Casting is a product obtained by pouring a liquid alloy into molds, in which, after cooling and solidifying, formation occurs. It can be a completely finished product or require further mechanical processing.

Divided into the following types:

- semi-finished products are ingots, which subsequently require a processing process;

- ingots processed under pressure;

- shaped castings – processed by cutting;

- finished products that do not require any mechanical processing are only cleaned or painted with decorative paint.

To produce castings, many types of metal and alloys, glass, plastic, wax and other starting materials are used. About 80% of blanks are obtained by sand casting, but the casting obtained in this way requires mandatory processing before being sent to the customer.

Foundry production makes it possible to obtain high-precision workpieces even with the most complex configuration, while gaps requiring processing are insignificant. The technology for producing castings is selected taking into account their size and production method.

There are three groups for producing castings:

1) in one-time forms;

2) according to soluble models;

3) casting in semi-permanent and combined type molds made of refractory materials:

These are the main types of casting, but in practice combined options are also used.

Lost wax casting

Investment casting allows the production of precision components, minimizing material waste, reducing the energy intensity of production and reducing the cost of subsequent processing of finished castings, and of any degree of complexity.

Lost wax casting technology uses a shell of ceramic, plaster or plastic that is formed around a wax mold. This mold is then melted and removed in a furnace and the metal is poured into the shell to create the casting.

The lost wax casting process occurs in several stages:

- Creation of an initial sample that reflects the configuration of the finished part, adjusted for thermal shrinkage of the workpiece;

- Making wax samples and creating a wooden model. It is assembled in such a way as to ensure delivery of the melt to all hard-to-reach parts of the casting;

- Creating a mold shell, where the entire wax model is dipped into a ceramic slurry, covered with a sand shell and sent to dry. These cycles are repeated until a shell of the desired thickness is created, which is set to the dimensions and configuration of the finished casting. Once the ceramic shell dries, it is strong enough to hold the molten metal during casting.

- Removal of wax, for which the entire assembly is placed in a steam autoclave to melt almost all the wax (the remains, impregnated with ceramic composition, are burned in the oven). Then the sprues are also removed;

- Melting and casting. The mold is preheated to a certain temperature and filled with molten metal, creating a metal casting. The lost wax casting process can produce a finished product from any alloy. Depending on its chemical composition, melting in air or vacuum can be used. Vacuum melting is used when reactive elements are present in the alloy.

- Final operations. After the casting has completely cooled, the mold shell is separated from the casting by displacement. In this case, the remains of the channels and sprues are cut off, and, if necessary, sandblasting, grinding and mechanical finishing of the casting are performed to the dimensions specified in the product drawing.

The technology includes a non-destructive testing stage, for which fluorescent, magnetic particle, radiographic or other quality control methods are used.

Advantages of the method:

- A wide range of masses of the resulting castings - from small to 300...350 kg.

- Versatility and complexity of shape, including those that cannot be obtained by metal-cutting on machines.

- Minimization of subsequent mechanical finishing.

- High precision and low roughness of the finished surface.

Investment casting is a good alternative to welding because many components can be combined into one complex-shaped casting.

Since the tool is quite complex to manufacture, this technology fully pays for itself in serial and mass production.

Characteristics of steel

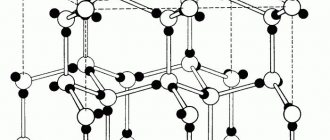

The basis of any grade of steel is iron and carbon. The amount of the latter varies within 0.1–2.14%. The higher its content, the better the quality of the steel. If the amount of carbon exceeds 0.6%, the alloy is called high-carbon. When the percentage of carbon exceeds 2.14, the material is called cast iron.

When steel is melted, alloying additives are added to it, which changes the mechanical properties of the alloy. These include:

- chromium;

- tungsten;

- cobalt;

- titanium;

- vanadium.

An important element in an alloy alloy is chromium. When its content is over 12%, the material acquires anti-corrosion characteristics. It is called stainless steel.

During steel production it is impossible to get rid of all impurities; some of them remain. These include:

- manganese;

- sulfur;

- silicon;

- phosphorus.

They degrade the quality of the alloy. Their percentage should be less.

