mm (unless another allowance is specified) and is included in each multiplicity.

Table 1

| External diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | ||||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | 3,0 | |

| 10 | 0,222 | 0,260 | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ |

| 10,2 | 0,227 | 0,266 | — | — | — | — | — | — | — | — | — |

| 12 | 0,271 | 0,320 | 0,366 | 0,388 | 0,410 | — | — | — | — | — | — |

| 13 | 0,296 | 0,349 | 0,401 | 0,425 | 0,450 | — | — | — | — | — | — |

| 14 | 0,321 | 0,379 | 0,435 | 0,462 | 0,489 | — | — | — | — | — | — |

| (15) | 0,345 | 0,408 | 0,470 | 0,499 | 0,529 | — | — | — | — | — | — |

| 16 | 0,370 | 0,438 | 0,504 | 0,536 | 0,568 | — | — | — | — | — | — |

| (17) | 0,395 | 0,468 | 0,539 | 0,573 | 0,608 | — | — | — | — | — | — |

| 18 | 0,419 | 0,497 | 0,573 | 0,610 | 0,719 | 0,789 | — | — | — | — | — |

| 19 | 0,444 | 0,527 | 0,608 | 0,647 | 0,687 | 0,764 | 0,838 | — | — | — | — |

| 20 | 0,469 | 0,556 | 0,642 | 0,684 | 0,726 | 0,808 | 0,888 | — | — | — | — |

| 21,3 | 0,501 | 0,595 | 0,687 | 0,732 | 0,777 | 0,866 | 0,952 | — | — | — | — |

| 22 | 0,518 | 0,616 | 0,711 | 0,758 | 0,805 | 0,897 | 0,986 | — | — | — | — |

| (23) | 0,543 | 0,645 | 0,746 | 0,795 | 0,844 | 0,941 | 1,04 | 1,13 | 1,26 | ¾ | — |

| 24 | 0,567 | 0,675 | 0,780 | 0,832 | 0,884 | 0,985 | 1,09 | 1,18 | 1,33 | — | — |

| 25 | 0,592 | 0,704 | 0,815 | 0,869 | 0,923 | 1,03 | 1,13 | 1,24 | 1,39 | — | — |

| 26 | 0,617 | 0,734 | 0,849 | 0,906 | 0,963 | 1,07 | 1,18 | 1,29 | 1,45 | — | |

| 27 | 0,641 | 0,764 | 0,884 | 0,943 | 1,00 | 1,12 | 1.23 | 1,35 | 1,51 | — | |

| 28 | 0,666 | 0,793 | 0,918 | 0,980 | 1,04 | 1,16 | 1,28 | 1,40 | 1,57 | — | |

| 30 | 0,715 | 0,852 | 0,987 | 1,05 | 1,12 | 1,25 | 1,38 | 1,51 | 1,70 | — | |

| 32 | 0,765 | 0,911 | 1,06 | 1,13 | 1,20 | 1,34 | 1,48 | 1,62 | 1,82 | 2,02 | |

Continuation of the table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | |

| 33 | 0,789 | 0,941 | 1,09 | 1,17 | 1,24 | 1,38 | 1,53 | 1,67 | 1,88 | 2,09 |

| 33,7 | — | 0,962 | 1,12 | 1,19 | 1,27 | 1,42 | 1,56 | 1,71 | 1,92 | 2,13 |

| 35 | — | 1,00 | 1,16 | 1,24 | 1,32 | 1,47 | 1,63 | 1,78 | 2,00 | 2,22 |

| 36 | — | 1,03 | 1,19 | 1,28 | 1,36 | 1,52 | 1,68 | 1,83 | 2,07 | 2,29 |

| 38 | — | 1,09 | 1,26 | 1,35 | 1,44 | 1,61 | 1,78 | 1,94 | 2,19 | 2,43 |

| 40 | — | 1,15 | 1,33 | 1,42 | 1,52 | 1,70 | 1,87 | 2,05 | 2,31 | 2,57 |

| 42 | — | 1,21 | 1,40 | 1,50 | 1,59 | 1,78 | 1,97 | 2,16 | 2,44 | 2,71 |

| 44,5 | — | 1,28 | 1,49 | 1,59 | 1,69 | 1,90 | 2,10 | 2,29 | 2,59 | 2,88 |

| 45 | — | 1,30 | 1,51 | 1,61 | 1,71 | 1,92 | 2,12 | 2,32 | 2,62 | 2,91 |

| 48 | — | — | 1,61 | 1,72 | 1,83 | 2,05 | 2,27 | 2,48 | 2,81 | 3,12 |

| 48,3 | — | — | 1,62 | 1,73 | 1,84 | 2,06 | 2,28 | 2,50 | 2,82 | 3,14 |

| 51 | — | — | 1,71 | 1,83 | 1,95 | 2,18 | 2,42 | 2,65 | 2,99 | 3,33 |

| 53 | — | — | 1,78 | 1,91 | 2,03 | 2,27 | 2,52 | 2,76 | 3,11 | 3,47 |

| 54 | — | — | 1,82 | 1,94 | 2,07 | 2,32 | 2,56 | 2,81 | 3,18 | 3,54 |

| 57 | — | — | 1,92 | 2,05 | 2,19 | 2,45 | 2,71 | 2,97 | 3,36 | 3,74 |

| 60 | — | — | 2,02 | 2,16 | 2,30 | 2,58 | 2,86 | 3,14 | 3,55 | 3,95 |

| 63,5 | — | — | 2,14 | 2,29 | 2,44 | 2,74 | 3,03 | 3,33 | 3,76 | 4,19 |

| 70 | — | — | 2,37 | 2,53 | 2,70 | 3,03 | 3,35 | 3,68 | 4,16 | 4,64 |

Continuation of the table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | |

