Protect your eyes | 10/30/2016

To carry out high-quality and safe welding work, in addition to specialized working tools, hand and face protection, additional equipment is recommended - successfully used by professional specialists and those who weld only from time to time, a magnetic welding square will make the work easier, more accurate and more accurate.

What is a magnetic square and what is it for?

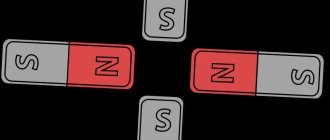

With its help, you can connect the metal sheets to be welded and hold them in this position until the welding is completed.

The square allows you to set the parts at the desired angle. If there must be a gap of a certain width between the parts, the square will cope with this task. This auxiliary element consists of two halves of a non-magnetic body, between which a powerful magnet is laid. A powerful permanent magnet or a switchable electromagnet can be used as a source of magnetic field.

Unlike clamps and other devices in which fixation is carried out using threaded clamps, a magnetic square holds parts in a given position using a magnetic field. This solution makes the square a more durable device, since its design has no moving parts, as well as threaded connections prone to breakage. Therefore, the square can last longer than a device with threaded clamps under equal operating conditions. In addition, installing angles saves the welder time, because now there is no need to tighten the clamps for a long time.

A magnetic square is, in fact, a welder’s “third hand”. It allows you to do without the help of a partner who will hold the structures being connected.

Features when choosing

As with the purchase of any product, you can choose a model with the same functionality and quality, but cheaper, without overpaying for the manufacturer’s brand .

Almost all models do not affect the welding arc in any way. However, the cheapest devices can negatively affect the final welding result, so it is better to avoid purchasing the cheapest devices.- Magnetic field power. The characteristic is simple - the stronger the field, the heavier elements it can hold. The most powerful devices have field power that allows them to hold objects weighing 35 kilograms.

- Number of corners. This is also a simple characteristic - the more there are, the more angles you can select in the device. For example, having purchased a magnet for welding at an angle of 90 degrees, you will have to buy an additional device if you need a different angle.

- If you have a sufficient budget, you should purchase a switchable welding magnet, since the ability to manipulate the magnetic field greatly facilitates manipulation of the device.

- If you need to weld complex structures, you should immediately think about purchasing universal devices.

In general, magnetic welding angles are a really useful and convenient device, which is very convenient to work with even alone. But we should not forget that low-quality devices can ruin the entire structure, so you need to approach their purchase wisely.

What types of angles are there?

Depending on the design and functionality, angles can be divided into several subgroups:

- Simple clamps built on the basis of permanent magnets. These are the cheapest magnetic clamps available on the domestic market, however, working with them is not always convenient.

- Detachable latches. They have a switch that allows you to turn off the magnetic field. After disconnecting, you can detach the latch from the metal, rather than tearing it off by applying powerful force. The most convenient devices of this class are those with switches located on both sides.

- Magnetic clamps. These devices will allow you to adjust the strength of magnetic attraction and the angle that can be set. The most advanced and expensive devices of this class allow you to install the parts to be connected in any position in three planes. However, the cost of such devices is very high, so they already belong to the professional class.

In addition to the above, we can mention homemade magnetic squares. It's not very difficult to make. In addition, such a device can set any angle, unlike store clamps, which set only fixed angles.

Cost of magnets for welding

As you know, the more bells and whistles a device has, the higher its cost and the more carefully you should choose the appropriate model.

The exact cost of a welding product depends on a number of factors:

- Exporting country.

- Manufacturing company.

- Type of device (square or universal device).

- Adhesion forces.

- Possibility of installing non-standard angles (applies to universal devices).

- Presence of a magnetic field activator.

Therefore, it is impossible to guess the exact cost. However, by visiting some online stores, you can determine the average price for certain products.

The arrow-shaped and triangular varieties have the lowest cost (approximately from 400 to 800 rubles). This is justified by the fact that there are many manufacturers from China on the market for such models.

An honorable second place in cost is occupied by hexagonal shapes without a magnetic field switch (from 450 to 900 rubles).

Third place is given to universal devices. The price range for these varieties is from 500 to 1600 rubles.

The most expensive products for welding are carbon-shaped devices with the ability to turn on or deactivate a magnetic field (cost from 2200 to 3400 rubles).

What signs should a high-quality square have?

Today, there are many models of welding angles on sale. It's quite difficult to choose between them. However, if you follow a few simple tips, you can find a quality square for little money.

Here are a few rules to follow when choosing a square:

- Never skimp on magnet power. A low-power square may turn out to be cheaper, but during operation it will only cause inconvenience if it falls off the parts being connected at the most inopportune moment. Most experts agree that the square should hold at least 20 kg of lift.

