Welding work requires maximum precision. It is convenient to secure structural elements in a certain position using a magnetic welding square. Manufacturers make magnetic fixtures for welders of various designs. They come with permanent and switchable magnets and differ in the load they can withstand.

Magnetic corners for welding

For welding work, magnetic holders with a certain size of corners are used. They produce universal designs with regulators; they secure the support bars to any angle. For home welding, craftsmen make their own compact squares from scrap materials.

What is a magnetic square and what is it for?

With its help, you can connect the metal sheets to be welded and hold them in this position until the welding is completed.

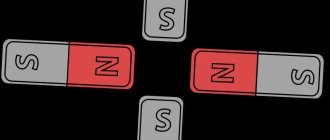

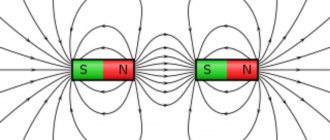

The square allows you to set the parts at the desired angle. If there must be a gap of a certain width between the parts, the square will cope with this task. This auxiliary element consists of two halves of a non-magnetic body, between which a powerful magnet is laid. A powerful permanent magnet or a switchable electromagnet can be used as a source of magnetic field.

Unlike clamps and other devices in which fixation is carried out using threaded clamps, a magnetic square holds parts in a given position using a magnetic field. This solution makes the square a more durable device, since its design has no moving parts, as well as threaded connections prone to breakage. Therefore, the square can last longer than a device with threaded clamps under equal operating conditions. In addition, installing angles saves the welder time, because now there is no need to tighten the clamps for a long time.

A magnetic square is, in fact, a welder’s “third hand”. It allows you to do without the help of a partner who will hold the structures being connected.

Purposes of use

Magnetic fasteners are used to achieve the following purposes:

- Convenient fastening of parts and simplification of their installation;

- Correct positioning of the planes to be welded;

- Fast assembly of structures;

- Setting certain angles for connected products;

- Accurate and precise welding to avoid gross mistakes;

- An effective replacement for bulky clamps and clamps.

Welding magnets allow you to adjust the fastening and assembly of elements in accordance with operating conditions. They have an adhesive force of 10 to 50 kilograms and make it possible to work with both shaped products and sheet metal. The main advantages of such devices are such important factors as reducing the period for preparing products for welding and reducing the labor intensity of the work process.

What types of angles are there?

Depending on the design and functionality, angles can be divided into several subgroups:

- Simple clamps built on the basis of permanent magnets. These are the cheapest magnetic clamps available on the domestic market, however, working with them is not always convenient.

- Detachable latches. They have a switch that allows you to turn off the magnetic field. After disconnecting, you can detach the latch from the metal, rather than tearing it off by applying powerful force. The most convenient devices of this class are those with switches located on both sides.

- Magnetic clamps. These devices will allow you to adjust the strength of magnetic attraction and the angle that can be set. The most advanced and expensive devices of this class allow you to install the parts to be connected in any position in three planes. However, the cost of such devices is very high, so they already belong to the professional class.

In addition to the above, we can mention homemade magnetic squares. It's not very difficult to make. In addition, such a device can set any angle, unlike store clamps, which set only fixed angles.

Characteristics of welding magnets

All magnetic devices involved in welding work can be divided into two types:

- Universal devices;

- Corner magnets for welding.

Universal devices have great functionality and are widely used in many industrial areas.

They are capable of connecting parts of flat, cylindrical and angular configurations at non-standard angles. Magnets allow you to fix the elements to be welded both in the horizontal and vertical planes. This is achieved by the ability to adjust the working angles of the magnet in a fairly wide range. The devices have good resistance to high temperatures and can withstand metal splashes. Thanks to the increased accuracy when installing parts, the welding seam is neat and of high quality. The use of universal devices allows you to expand the scope of a specialist’s activity and reduce labor costs for welding work.

The advantages include factors such as convenient positioning, ease of operation, good magnetic field strength and no effect on the quality of the welding arc. The disadvantages are a decent cost and the availability of these devices only in highly specialized retail outlets.

A magnet for angle welding is the most popular device among domestic specialists today. It is simple in design and has an affordable price. This device is designed to install and secure in the desired position metal segments used in the assembly and welding of various structural objects.

The square helps to quickly and reliably connect parts when performing operations with metal angles, profiles, pipes (round, rectangular) and sheet steel.

Magnets come in three forms:

- Arrow-shaped;

- Triangular;

- Hexagonal.

What signs should a high-quality square have?

Today, there are many models of welding angles on sale. It's quite difficult to choose between them. However, if you follow a few simple tips, you can find a quality square for little money.

Here are a few rules to follow when choosing a square:

- Never skimp on magnet power. A low-power square may turn out to be cheaper, but during operation it will only cause inconvenience if it falls off the parts being connected at the most inopportune moment. Most experts agree that the square should hold at least 20 kg of lift.