| 73 | ¾ | ¾ | 2,47 | 2,64 | 2,82 | 3,16 | 3,50 | 3,84 | 4,35 | 4,85 |

| 76 | — | — | 2,58 | 2,76 | 2,94 | 3,29 | 3,65 | 4,00 | 4,53 | 5,05 |

| 88 | — | — | — | — | 3,21 | 3,60 | 4,00 | 4,38 | 4,96 | 5,54 |

| 89 | — | — | — | — | 3,45 | 3,87 | 4,29 | 4,71 | 5,33 | 5,95 |

| 95 | ¾ | — | — | — | — | — | 4,59 | — | 5,70 | — |

| 102 | ¾ | ¾ | ¾ | — | — | 4,45 | 4,93 | 5,41 | 6,13 | 6,85 |

| 108 | ¾ | — | — | — | — | 4,71 | 5,23 | 5,74 | 6,50 | 7,26 |

| 114 | — | — | — | — | — | 4,98 | 5,52 | 6,07 | 6,87 | 7,68 |

| 127 | — | — | — | — | — | 5,56 | 6,17 | 6,77 | 7,68 | 8,58 |

| 133 | — | — | — | — | — | 5,82 | 6,46 | 7,10 | 8,05 | 8,99 |

| 140 | — | — | — | — | — | 6,13 | 6,81 | 7,48 | 8,48 | 9,47 |

| 152 | ¾ | — | — | — | — | 6,67 | 7,40 | 8,13 | 9,22 | 10,30 |

| 159 | — | — | — | — | — | 6,98 | 7,74 | 8,51 | 9,65 | 10,79 |

| 168 | — | — | — | — | — | 7,38 | 8,19 | 9,00 | 10,20 | 11,41 |

| 177,8 | — | — | — | — | — | 7,81 | 8,67 | 9,53 | 10,81 | 12.08 |

| 180 | — | — | — | — | — | — | — | — | — | — |

| 193,7 | — | — | — | — | — | — | 9,46 | 10,39 | 11,79 | 13,18 |

| 219 | — | — | — | — | — | — | — | — | 13,35 | 14,93 |

| 244,5 | — | — | — | — | — | — | — | — | — | — |

Continuation of the table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | ||||||||||

| 3,0 | 3,2 | 3,5 | 3,8 | 4,0 | 4,5 | 5,0 | 5,5 | 6,0 | 7,0 | 8,0 | |

| 26 | — | — | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ |

| 27 | — | — | — | — | — | — | — | — | — | — | — |

| 28 | — | — | — | — | — | — | — | — | — | — | — |

| 30 | — | — | — | — | — | — | — | — | — | — | — |

| 32 | 2,15 | — | — | — | — | — | — | — | — | — | — |

| 33 | 2,22 | — | — | — | — | — | — | — | — | — | — |

| 33,7 | 2,27 | — | — | — | — | — | — | — | — | — | — |

| 35 | 2,37 | — | — | — | — | — | — | — | — | — | — |

| 36 | 2,44 | — | — | — | — | — | — | — | ¾ | ¾ | ¾ |

| 38 | 2,59 | — | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ |

| 40 | 2,74 | — | — | — | — | — | ¾ | ¾ | ¾ | ¾ | ¾ |

| 42 | 2,89 | — | — | — | — | — | — | — | — | — | ¾ |

| 44,5 | 3,07 | — | — | — | — | — | — | — | — | — | — |

| 45 | 3,11 | — | — | — | — | — | — | — | — | — | ¾ |

| 48 | 3,33 | 3,54 | 3,84 | — | — | — | — | — | — | — | — |

| 48,3 | 3,35 | 3,56 | 3,87 | — | — | — | — | — | — | — | — |

| 51 | 3,55 | 3,77 | 4,10 | — | — | — | — | — | — | — | — |

| 53 | 3,70 | 3,93 | 4,27 | — | — | — | — | — | — | — | — |

| 54 | 3,77 | 4,01 | 4,36 | — | — | — | — | — | — | — | — |

Continuation of the table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||||

| 3,0 | 3,2 | 3,5 | 3,8 | 4,0 | 4,5 | 5,0 | 5,5 | 6,0 | 7,0 | 8,0 | 9,0 | |

| 57 | 4,00 | 4,25 | 4,62 | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ | ¾ |

| 60 | 4,22 | 4,48 | 4,88 | 5,27 | — | — | — | — | — | — | — | — |

| 63,5 | 4,48 | 4,76 | 5,18 | 5,59 | — | — | — | — | — | — | — | — |

| 70 | 4,96 | 5,27 | 5,74 | 6,20 | 6,51 | — | — | — | — | — | — | — |

| 73 | 5,18 | 5,51 | 6,00 | 6,48 | 6,81 | — | — | — | — | — | — | — |

| 76 | 5,40 | 5,75 | 6,26 | 6,26 | 7,10 | 7,93 | 8,75 | 9,56 | ¾ | — | — | — |

| 83 | 5,92 | 6,30 | 6,86 | 7,42 | 7,79 | 8,71 | 9,62 | 10,51 | — | — | — | — |

| 89 | 6,36 | 6,77 | 7,38 | 7,98 | 8,38 | 9,38 | 10,36 | 11,33 | — | — | — | — |

| 95 | — | 7,24 | — | — | — | — | 11,10 | — | — | — | — | — |

| 102 | 7,32 | 7,80 | 8,50 | 9,20 | 9,67 | 10,82 | 11,96 | 13,09 | — | — | — | — |

| 108 | 7,77 | 8,27 | 9,02 | 9,76 | 10,26 | 11,49 | 12,70 | 13,90 | — | — | — | — |

| 114 | 8,21 | 8,74 | 9,54 | 10,33 | 10,85 | 12,15 | 13,44 | 14,72 | — | — | — | — |

| 127 | 9,17 | 9,77 | 10,66 | 11,55 | 12,13 | 13,59 | 15,04 | 16,48 | — | — | — | — |

| 133 | 9,62 | 10,24 | 11,18 | 12,11 | 12,73 | 14,26 | 15,78 | 17,29 | — | — | — | — |