An important characteristic of an alloy is its melting point. It is located in the range of 1350–1521 degrees. Carbon and alloying additives influence the increase in this value. It is necessary to know the temperature indicators accurately, since heating should be carried out 100–150 degrees higher than permissible.

Manganese

Die casting

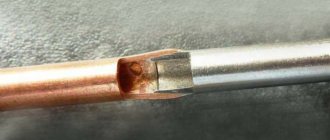

All types of chill casting are a group of methods especially suitable for producing castings from non-ferrous alloys - aluminum, magnesium and brass. Before casting, the functional surfaces of the molds are treated with a special kaolin or similar coating, which will effectively separate the surfaces. Molds that cannot be removed from the mold are often made using sand cores. After casting, the cores are destroyed.

Compared to sand casting, the solidification of the mold occurs faster due to better thermal conductivity. A casting is formed with a relatively fine and dense material structure, which, at the same time, has better mechanical properties compared to a casting from the same material, but cast in a sand mold.

Advantages of die casting:

- due to faster solidification, chill casting has better mechanical properties and a relatively fine and dense material structure;

- slight surface porosity;

- high dimensional accuracy and reduced surface roughness;

- reduction of metal loss coefficient.

Chill casting is a good choice for producing medium-sized castings for runs of 1,000 to 10,000 pieces, with a minimum production run of 100 pieces.

The process is used to produce medium-sized castings of instrument housings, drive covers, racks, brass or steel sealing inserts (nuts, bearing housings, pins, etc.).

Historical reference

The most ancient products (blanks of beads, plate overlays and pendants, fishhooks, etc.), cast from native copper in open molds and processed by hot forging, were discovered during excavations of the “pre-ceramic Neolithic” monuments of the Middle East, dated to the end. 8th – 7th millennium BC e. (Magzaliya, Chayenu-Tepezi, Çatalhöyük, etc.). Lithuania in detachable and composite stone forms (tools, weapons, jewelry, religious objects, etc.) originated in the Chalcolithic of the Southeast. Europe in the system of the Balkan-Carpathian metallurgical province (5–4th millennium BC). L. in closed stone, clay and metal. forms and melted models spreads in the Early Bronze Age in the system of the Circumpontic metallurgical province, reaching its peak in the Old World in the Late Bronze (2nd - early 1st millennium BC) and early Iron Ages. L. technology was widely used in the Middle Ages.

In Russia, in 1479, the first foundry was built - the “cannon hut” (Moscow). During the reign of Ivan IV, foundries were created in Tula, Kashira and other cities; under Peter I - foundries in the Urals, in the south and north of Russia. states. One of the largest castings in the world, made in 1873 at the Perm plant, is the chabot (the lower part that receives the impact) of a steam hammer (650 tons). The skill of the old Russian foundry workers is well known. factories - Kaslinsky, Putilovsky, Sormovsky, Kolomensky, etc. Until the 19th century. in L. they used the previously accumulated centuries-old experience of craftsmen. Only at the beginning 19th century were laid down theoretically. fundamentals of foundry technology. Growing up at work. scientists P. P. Anosov, N. V. Kalakutsky and A. S. Lavrov, D. K. Chernov for the first time scientifically explained the processes of crystallization, the occurrence of liquation and internal. stresses in castings, ways to improve the quality of castings are outlined.

Under pressure

Injection molding is a manufacturing process adapted for the production of parts in high volumes. The casting mold includes a sprue channel through which the molten material exits the nozzle of the injection molding machine. The mold has a system of channels that connect to the sprue (usually inside or as part of the mold) and direct the molten material into the mold cavity. The part of the channel after the slider, called the gate, leads directly into the tool cavity. After the injection mold cycle (usually lasting only a few seconds), the entire melt is cooled, leaving a solidified casting in the sprue, runners, and mold cavity.

The main advantage of the injection molding method is the ability to mass produce castings. The initial costs of implementation and development of production are quite high, but subsequently the cost per unit of production becomes extremely low.

Other benefits of the process:

- low defect rate (compared to traditional production processes, including CNC machining);

- reduction of production waste due to small losses of metal in the sprues, guides, and the location of holes for the melt outlet;

- possibility of producing parts from thermosetting plastics.

