Scope of metallization of plastics

The scope of application of metallization is the production of finished products from dielectrics, which, having some properties of a metal part, have less weight and are much cheaper to produce. For example, parts made using injection molding machines or parts made by injection molding. Such parts can be used in industries where the mass of parts is important, for example, in the aircraft industry. A separate area is the production of conductive layers in the manufacture of printed circuit boards.

This type of electroplating, known as galvanoplasty, is essentially the process of applying a layer of metal to a mold or workpiece made of wax, plaster or other plastic material. Using electroplating methods, metal copies of art objects, bas-reliefs, sculptures, various artistic products such as metallized tree leaves, flowers, fruits and much more are made.

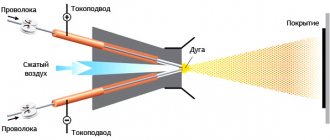

Ion-vacuum sputtering

The main advantage of this method is that there is no need to heat the evaporator very much. The metal is atomized by bombardment with negatively charged gas ions. The creation of such an environment is possible thanks to special discharges inside the working chamber. For this purpose, the equipment uses a magnetic cooling system. A glow discharge for sputtering the sprayed element is created between 2 electrodes due to the supply of high voltage voltage up to 4 kV. A gas environment with a pressure of up to 0.6 Pascal is created in the working chamber. Vacuum ion-plasma sputtering is also performed using specialized equipment using a similar principle.

Main tasks of metallization

Depending on the area of application of metallized parts, the galvanizer is faced with diametrically opposed tasks. If in the first case, in order to obtain a high-quality finished product from metallized plastic, it is necessary, first of all, to ensure the strength of adhesion of the metal layer to the surface of the dielectric, then when implementing electroforming methods it is necessary to ensure free removal of the mold, often without its destruction.

In electroplating, this problem is solved quite simply; highly dispersed graphite or a special conductive varnish is used to form a thin layer of conductive material for the purpose of further applying a layer of nickel, copper or other metal to the surface of the product by the galvanic method. We will write more about electroplating methods, various techniques, and process features in one of the following articles; now we will focus on the production of finished parts from dielectrics using the metallization method.

As stated above, to obtain a high-quality product, it is first necessary to ensure sufficient adhesion strength of the metal layer to the surface of the dielectric. For plastic products, an adhesion strength of 0.8-1.5 kN/m for peeling and 14 MPa for peeling is considered sufficient. These values are ensured by thoroughly preparing the surface of the part before applying the metal layer, as well as by monitoring the uniformity of the composition of the initial raw materials of the parts. For products produced by injection molding or molding, the use of any release agents, which could have a negative effect on the adhesion strength of the layer and the base, is excluded.

Precautionary measures

Acetone is a very dangerous liquid that has an extremely negative effect on the human body. Therefore, it is allowed to make liquid plastic with your own hands only if the following precautions are strictly observed:

- Before working with acetone, you must carefully study the instructions for its use. It is indicated on the container label.

- Special sealed safety glasses should be used. They will protect your eyes in case of liquid drops and vapors. Working without them can cause serious eye injury.

- Acetone is toxic, so it should only be used in a well-ventilated area. In this case, it is necessary to use respiratory protection.

- This is a highly flammable product. Therefore, liquid plastic is made with your own hands away from sources of open fire. Smoking is strictly prohibited when performing work.

- Residues of acetone must not be poured into the sewer system.

- At the end of the process, as well as after pouring the finished plastic into molds, you must thoroughly wash your hands.

Metallization methods and surface preparation

There are three methods of metallization - physical, chemical and galvanic, which allow solving various problems and require their own approaches to preparing the surface of dielectrics for the metallization process. A universal method that allows us to obtain products with the highest possible characteristics is the galvanic (electrochemical) method, which is divided into several stages:

- mechanical preparation of the surface of parts - removal from the surface of waste material remaining during manufacturing (molding or casting), cleaning of recessed areas (grooves, holes), etc.;

- chemical surface preparation – degreasing and etching;

- sensitization and activation of the surface with special compounds and reagents;

- applying a conductive sublayer using a chemical method;

- applying galvanic coating to a metallized surface.

The task of the galvanizing department specialists is to ensure that, as a result of these stages, the basic conditions for obtaining a high-quality coating are ensured - the necessary cleanliness of the surface of the part, the specified roughness and the absence of organic substances on the surface.

Mechanical methods of surface preparation depend on the material of the product and the method of manufacturing the initial parts and, as a rule, come down to a simple operation of mechanically cleaning the surface from production waste.

Degreasing of the surface of plastic parts is carried out in a solution containing:

- trisodium phosphate 30-40 g/l;

- sodium hydroxide 8-10 g/l;

- sodium liquid glass 5-7 g/l;

- sodium carbonate 40-45 g/l.

The process takes place at a temperature of 40-500C for 3-5 minutes.

The adhesive properties of a metal coating largely depend on the quality of etching of the parts. During the etching process, micropores and microcracks are formed on the surface, which provide sufficient adhesion strength of the coating to the base. For etching, a solution is used that is almost similar in composition to the chromium plating electrolyte - 100 g/l sulfuric acid and 30 g/l chromic anhydride. The process takes place at a temperature of 600C for 1-5 minutes.