| 140 | 10,14 | 10,80 | 11,78 | 12,76 | 13,42 | 15,04 | 16,65 | 18,24 | — | — | — | — |

| 152 | 11,02 | 11,74 | 12,82 | 13,89 | 14,60 | 16,37 | 18,13 | 19,87 | — | — | — | — |

| 159 | 11,54 | 12,30 | 13,42 | 14,52 | 15,29 | 17,15 | 18,99 | 20,82 | 22,64 | 26,24 | 26,24 | — |

| 168 | 12,21 | 13,01 | 14,20 | 15,39 | 16,18 | 18,14 | 20,10 | 22,04 | 23,97 | 27,79 | 31,57 | — |

| 177,8 | 12,93 | 13,78 | 15,04 | 16,31 | 17,14 | 19,23 | 21,31 | 23,37 | 25,42 | 29,49 | 33,50 | — |

| 180 | — | — | — | — | 17,36 | — | 21,58 | — | — | — | — | — |

| 193,7 | 14,11 | 15,03 | 16,42 | 17,80 | 18,71 | 21,00 | 23,27 | 25,53 | 27,77 | 32,23 | 36,64 | — |

| 219 | 15,98 | 17,03 | 18,60 | 20,17 | 21,21 | 23,80 | 26,39 | 28,96 | 31,52 | 36,60 | 41,63 | 46,61 |

| 244,5 | 17,87 | 19,04 | 20,80 | 22,56 | 23,72 | 26,63 | 29,53 | 32,42 | 35,42 | 41,00 | 46,66 | 52,27 |

| 273 | — | — | 23,26 | 25,23 | 26,54 | 29,80 | 23,05 | 36,28 | 39,51 | 45,92 | 52,28 | 58,60 |

Continuation of the table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 3,5 | 3,8 | 4,0 | 4,5 | 5,0 | 5,5 | 6,0 | 7,0 | 8,0 | 9,0 | |

| 325 | ¾ | ¾ | 31,67 | 35,57 | 39,46 | 43,34 | 47,20 | 54,90 | 62,54 | 70,14 |

| 355,6 | — | — | 34,68 | 38,96 | 43,23 | 47,49 | 51,73 | 60,18 | 68,58 | 76,93 |

| 377 | — | — | 36,79 | 41,34 | 45,87 | 50,39 | 54,90 | 63,87 | 72,80 | 81,68 |

| 406,4 | — | — | 39,70 | 44,60 | 49,50 | 54,38 | 59,25 | 68,95 | 78,60 | 88,20 |

| 426 | — | — | 41,63 | 46,78 | 51,91 | 57,04 | 62,15 | 72,33 | 82,47 | 92,55 |

| (478) | — | — | — | — | 58,32 | 64,09 | 69,84 | 81,31 | 92,73 | 104,10 |

| 530 | — | — | — | — | 64,74 | 71,14 | 77,54 | 90,29 | 102,99 | 115,64 |

| 630 | — | — | — | — | — | — | — | 107,55 | 122,72 | 137,83 |

| 720 | — | — | — | — | — | — | — | 123,09 | 140,47 | 157,81 |

| 820 | — | — | — | — | — | — | — | 140,35 | 160,20 | 180,00 |

| 920 | — | — | — | — | — | — | — | 157,61 | 179,93 | 202,20 |

| 1020 | — | — | — | — | — | — | — | — | 199,66 | 224,39 |

| 1120 | — | — | — | — | — | — | — | — | 219,39 | 246,59 |

| 1220 | — | — | — | — | — | — | — | — | — | 268,79 |

| 1420 | — | — | — | — | — | — | — | — | — | — |

Continuation of the table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | ||||||||||

| 10 | 11 | 12 | 13 | 14 | 16 | (17) | 17,5 | 18 | 19 | 20 | |

| 325 | ¾ | — | — | — | — | — | — | — | — | — | — |

| 355,6 | 85,23 | — | — | — | — | — | — | — | — | — | — |

| 377 | 90,51 | — | — | — | — | — | — | — | — | — | — |

| 406,4 | 97,76 | 107,26 | 116,72 | — | — | — | — | — | — | — | — |

| 426 | 102,59 | 112,58 | 122,52 | — | — | — | — | — | — | — | — |

| (478) | 115,42 | 126,69 | 137,91 | — | — | — | — | — | — | — | — |

| 530 | 128,24 | 140,79 | 153,30 | 165,75 | 178,15 | 202,82 | 215,07 | 221,18 | 227,28 | 239,44 | 251,55 |

| 630 | 152,90 | 167,92 | 182,89 | 197,81 | 212,68 | 242,27 | 257,00 | 264,34 | 271,67 | 286,30 | 300,87 |

| 720 | 175,10 | 192,33 | 209,52 | .226,66 | 243,75 | 277,79 | 294,73 | 303,18 | 311,62 | 328,47 | 345,26 |

| 820 | 199,76 | 219,46 | 239,12 | 258,72 | 278,28 | 317,25 | 336,65 | 346,34 | 356,01 | 375,32 | 394,58 |

| 920 | 224,42 | 246,59 | 268,71 | 290,78 | 312,81 | 356,70 | 378,58 | 389,50 | 400,40 | 422,18 | 443,91 |

| 1020 | 249,08 | 273,72 | 298,31 | 322,84 | 347,33 | 396,16 | 420,50 | 432,65 | 444,79 | 469,04 | 493,23 |

| 1120 | 273.74 | 300,85 | 327,90 | 354,90 | 381,86 | 435,62 | 462,43 | 475,81 | 481,19 | 515,89 | 542,55 |

| 1220 | 298,40 | 327,97 | 357,49 | 386,96 | 416,38 | 475,08 | 504,35 | 518,97 | 533,58 | 562,75 | 591,88 |

| 1420 | 347,73 | 382,23 | 416,68 | 451,08 | 485,44 | 554,00 | 588,20 | 605,29 | 622,36 | 656,46 | 690,52 |