Injection molding can be reproduced in any volume, since the durability of the molds is very high. This ensures uniform quality of castings and stability of their characteristics during large-scale production.

Injection molding technology virtually eliminates any modification of the shape of finished products.

Classification

In addition, there is a classification according to the method of using steel:

Steel classification

- Construction - an ordinary material with good weldability.

- Structural – characterized by a high carbon content, suitable for frames, roofing, and rail manufacturing.

- Instrumental – used for cutting tools (cutter, chisel, chisel, drill, file, etc.).

- Alloyed - a universal mixture with a special admixture. Subtype – low-alloy steel for harsh climatic conditions.

- Special purpose steel is used in precision shipbuilding and electrical engineering.

Weldability is another important criterion for steel casting, which became the basis for dividing alloys into groups. This property is determined by the ability to deoxidize:

- Calm - completely deoxidized, contain a minimal amount of non-metallic impurities.

- Semi-calm, similar in quality to calm.

- Boiling steels are non-oxidized steels with a high percentage of non-metallic components.

For convenience, a special marking was introduced, which allows you to determine what type a particular alloy belongs to and what basic characteristics it has. It is important to remember that there is no global system, and each country has its own. Thus, on the territory of Russia it is customary to adhere to numerical and alphabetic designations.

Under regulated pressure

A type of injection molding that provides better process control. There are many factors that can affect the quality of the final product. The following variables play an important role in the controlled injection molding process:

- The rate at which molten metal is introduced into the mold cavity. It is important that the molten metal completely fills the cavity before it begins to solidify. If the metal flow rate is not ideal, it will negatively impact the strength of the final product.

- Injection pressure, which directly affects the rate at which molten metal enters the mold cavity. In controlled injection molding, the injection pressure is increased to improve sealing. A combination of high injection pressure and larger gate sizes is used to ensure structural stability of the casting. This in turn improves the overall mechanical properties of the casting, particularly the tensile strength.

- The time required for the molten metal to fill the cavity depends on the speed of the metal at the gate and the area of the gate. If the gate is large, the injection speed can be low, but if the gate is small, the injection speed must be high in order to completely fill the cavity.

For injection molding, alloys of metals and alloys are used, which are characterized by increased casting properties (fluidity).

An important factor affecting the castability of an alloy is the solidification interval. If the difference between the solid and liquid point of the alloy is large, controlled pressure casting is not used.

Foundry Process

Steel is an alloy with unique physical and chemical characteristics, in which iron accounts for 45% of the mass fraction of the material, less than 2% is carbon, and the rest is distributed among other chemical elements.

Thanks to this ratio of components, steel products are distinguished by high performance parameters that are not characteristic of other metals. Modern casting technology involves the use of several types of steels: structural, tool and alloy grades. Foundry production is a rapidly developing sector of industry, designed for mass production of shaped products. The purpose of this method is to obtain a workpiece that is as close as possible in geometric parameters to the final product specified by the technological conditions. To do this, metal molten in special electric furnaces is poured into disposable or reusable molds. The cooled casting is removed from the matrix and is a finished part or blank. The latter is subject to mechanical processing (countersinking, milling, grinding, etc.).

The choice of one or another casting method depends on operating conditions, purpose and volume of produced parts. The quality of the finished product is influenced by many factors, such as the material and thickness of the matrix, pouring speed and conditions, and cooling time.

In shell forms

Shell casting is used to produce cylinder heads, connecting rods and other machine parts where increased precision is required. This process requires a sand mold, and a special type of resin-coated sand is used.

The process provides a number of advantages:

- the ability to create complex shapes with the highest precision;

- low labor costs;

- suitable for most metals and alloys;

- used for any scale of production;

First, the sand is thoroughly mixed with resin, which acts as a binder. Then the sand is poured into a heated mold, the temperature of which usually reaches 750...13000C. The heated mold initiates a reaction with the resin-coated sand. When sand comes into contact with a hot mold, a shell forms on the inner surface of the mold. Next, excess sand is removed from the mold, and then the shell itself is removed, for which ejector pins are used. The ejector is built into the mold itself, making it easy to remove the newly created shell without damaging it.

