Welding work, like any other production activity, requires the presence and observance of certain rules so that the welding process is as productive as possible and the welded joints are of high quality. In Russia and some countries of the former USSR, such rules are established by documents SNiP (building codes and regulations), GOST (state standard), ENiR (uniform norms and prices), SP (code of rules) and others.

When starting a job for the first time, novice welders are often faced with ignorance of SNiPs and GOSTs, and this is not surprising. After all, the welder is faced with the task of studying and understanding dozens of regulatory documents written in an official business style, and this takes a lot of time. We decided to help you and, based on the rules used in construction and welding, we have compiled a list of the most important standards that you should know before starting work. We will teach you how to calculate the welding time per 1 m of seam and calculate how many meters per day you need to weld, we will tell you how to carry out quality control of welded joints and what are the requirements for welded structures.

Welding standards

First, let's figure out why standards are needed at all and what they are. First of all, standards regulate the quality and speed of work. The standards are also influenced by the welding method, the functionality of the welding equipment used in welding, and the qualifications of the welder. After all, an experienced master can do twice as much work per shift as a novice worker. The welder’s workplace is also taken into account, and special attention is paid to its organization.

Modern standards regulate the time that a welder must spend on his work, the amount of work performed (for example, the number of welded metal products per shift), the consumption of electricity and materials (electrodes, welding equipment, etc.). Let's take a closer look at each of the standards.

Time standards

In most countries of the former USSR, there are so-called uniform time standards for making 1 m of seam. They are usually specified in regulatory documents. But, despite this, each welder must be able to independently calculate welding time, since this is one of the most important indicators of his productivity. The time standard consists of how many minutes the welder must spend on the immediate welding process, and how many minutes he must spend on preparatory and/or other production operations. In general, there are three production operations that make up the norm:

- Basic production operation. This includes the procurement of materials for welding and metal, its processing and preparation for welding. This also includes the welding process itself.

- Auxiliary production operation. This includes quality control of welded joints and seams, as well as transportation of the finished part to the next workshop.

- Additional time. It is also regulated and given specifically so that the welder can carry out maintenance of the welding process 1 and put the part into storage, if necessary, between the main and auxiliary operations.

Also note that before calculating the welding time, you need to take into account other processes that take even a few seconds during operation. Such processes include setting up the welding machine, the time spent igniting and burning the arc when welding special types of metals, time spent changing rods, applying flux or cleaning the seam, and the like. Also, do not forget to take into account that the welder needs time to care for the workplace and to rest (for this you need to subtract about 20% of the time received).

We wrote above that the qualifications of the welder, as well as his experience, are also taken into account. This is usually calculated using a special coefficient. During the calculations, we obtain a figure that is the equivalent of a qualification. Simply put, each qualification is assigned a number, which is then used in calculations.

The calculation can be done in different ways, but the most common is work units. One work unit is equal to one welded product. The higher the qualification, the more units the welder must perform per shift. If the volume of work is too large and does not allow calculation in units, then the time required to complete 1 m of seam is calculated in minutes. As you can see, the time standard includes many operations that should be taken into account when calculating. We'll talk about how to make the calculation later, but for now let's look at the rest of the rules.

Production rate

Output rate is essentially just the amount of work you complete in a certain amount of time. As we said above, the norm can be expressed in the number of products or in meters of weld that you managed to weld in an hour or per shift. The production norm can be simply one of the components of the time norm, or it can exist as an independent rule.

To make it clearer, we will give a simple example. Let’s say a welder needs to weld 24 meters of seam per shift. We calculate everything: the time that needs to be spent setting up the equipment, preparing the metal, igniting the arc, the welding process, and so on, plus we don’t forget to add time for rest. In total, for a welder of average qualification the norm will be 3 meters of seam in 1 hour. Accordingly, per day (assuming an 8-hour working day) the welder must make 24 meters of seam.

Electricity consumption standards

Another equally important rule that should not be forgotten. It is necessary to calculate the cost of welding work and the finished product. Often, consumption is calculated in kilowatt-hours that the welder spent on his work. Readings are taken from the meter.

Component consumption rate

As you understand, during welding you consume not only electricity and time, but also components: electrodes, gas, flux, wire, etc. This also includes the natural wear and tear of equipment used in welding. Not only equipment is subject to wear, but also specific elements required for special types of welding. For example, contact jaws, roller guides, contact plates and much more. All this needs to be taken into account. By the way, in this article we described in some detail how to calculate the consumption of welding wire. Be sure to read it.

In this case, the degree of wear can depend on many factors, for example, on the material from which the components are made, on the metal that you are welding, and even on the mode set in the welding machine. It is important to consider all these factors, since they also affect the cost of your work and the finished product. As you understand, standardization of welding work is simply necessary in a production environment.