Continuation of the table. 1

| Outer diameter, mm | Theoretical weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||||

| 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | |

| 530 | 263,61 | 275,62 | 287,58 | 299,49 | — | — | — | — | — | — | ¾ | — |

| 630 | — | — | — | — | — | — | — | — | — | — | ¾ | — |

| 720 | 362,01 | 378,70 | 395,35 | 411,95 | 411,95 | 428,49 | 444,99 | 461,44 | 477,84 | 510,49 | — | — |

| 820 | 413,79 | 432,96 | 452,07 | 471,13 | 490,15 | 509,11 | 528,03 | 546,89 | 565,71 | 584,48 | — | — |

| 920 | — | — | — | — | — | — | — | — | — | — | ¾ | — |

| 1020 | 517,37 | 541,47 | 565,51 | 589,51 | 613,45 | 637,35 | 661,20 | 685,00 | 708,75 | 732,45 | 756,10 | 779,70 |

| 1120 | — | — | — | — | — | — | — | — | — | — | — | — |

| 1220 | — | — | — | — | — | — | — | — | — | — | — | — |

| 1420 | — | — | — | — | — | — | — | — | — | — | — | — |

Notes:

1. When manufacturing pipes in accordance with GOST 10706, the theoretical weight increases by 1% due to the strengthening of the seam.

2. By agreement between the manufacturer and the consumer, pipes with dimensions of 41.5´1.5-3.0 are manufactured; 43´1.0; 1.53.0; 43.5´1.5-3.0; 52´2.5; 69.6´1.8; 111.8´2.3; 146.1´5.3; 6.5; 7.0; 7.7; 8.5; 9.5; 10.7; 152.4´1.9; 2.65; 168´2.65; 177.3´1.9; 198´2.8; 203´2.65; 299´4.0; 530´7.5; 720´7.5; 820´8.5; 1020´9.5; 15.5; 1220´13.5; 14.6; 15.2 mm, as well as with intermediate wall thickness and diameters within the limits of the table. 1.

3. Pipe sizes enclosed in brackets are not recommended for new design.

3.1. Pipes of measured and multiple lengths are manufactured in two length accuracy classes:

I - with cutting ends and deburring;

II - without facing and deburring (with cutting in the mill line).

3.2. Maximum deviations along the length of measuring pipes are given in table. 2.

table 2

| Pipe length, m | Maximum deviations along the length of measuring pipes, mm, classes | |

| I | II | |

| Up to 6 incl. | +10 | +50 |

| St. 6 | +15 | +70 |

3.3. Maximum deviations along the total length of multiple pipes should not exceed:

+ 15 mm - for pipes of class I accuracy;

+ 100 mm - for pipes of class II accuracy.

3.4. At the request of the consumer, pipes of measured and multiple lengths of class II accuracy must have ends with pointed ends on one or both sides.

4. Maximum deviations for the outer diameter of the pipe are given in table. 3.

Table 3

| Outer diameter of pipes, mm | Limit deviations in outer diameter with precision manufacturing | |

| ordinary | increased | |

| 10 | ±0.2 mm | ¾ |

| From 10 to 30 incl. | ±0.3 mm | ±0,25 |

| » 30 » 51 » | ±0.4 mm | ±0,35 |

| » 51 » 193,7 » | ±0,8% | ±0,7% |

| » 193,7 » 426 » | ±0,75% | ±0,65% |

| » 426 » 1020 » | ±0,7% | ±0,65% |

| » 1020 | ±0,6% | ±6.0 mm |

Note.

For diameters controlled by perimeter measurements, the largest and smallest perimeter limits are rounded to the nearest 1 mm.

5. At the request of the consumer, pipes in accordance with GOST 10705 are manufactured with a one-sided or offset tolerance on the outer diameter. One-sided or shifted tolerance should not exceed the sum of the maximum deviations given in table. 3.

6. Maximum deviations in wall thickness must correspond to:

± 10% - for pipe diameters up to 152 mm;

GOST 19903 - for pipe diameters over 152 mm for the maximum sheet width of normal accuracy.

By agreement between the consumer and the manufacturer, it is allowed to manufacture pipes with a one-sided tolerance for wall thickness, while the one-sided tolerance should not exceed the sum of the maximum deviations for wall thickness.

7. For pipes with a diameter of over 76 mm, a thickening of the wall at the burr by 0.15 mm is allowed.

8. Pipes for pipelines with a diameter of 478 mm and more, manufactured in accordance with GOST 10706, are supplied with maximum deviations for the outer diameter of the ends given in table. 4.

Table 4

mm

| Pipe outer diameter | Maximum deviations in the outer diameter of the ends for manufacturing accuracy | |

| increased | ordinary | |

| From 478 to 720 incl. | ±1,5 | ±2,5 |

| St. 720 » 1020 » | ±2,0 | ±2,5 |

| » 1020 | ±3,5 | ±4,0 |

9. The out-of-roundness and uniformity of pipes with a diameter of up to 530 mm inclusive, manufactured in accordance with GOST 10705, must be no more than the maximum deviations for the outer diameter and wall thickness, respectively.

Pipes with a diameter of 478 mm or more, manufactured in accordance with GOST 10706, must be of three accuracy classes for ovality. The ovality of the pipe ends should not exceed:

1% of the outer diameter of pipes for 1st accuracy class;

1.5% of the outer diameter of pipes for 2nd accuracy class;

2% of the outer diameter of pipes for 3rd accuracy class.

The ovality of the ends of pipes with a wall thickness of less than 0.01 outer diameter is established by agreement between the manufacturer and the consumer.

10. The curvature of pipes manufactured according to GOST 10705 should not exceed 1.5 mm per 1 m of length. At the request of the consumer, the curvature of pipes with a diameter of up to 152 mm should be no more than 1 mm per 1 m of length.

The total curvature of pipes manufactured in accordance with GOST 10706 should not exceed 0.2% of the pipe length. The curvature per 1 m length of such pipes is not determined.