Indications and contraindications for the installation of cast dentures

Despite the fact that modern medical technology has advanced quite far, the use of cast dentures in the form of bridges or individual crowns is often used in connection with many indications. Prosthetic dentures, which are important for chewing food, are often replaced with just such prosthetic structures for teeth, because they replace several teeth at once. At the same time, financial savings occur.

This type of prosthesis is used for the restoration of teeth with a short crown part. The fact is that such a pathology makes it impossible to install structures using more modern techniques and prostheses made from other materials. In addition, this type of structure is used to replace dentures that have already served their purpose.

However, this type of dentures is not used in people with poor blood clotting, the presence of tumor diseases, bone damage, allergies to painkillers and acute inflammatory processes. Dentists often do not recommend the installation of cast dentures for people with malocclusion, poor oral hygiene, and those who suffer from high grinding of chewing teeth.

Centrifugal casting

Centrifugal casting is a process that produces high-strength castings. This technology is chosen for products such as jet engine compressor housings, hydraulic wear rings, and many defense products.

The steps in the centrifugal casting process begin with pouring molten metal into a preheated die. The mold can be oriented along either a vertical or horizontal axis depending on the part configuration.

As the mold rotates while pouring molten metal, centrifugal force distributes the molten metal into the mold under pressure up to 100 times the force of gravity. The combination of this pressure, controlled solidification and secondary refining produces products of the highest quality.

As the mold begins to fill, the denser molten metal is pressed against the wall. Directional solidification of the strong metal occurs from the periphery of the mold towards the channel, while less dense material, including impurities, moves towards the inner diameter.

After the casting has hardened, the part is removed from the mold, and residual contaminants remaining on the surface of the casting are subjected to mechanical processing - cleaning.

A variant of the technology is centrifugal casting in a vacuum. It is used when part accuracy and control of atmospheric exposure are critical because some alloys, including nickel-cobalt alloys, are reactive to oxygen.

Important: Centrifugal vacuum casting provides very high reliability for products often used in the aerospace and military industries.

The importance of steel in global industry

Metallurgy - steel production

The global steel industry is one of the most developed branches of metallurgy. Despite the recent decline in production due to the financial crisis of 2012, steel casting has received a new impetus and is now rapidly gaining momentum. The annual demand for this method is steadily increasing due to trends towards urbanization and industrialization. The main buyers of steel products are countries with well-developed infrastructure and industry. Steel production in the world accounts for about 90% of the volume of all metals.

Steel is widely used in the construction of roads, buildings and infrastructure: the largest stadiums, airports and bridges usually have a steel skeleton. Bolts, nails and screws are also made by casting steel into special molds. Despite the growing share of aluminum in the world market, steel casting will not lose its position for a long time. At the same time, steel production is characterized by cyclicality and, consequently, relative instability.

According to gasified models

It is a technology for producing high-quality castings using an initial model (blank) obtained from a material that, when pouring molten metal into a mold, is saturated with released gases.

As a result of the action of high temperatures, which manifests itself during the process of pouring the melt into the mold, the model is first destroyed and then melted. Destruction products in a drop-like state are blown out by a continuous gas flow. In this case, in the processing zone, depending on the design of the installation, either negative pressure or vacuum is created. Under the influence of the pressure difference inside and outside the container, the vacated space is occupied by a metal melt, which recreates in detail the configuration and dimensions of the casting.

Metals for pouring

Black metals

In the metallurgical industry, a distinction is made between non-ferrous and ferrous metals. Blacks include iron, manganese, chromium and alloys based on them. This includes all steels, cast irons and ferroalloys. Ferrous metals account for more than 90% of the world's consumption of metal alloys. Steel is used to produce hulls and parts of vehicles from scooters to supertankers, building structures, household appliances, machine tools and other industrial equipment.

Cast iron

Cast iron is an excellent metal for casting large, strong, durable structures that are not subject to bending or twisting stresses.

Non-ferrous metals, in turn, depending on their physical properties, and above all, specific gravity, are divided into two large groups

Light non-ferrous metals

This group includes aluminum, titanium, magnesium. These metals are less common than iron and are more expensive. They are used in those industries where it is necessary to reduce the weight of a product - the aerospace industry, the production of high-tech weapons, the production of computing and telecommunications equipment, smartphones and small household appliances.