Now that we have dealt with the standards, let's move on directly to calculating the time we need to spend on welding and see what standards modern construction documents offer us.

Welder's mark: what is it for?

Near welded joints of pipelines, metal frames, gas equipment, etc. It is not uncommon to see embossed letters and numbers. This is the welder's mark, which must accompany those connections that will be used at hazardous sites. Let's figure out how you can get a welder's mark, how it is deciphered and where it is placed.

Purpose of the mark

The welder’s personal mark is a device with which an imprint is placed near the welded joint. Branding of the part is necessary if the work was carried out on particularly critical structures.

Only a welding specialist who has passed the NAKS certification has the right to leave a stamp imprint next to the seam.

By doing this, the welder confirms that the work was done efficiently and that he has taken responsibility for the result.

Each NAKS welder's mark bears a number that has no analogues. If seam defects are identified, it will not be difficult to determine who owns the mark. Information can be found in the unified database of welders.

The position of the specialist, his rank and type of activity, the area of NAKS certification and the date of the last examination, as well as the number of the mark are indicated there.

Such precautionary measures when working at hazardous facilities are prescribed by the FPN “Welding at HPFs,” which came into force on October 8, 2014 and are in effect to this day.

What does the mark look like?

The welder's personal mark looks like a metal rod with a round or square cross-section. It is made of tool steel, the strength of which must be at least 50-60 HRC. On one side there is a mirror designation consisting of letters and numbers. The second side is the percussion side.

If you apply a sharp force to it, a direct image will appear on the part. The depth of the stamp imprint, as well as its other parameters, is regulated by GOST 25726-83.

The height of numbers and letters, as a rule, is 6 mm, however, the management of a particular enterprise may provide for other cipher sizes.

Decoding

The welder's mark code is purely individual. Thanks to this, it is almost impossible to confuse employees, even if the enterprise has a high staff turnover or employs employees who work on a rotational basis. As a rule, such a mark must contain the following information in encrypted form:

- Name of the specialist

- His name and patronymic,

- Date of Birth.

The placement of components occurs randomly in an automatic mode, however, there are impact marks on which the first letters of his last name are used to identify a specialist. Please note that the cipher is assigned without the right to change. That is, if an employee changes his welding method or undergoes repeated or extraordinary certification, his mark will remain the same.

If a specialist passed the NAKS certification before the FNP “Welding at hazardous production facilities” came into force, then his mark can be used until the next certification. After this, he will be issued a new mark with a different code, which will not change during subsequent certifications.

The arrangement of symbols on the brand may be as follows:

- The characters are placed in two lines, there is no frame.

- The symbols are arranged in two lines and have a frame.

- Numbers arranged on one line and enclosed in a rhombus.

- Numbers that fit on one line, framed by a circle.

- Numbers located on one line and enclosed in a square.

- Numbers on one line without frame.

What needs to be branded

NAKS welders put their mark on critical structures that are subject to special requirements regarding reliability and safety. For example, on gas, boiler, hoisting and transport, oil and gas production equipment, building structures, near pipeline welds, etc.

The print must be applied to metal surfaces whose thickness exceeds 6 mm. If the thickness is less than 6 mm or welds are to be applied to the reinforcement, the stamp does not need to be used. After applying the print, it is necessary to fill out a welding log and a weld test report.

Where exactly is the mark placed?

The welder’s personal mark must be affixed in the place prescribed in the technological documents. If such recommendations are not provided, then it is placed on the area to be welded, at a distance of no less than 40 mm from the boundary.

If the welding connection was carried out by one specialist, then he leaves his impression near the marked starting point.

If several welders took part in the work, then each of them is obliged to leave an impression at the beginning and end of the seam.

When connecting pipes or complex structures, where welding is performed on both the outer and inner sides, the imprint should be on the outer side. If the welding of the sides was carried out by different specialists, then the marks of the performers should be located in the form of a fraction. The numerator should be entered by the one who welded the external seam, the denominator should be entered by the one who welded the internal one.

If it is necessary to affix a stamp after making a circular seam, then this must be done at the intersection of this seam with the longitudinal ones.

If the seam connection is long, impressions must be repeated every two meters. To mark the place of branding, it is outlined with bright indelible paint.

The print must be neat and readable throughout the entire operation of the welded parts.

How to get a welder's mark

An order to assign a mark to a welder is the final stage of obtaining a personal mark. It is preceded by NAKS certification. To successfully pass all tests, you need to have the experience required by the rules, have good knowledge of the theory of welding production and cope with the practical part of the exam. The stamp will be issued along with the certificate.

What the NAKS certification is and how to pass it can be found here.

An order to assign a mark to a welder is drawn up by the institution that carries out welding work. The document can be formulated in any form. Most often, it specifies the types of structures that must be branded, as well as a list of additional functions of the owner of the brand.