11. Technical requirements must comply with GOST 10705 and GOST 10706.

Examples of symbols:

Pipe with an outer diameter of 76 mm, a wall thickness of 3 mm, measured length, class II length accuracy, made of St3sp steel, manufactured according to group B of GOST 10705-80:

The same, increased accuracy in outer diameter, length, multiple of 2000 mm, 1st accuracy class in length, from steel grade 20, manufactured according to group B of GOST 10705-80:

Pipe with an outer diameter of 25 mm, a wall thickness of 2 mm, a length multiple of 2000 mm, class II accuracy in length, manufactured according to group D GOST 10705-80;

Pipe with an outer diameter of 1020 mm, increased manufacturing accuracy, wall thickness 12 mm, increased accuracy in the outer diameter of the ends, 2nd class accuracy in ovality, unmeasured length, made of St3sp steel, manufactured according to group B of GOST 10706-76

Note.

In the symbols of pipes that have undergone heat treatment throughout the entire volume, the letter T is added after the words “pipe”; pipes that have undergone local heat treatment of the weld, the letter L is added.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR Ministry of Metallurgy

DEVELOPERS

V. P. Sokurenko,

Ph.D.

tech. sciences; V. M. Vorona,

Ph.D.

tech. Sciences; P. N. Ivshin,

Ph.D.

tech. Sciences; N. F. Kuzenko, V. F. Ganzina

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the Committee of Standardization and Metrology of the USSR dated November 15, 1991 No. 1743