- If money allows, it is worth buying a switchable angle. It is much easier to remove after finishing work, which saves the welder’s time and effort. To disconnect the square, simply flip the switch. It is especially convenient to use squares with switches located on both sides. After turning off the magnet, the square can be easily cleaned of adhering metal dust.

- It is better if the product is designed to accommodate not just one angle, but several. Most modern angles allow you to set five or six different angles.

- Before purchasing, you should check how firmly the chosen square can hold the connected parts. Profiles secured with a square should not move from their place even after an attempt to move them with powerful muscular effort.

- It's a question of price. It is clear that a high-quality tool cannot be too cheap. A decent quality square suitable for household work can cost between 300-500 rubles. However, it is better to take several pieces at once. If you take magnetic devices for professional work, the cost can fluctuate around 3 thousand rubles and more. An example of a good quality square sold at an affordable price is the magnetic locking fixtures developed by Smart Solid.

What rules must be followed when using a square?

Before you start using a square, you should carefully remember the rules for safe work with this tool and always adhere to them in your work.

Firstly, it is worth considering the weight that the square can hold and not exceed it. A part that comes off at the most unexpected moment can cause defects or cause injury. So make sure the magnet is powerful enough to hold it. The most powerful magnets for holding heavy parts can withstand loads of up to 34 kg! Fixed parts should not wobble when force is applied to them.

Secondly, it is worth remembering that when heated from welding, the metal is deformed. Therefore, there is an additional load on the square, which may exceed the ability of the square to hold parts. To avoid unexpected drop of the square and divergence of the seam, before starting to weld the seam, tack the parts at several points on both sides of the installed magnetic clamp. After this, the metal will no longer diverge from thermal deformation after welding the main seam.

The third rule is due to the fact that the magnetic field from a strong magnet can deflect the electric arc to the side. Therefore, do not forget to remove the angles from their installation sites when approaching them. The process of removing and installing the square can be facilitated by the use of switchable magnetic clamps.

Do not neglect these simple rules, and working with a magnetic square will always be easy and safe for you.

Homemade welding magnet

Is it possible to make magnetic angles for welding with your own hands? No problem, because their design is quite simple. What will you need for this?

- Round magnet with a diameter of 80-90 mm and a thickness of 15 mm.

- Steel sheet 2 mm thick.

- Four M6 bolts 40 mm long and nuts for them.

Templates of the required configuration are cut out of the sheet (use a grinder). There should be two templates. Please note that the size of products cut from a steel sheet should not be less than the diameter of the magnet. All edges are adjusted exactly to the required angles, they are necessarily ground to maximum cleanliness. The surfaces are also polished so that rust and other defects do not reduce the strength of the magnetic field.

A magnet is installed on one of the templates exactly in the middle, and marks are made for fasteners. There should be four holes: three in the corners, one in the middle. Using the marks, through holes are drilled in two templates.

The angle tool is assembled by installing M6 bolts into the holes. In this case, it is necessary to install nuts not only on the end of the bolt, but also between the templates, so that during the process of screwing in the threaded connection, the corners of the homemade tool do not bend. It is important that the round magnet does not protrude beyond the edges of the templates. The shanks of the bolts that extend onto the nuts must be cut with a grinder. Here is the technology to make your own magnet for welding work with your own hands. A magnetic welding fixture is a simple but necessary tool. Today it is used by both professionals and welders just starting out.

Magnetic squares Smart Solid: the choice of professionals

The Smart Solid company produces several model lines of magnetic fasteners. Here are several models from this manufacturer that are in greatest demand in our country.

- MAG 613/614/615 . _ _ _ The clamps of this series are built on the basis of permanent magnets. 30°, 45°, 60°, 75°, 90°, 135° - angles that can be set using angles from this model range. The three models differ only in size and the weight they can hold. All angles in this series use powerful ferrite alloy magnets. The magnetic square of the 615th model (the highest model in the line) can withstand weight up to 34 kg!

- MAG601 / MAG602 / MAG603 is another model series that differs only in size and power. The set angles are the same in all models of the series and are 45°, 90°, 135°. Ferrite non-switchable magnets can hold weight from 11 kg for the younger model to 34 kg for the older one. In this range, you can choose a device suitable for any job.

- MAG 610 is not one square, but a set of four magnetic clamps of the same shape. 45°, 90°, 135° - angles that can be set using these squares. Each of them can withstand up to 4 kg of load, but thanks to the distribution of force between the four fixing elements, the set can hold parts with much larger weights. Flat profile, pipes, strips, metal profiles - the square holds parts of various shapes equally well. The magnets used in the design of the product are non-switchable and made of ferrite.