Details

Overview of methods

Features of obtaining galvanic coating

First of all, the galvanic layer will ensure the metal’s resistance to corrosion processes. When galvanizing, the parts will be in dense electrolytes. Thus, for the operation to be successful, special weights will be hung on the parts.

Please note that electroplated coatings will differ from metal ones in that they require a much larger number of contacts to create. The process of galvanizing plastic will also be characterized by the complexity of the preparation stage, because in this case it will be much more difficult to ensure an excellent degree of adhesion.

Adhesive properties of materials

A little more about metallization of plastics. The adhesion will be characterized by the quality of adhesion by different types of elements (in this case, we will talk about adhesion between plastic and metal). The adhesion strength between plastic and metal coatings should be between 0.8 and 1.5 kN per meter for peeling, and equal to 14 mPa for tensile strength. The maximum possible degree of adhesion achievable with modern technological means is approximately 14 kN per meter. The adhesion properties of materials will be one of the rather complex phenomena. It can also be said that there is no single theory that can fully answer all questions regarding the adhesion of various types of materials to each other.

From the point of view of chemical science, adhesion is a chemical relationship between bodies of different types. Chemical interactions can be seen on plastic surfaces. At such sites there are functionally active groups that will come into contact with metals or coat metal surfaces with oxides. The molecular approach interprets adhesion as a consequence of the presence of intermolecular forces on the interfacial surface, as well as the interaction of two poles or the appearance of hydrogen bonds.

This will explain, for example, the adhesion of wet etched polyethylene films after drying. Speaking from the point of view of electrical theory, adhesive properties appear due to the fact that when a pair of bodies interacts, a double electrical layer appears. As a result of this action, the layer will not allow the bodies to move away from each other, because electrostatic forces of mutual attraction of different charges work.

According to the diffusion theory (the most popular), adhesion will occur due to interactions of the intermolecular type, which features clearly manifest themselves when molecules penetrate each other into the surface layers. At the same time, a certain intermediate layer appears, as a result of which one can observe the absence of a clear boundary between the materials. And finally, the mechanical version of the theory would explain adhesion by an anchor type of clutch that protrudes pieces of metal into recesses on a plastic surface. Such depressions are quite small in area (several micrometers), but when chemically deposited metal gets into them, so-called mechanical locks appear.

Other parameters will also affect adhesion, including the following:

- Strength characteristics of plastic.

- The presence of chemically active groups on the surface of plastics favors the reaction.

- The presence of stimulants of adhesion processes, which can otherwise be called promoters (tin and chromium compounds, as well as plasticizers).

- The absence of anti-promoters that can prevent the strengthening or even destruction of the intermediate type of layer.

- The structure of the material that is chemically deposited, as well as the parameters under which deposition occurs.

Let's look at a couple more methods

Vacuum metallization method

The technology for vacuum metallization of plastics will consist of spraying nichrome or aluminum onto the surface of the plastic using a vacuum. The application of metal to plastic using a vacuum is carried out in a special chamber. The technique is widely used for applying metal films to various surfaces, for example, automobile parts, plumbing fixtures, plastic fittings, lighting equipment, etc. To clean metal, special paint and varnish compositions are used, which are characterized by an increased degree of hardness and resistance to moisture.

Metallization process at home

There are only a few known methods for independently applying metal to a plastic coating. The most accessible of them is chemical. In this case, no specialized equipment is required. The metals used for the process are copper and silver. The resulting film will be only a few microns thick, but it will give the base a beautiful appearance with a metallic-type sheen.

Metallization with copper

Before starting treatment, the surface should be sanded and degreased as best as possible. If the part has bulges (defects), these should be carefully eliminated. Apply abrasives to the surface and wipe the surfaces with a swab. If you are dealing with polyacrylates, for degreasing you will need a solution of caustic soda, in which the parts must be soaked for 24 hours.

It is recommended to use gasoline to degrease polyamides. When the product is degreased, it should be washed in distilled water, and then kept in a 0.5% solution of stannous chloride and hydrochloric acid (0.04 kg per liter) for 60 seconds.

This process is called sensitization. Its goal will be to obtain a film of tin hydroxide on plastic. After this process, the surface should be activated. To do this, soak the part for 3-4 minutes in a solution of silver nitrate (2 grams of silver per 1 liter and 2 grams of ethyl alcohol).

Next, place the product in a solution that consists of the following ingredients:

- Copper carbonate – 0.2 kg per 1 liter.

- Glycerin (90%) – 0.2 kg per 1 liter.

- Caustic soda (20%) – 1 liter.

The solution temperature should be from +18 to +25 degrees, and the processing time will be 1 hour.

Metallization with silver

Pre-treatment of plastic should be carried out in the same way as in the case of copper - sand and apply a layer of abrasive. Wash the surface in soapy water, and then in distilled water.

The product should be degreased using the following solution:

- Chromic anhydride – 0.1 kg per liter.

- Iron sulfate – 0.01 kg per liter.

