The group of electrodes for surfacing is represented by grades that are intended for manual surfacing of surface layers of worn parts. This deposited layer has special properties (except for the brands of electrodes intended for surfacing parts made of non-ferrous metals). Surfacing electrodes are manufactured and supplied in accordance with the requirements of GOST 9466-75 and 10051-75.

In some cases, welding electrodes are also used for surfacing, such grades, for example, are intended for welding corrosion-resistant, high-alloy, heat-resistant and heat-resistant steels.

Surfacing electrodes for restoring surface layers according to GOST 10051-75, according to the hardness and chemical composition of the deposited metal at normal temperature, are divided into 44 types (for example, E-13Х16Н8М5С5Г46, E-110Х14В13Ф2, E-16G2ХМ). Manufacturers of many brands regulate the deposited metal with technical conditions.

Conditional division into groups

Depending on the operating conditions and the adopted alloying system for the resulting deposited metal, surfacing electrodes (electrodes for surfacing) are conventionally divided into the following 6 groups (for example, brands/types of electrodes (types of metal) are written below, links to all these brands are further on this page ):

- The 1st group of electrodes ensures the production of low-alloy, low-carbon deposited metal with properties of high resistance to shock loads under friction conditions . (OZN-300M/11G3S, OZN-400M/15G4S, NR-70/E-30G2ХМ, TsNIIN-4/E-65Х25Г13Н3)

- The 2nd group of electrodes ensures the production of low-alloy, medium-carbon deposited metal with properties of high resistance to shock loads under friction conditions at normal and elevated operating temperatures (up to 600-650 degrees C). (EN-60M /E-70Kh3SMT, TsN-14, 13KN/LIVT /E-80Kh4S, OZSh-3 /E-37Kh9S2, OZI-3 /E-90Kh4M4VF)

- The 3rd group of electrodes ensures the production of alloyed or highly alloyed carbon deposited metal with properties of high resistance to shock loads under conditions of abrasive friction . (OZN-6 /90Kh4G2S3R, OZN-7 /75Kh5G4S3RF, VSN-6 /E-110X14V13F2, T-590 /E-320Kh25S2GR)

- Group 4 of electrodes ensures the production of high-alloy carbon deposited metal with properties of high resistance to high pressures and high operating temperatures (up to 650-850 degrees C). (OZSh-6 /10Kh33N11M3SG, UONI-13/N1-BK /E-09Kh31N8AM2, OZI-5 /E-10K18V11M10Kh3SF)

- The 5th group of electrodes ensures the production of austenitic highly alloyed deposited metal with properties of high resistance to conditions of erosion-corrosion wear and friction at elevated operating temperatures (up to 570-600 degrees C). (ЦН-6Л/Э-08Х17Н8С6Г)

- The 6th group of electrodes ensures the production of highly alloyed dispersion-strengthened deposited metal with properties of high resistance to severe temperature and deformation conditions (up to 950-1100 g C). (OZSh-6 /10Kh33N11M3SG, OZSh-8 /11Kh31N11GSM3YuF)

Abrasion resistant surfacing electrodes

Surfacing is a method of applying a layer of molten filler metal to the base metal. Abrasion-resistant deposition electrodes create a new layer on parts with excellent mechanical properties and characteristics. By using them you can:

- bring the product back to its original form,

- return it to its geometric dimensions,

- impart new valuable qualities,

- increase wear resistance and ability to withstand temperatures.

Surfacing electrodes, resistant to abrasive wear, are used in the repair of a wide variety of equipment. These can be gear drums, crosses, shafts, sprockets, axles, reflective plates, switch crosses, augers, crushers . In this case, it is recommended to use surfacing electrodes of the OZN-400M, TsNIIN-4, OZN-7M brands.

When performing excavation work, track chain links, excavator buckets, bulldozer blades, and ripper tips are subjected to abrasive wear. It is necessary to protect these parts from stress and destruction by using the electrode brand T-590 and T-620, OK Weartrode 35. Their rod is made of carbon steel, the coating contains ferroboron, boron carbide, ferrochrome, ferrotitanium.

[ads-pc-2][ads-mob-2]

general information

So, metal surfacing is a method of restoring or strengthening a weld. During the work, a new layer is formed on the joint surface. There can be several layers if necessary. This technology is not similar to the formation of a seam; it is important not to confuse surfacing and welding.

To perform surfacing, electrodes from special groups are used, there are 6 of them in total. Each group is intended for certain metals and provides the surfacing layer with individual properties and characteristics. We'll talk about groups later. The production of surfacing electrodes is regulated by GOSTs No. 9466-75 and No. 10051-75.

Professional welders can use conventional electrodes for surfacing that are not intended for this purpose. They often use grades sharpened for welding heat-resistant and anti-corrosion steels. We do not recommend that beginners and even practicing craftsmen use conventional electrodes for surfacing purposes. The result will most likely disappoint you. Many years of experience and constant practice are important here.