[Total: 1 Average: 5/5]

Calculation of time spent on welding

Time standards for welding work are established for a reason, you could understand this after reading the last section. As you remember, our productivity indicator is either the number of products that you welded or the meters of welds that you welded.

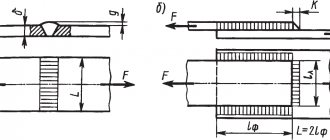

Below is a table in which you can see the uniform time standards for one-sided welding of butt joints without beveled edges. These standards are taken from ENiR (Collection E22, section “Welding work”). You can also find standards in SNiP for welding. The standard time for welding may differ depending on many factors: from the type of seam to, again, the qualifications of the craftsman. Now let's get down to direct calculations, since every master must know this and apply it in practice.

Calculations

To calculate the time for making 1 meter of seam with an electric arc, formulas are used. The most universal formula is as follows:

t0 is fundamental time, usually measured in hours and sometimes in minutes.

L is the length of the seam, usually 1 m of seam is measured in meters or centimeters.

F is the cross-sectional area of the seam, measured in square centimeters.

7.85 is an example of the density of the deposited metal, taken in grams per cubic centimeter, you must substitute your density value.

I is the value of the welding current, measured in amperes.

Kn is the deposition factor.

To calculate how much time a welder spends on work per day, simply multiply the resulting figure by the number of working hours.

If you need to calculate the time spent on gas welding, then use the following formula:

S is the thickness of the metal being welded, indicated in millimeters.

K is a coefficient, it depends on the type of metal used in welding (for low-carbon steel this coefficient is 4-5; for alloy steel, cast iron, brass and bronze - 6, for copper - 3, and for aluminum and its alloys - 4 ).

It would also be useful to remember the formula for calculating the time spent on oxygen cutting:

L is the cutting length, indicated in millimeters.

v is the cutting speed, denoted by mm in mi.

How to organize your workplace

In order for a welder to fulfill all the norms assigned to him per day, he needs to properly organize his workplace. Agree, sitting on an uncomfortable chair or with an incorrect desktop height is difficult to meet the norm. Our goal is to maximize labor productivity. Usually at work there are so-called NOT plans (scientific organization of labor). They describe in detail what kind of workplace you are entitled to. In the picture below you can see a workplace that complies with the rules.

In addition to physical comfort, the workplace must comply with safety regulations. Also, the welder should have easy access to all the necessary tools so as not to waste time looking for an electrode or a new part.

Marking welds instructions - Metalworker's Handbook

We offer production according to your individual drawing or sketch of a welder's mark for marking welds and metal structures. The welder's mark is made using the same technology as the impact mark and is a metal rod made of U8A tool steel with a hardening hardness of 52-56 HRC.

On one side of the rod a mirrored alphabetic and numerical designation is engraved, the other is intended for striking. After applying the image to the working part of the welder's mark, it is hardened in a high-temperature industrial furnace, after which the mark is ready for use.

As a result of the impact, a direct relief image remains on the product.

The welding mark, which is made in accordance with GOST 25726-83, must contain letters and numbers measuring about 6 mm. In the case of special work, it is allowed to use a sign of a larger or smaller size, and this circumstance is discussed with the management of the organization and made known.

The main rule of welder identification is that when stamping metal products, it is not allowed to form riveting, welding, or reduce the thickness of the metal; the imprint itself must be readable and neat. The safety of markings must be at the highest level throughout the entire period of operation of the structure.

Quality control of welding work

We're done with the standards, now let's talk about what the welder should do after welding. First of all, he must carry out quality control of welding work. In large industries this is done by individuals, but in most factories this responsibility is assigned to a welder. The topic of quality control is quite extensive, so let’s look at it in more detail.

Control of welding work can be divided into three stages:

- Welder qualification check

- Quality control of welded parts

- Visual and mechanical quality control of welded joints

Let's take a closer look at each stage.

Qualification check

Before allowing a welder to work, you need to check the compliance of his skills and assigned qualifications. Each welder must present documents with a welding permit and make a test weld on a sample of the part given to him. During the test, you need to use the same electrodes and the same metals as during the main work. The samples are then sent for examination and examined. If the welder’s work complies with the standards, then the master is allowed to weld.

Quality control of welded parts

Before work, you need to check the quality of the parts that need to be welded. Parts must have appropriate documents and be made of certified metal. Before welding, the parts must be carefully inspected to find out if there are any defects. In general, the quality of parts is also regulated by standards. You can study them separately by reading SNiPs and GOSTs.

Visual and mechanical quality control of welded joints

This is the final stage, which is carried out after welding. First you need to clean the seam from slag and particles of splashed metal. Then you need to inspect the seam. Ideally, the seam should have a fine-scale structure, and the transition from seam to metal should be smooth. The height of the seam should not exceed 3 millimeters, ideally 1 millimeter.