Titanium

Titanium, due to its excellent interaction with the tissues of the human body, is widely used for prosthetics of bones, joints and teeth.

Heavy non-ferrous metals

These include copper, tin, lead, zinc and nickel. They are used in the chemical industry, production of electrical materials, electronics, transport - wherever sufficiently strong, elastic and corrosion-resistant alloys are required.

Copper

Zinc

Nickel and its alloys

Noble metals

This group includes gold, silver, platinum, as well as rarer ruthenium, rhodium, palladium, osmium, and iridium.

The first three have been known to man since prehistoric times. They were rarely (relative to copper and iron) found in nature and therefore served as a means of payment, material for valuable jewelry and ritual objects.

Gold and platinum

With the development of civilization, gold and platinum retained their role as a means of accumulating wealth, but they became very widely used in industry and medicine due to their unique physical and chemical properties.

Continuous casting

A process that allows metals and alloys to stretch, shape, and harden without having to interrupt the pour. At the same time, waste is reduced, the yield of finished products is increased, and the economic efficiency of production is improved.

Battery grids are manufactured using continuous injection molding. Using a water-cooled roller and mold system reduces the chance of impurities and provides a better thickness ratio.

Stages of denture casting

The process of making dentures by casting is long and labor-intensive - during the work, dental technicians and dentists carry out measures to cast and adjust prosthetic structures for a specific oral cavity. The work consists of several stages.

First of all, to correctly determine the parameters of dentures, impressions of the lower and upper jaws are taken. To obtain two-layer impressions of teeth, impressions are made in two stages: first with base material, and then with corrective material. Taking dental impressions is done in two ways:

- Without additional orthopedic means – used in case of preparation of tooth heads;

- Using orthopedic devices in the form of screws or other components. After this, the two-layer impression is removed with corrective material. Such prints are more accurate.

The process of taking impressions to make dentures takes only a few minutes and is not accompanied by pain, so anesthesia is not required. After this stage is completed, production of the working model begins. This blank is made from an alloy using nickel, gold, cobalt or titanium. Since this stage is quite long and takes from 5 to 30 days, the patient can have a temporary prosthesis made from cheaper materials installed during this time

Before starting modeling, the stamp is varnished to avoid unevenness. To obtain crowns, a set of waxes and a number of medical technical means are used to melt the material and give the prosthesis model the desired shape.

Modeling of the tooth crown begins with obtaining a cap by dipping a modeling stamp into a mass of molten dipping wax, which is maintained by a wax melter in the consistency that allows obtaining the required wall thickness of the cap. The wall thickness of the wax model of the cap used for lining with metal ceramics is very small - less than half a millimeter. This is the optimal thickness for the material to be cast well.

Then, using an electric spatula, the technician adds other waxes: cervical, modeling, milling. A gating system is formed from wax wire of the required diameter. The number and size of elements of the gating system are chosen so as to ensure not only filling of the mold, but also compensation for the decreasing volume of material due to shrinkage processes, otherwise pores and cavities in the casting are possible.

The next step is to make a casting mold from wax. It is important that the material is treated with a liquid that reduces the tension of the wax and fills small cavities. Another significant point is the same temperature of the material for all parts of the denture. The formation of the alloy structure and the quality of the casting of the product depend on this.

The production of a casting mold includes the procedure for obtaining a duplicate of the plaster model. Such a blank is made from a refractory alloy, and its internal contours must correspond to the contours of the model. During this process, the wax is burned off and the mold is heated to high temperatures necessary to melt the metal used. After this, the alloy is melted and cast. To avoid receiving a defective product, it is necessary to prevent overheating of the material. Otherwise, the product will turn out rough due to the destruction of the mold and the penetration of metal into its walls. Such a labor-intensive process requires high professionalism and the presence of certain knowledge and skills from the dental technician.

Once the design blank has been polished and matched to the patient’s dental impressions, decorative plastic or ceramic coverings are installed. However, this stage is optional, it depends on the wishes of the patient. It should be taken into account that ceramics is a more durable and strong material for installation on dental crowns; in addition, it looks very aesthetically pleasing after installing the prosthesis in the oral cavity.