Surfacing electrodes, shock resistant

Electrodes for surfacing work, resistant to shock loads, are used in the repair of crushing equipment, for example, tongs, beaters, armor and rollers, cones, housings. The brands used are OK 13Mn, previously called OK 86.08, OK Weartrode 55, T-590N, T-590 and T-620. With their help, you can fuse four or more layers. T-590N is designed for those who decide to repair a part and forget about it for a long time.

Grades T-590 and T-620 deposit a layer that is not subject to cracking upon impact. They are wear-resistant , bond well with the base metal, and help extend the service life of products several times.

Electrodes of the OMG-N, TsNIIN-4 , OZN-7M , OZN-400M , OZN-300M types create hard deposited metal. The value of 45-65 HRC will be in the second layer.

For surfacing parts made of stainless steel, grades TsN-6L, TsN-12M-67 .

When working with copper you need Komsomolets-100. Bronze surfacing is performed by OZB-2M.

Carbide electrodes for surfacing

Carbide electrodes used for surfacing help restore the geometry of many types of parts. ESAB OK 84.42 (discontinued) grades are suitable for non-alloy steel. Surfacing of products made from carbide steels exposed to abrasive and impact can be done using Hilco Hardmelt 600, UTP PUR 600, ESAB OK 83.53 (discontinued) . They are also suitable for restoring cutting measuring tools and mechanisms operating under high wear.

The metal layer deposited using a tubular electrode of the HRT 60/ХРТ 60 grade cannot be machined. HB 61 B/ХБ 61 Б, HBA/ХБА can be used successfully with hard alloys. With their help, track surfaces, cutters, and buckets are repaired. They have a high hardness of 55-63 HRC. They come in diameters of 3.2-12 millimeters.

Principles for selecting surfacing electrodes

The effectiveness of surfacing is determined by the correctly selected final goal of the process - welding with a simultaneous increase in mechanical and/or corrosion strength, or a change in the characteristics of the original workpiece. The first goal is important when processing highly loaded machine parts and structures, and the second is important when hardening tooling.

Important! All carbide electrodes have very high compressive strength, which is usually accompanied by reduced ductility and shear strength. Such surfacing materials should be used in such a way that, as a result of the thermal impact on the treated steel surface, compressive stresses arise there. With high impact resistance after hard surfacing, the applied layer will not be destroyed in the event of an impact.

When choosing metal electrodes, it is worth remembering that the best performance characteristics are those that contain high-speed steels, austenitic manganese steels, combined alloys of the chromium-cobalt-tungsten system, austenitic iron with a high chromium content, as well as nickel alloys with chromium and boron.

Welding features of some brands

T-620 - often used for work in lower and inclined positions. Available in diameter 4-5 mm. It is used when working with rapidly wearing metal and cast iron parts that also operate under impact, so they can be called electrodes for wear-resistant surfacing. In some cases, it requires calcination at +180-+200 degrees for 2-3 hours. You should not use it to create more than two layers on metal and one on cast iron. The electrode melts under alternating current, constant direct polarity. (Learn more about surfacing electrodes T 620).

TsNIIN-4 - often used for surfacing crosspieces when eliminating casting defects. It is recommended to work with them in the down position. Available in 4 mm diameter. Sometimes calcination is required before welding at +160-+200°C for an hour. (Learn more about electrodes for surfacing crosspieces TsNIIN-4)

TS-2 – allows for subsequent hardening of the part to increase hardness. They can operate with alternating and direct current, short arc. It is possible to create a layer up to 4 mm, after which it can be processed by removing 1-1.5 mm. This is a brand of iron-chromium electrodes, a cast hard alloy of stellite, such as sormite. They can be used to repair hardened parts. (Learn more about surfacing electrode TsS-2).

OZSh-6 – produced with a diameter of 2.5-4 millimeters. Used for working in the down position. Hardness 52-50 HRC. It is used when working with metallurgical and machine tools operating at thermal fatigue of +950 degrees. (More details about surfacing electrodes OZSh-6).

ZELLER L61 . Also watch the video where surfacing with ZELLER L61 electrode is demonstrated.

[ads-pc-3][ads-mob-3]

Methods for restoring parts by surfacing and welding

Restoration of operational damage can be performed using various welding methods:

- automatic submerged arc welding with solid or cored wire

- mechanized gas-shielded electric arc welding with solid or flux-cored wire

- argon arc automatic and mechanized welding with filler wire

- plasma welding and plasma spraying

- manual electric arc welding with a coated electrode.

In relation to the products offered by our company, namely coated electrodes and welding wire, we will focus on two methods of electric arc welding - manual arc welding with a consumable (coated) electrode and mechanized arc welding with a consumable electrode in a shielding gas environment. When using self-shielded flux cored welding wires, the use of shielding gas is not necessary.