- MAG 605/606 is a series of switchable magnetic clamps designed for setting angles of 45°, 90°, 135°. As in other series, the magnetic latches have the same shape and angles. Thanks to the ability to turn off, the magnet is convenient to remove and replace. You can cope with this task even with one hand! The older model in the series is capable of handling a load of 24 kg.

So, magnetic angles from Smart Solid are a useful tool that can significantly facilitate a welder’s work. When used correctly, they can allow small-scale welding work to be carried out quickly and efficiently. Several squares of different designs will successfully complement the arsenal and will help in work activities, both for a professional welder and for a beginner who is just beginning to master this skill.

Corner magnets for welders (Twin Pack)

A quick overview of such useful devices as corner magnets that can be used instead of clamps when welding. Suitable as a useful tool and gift for yourself/a man/friend/relative. They help the welder hold metal parts when he “grabs” the structure, including using magnets, you can set the desired angle (30°, 45°, 60°, 90°). Very powerful, made on the basis of rare-earth magnets. In short, I bought it on sale, the product turned out to be useful and of high quality, so my wait was not in vain))))

Description and photo in detail under the cut Greetings to all visitors to the Mysku website!

A short review of tools for welders. These devices are called differently: Magnets for welding, angles for welding, magnetic clamps, devices for the welder. In the original, the lot is called: Welding Magnet/Neodymium Magnetic Clamp, that is, a magnetic clamp.

Appearance of magnets

I bought magnets on sale for $16 and a penny, the main discussion can be read on the page with the promotion.

Sold at 2pcs/lot

For normal use, for example, to weld a box or tank, a minimum of 4 pieces is required, and preferably 8, then not just the angle can be set, but the parallelism of the parts.

Instructions for use from the description

Using different sides (angles) of a magnet

The welding magnet itself is small. There are bigger and more powerful ones.

Characteristics:

Brand: LISHUAI Part number: WM4-304590S Installation angles: 30°, 45°, 60°, 90° Features: Hole in the center, plastic jacket with a magnet. Pull force: 15 kg Size: 50x60mm Magnet type: Neodymium magnet

Now about the parcel. Everything came in a big box

Total weight more than half a kilogram

Inside it is packed so that nothing unnecessary is attached to the parcel.

The parcel contains two packages of two magnets (I ordered a couple of lots). Although it was necessary to take 8 at least - it’s more convenient

Photo of a blister pack with information (brief instructions)

The weight of one package is more than 200 g

The packaging contains brief information on use

Appearance of magnets. There is also a sticker on the case with useful information

Look, magnets are magnetized to each other and to everything. It’s convenient that there is a plastic shirt on the magnetic part itself - it will protect against metal debris

Magnet dimensions, as stated above - 50*60 mm

Thickness about 1 cm

The triangular body has the following angles: 90°, 60° and 45°.

The inscriptions on the sticker remind you of how to use

Photo of a plastic shirt

The mass of one magnet is slightly less than 100 g

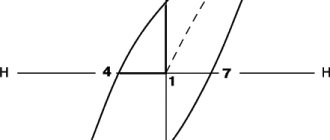

Claimed breakout force is 15kg. It’s just not specified for which side. The contact area of the magnet is different for different sides. The wide side (60 mm) holds stronger, the broken side (with angles of 45°-60°) holds somewhat weaker. I tried to evaluate the strength with a simple steelyard

I was only able to photograph 7 kg. Then it was about 7.5 kg and there was already a liftoff (I can’t film the moment of liftoff - I’ll try to record a video). Not sure about the correctness of the strength testing technique itself

Well, just a quick note on how to use it - it’s very convenient to grab ferrous metals before welding.

Set the size, install the magnets. If you set 2, then you do not need to set perpendicularity, since this is ensured by a pair of magnets. Well, plus a right angle

Example of a 45° angle

Angle 60°.

In fact, only the 90° angle is most often used, and it is most convenient to use magnets in pairs

In short, the magnets are good, well thought out, and useful. Somewhat expensive, especially if you take a set of 4-8-16 pcs. But if you take it as a gift, that’s it!

If you are comparing with cheap magnets from hardware stores, try to find out what kind of magnet is there (they also put cheap magnets in them, the pull-out force is much less). So magnets are the best! Unless it makes sense to look for more powerful/larger magnets for a specific application, or take switchable magnets (with a switch on the body). In general, there are a lot of similar things in the store, there are magnets with different angles or different sizes, with switches, pad magnets, terminal magnets

Switchable magnets

Thank you for watching!