If welding rules are not followed, defects will form almost immediately, so a visual inspection can help identify 50% of problems before the part is subjected to more serious testing. During visual inspection, cracks, excessive porosity of the joint, excessive slagging, and unwelded seams can be detected.

After a visual inspection, the seam must be subjected to mechanical tests. With their help, the tensile strength of the connection is determined. If deficiencies are found, additional inspection is carried out to confirm the presence of defects. If, after a second check, the negative result is confirmed, the welder will be removed from work and sent to advanced training courses.

Mechanical testing can reveal additional defects that are not visible during visual inspection. This may be lack of penetration of the root of the seam, lack of lateral penetration, burn-through or internal cracks. If the welding seam is long, then cutting out the defective area is allowed.

Ultrasonic testing of welded joints

Ultrasound can be used to check the quality of welds. The principle of operation is simple: the device generates ultrasonic waves with a frequency of up to 20 thousand Hz, which easily penetrate the pores of the seam and begin to be reflected from internal cracks and or voids, if any. The sound wave is straight, but if there is a defect in its path, it becomes bent.

Such work is usually entrusted not to a welder, but to a special operator who records all defects on the device monitor and records the test results in detail. In general, this is one of the most popular ways to detect defects hidden from view.

We have listed the most popular methods of quality control. Of course, there are other methods, but the ones listed above have long proven themselves to be the most effective. Especially in large-scale production environments. After quality control of welding work has been carried out, the results must be recorded in a journal and on a drawing.

Marking of welds GOST

Welding is a profession that requires great attention and responsibility. When a welder performs important work, management must be sure that all welded joints are performed correctly.

However, how can an inspection reveal who carried out certain welding works? A welder's mark helps resolve this issue quickly and without problems.

This requirement was legislatively approved a long time ago, but in connection with the entry into force of new norms and regulations in the field of industrial safety, some changes have appeared regarding the welder's mark.

In general, the order of the Federal Service for Environmental, Technological and Nuclear Supervision is aimed at enhancing the quality of work and minimizing all kinds of violations when working with heavy metal structures at hazardous production facilities. At the same time, much attention in the FNP “Welding at HPF” is paid specifically to the identification of the worker who performed the welding activities.

Why is a welder's mark necessary?

Metal structures are used throughout the construction of most industrial buildings. The elements are connected to each other using welding. It is impossible to unambiguously determine whether the seam will be strong and durable - this is done by the inspection commission.

A timely identified defect allows you to avoid huge expenses associated with deformation and collapse of metal structures.

Therefore, when performing work related to surfacing, welding at hazardous production facilities, each welder is required to put his own code next to the work performed - a mark that allows you to quickly determine who owns the work with the identified violation.

Federal rules and regulations, which are aimed at safe operation in difficult production facilities, came into force on October 8, 2014.

Until this time, identification numbers were already widely used, but there was no single database from which one could find out all the necessary information about the welder: position, date of certification, type of activity, area of certification.

Type and code of the mark

The welder's mark is a metal rod, which is made of tool steel with a hardening hardness of 55-60 HRC. The rod, one side of which is flat and the other with an engraved image, is subjected to an impact, in place of which a clear relief is formed.

After the documented approval of the code to each employee, the organization must provide impact stamps.

In some cases, the first letters of the surname or numbers are used as identification, but most often the code is generated automatically, without changing during renewal, certification or changing the welding method.

The mark code is assigned to the welder - this avoids confusion that may arise in the future.

The welding mark, which is made in accordance with GOST, must contain letters or numbers measuring about 6 mm. In the case of special work, it is allowed to use a sign of a larger or smaller size, and this circumstance is discussed with the management of the organization and made known.

The main rule for identifying a welder is that when branding metal structures, there should be no work hardening, hardening or reduction in the thickness of the metal. The safety of markings must be at the highest level throughout the entire period of operation of the structure.

Where and in what cases is it placed?

In accordance with paragraph 21 of the FNP “Welding at hazardous production facilities”, all welded joints with a wall thickness of more than 6 mm must be marked with identification numbers of the welders who performed the work. Also, according to GOST 25225-82, the welder is obliged to indicate the place of work performed with a mark or brand.

Typically, the welder's mark is affixed on vertical structures, when connecting metal beams, in the case of fastening a ceiling base - there can be a huge number of options.

It is also worth noting that in the case of fastening reinforcement or welding elements with a thickness of less than 6 mm, the use of a mark is not necessary - in this case it is necessary to apply the requirements of production technical documentation.

The welder, immediately after carrying out welding work at hazardous production facilities, is required to affix a mark next to the completed seam. At the same time, a log of welding work, test reports of welded joints are filled out, and all the executive documentation required by law is drawn up.

The Federal norms and rules also contain a clause stating that when welding operations are performed by one welder, it is not necessary to indicate the identification code on all seams.