After degreasing, the part must be washed again in distilled water. The sensitization process should be carried out in a solution of stannous chloride (only 2 grams per 1 liter).

Next, place the product in a solution containing the following components:

- Silver nitrate – 3 grams per 1 liter.

- Caustic soda – 3.5 grams per 1 liter.

- Ammonia (25%) – 8 milliliters per 1 liter.

- Glucose – 2.5 grams per 1 liter.

To remove silver from the surface of plastic, you will need the following solution:

- Chromium anhydride – 10 grams per 1 liter.

- Sulfuric acid – 3 grams per 1 liter.

We recommend treating the uniform film with a layer of varnish, which will protect the plastic. Further surface treatment by galvanic method is also possible.

Plastic metallization process

Sensitization is the process of chemically depositing a thin layer of catalyst on the surface. Plastic products are placed in a solution of 30-40 g/l tin dichloride and 30-40 g/l hydrochloric acid at shop temperature, then washed in distilled water and the surface is activated in a solution of 1-2 g/l palladium dichloride and 1-2 ml/l hydrochloric acid for 3-5 minutes. The thin layer of palladium that forms as a result catalyzes the deposition of copper from the electroless copper plating solution:

- copper sulfate 100 g/l;

- caustic soda 100 g/l;

- sodium carbonate (anhydrous) 30 g/l;

- glycerin 100 g/l;

- formalin 33% 25-35 ml/l.

The chemical deposition process of copper takes place at shop temperature for 20 minutes. As a result, a ready-made metal sublayer is obtained for further galvanic deposition of metal. The galvanic process takes place in standard electrolytes of nickel plating, copper plating, tin plating or chrome plating and differs from classical electroplating only in the features of fastening conductive contacts. The metallization process is also completed in the standard way - the parts are washed and dried.

You may be interested in the following articles:

|

Nickel plating of plastics

After activation (without rinsing!) the parts are immediately transferred to a nickel plating . There is a choice of solutions (g/l):

- Nickel sulfate - 30, sodium hypophosphite - 10, sodium acetate - 10. Solution temperature 90 °C, metal film growth rate 15 µm/h.

- Nickel chloride - 30, sodium hypophosphite - 10, sodium citrate - 100, ammonium chloride to pH = 8-9. Solution temperature 90 °C, growth rate 6 µm/h.

- Nickel chloride - 30, sodium hypophosphite - 10, sodium citrate - 10. Solution temperature 85 °C, growth rate 5 µm/h.

Solutions are prepared in the following sequence. First, all components except sodium hypophosphite are dissolved in most of the water. It is separately dissolved in a small part of water. Immediately before loading the parts, both solutions are mixed.

For clients in Moscow

We will be happy to answer any questions by calling our Moscow office:

So friends, everything worked out! As planned)) While the most stubborn continue to eat the cactus and restore the plastic ones!

o_O Visteon2, a group of enterprising comrades =)), having cooperated and found each other)) did it - namely, they restored the metal reflectors of the Visteon1 lenses (which were installed at one time on the pre-Restyle Mondeo4, Land Rover, Jaguar, Volvo and a bunch of other brands) by vacuum deposition of aluminum. It was done in the St. Petersburg JSC "VIMA" (not an advertisement! For the sake of truth) ... for the clear, without a hitch, organization of this event, I express categorical respect and respect! 111 Denis (aka dionis-spb) Denis, you are a man! good!)) thank you so much again, nothing would have happened without you!

There's only a little left! put it in place... as the men used to say at my first job: “... - start and finish. "=))

stay tuned! it will be interesting)

PS The budget for this action is total! taking into account the purchase of used modules, their triple transportation (to me, from me to St. Petersburg and ready back to me)... specifically, the restoration itself cost about 1,700 rubles. for a pair of reflectors, according to the small wholesale price list =)) from the previous entry

Issue price: 3,700 ₽

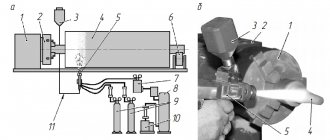

Equipment for vacuum deposition

Vacuum metallization plants are quite complex and expensive equipment that consume a lot of electricity. To create a complex technological cycle, a fairly spacious room is required, since several multifunctional devices must be placed. Main components of the vacuum system:

- Power supply and control unit in conjunction with a source of condensed metals.

- Gas distribution system that creates a vacuum space and regulates gas flows.

- Working chamber for vacuum metallization.

- Unit for thermal control, control of spraying thickness and speed, coating properties.

- A transporting unit responsible for changing the position of workpieces, feeding them and removing them from the chamber.

- Unit blocking devices, gas filters, dampers and other auxiliary equipment.

Magnetron and ion-plasma vacuum equipment comes in different sizes, from small, with chambers of several liters, to very large, with chamber volumes of several cubic meters.

has sufficient production capacity and appropriate equipment to provide various methods of vacuum deposition. From us you can order ion-plasma coating of products made from any materials with metals such as titanium, copper, aluminum, brass, chrome, various alloys, etc. We guarantee high quality work and reasonable prices.