3. INSTEAD GOST 10704-76

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 10705-80 | 3, 5, 9, 11 |

| GOST 10706-76 | 8, 9, 11 |

| GOST 19903-74 | 6 |

5. REPUBLICATION. December 1996

GOST 10006-80 (Metal pipes. Tensile test method) GOST 103-2006 (High-rolled hot-rolled steel strip) GOST 103-76 (Hot-rolled steel strip) GOST 10498-82 (Seamless extra-thin-walled pipes made of corrosion-resistant steel) GOST 1050- 88 (Rolled products, calibrated, with special surface finishing from high-quality carbon structural steel) GOST 1060-83 (Seamless cold-deformed steel pipes for shipbuilding) GOST 10702-78 (Rolled products from high-quality structural carbon and alloy steel for cold extrusion and upsetting) GOST 10704 -91 (Straight-seam electric-welded steel pipes) GOST 10705-80 (Electric-welded steel pipes) GOST 10706-76 (Straight-seam electric-welded steel pipes) GOST 10707-80 (Cold-deformed electric-welded steel pipes) GOST 10884-94 (Reinforcing steel thermomechanically strengthened for reinforced concrete ny designs) GOST 10885-85 (Hot-rolled two-layer corrosion-resistant steel sheet) GOST 11017-80 (High-pressure seamless steel pipes) GOST 11068-81 (Electric-welded pipes made of corrosion-resistant steel) GOST 11249-80 (Folded brazed steel pipes, two-layer) GOST 11268 -76 (rolled thin sheets for special purposes from structural alloyed high-quality steel) GOST 11269-76 (rolled sheets and broadband universal special-purpose from structural alloyed high-quality steel) GOST 1133-71 (Forged round and square steel) GOST 11474-76 (Bent steel profiles ) GOST 11706-78 (Pipes. Test method for ring expansion with a cone) GOST 12004-81 (Reinforcing steel. Tensile test methods) GOST 12132-66 (Electric-welded and seamless steel pipes for the motorcycle industry) GOST 12501-67 (Pipes. Torque test method) GOST 13603-89 ( Twisted wire mesh with hexagonal cells) GOST 13663-86 (Profile steel pipes) GOST 1414-75 (Rolled products from structural steel with high machinability) GOST 14162-79 (Small-sized steel tubes (capillary)) GOST 1435-99 (Rods, strips and coils of tool non-alloy steel) GOST 14637-89 (Rolled thick sheets of carbon steel of ordinary quality) GOST 14918-80 (Thin sheet galvanized steel from continuous lines) GOST 14955-77 (High-quality round steel with special surface finishing) GOST 14959-79 ( Rolled products from spring-spring carbon and alloy steel) GOST 1577-93 (Rolled sheets of thick and broad sheets from structural high-quality steel GOST 16523-97 (Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose) GOST 17066-94 (Rolled thin sheets of high-quality steel strength) GOST 17375-2001 (Seamless welded pipeline parts made of carbon and low-alloy steel. Steeply bent bends type 3D (R~1.5DM) GOST 17376-2001 (Seamless welded pipeline parts made of carbon and low-alloy steel. Tees) GOST 17378-2001 (Seamless welded pipeline parts made of carbon and low-alloy steel. Transitions) GOST 17379-2001 (Parts seamless welded pipelines made of carbon and low-alloy steel. Elliptical plugs) GOST 17380-2001 (Seamless welded pipeline parts made of carbon and low-alloy steel. General technical conditions) GOST 17410-78 (Non-destructive testing. Seamless cylindrical metal pipes) GOST 18968-73 (Rods) and strips made of corrosion-resistant and heat-resistant steel for steam turbine blades) GOST 19040-81 (Metal pipes. Tensile test method at elevated temperatures) GOST 19265-73 (Rods and strips made of high-speed steel) GOST 19277-73 (Seamless steel pipes for oil and fuel lines) GOST 19281-89 (Rolled steel made of high strength) GOST 19282-73 (Low-alloy thick sheet and broadband universal steel) GOST 19425-74 (I-beams and special steel channels. Assortment) GOST 19771-93 (Equal flange bent steel angles. Assortment) GOST 19772-93 (Unequal flange bent steel angles. Assortment) GOST 19903-74 (Hot rolled sheets. Assortment) GOST 19904-90 (Cold rolled sheets. Assortment) GOST 20 072 -74 (Heat-resistant steel) GOST 20295-85 (Welded steel pipes for main gas and oil pipelines) GOST 21729-76 (Structural cold-deformed and heat-deformed pipes from carbon and alloy steels) GOST 21945-76 (Seamless hot-rolled pipes from titanium-based alloys) GOST 22786 -77 (Seamless bimetallic pipes for shipbuilding) GOST 22897-86 (Cold-deformed seamless pipes from titanium-based alloys) GOST 23118-99 (Steel building structures. General technical conditions) GOST 23270-89 (Blank pipes for machining) GOST 23279 -85 (Welded reinforcement mesh for reinforced concrete structures and products) GOST 24030-80 (Seamless pipes made of corrosion-resistant steel for power engineering) GOST 24045-94 (Bent steel sheet profiles with trapezoidal corrugations for construction) GOST 24982-81 (Rolled sheet metal corrosion-resistant heat-resistant and heat-resistant alloys) GOST 25054-81 (Forgings from corrosion-resistant steels and alloys) GOST 25577-83 (Bent closed welded square and rectangular steel profiles) GOST 2590-2006 (High-rolled hot-rolled round steel) GOST 2591- 06 (Rolled hot-rolled square steel) GOST 26020-83 (Hot-rolled steel I-beams with parallel flange edges) GOST 26131-84 (Forgings from heat-resistant and heat-resistant alloys) GOST 2715-75 (Metal mesh) GOST 27772-88 (Rolled steel for construction structures) GOST 28548-90 (Steel pipes. Terms and definitions) GOST 2879-06 (Rolled hot-rolled hexagonal steel. Assortment) GOST 28800-90 (Metal pipes. Method for determining moisture on the inner surface of pipes) GOST 30136-95 (Roll rod made of carbon steel of ordinary quality) GOST 30245-2003 ( Steel bent closed welded square and rectangular profiles for building structures) GOST 30246-94 (rolled thin sheets with protective and decorative paint coating for building structures) GOST 30564-98 (Seamless hot-deformed pipes from carbon and alloy steels with special properties) GOST 30753- 2001 (Seamless welded pipeline parts made of carbon and low-alloy steel. Steeply curved bends type 2D (R~DN)) GOST 3262-75 (Steel water and gas pipes) GOST 3306-88 (Grids with square cells made of steel corrugated wire) GOST 3728-78 ( Pipes. Bend test method) GOST 380-2005 (Ordinary quality carbon steel. Grades) GOST 3836-83 (Electrical steel, non-alloyed, thin sheet and strips) GOST 3845-75 (Metal pipes. Hydraulic pressure test method) GOST 4041-71 (Rolled sheets for cold stamping from high-quality structural steel) GOST 4543-71 (Rolled sheets from alloy structural steel) GOST 5005-82 (Electric-welded cold-formed steel pipes for cardan shafts) GOST 5267.1-90 (Channel bars . Assortment) GOST 5336-80 (Single woven steel mesh) GOST 535-2005 (Rolled bars and shaped steel from carbon steel of ordinary quality) GOST 550-75 (Seamless steel pipes for the oil refining and petrochemical industry) GOST 5520-79 (Rolled sheets from carbon, low-alloy and alloy steel for boilers and pressure vessels) GOST 5582-75 (Corrosion-resistant, heat-resistant and heat-resistant thin-sheet rolled products) GOST 5654-76 (Hot-deformed seamless steel pipes for shipbuilding) GOST 5781-82 (Hot-rolled steel for reinforcement / used structures) GOST 5949-75 (Grade and calibrated steel, corrosion-resistant, heat-resistant and heat-resistant) GOST 5950-2000 (Rods, strips and coils of tool alloy steel) GOST 6765-75 (Three-layer hot-rolled sheet and broadband (universal) steel) GOST 7062-90 (Forgings made of carbon and alloy steel, produced by forging on presses) GOST 7350-77 (Corrosion-resistant, heat-resistant and heat-resistant thick sheet steel) GOST 7417-75 (Calibrated round steel. Assortment) GOST 7566-94 (Metal products. Reception, marking, packaging, transportation and storage) GOST 7829-70 (Forgings made of carbon and alloy steel, manufactured by hammer forging) GOST 82-70 (Hot-rolled broadband universal steel) GOST 8239- 89 (Hot-rolled steel I-beams. Assortment) GOST 8240-97 (Hot-rolled steel channels. Assortment) GOST 8278-83 (Bent steel channels, equal flange) GOST 8281-80 (Bent steel channels, unequal flange) GOST 8478-81 (Welded mesh for reinforced concrete structures) GOST 8509-93 (Hot-rolled steel angles, equal flange. Assortment) GOST 8509-93 Appendix (Hot-rolled steel profiles) GOST 8510-86 (Hot-rolled steel angles, unequal flange) GOST 8559-75 (Calibrated square steel) GOST 8560-78 (Calibrated hexagonal rolled products. Assortment) GOST 8568-77 (Steel sheets with rhombic and lentil corrugation) GOST 8639-82 (Square steel pipes. Assortment) GOST 8642-68 (Oval steel pipes. Assortment) GOST 8644-68 (Steel flat-oval pipes. Assortment) GOST 8645-68 (Rectangular steel pipes. Assortment) GOST 8646-68 (Steel pipes with hollow ribs. Assortment) GOST 8694-75 (Pipes. Expansion test method) GOST 8695-75 (Pipes. Flattening test method) GOST 8696-74 (Electric-welded steel pipes with a spiral seam for general purposes) GOST 8706-78 (Expanded steel sheets) GOST 8731-87 (Hot-deformed seamless steel pipes) GOST 8732-78 (Hot-deformed seamless steel pipes. Assortment) GOST 8733-74 (Cold-deformed and heat-deformed seamless steel pipes) GOST 8734-75 (Cold-deformed seamless steel pipes. Assortment) GOST 8943-75 (Ductile iron connecting parts with cylindrical threads for pipelines. Nomenclature) GOST 8944-75 (Ductile iron connecting parts with cylindrical threads for pipelines. Technical conditions) GOST 8946-75 (Ductile iron connecting parts with cylindrical threads for pipelines. Passing elbows) GOST 8947-75 (Connecting parts made of ductile cast iron with cylindrical threads for pipelines. Transition elbows) GOST 8948-75 (Connecting parts made of ductile iron with cylindrical threads for pipelines. Straight tees) GOST 8949-75 (Connecting parts made of ductile cast iron with cylindrical threads for pipelines. Transition tees) GOST 8950-75 (Ductile iron connecting parts with cylindrical threads for pipelines. Tees with two transitions) GOST 8951-75 (Ductile iron connecting parts with cylindrical threads for pipelines. Straight crosses) GOST 8952-75 (Connecting parts made of ductile cast iron with cylindrical threads for pipelines. Transition crosses) GOST 8953-75 (Connecting parts made of ductile cast iron with cylindrical threads for pipelines. Crosses with two transitions) GOST 8954-75 (Connecting parts made of ductile cast iron with cylindrical threads for pipelines. Straight short couplings) GOST 8955-75 (Connecting parts made of malleable cast iron with cylindrical threads for pipelines. Straight long couplings) GOST 8956-75 (Connecting parts made of ductile iron with cylindrical threads for pipelines. Compensating couplings) GOST 8957-75 (Connecting parts made of ductile iron with cylindrical threads for pipelines. Transitional couplings) GOST 8958-75 (Connecting parts made of ductile cast iron with cylindrical threads for pipelines. Double nipples) GOST 8959-75 (Connecting parts made of ductile cast iron with cylindrical threads for pipelines. Connecting nuts) GOST 8960-75 (Connecting parts made of ductile iron with cylindrical threads for pipelines. Fittings) GOST 8961 -75 (Ductile iron connecting parts with cylindrical threads for pipelines. Lock nuts) GOST 8962-75 (Ductile iron connecting parts with cylindrical threads for pipelines. Caps) GOST 8963-75 (Ductile iron connecting parts with cylindrical threads for pipelines. Plugs) GOST 8965-75 (Steel connecting parts with cylindrical threads for pipelines P = 1.6 MPa) GOST 8966-75 (Steel connecting parts with cylindrical threads for pipelines P = 1.6 MPa. Straight couplings) GOST 8967-75 (Steel connecting parts with cylindrical threads for pipelines P = 1.6 MPa. Nipples) GOST 8968-75 (Steel connecting parts with cylindrical threads for pipelines P = 1.6 MPa. Lock nuts) GOST 8969- 75 (Steel connecting parts with cylindrical threads for pipelines P = 1.6 MPa. Slopes) GOST 9045-93 (Cold-rolled thin sheets from low-carbon quality steel for cold stamping) GOST 9234-74 (Bent sheet steel profiles with trapezoidal corrugation. Assortment) GOST 9567-75 (Precision steel pipes. Assortment) GOST 9583-75 (Cast iron pressure pipes, manufactured by centrifugal semi-continuous casting methods. Technical conditions) GOST 9940-81 (Seamless hot-deformed pipes made of corrosion-resistant steel) GOST 9941-81 (Seamless pipes cold- and heat-deformed from corrosion-resistant steel) GOST R 51285-99 (Twisted wire mesh with hexagonal cells for gabion structures) GOST R 51393-99 (Cold-rolled thin-sheet and bent profiles from corrosion-resistant steel for carriage building GOST R 52079 -2003 (steel welded pipes for trunk gas pipelines, oil pipelines and petroleum products) GOST R 52146-2003 (rental of a thin-leaf croaked and cold-rocked hot with a polymer coating with continuous lines) GOST R 52246-2004 (maintenance of leaf-shaped sheet) GOST R 5254-2006 (about cat welded reinforcement of periodic profile of classes A500C and B500C for reinforcing reinforced concrete structures) GOST R 53383-2009 (Seamless hot-deformed steel pipes) GOST R 53580-2009 (Steel pipes for field pipelines) GOST R 54157-2010 (Profile steel pipes for metal structures) GOST R 54159-2010 (Seamless and welded cold-deformed steel pipes for general purposes) GOST R 54384-2011 (Steel. Definition and classification by chemical composition and quality classes) GOST R 54432-2011 (Flanges of fittings, connecting parts and pipelines for nominal pressure from PN 1 to PN 200) GOST R 54864-2011 (Hot-deformed seamless steel pipes for welded steel building structures) GOST R 9.316-2006 (Thermal diffusion coatings, zinc)