This is explained by the fact that the construction plan already contains a designation of the person performing the work - to avoid repetition and eliminate unnecessary red tape, it is enough to indicate the mark code in a place accessible for inspection, while enclosing it in a frame with indelible paint.

At the same time, if several workers worked on one weld of high complexity at once, it is necessary for each welder to leave his own code.

Welder's mark

We offer production according to your individual drawing or sketch of a welder's mark for marking welds and metal structures. The welder's mark is made using the same technology as the impact mark and is a metal rod made of U8A tool steel with a hardening hardness of 52-56 HRC.

On one side of the rod a mirrored alphabetic and numerical designation is engraved, the other is intended for striking. After applying the image to the working part of the welder's mark, it is hardened in a high-temperature industrial furnace, after which the mark is ready for use.

As a result of the impact, a direct relief image remains on the product.

The welding mark, which is made in accordance with GOST 25726-83, must contain letters and numbers measuring about 6 mm. In the case of special work, it is allowed to use a sign of a larger or smaller size, and this circumstance is discussed with the management of the organization and made known.

The main rule of welder identification is that when stamping metal products, it is not allowed to form riveting, welding, or reduce the thickness of the metal; the imprint itself must be readable and neat. The safety of markings must be at the highest level throughout the entire period of operation of the structure.

Requirements for welds

It is also advisable for the welder to know the requirements for welds of metal structures. This will contribute to proper quality control and adequate assessment of your work.

Requirements for the mechanical properties of a welded joint

Welding metal structures or welding pipelines implies the absolute strength and reliability of the welds. This can only be achieved if the requirements for the mechanical properties of the joints are fully met. Based on GOSTs and rules, we have identified the following basic properties of the seam that must be observed in order to obtain a high-quality connection:

- The relative elongation of the weld metal should not be less than 15-16%.

- Impact strength must be at a high level. To find out this parameter, you need to conduct a test: check the reaction of the seam at the average daily temperature, and the test must be carried out for a week at the lowest temperature in your region. The minimum value of impact strength is 29 J/sq.cm.

- The tensile strength of the weld should be similar to that of the metal used for welding. A lower resistance value is not allowed.

- The hardness of the metal should be 350 HV for welded structural elements belonging to group 1, and 400 HV for welded elements of all other structures. These rules are regulated by SNiP II-23.

Weld quality requirements

When welding metal structures, it is extremely important to pay attention to the quality of the seam itself. Previously, we talked about how the quality control of welding joints is carried out, now we will talk about the classification of seams based on their quality. So, seams come in three categories:

- First category. Best quality. This category may include any type of seams that have special requirements for durability and reliability. Seams of the first category must withstand enormous loads and ensure reliable connection of complex metal structures, including industrial ones. Seams of the first category are used to weld metal frames of buildings and the hull of ships. Also in the first category are seams designed for long-term use in harsh climatic conditions. For example, in the Far North.

- Second category. Medium quality. This is the most common category and includes any type of tear-resistant seam. In general, most compounds can be classified into this category. A striking example is the seams used to weld car bodies. Such seams can withstand relatively large loads, but are not designed for use in harsh conditions.

- Third category. Below the average. Seams of this category are not necessarily the worst in quality, but they definitely cannot be applied to critical structures. But you can weld auxiliary metal structures, saving time and effort.

Other requirements for welded joints

Requirements for welded structures and seams can be very diverse, and in addition to those indicated above, there are a number of features that are worth knowing before starting work. Within the scope of this article, we will not be able to describe all the features, since the welding process has many nuances. We recommend that you familiarize yourself with SNiPs on the topic that interests you. There you can find all the necessary information about the location of the welding joint, its recommended length and thickness for each type of structure and metal. Think of norms not as a set of rules, but as a convenient cheat sheet for work.

Marking welds instructions

We offer production according to your individual drawing or sketch of a welder's mark for marking welds and metal structures. The welder's mark is made using the same technology as the impact mark and is a metal rod made of U8A tool steel with a hardening hardness of 52-56 HRC.

On one side of the rod a mirrored alphabetic and numerical designation is engraved, the other is intended for striking. After applying the image to the working part of the welder's mark, it is hardened in a high-temperature industrial furnace, after which the mark is ready for use.

As a result of the impact, a direct relief image remains on the product.

The welding mark, which is made in accordance with GOST 25726-83, must contain letters and numbers measuring about 6 mm. In the case of special work, it is allowed to use a sign of a larger or smaller size, and this circumstance is discussed with the management of the organization and made known.

The main rule of welder identification is that when stamping metal products, it is not allowed to form riveting, welding, or reduce the thickness of the metal; the imprint itself must be readable and neat. The safety of markings must be at the highest level throughout the entire period of operation of the structure.