Popular manufacturers

Electrodes from such manufacturers as Castolin-Eutectic, LINCOLN ELECTRIC, ESAB, ASKAYNAK . The brands of these companies can be found in almost any store.

The ESAB concern produces a full range of welding materials and MMA electrodes.

LINCOLN ELECTRIC is a very large international holding company that produces abrasion and impact resistant electrodes Wearshield 15CrMn, Wearshield MI. The company has developed a large list of products.

The manufacturer ASKAYNAK produces brands of electrodes for surfacing AS SD ABRA Nb, AS SD ABRA Cr. They have excellent abrasion resistance. LINCOLN ELECTRIC has 50% of this company.

The Ukrainian manufacturer PlasmaTek produces, for example, T-590 and T-620 under the Monolith brand. [ads-pc-4][ads-mob-4]

Comparative metal efficiency of surfacing electrodes and their designation

In descending order of wear resistance, the composition of surfacing electrodes contains tungsten carbide, molybdenum carbide, chromium carbide, as well as multicomponent carbides.

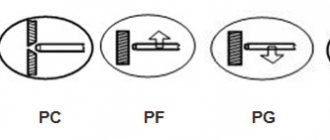

Brands of electrodes take this circumstance into account. Common markings for surfacing electrodes include:

- Electrode type;

- Name of the electrode corresponding to the required GOST;

- Electrode diameter, mm;

- Special requirements for the surface to be deposited (optional);

- Electrode index with parameters of mechanical properties of the deposited layer;

- Mode of application;

- GOST number according to which the electrode is manufactured.

Key points on surfacing with electrodes

IMPORTANT! The chemical properties of the deposited metal layer, the composition of the electrode, must almost completely coincide with the characteristics of the steel of the part being repaired.

This is important to consider when choosing a brand or type. The operating principle of the surfacing method is based on melting the electrode under the influence of a welding arc, creating one or several layers. How many there will be must be determined by paying attention to the properties of the part, depending on the requirements.

Good quality characteristics of the layer created by the welder are achieved depending on the depth of metal penetration. This figure should be minimal. This is important to take into account; it is necessary to achieve as little mixing of the welded steel as possible with the base steel. The welder must try to obtain a minimum residual stress and avoid deformation of the part he is processing . This requirement can be met only by observing the previous two, choosing the right electrode and minimal welding .

It is important to reduce the allowance values that are permissible during subsequent processing of parts after welding to the norms, and not to exceed them.

It is recommended to fuse a layer of metal with an electrode as much as required, and no more.

To prevent warping, it is best to carry out fusing in separate sections, and it is recommended to start laying each subsequent roller on the opposite side to the previous one.

Only by following these simple rules can protection of the deposited metal be achieved from the destructive effects of gases. The result is a dense layer that does not have pores, any types of cracks and foreign inclusions. It is also important to take into account that the surface of the part being repaired must be thoroughly cleaned of oil, traces of corrosion, rust and any other types of contaminants before starting surfacing work.

Video

Watch the video where a craftsman melts a plowshare:

Surfacing process

During the technological process, which is the surfacing of an additional layer, the position is lower, or, in some cases, inclined, vertical and semi-vertical, limited ceiling. There are various surfacing schemes for both flat and shaped surfaces.

In addition to consumable electrodes, the following are used as surfacing materials:

- cored wire;

- flux-cored tape;

- flux;

- gas consisting of oxygen and acetylene.

With the recommended consumption of inert gases, which act as protection, high-quality weld metal is formed, which does not contain various inclusions.

Materials for surfacing are:

- Steel surfacing wire having a solid cross-section. The main requirement is hardness. The steel used is carbon, alloy and high-alloy.

- Covered electrodes of forty-four types, manufactured in accordance with the requirements of GOST 100051-75.

- Cast rods for surfacing.

- Flux cored wire available in various grades.

- Granular powdered alloys that are used in the form of powder mixtures. For example, Stalinit M is used for surfacing bulldozer blades and excavator bucket visors, and the Vakar brand is used for surfacing during the repair and manufacture of drilling tools.

- Powder belts, which are used for surfacing rollers, wheels, bulldozer knives, and bowls of blast furnace apparatus. The advantages of using flux-cored tapes include high melting efficiency, a large covered area for each pass, and the ability to work at high current values.

There are various surfacing methods available. The most widely used surfacing method is the arc method. This is considered a universal method that is used in industry and the domestic sphere. The popularity of the method is due to its simplicity, convenience and the absence of the need for additional devices.

Working with flat surfaces can be used to create narrow or wide rollers. Disadvantages include low productivity and large penetration depth.

The type of surfacing electrode is selected depending on the chemical composition of the base material, and the diameter depends on the thickness and shape of the workpieces. The need for preheating depends on the brands of electrodes used. Before starting the metal surfacing process, it is necessary to pre-clean the surfaces of the product from dirt, grease stains and paint.