Manufacturing method and assortment of sheet steel

These products are produced by rolling. Available in single sheets or rolls. The edge on these products can be cut off, or can retain the shape acquired after processing.

Sheet steel is produced using the rolling method and is supplied in coils or sheets.

The division of these products into types is carried out on the basis of the following characteristics:

- rolling method;

- rolling accuracy;

- surface quality;

- sheet thickness;

- degree of extension.

Steel sheets are produced by cold-rolled and hot-rolled methods. There are two types of precision products - normal and high strength. The degree of traction is divided into deep and normal. The thickness of the sheets varies from 2 to 5 mm. The surface can be corrugated, grooved or smooth.

Regulatory government documents:

- GOST 19903-74 – assortment of hot-rolled metal sheets;

- GOST 19904-90 – assortment of cold-rolled sheets;

- GOST 16523-97 – technical specifications.

Sheet steel can be normal or high strength.

Sheet metal is actively used in mechanical engineering and construction. It is used for welding structures, plating, making casings, sarcophagi. Can be used as blanks for other products (household appliances, appliances, etc.)

Classification

Rolled metal products are classified according to:

- Composition – black (low-carbon steel), stainless (stainless steel), non-ferrous (aluminum, copper, other non-ferrous metals and their alloys). The most widespread is ferrous metal.

- Production technologies – cold and hot rolled. Hot-rolled metal products are cheaper and therefore are in great demand. Cold-rolled metal products have better characteristics and greater geometric dimensional accuracy.

- Quality of surface treatment – matte, mirror, polished, calibrated.