Welder's mark code

Each welder carrying out his labor activity at industrial safety facilities is assigned an individual brand code, in other words, his personal sign, which is a kind of signature of the work performed.

The welder's mark is assigned during certification. The mark code is assigned to the welder - this avoids confusion.

An order to assign a mark to a welder is written in any form, which may indicate the types of structures being welded and additional powers of the performer.

https://www.youtube.com/watch?v=yww-vPMWEAA

After documentary approval of the code to the employee, the organization must provide impact stamps.

In some cases, the first letters of the last name or numbers are used as identification, but most often the code is generated automatically based on the welder’s full name and date of birth, without changing when renewing, passing certification or changing the welding method.

There are several options for welding marks: numbers in two lines without a frame, numbers in two lines with a frame, numbers in a rhombus, square, equilateral triangle and without them. All characters have a font height of 3 to 5 mm.

Federal rules and regulations, which are aimed at safe operation in difficult production facilities, came into force on October 8, 2014.

Until this time, identification numbers were already widely used, but there was no single database from which one could find out all the necessary information about the welder: employee’s position, certification date, brand code, category, type of activity, certification area.

Information about welder mark codes must be posted in the public register of certified personnel on the Internet. The brand codes assigned during certification must be assigned to welders by order of the organization performing welding work.

If the welder was certified before the FNP “Welding at hazardous production facilities” came into force, then he will retain the mark that was issued to him earlier and enshrined in the order of the enterprise. It is valid until the next certification, and then, after passing it, a new mark is issued in accordance with the requirements of the Federal Tax Service.

Why do you need a welder's mark?

Welding is a profession that requires great attention and responsibility.

When a welder performs important work, management must be sure that all welded joints are correctly completed.

However, how can an inspection reveal who carried out certain welding works? A welder's mark quickly helps resolve this issue. This requirement was approved by law.

https://www..com/watch?v=ZbnEIr5ITFc

Metal structures are used everywhere in the construction of most industrial buildings and structures. The elements are connected to each other using welding. It is impossible to unambiguously determine whether the seam will be strong and durable - this is done by the inspection commission.

A timely identified defect allows you to avoid huge expenses associated with deformation and collapse of metal structures. Therefore, when performing work related to surfacing, welding at hazardous production facilities, each welder is required to put his own code next to the work performed - a mark that allows you to quickly determine who owns the work with the identified violation.

How to get a welder's mark?

The welder's mark is a mandatory element of a worker certified by the National Welding Control Agency (NAKS).

The structural unit of the welding production certification system, after successfully passing all tests, issues a mark code along with an attestation certificate.

In accordance with the requirements of NAKS, welders are allowed to perform work that is documented.

Welder's mark. Where and why is it placed?

Welding is a profession that requires great attention and responsibility. When a welder performs important work, management must be sure that all welded joints are performed correctly.

However, how can an inspection reveal who carried out certain welding works? A welder's mark helps resolve this issue quickly and without problems.

This requirement was legislatively approved a long time ago, but in connection with the entry into force of new norms and regulations in the field of industrial safety, some changes have appeared regarding the welder's mark.

In general, the order of the Federal Service for Environmental, Technological and Nuclear Supervision is aimed at enhancing the quality of work and minimizing all kinds of violations when working with heavy metal structures at hazardous production facilities. At the same time, much attention in the FNP “Welding at HPF” is paid specifically to the identification of the worker who performed the welding activities.

Where and when are they stamped?

According to paragraph 21 of the FNP “Welding at HPFs,” welded joints whose walls are thicker than 6 millimeters must be marked with the number of the welder who performed the work. And according to GOST 25225-82, the welder must mark his place of work with his mark.

Where exactly is it customary to place the mark? Primarily on the following structures: metal channels and beams; ceiling bases; It is possible (but not necessary) to use a stamp in fastening reinforcement or welding elements less than 6 millimeters. After completing welding work at hazardous production facilities, the welder is required to affix a mark next to the completed seam. After this, it is necessary to fill out a work log and connection test reports.

Technical conditions for the manufacture of welding structures

Technical standardization is extremely important; it regulates the entire welding process. The final result at an assembly and welding plant of any scale depends on the correct organization of work. Technical specifications for the manufacture of a welded structure are, in fact, a set of documents that you can read and find out all the information about a particular part. These documents describe all stages of the welding process: from preparation to transportation. The classic package of documents consists of drawings of the finished product, technical specifications and a production program (it can be approximate). Let's take a closer look at this.

Let's start with the drawings. Not a single more or less professional welding can do without them, since it is impossible to accurately determine “by eye” where the seams should be. This is especially true for particularly critical metal structures, which can cause harm to humans if welded incorrectly and subsequent destruction.