The process of manufacturing a working model of the structure involves sandblasting and fitting in 2 stages:

- On the model;

- In the patient's mouth.

If the prosthesis meets the necessary requirements, then at this stage it can be installed. In other cases, the design is returned to the dental technician for revision.

Metal casting in CTS

The acceleration of the casting process led to the development of cold-hardening mixtures (CMC), which have become widespread. They have certain disadvantages. For example, some self-drying oils create a form that requires long drying periods, especially when air access is prevented. Urea-based synthetic resins, which are also designed for use as CTS, have very low breakdown temperatures, which in turn limits the versatility of the resulting form. Sand mixtures containing furan-based acid-curing resins (another but relatively new cold-curing binder) also have certain limiting characteristics. For example, they tend to cause the mold to stick to the casting, and the outgassing that normally accompanies pouring molten metal into molds becomes very pronounced and turbulent.

Modern CTS compositions are formed using binders containing at least one diphenylmethane ethoxylin resin or diphenol derivatives, to which at least one organic compound containing many reactive amino groups is added as a hardener.

Very good results are obtained when ethoxylin resins are synthesized from para-substituted diphenylmethane derivatives, especially bisphenol. Moreover, their epoxy equivalent exceeds 170.

Among the organic compounds that can be used as hardeners, promising compositions are those having many reactive amino groups and especially polymers (linear or ring), which include from two to five = NCH CH groups.

History and essence of technology

In ancient times, steel was produced in shaft furnaces using the cheese-blowing method. Charcoal was used for this. Iron was mined from ore. At the same time, small pieces of cast iron were used as raw materials. Melting was carried out in crucibles. The quality of the resulting material was high, but low-productivity. However, this is exactly the method used to obtain Damascus steel.

Later, cast iron was processed using critical processing. It was being refined in a screaming throat.

In the 18th century, puddling technology began to be introduced. The starting material was also cast iron. The disadvantage of the technology was low productivity.

The open-hearth production method was developed in the 19th century. It turned out to be so successful that it was used for 100 years. And only then in the 50s it was replaced by the oxygen converter process.

The process of installing cast dentures

Installation of metal or metal-ceramic cast dentures is a lengthy process, and this is due not only to the length of time it takes to manufacture the structure. The fact is that before installing a denture, it is necessary to bring the oral cavity to the standards of health and hygiene. If there are teeth affected by caries, they are first treated and filled. Those teeth that cannot be treated are removed. It is important to cure all oral inflammations, if any.

Only after the teeth and gums have been cured and the oral cavity has been sanitized, do dental prosthetics begin. At the initial stages, the supporting teeth are ground for the prosthesis. Often healthy teeth fall under this procedure, so the fact that cast dentures make it possible to preserve them and protect them from destruction plays a special role.

Next, impressions of the upper and lower dentition are taken. This is necessary even if the denture will replace only a certain area of the teeth, because the product must fit naturally and comfortably in the oral cavity.

After this, the patient begins a waiting period. At this time, dental technicians make a prosthetic structure, grind it, and line it with ceramics or plastic material. After the design is ready, the first fitting takes place in the oral cavity. In some cases it is the only one. If the denture is made with high quality and fits exactly in size, the doctor will secure it in the mouth with dental cement. If the design does not meet the requirements of comfort and quality, it will be returned to the dental technician for revision. After all corrections, the structure is installed in the mouth.

Where to sell alloy wheels for scrap?

Scrap aluminum wheels in Moscow are readily purchased by a huge number of collection points that are ready to offer attractive conditions. But in order to choose a truly advantageous offer, which involves getting a good profit with a minimum of labor costs, you need to competently approach the choice of a company that buys non-ferrous metals.

First of all, pay attention to experience in the market and availability of licenses to operate. An important criterion is the correspondence of prices to market prices. We also recommend that you read real reviews from customers who have taken advantage of the offers offered by collection points.

You can learn more about the delivery of discs for scrap metal, the price of stamped, cast and forged models and the conditions for the sale of scrap at one of the collection points in Moscow or by phone.