- Types of products – rolled pipes, sheets, shaped, long products.

- Profile size – small, medium, large.

Variety of types and forms of high-quality and shaped products

Rolled metal products are standardized products. According to GOST 535-2005, the peculiarity of this type of product is that the diameter of the metal product has one of the geometric shapes: square, hexagon, rectangle or circle.

What is a channel: range, characteristics, areas of application (read more)

Characteristics that determine the assortment:

- profile shape;

- its dimensions;

- metal processing method.

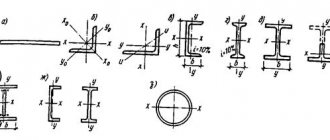

Depending on the form, varietal products are divided into the following types:

- simple;

- shaped;

- special

Varietal products, depending on their shape, are divided into simple, special and packaged.

Simple forms include:

- Circle – hot-rolled steel with a round profile, which is used for the manufacture of fittings, wire, gratings, decorative elements, monolithic structures. Regulated by the provisions of GOST 5751-82.

- Square – hot-rolled steel with a square profile. It comes in small and large sizes and is used in various industrial sectors for welded structures. Produced in accordance with GOST 2591-88.

- Hexagon. Used as blanks for the manufacture of other products, such as bolts.

- Strip is a high-strength sheet used for reinforced concrete products in mechanical engineering.

Channels are U-shaped and belong to packaged products.

Products classified as shaped products are channels and beams. The beams have the shape of a beam. They are used in construction when it is necessary to make a durable frame. Channels are U-shaped products characterized by rounded corners. Used to create ceilings.

Channel characteristics: channel weight, size table, cost of profiles (read more)

Special forms of rolled products are wheels and round fittings. Wheels are used in mechanical engineering, reinforcement is used to strengthen structures.

Sheet steel

Flat sheet metal is widely used in the installation of metal structures. Plates are made from sheets, which are used to connect various elements of metal structures such as angles, channels, I-beams. Smooth rolled products are also used to create “scooter” pipes and various elements of ventilation ducts.

Products of corrugated sheet metal, due to their lightness and corrugated surface, serve as flooring and ladders in places where slipping needs to be reduced. Expanded metal sheets (PVL) are also used for these purposes.

Profiled sheets, otherwise called corrugated sheets, quickly took root in our country. They are quite often used as roofing material, they are used to line the walls of buildings, and are used for the construction of fences and other enclosing structures. Such widespread use has forced suppliers to constantly expand their range of products that can solve specific problems.

A400 and A500S fittings: general characteristics and differences

One of the types of rolled metal products used for various industrial purposes is fittings. This is a round metal rod with a ribbed surface. This product is produced in the form of segments of a certain length or in coils. There is also fittings with a smooth surface.

The fittings come with a smooth and ribbed surface, and are produced in the form of individual sections or in a coil.

GOST for fittings 5781-82 regulates technical conditions. GOST 10884-94 was created for reinforced reinforcement. The main area of application is construction. This type of rolled metal is used to reinforce reinforced concrete products and create frames. The full range of fittings is divided into VI classes. The most popular types of products (A400 and A500C) belong to class A III. The reinforcement has a profile with two ribs and a transverse projection.

Reinforcement: range of reinforcement, weight, length, calculations, GOST standards (read more)

In many ways, the characteristics of the A400 and A500C fittings are identical, which determines their belonging to the same class. But differences in the chemical composition, namely less carbon and more alloying additives, give the A500C type a greater degree of flexibility, which contributes to the formation of a more durable seam when using arc welding. The letter “C” indicates the possibility of using this type of welding.

In construction, reinforcement of classes I–IV is more often used. For the foundation, the diameter of this metal product must be at least 10 mm. In mine construction, for the reinforcement of bridges and underground structures, products of classes V–VI are used. The class table contains a range of A500C reinforcement for strengthening reinforced concrete structures.

Note! When replacing grade A400 with A500C, due to the possibility of using electric arc welding and improving the quality of joints, the consumption of reinforcement is reduced and the strength of the concrete structure is increased.

The A400 and A500C fittings belong to the same class, so most of their characteristics are the same.

Read the continuation of the article on the next page. To move to the next part of the article, use the page navigation numbers.

TABLE OF CORRESPONDENCE OF PIPE DIAMETERS IN MM AND INCHES

| Nominal diameter of the pipe (Dy), mm | Thread diameter (G), inch | Pipe outer diameter (Dн), mm | ||

| Steel water and gas pipe | Seamless steel pipe | Polymer | ||

| 10 | 3/8″ | 17 | 16 | 16 |

| 15 | 1/2″ | 21,3 | 20 | 20 |

| 20 | 3/4″ | 26,8 | 26 | 25 |

| 25 | 1″ | 33,5 | 32 | 32 |

| 32 | 1 1/4″ | 42,3 | 42 | 40 |

| 40 | 1 1/2″ | 48 | 45 | 50 |

| 50 | 2″ | 60 | 57 | 63 |

| 65 | 2 1/2″ | 75,5 | 76 | 75 |

| 80 | 3″ | 88,5 | 89 | 90 |

| 90 | 3 1/2″ | 101,3 | 102 | 110 |

| 100 | 4″ | 114 | 108 | 125 |

| 125 | 5″ | 140 | 133 | 140 |

| 150 | 6″ | 165 | 159 | 160 |

DIMENSIONS OF VGP-PIPES ACCORDING TO GOST 3262-75

Main dimensions of the VGP pipe: 15 mm (1/2″ inch); 20 mm (3/4″); 25 mm (1″); 32 mm (1 1/4″ inches and a quarter); 40 mm (1 1/2″); 50 mm (2″). There are also the following DNs: 10 mm, 65 mm, 80 mm, 90 mm, 100 mm and even 125 mm - but they are rarely used and, as a rule, are replaced by other types of steel pipes (for example, electric welded). Most often, 3/4″ pipes are used for risers, and 1/2″ for internal wiring.