The drawings usually contain information about what metal is used in the manufacture of the product, what features it has, what size and thickness of the metal is used, what types of welds are used in welding, etc. The drawing is submitted to the chief engineer for verification, and work begins only after approval. If the engineer finds inaccuracies, the welder (or a separate designer) needs to make a new, corrected drawing. Now let's talk about technical conditions, as a separate component of the package of documents. GOST No. 15001-69 says that technical conditions should be selected in accordance with the drawings, expected operating conditions of the product and accumulated experience. In simple words, the technical specifications describe where and under what conditions the part will be used, whether it will cause harm, etc.

The technical specifications also indicate the operating features of the structure or part. For example, the product may not be intended for use at sub-zero temperatures or under increased mechanical loads. All this information must be indicated in the technical conditions in order to avoid problems. So there are several types of designs: especially responsible, responsible and all others. Based on the type, the corresponding conditions are prescribed.

And the last act included in the documentation package is the release program. As we indicated earlier, it may be approximate. This indicates the number of products that need to be produced within a certain period. This information is needed not for accounting of manufactured products, but as a basis for using a particular set of welding equipment and proof of the economic feasibility of using such a set in work.

The production process consists of many stages and it is extremely important to follow their sequence and not deviate from generally accepted norms. This will help produce products quickly, efficiently and inexpensively.

Welder's mark: assignment rules, requirements and features

The profession of a welder is not as simple as it may seem to the average person at first glance.

Otherwise, special certification would not have been carried out, there would have been no qualification tests of specialists’ knowledge to extend their rank or increase it. So we can say that the work of a welder is responsible and complex, because it is he who performs labor-intensive and important welded joints and seams. A mandatory element required by highly qualified specialists is the welder’s mark. We'll talk about it today.

What is a stamp

A brand is usually called a hand tool made in the form of a metal rod. It is made of tool steel, the strength of which is 50-60 HRC. The welder's mark is made in accordance with GOST 25726-83.

A mirror designation must be stamped on one side of the instrument: alphabetic and digital. The second side is intended for striking, as a result of which an even relief image should be obtained.

Type and code

In some cases, the first letters of the welder's last name or a series of numbers are used as identification. But most often the welder’s mark code is generated automatically. The basis is the specialist’s date of birth, his last name, first name and patronymic. Usually the mark does not change either during renewal, or when passing certification, or when changing the welding method.

There are several versions of the instrument. For example, numbers in two lines - without a frame or with a frame, numbers in a triangle, rhombus or square.

The height of the symbols is usually 6 millimeters, however, in cases where the welder performs special work, a larger or smaller mark may be used.

It is worth noting that this circumstance must first be discussed with management!

Why do you need a stamp?

When welding particularly critical metal structures, certified welders make an impression with their mark next to the welded seam.

This procedure is a sign of confirmation that a certain connection has been completed by the welder whose stamp numbers are applied to this product.

That is, the assignment of a welder’s mark can be called the assignment of a kind of signature that confirms the high-quality performance of welding work.

It is impossible to confuse welders - each mark is called personal because it bears an individual number. If some kind of defect or defect was suddenly discovered, the mark could be used to identify the performer who performed poor-quality work.

By the way, on October 8, 2014, federal norms and rules regulating certain requirements for work at hazardous facilities came into force. Thanks to this innovation, a single database has appeared that contains information about all certified welders.

The database contains information about the position, date of certification and its field, code of the welder's mark, category, type of activity.

According to paragraph 21 of the FNP “Welding at HPFs,” welded joints whose walls are thicker than 6 millimeters must be marked with the number of the welder who performed the work. And according to GOST 25225-82, the welder must mark his place of work with his mark.

Where exactly is it customary to place the mark? Primarily on the following structures:

- metal channels and beams;

- ceiling bases;

- It is possible (but not necessary) to use a stamp in fastening reinforcement or welding elements less than 6 millimeters.

After completing welding work at hazardous production facilities, the welder is required to affix a mark next to the completed seam. After this, it is necessary to fill out a work log and connection test reports.

How to put a stamp

Every certified welder should know how to apply a mark correctly. It is customary to place it at a distance of 20-50 millimeters from the edge of the weld. It is necessary to put a stamp on the outside.

If the seams on the outer and inner sides are welded by different specialists, the marks are placed on the outer side - through the shot.

The numerator is the mark of the specialist who welded the parts from the outside, the denominator, in turn, is the welder on the inside.

For longitudinal seams, the welder's mark must be placed at the beginning of the seam and at its end. It is important to maintain a distance of 100 millimeters from the circumferential seam.

If the welder performed a circumferential seam, he knocks out a mark at the intersection of the circumferential seam with the longitudinal ones. The mark is repeated every two meters. It is worth noting that each such seam must have at least two marks.

The place where each seam is branded must be enclosed in a clearly visible frame of indelible paint.