- If money allows, it is worth buying a switchable angle. It is much easier to remove after finishing work, which saves the welder’s time and effort. To disconnect the square, simply flip the switch. It is especially convenient to use squares with switches located on both sides. After turning off the magnet, the square can be easily cleaned of adhering metal dust.

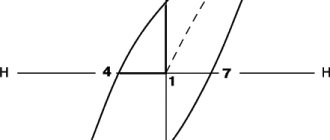

- It is better if the product is designed to accommodate not just one angle, but several. Most modern angles allow you to set five or six different angles.

- Before purchasing, you should check how firmly the chosen square can hold the connected parts. Profiles secured with a square should not move from their place even after an attempt to move them with powerful muscular effort.

- It's a question of price. It is clear that a high-quality tool cannot be too cheap. A decent quality square suitable for household work can cost between 300-500 rubles. However, it is better to take several pieces at once. If you take magnetic devices for professional work, the cost can fluctuate around 3 thousand rubles and more. An example of a good quality square sold at an affordable price is the magnetic locking fixtures developed by Smart Solid.

What rules must be followed when using a square?

Before you start using a square, you should carefully remember the rules for safe work with this tool and always adhere to them in your work.

Firstly, it is worth considering the weight that the square can hold and not exceed it. A part that comes off at the most unexpected moment can cause defects or cause injury. So make sure the magnet is powerful enough to hold it. The most powerful magnets for holding heavy parts can withstand loads of up to 34 kg! Fixed parts should not wobble when force is applied to them.

Secondly, it is worth remembering that when heated from welding, the metal is deformed. Therefore, there is an additional load on the square, which may exceed the ability of the square to hold parts. To avoid unexpected drop of the square and divergence of the seam, before starting to weld the seam, tack the parts at several points on both sides of the installed magnetic clamp. After this, the metal will no longer diverge from thermal deformation after welding the main seam.

The third rule is due to the fact that the magnetic field from a strong magnet can deflect the electric arc to the side. Therefore, do not forget to remove the angles from their installation sites when approaching them. The process of removing and installing the square can be facilitated by the use of switchable magnetic clamps.

Do not neglect these simple rules, and working with a magnetic square will always be easy and safe for you.

Magnetic squares Smart Solid: the choice of professionals

The Smart Solid company produces several model lines of magnetic fasteners. Here are several models from this manufacturer that are in greatest demand in our country.

- MAG 613/614/615 . _ _ _ The clamps of this series are built on the basis of permanent magnets. 30°, 45°, 60°, 75°, 90°, 135° - angles that can be set using angles from this model range. The three models differ only in size and the weight they can hold. All angles in this series use powerful ferrite alloy magnets. The magnetic square of the 615th model (the highest model in the line) can withstand weight up to 34 kg!

- MAG601 / MAG602 / MAG603 is another model series that differs only in size and power. The set angles are the same in all models of the series and are 45°, 90°, 135°. Ferrite non-switchable magnets can hold weight from 11 kg for the younger model to 34 kg for the older one. In this range, you can choose a device suitable for any job.

- MAG 610 is not one square, but a set of four magnetic clamps of the same shape. 45°, 90°, 135° - angles that can be set using these squares. Each of them can withstand up to 4 kg of load, but thanks to the distribution of force between the four fixing elements, the set can hold parts with much larger weights. Flat profile, pipes, strips, metal profiles - the square holds parts of various shapes equally well. The magnets used in the design of the product are non-switchable and made of ferrite.

- MAG 605/606 is a series of switchable magnetic clamps designed for setting angles of 45°, 90°, 135°. As in other series, the magnetic latches have the same shape and angles. Thanks to the ability to turn off, the magnet is convenient to remove and replace. You can cope with this task even with one hand! The older model in the series is capable of handling a load of 24 kg.

So, magnetic angles from Smart Solid are a useful tool that can significantly facilitate a welder’s work. When used correctly, they can allow small-scale welding work to be carried out quickly and efficiently. Several squares of different designs will successfully complement the arsenal and will help in work activities, both for a professional welder and for a beginner who is just beginning to master this skill.

What to look for when choosing a magnetic corner

When choosing a magnetic corner for welding, it is recommended to pay attention to the following:

- For what purpose and what will the magnetic holder be used for? If you are doing simple welding work, then a regular magnetic corner with a set of commonly used angles will be enough;

- The next point to pay attention to is the holding strength. The higher it is, the heavier the structure can be assembled. This is a very important parameter that you should definitely pay attention to when choosing;

- And thirdly, this is the quality of the magnet, which can change its properties when heated.

Magnetic corners for welding are not a luxury, but a necessary attribute of a welder, which allows you to reduce the time for assembling workpieces and generally make welding work easier.