Another point of the Federal norms and rules states: if all welding work at a site is carried out by one welder, there is no need to indicate an identification code on each connection. One stamp, located in a place accessible for inspection, is enough. At the same time, if several specialists were working on one complex connection, everyone should leave their own cipher.

Important information

When applying a mark, the welder does not have the right to form riveting or hardening on the products, or to reduce the thickness of the product. And the print itself must be neat and easy to read – even over a long period of use.

How and where to get a stamp

Assigning a mark to a welder, a sample order for which you can see below, is a rather complicated process. To do this, it is necessary to undergo certification by NAKS - the National Welding Control Agency. This agency is a structural division of SASv - the so-called Welding Certification System.

In order to pass certification, you must successfully pass various tests. Only after this, along with the certification certificate, the welder is given a mark code.

Please note: a mark that was issued before the Federal Tax Code came into force is valid only until the next certification. If it is successfully completed, the specialist receives a new one that meets the new standards.

Order on assigning a mark to a welder: sample, form

Clause No. 8 of the FNP states that after brand codes are assigned to welders, they are assigned to these specialists. The order is signed by the organization performing the welding work. We bring to your attention a sample order for a welder's mark.

Nothing complicated, as you can see. In addition, the order to assign a personal brand is usually written in free form. It may indicate the types of structures being welded and other powers of the welder.

Bottom line

Inspection methods are necessary to inspect seams produced using welding equipment. Depending on the requirements for products, testing options may vary.

For parts that do not require great resistance to mechanical and plastic loads, only a visual inspection may be sufficient. While large enterprises often require additional checks using mechanical tests and radiation methods.

Quality assurance during production

Ensuring product quality in the process is ensured by:

1) planning and organization of work:

— technical control and testing of products;

— control of production technology;

— technical diagnostics of equipment;

— technical diagnostics of support systems;

— monitoring the state of the production environment;

2) metrological assurance of production and product quality;

3) control and testing at various stages of product production;

4) control of technological discipline;

5) carrying out preventive maintenance and scheduled maintenance of equipment;

6) ensuring the quality of manufacturing of the tools, equipment and accessories used;

7) certification of production, technological processes, workplaces, equipment, fixtures, tools, parts and assembly units of our own manufacture;

quality assurance during intra-shop and inter-shop transportation;

9) highly qualified personnel and production discipline;

10) functioning of the system for accounting and assessing costs to ensure product quality.

Management of production processes is necessary in order to counteract various factors affecting production and leading to deviations of processes from the established values of their characteristics. Production process management must form a closed cycle and contain:

— process (product) monitoring to detect deviations; — analysis of data obtained during control to determine the causes of deviations and take the necessary corrective measures; — informing the process operator about the necessary corrective measures; — process regulation.

Production process management methods:

SELF-CHECK - the operator himself checks important quality indicators after completing any operation or work; can be visual or performed using gauges or simple instruments (the main advantage is simplicity and speed of use);

SAMPLE CHECK - consists of checking several products at certain intervals in order to make sure that they meet certain requirements for their quality; carried out by shop foremen or special controllers;

CONTROL BY STAGE or CONTROL IN THE PRODUCTION PROCESS requires checking the product after each operation or group of operations, as a result of which important quality characteristics are formed in the product; control points are located, as a rule, directly at the production site, where parts are transferred to inspectors after each important stage of processing; during stage-by-stage control, the relevant characteristics of the product are checked according to drawings and technical specifications;

STATISTICAL PROCESS CONTROL METHODS are based on the principle that all processes have inherent variability; If a variability model can be created, it can be used to predict and indicate when a process requires corrective action in order to remain controllable; The advantages of these statistical methods are as follows:

- they provide information about the probability of defective outputs before they are actually received; — to maintain a high level of quality, they do not require physical control of each product or part.

Control methods are:

— frequency distribution; — control cards; - pre-control checks.

To ensure the quality of final products consisting of several parts and/or assemblies produced in-house, quality management must cover the various stages of production of all these components and assemblies. For this purpose, a network of control points is created at strategic points of production. At each control point, the quality characteristic being monitored must be clearly defined, and the points must be provided with qualified personnel and appropriate testing equipment to perform this function. For a network of control points to function effectively, they must be provided with detailed instructions.

The nonconforming product must be identified by the appropriate code or mark. If there are products that do not meet the requirements, the production process stops. The manufacturer must have a method for physically separating nonconforming items, which must be stored in a secluded area under control to prevent use of the items. An analysis of nonconforming products is performed to make one of the following decisions:

— acceptance under existing conditions (if the discrepancy is insignificant and does not affect the performance of the final product; if there is a customer, then this is agreed with him); — processing (if it is possible to correct the discrepancy); — repair (if it is possible to repair or reprocess the product); — regrading (the product is assigned the lowest quality category, the requirements of which it meets); - defective (the product must be removed as defective and disposed of as waste).